Presser foot device of seam plainer

A technology of presser foot device and lockstitch sewing machine, which is applied in the direction of sewing machine components, cloth pressing mechanism, sewing equipment, etc. It can solve the problems of reduced work efficiency, uneven feeding, and staggered upper and lower layer materials, so as to improve work efficiency and feed materials. Smooth, avoiding the effect of misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

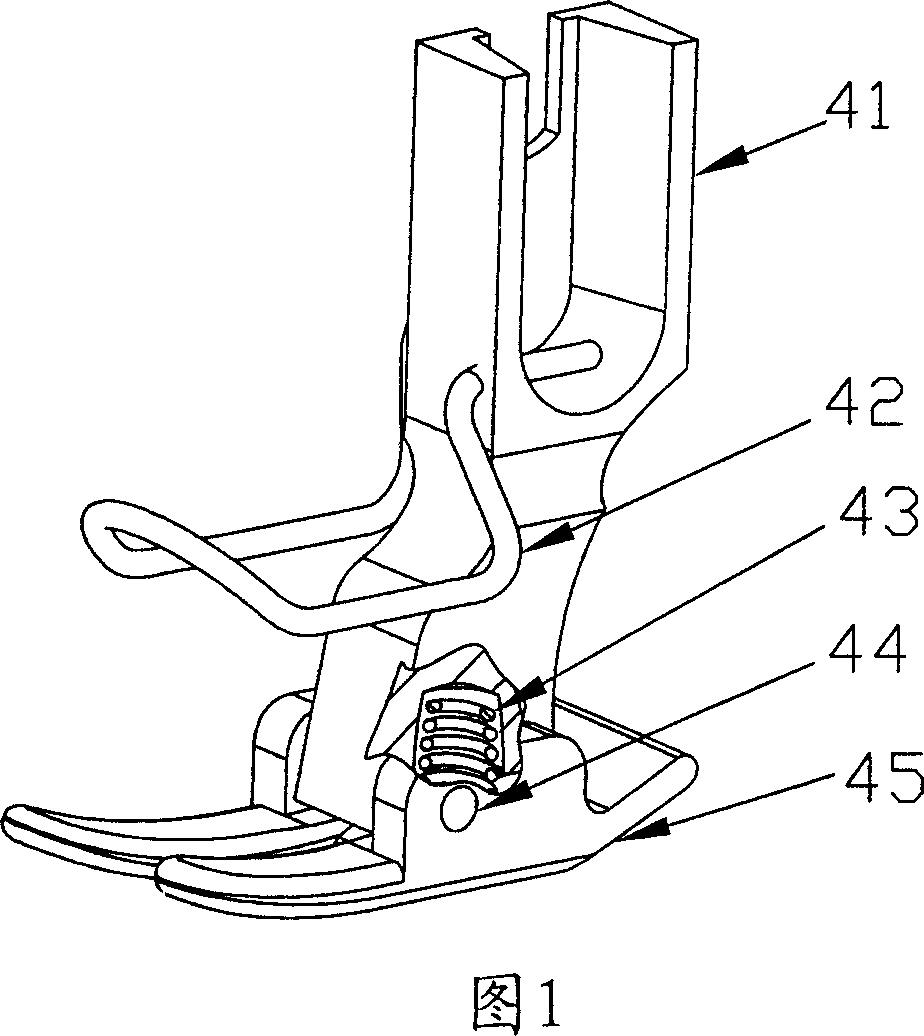

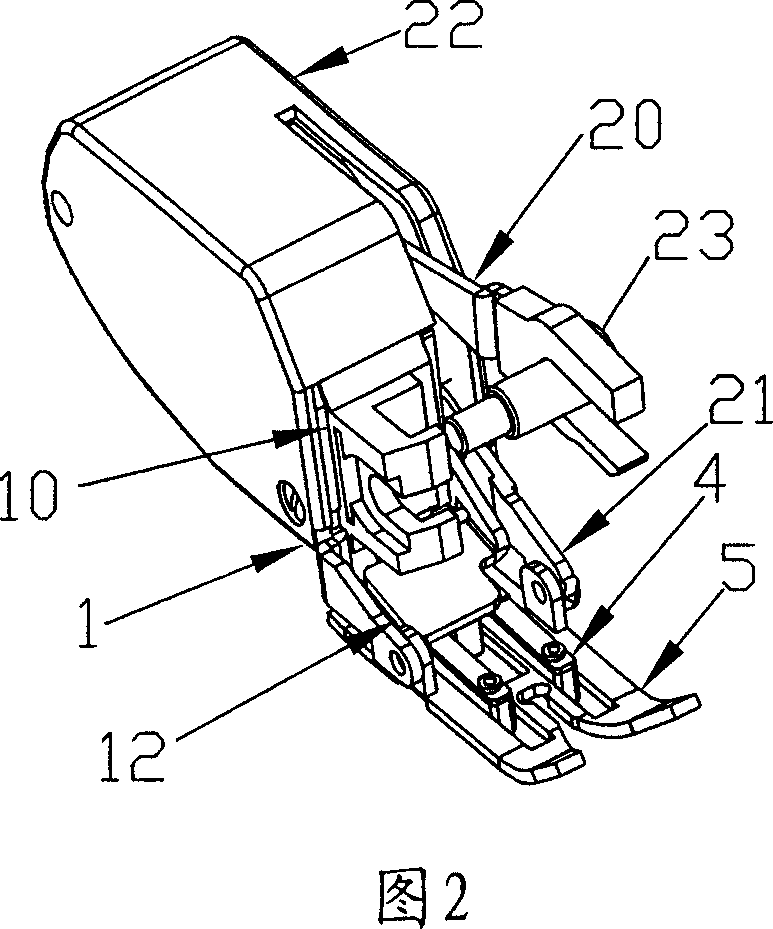

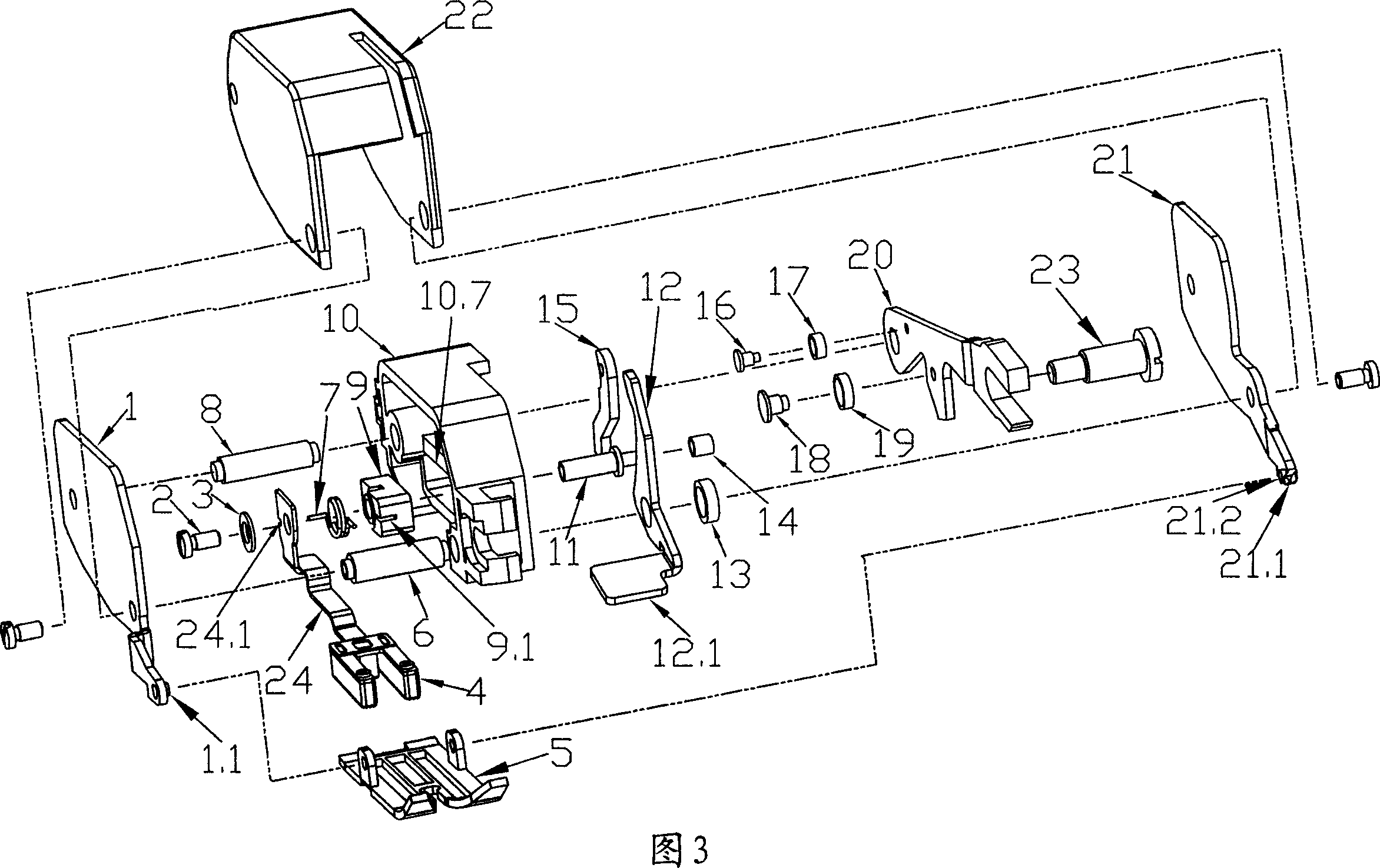

[0019] Referring to Fig. 2, the present invention is encapsulated by a case 22, and the fork at the end of the driving rod 20 passing through the opening groove on the case 22 is movably matched with the needle clamp screw 23, and the connecting part of the skeleton 10 is passed through the front side of the case 22, which is convenient Fixed with the pressure rod. The left and right splints 1, 21 are installed in the casing 22, and the front end is respectively shaped on a protruding shaft, and the protruding shaft is axially connected with the presser foot base plate 5 rear ends. The feeding block 4 is movably installed in the groove of the presser foot base plate 5, and is driven by a transmission mechanism to run back and forth in the groove; the pressing plate 12 is arranged on the top of the feeding block 4.

[0020] With reference to Fig. 3, the feeding block transmission mechanism of the present invention is made up of driving rod 20, driving lever 15, pressing plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com