Double-die carrying hand structure of flower basket cover

A flower basket and material receiving rod technology, which is applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low efficiency, instability, high labor input cost, etc., to improve production efficiency, stabilize material receiving, and eliminate The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

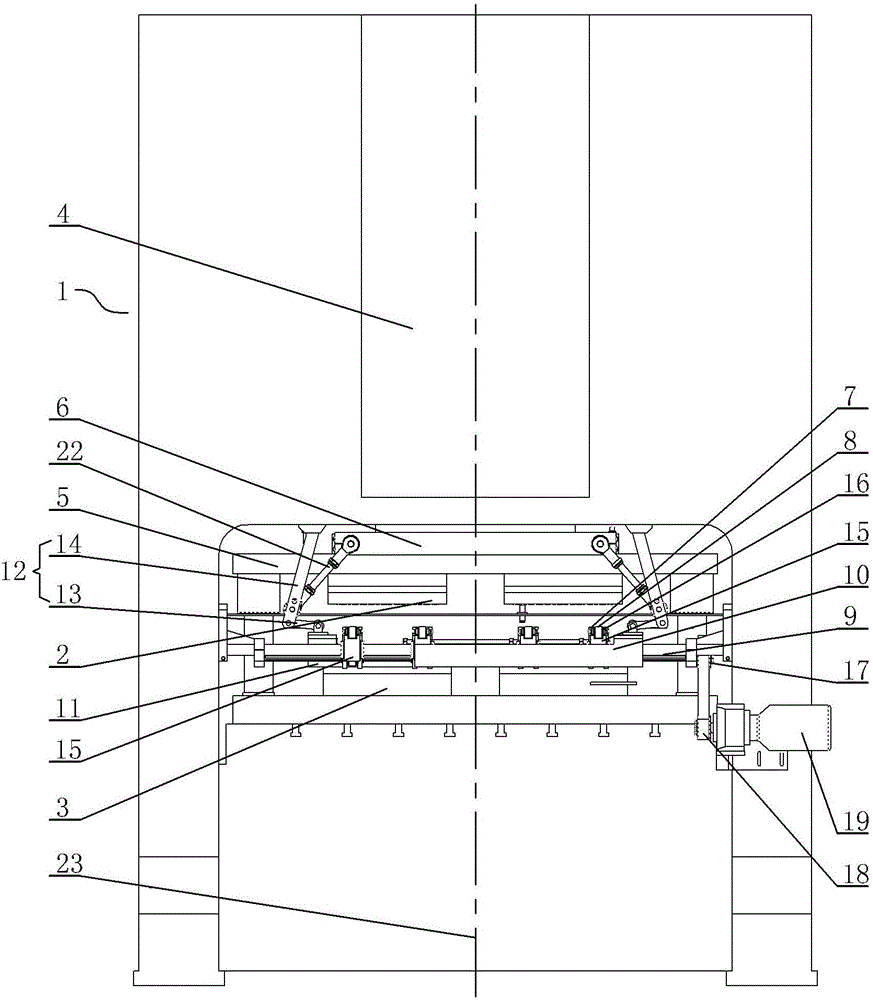

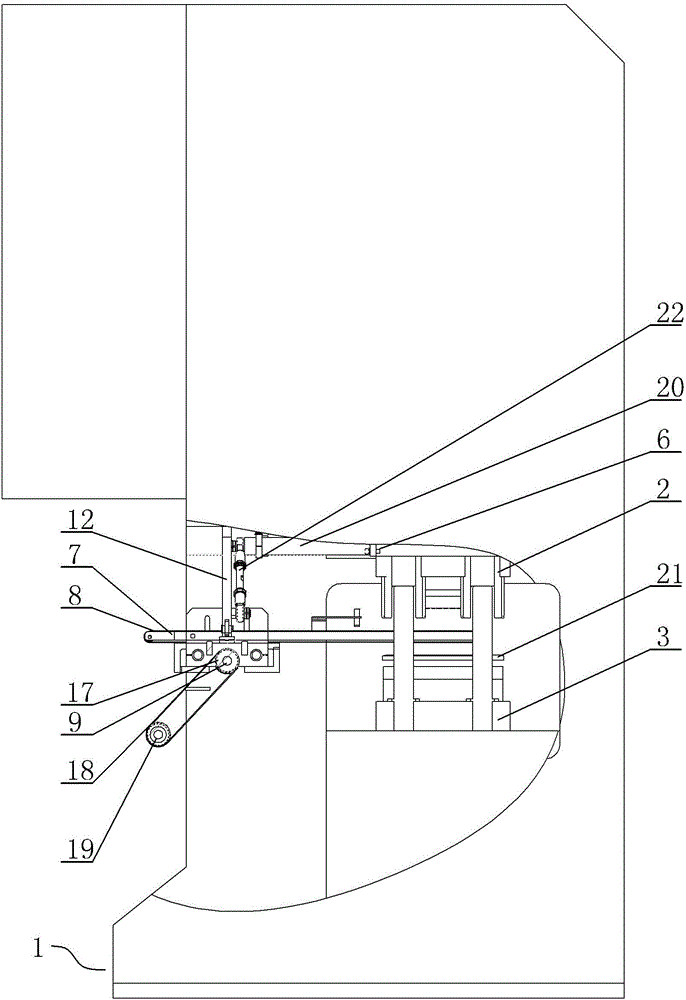

[0015] A double-mode material receiving hand structure for a flower basket cover, see figure 1 , figure 2 : It includes a bed body 1, two pairs of upper dies 2 and lower dies 3 are respectively arranged on the bed body 1, the two upper dies 2 are horizontally arranged side by side, and the lower ends of the gantry punches 4 are respectively connected to the two pairs of the lower ends by connecting pieces 5. An upper die 2, which also includes an upper slide block 6, the upper slide block 6 is connected with the upper die 2 and can slide up and down together, a pair of connecting rods 7 are respectively arranged between each pair of upper die 2 and the lower die 3, each pair of butt joints Material rod 7 comprises two, and each material receiving rod 7 is arranged with conveyer belt structure 8 along the length direction, and material receiving rod 7 is built-in runner to drive conveyor belt structure, and each material receiving rod 7 is all provided with support structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com