High-concentration engineering plastic flame-retardant master batch and preparation method thereof

A technology of engineering plastics and flame-retardant masterbatches, which is applied in the field of high-concentration engineering plastics flame-retardant masterbatches and its preparation, and can solve the problems of insufficient continuity and stability of feeding materials, insufficient dispersion of flame-retardant masterbatches, and flame-retardant masterbatches. Unable to produce and other problems, to achieve the effect of maintaining production continuity, reducing powder settlement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

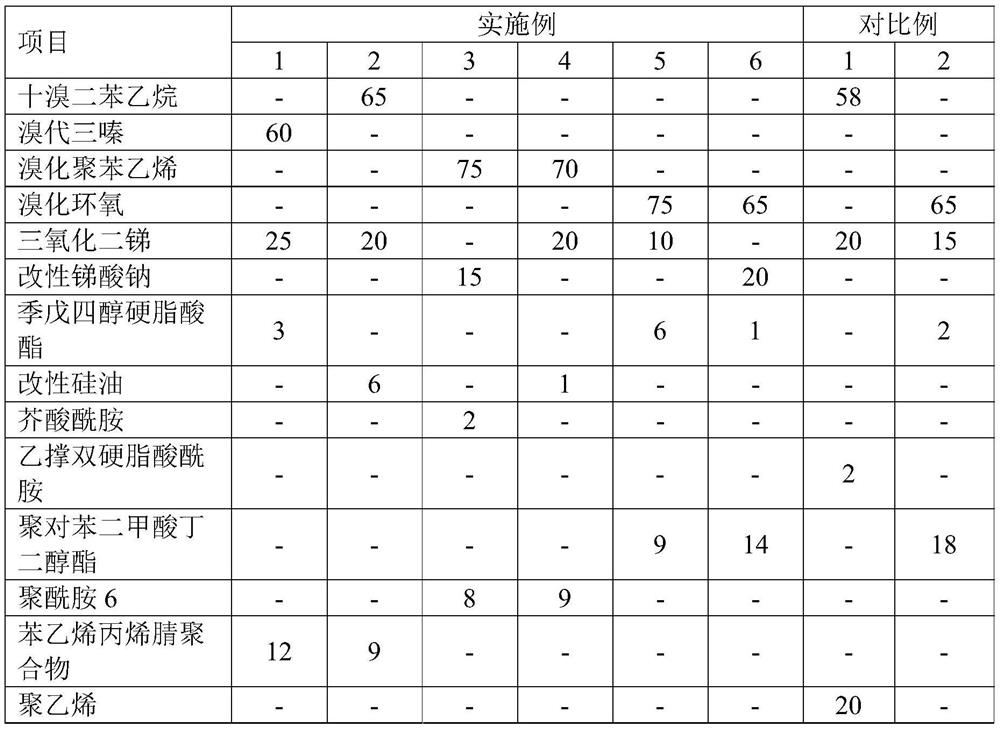

Examples

Embodiment

[0032] (1) Put the raw materials into the mixer according to the proportioning ratio, and mix them;

[0033] (2) The dispersant is heated to melt, and then in the process of stirring and mixing in the mixer of step (1), the molten dispersant is atomized and sprayed to the mixer, together with the materials in step (1) at 400r / m The composition was obtained after mixing for 160s at the rotating speed of min;

[0034] (3) Extrude the composition obtained in step (2) through a twin-screw extruder, wherein the length-to-diameter ratio of the twin-screw extruder is 40:1-60:1, and the temperature is controlled in sections: the conveying section is 240°C, and the melting Section 250°C, metering section 250°C for melt extrusion granulation to obtain high-concentration engineering plastic flame retardant masterbatch;

[0035] (4) The melt-extruded material is fed into the single-screw extruder by the cone double feeder and extruded. The temperature of the twin-screw extruder is contro...

Embodiment 3

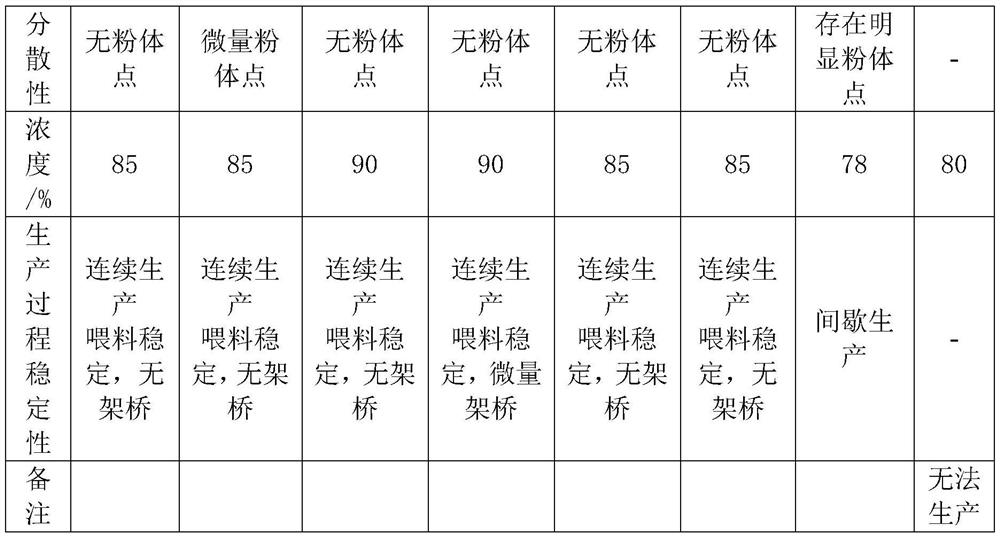

[0045] The flame retardant concentration of embodiment 3 and embodiment 4 is all at 90%, and the content of the brominated flame retardant in embodiment 3 is higher than embodiment 4, two embodiments have added modified sodium antimonate and di Antimony oxide, as can be seen from the production stability, the embodiment 4 has produced trace bridging, and the embodiment 3 stability that has added modified sodium antimonate is better than the embodiment 4 that does not add modified sodium antimonate, has illustrated Modified sodium antimonate has obvious advantages in improving the dispersibility of materials and improving production stability.

[0046]Adopt twin-screw mixing and single-screw extrusion granulation continuous production technology, continuous production, stable feeding, can produce high glass transition temperature or high melting point carrier resin (such as PBT, PA6) flame retardant masterbatch. The flame retardant masterbatch produced by continuous production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com