Arc automatic welding machine

An automatic welding machine, welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of low welding efficiency, and achieve the goal of improving welding efficiency, avoiding multiple welding, and fast and stable feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

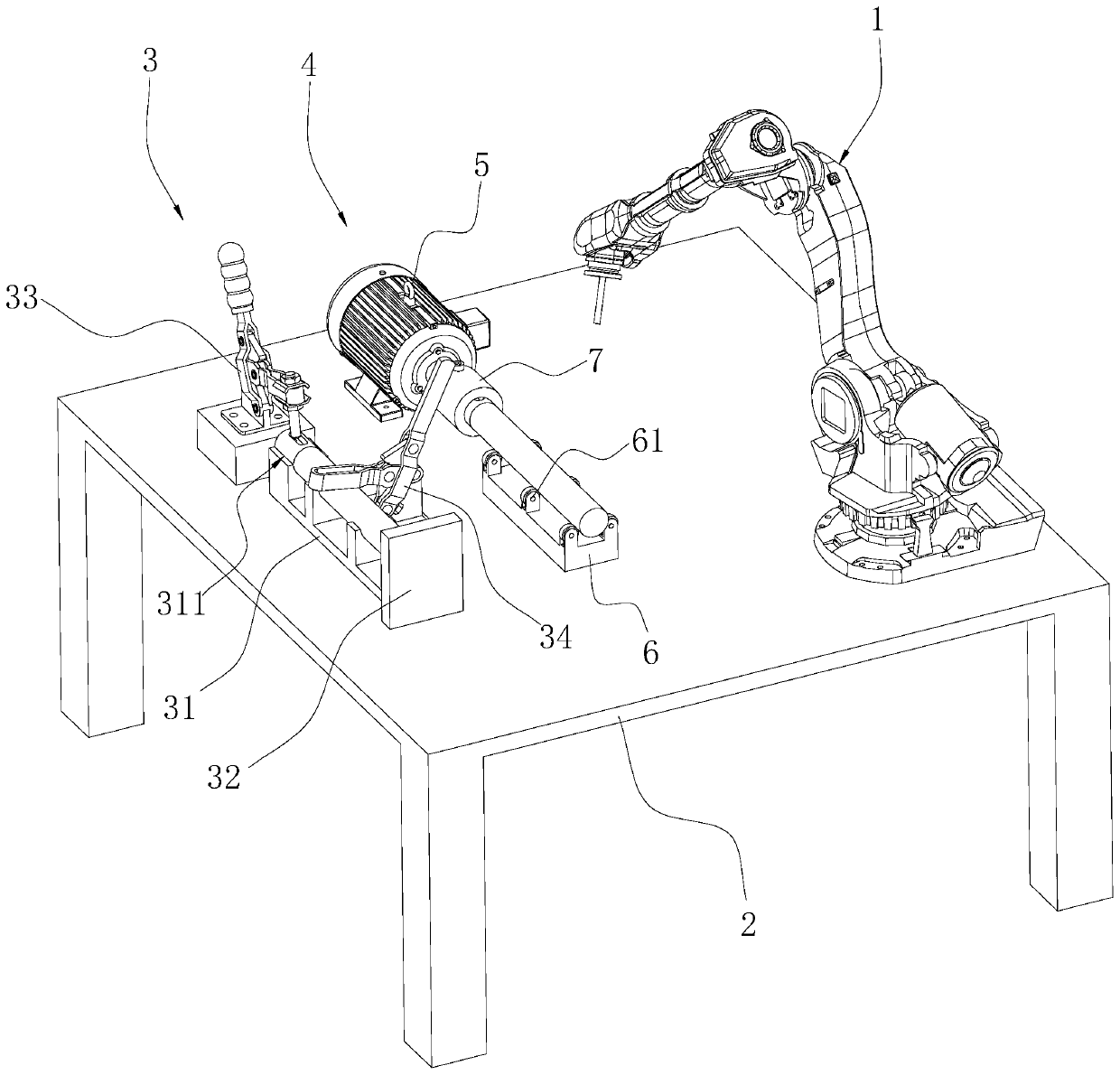

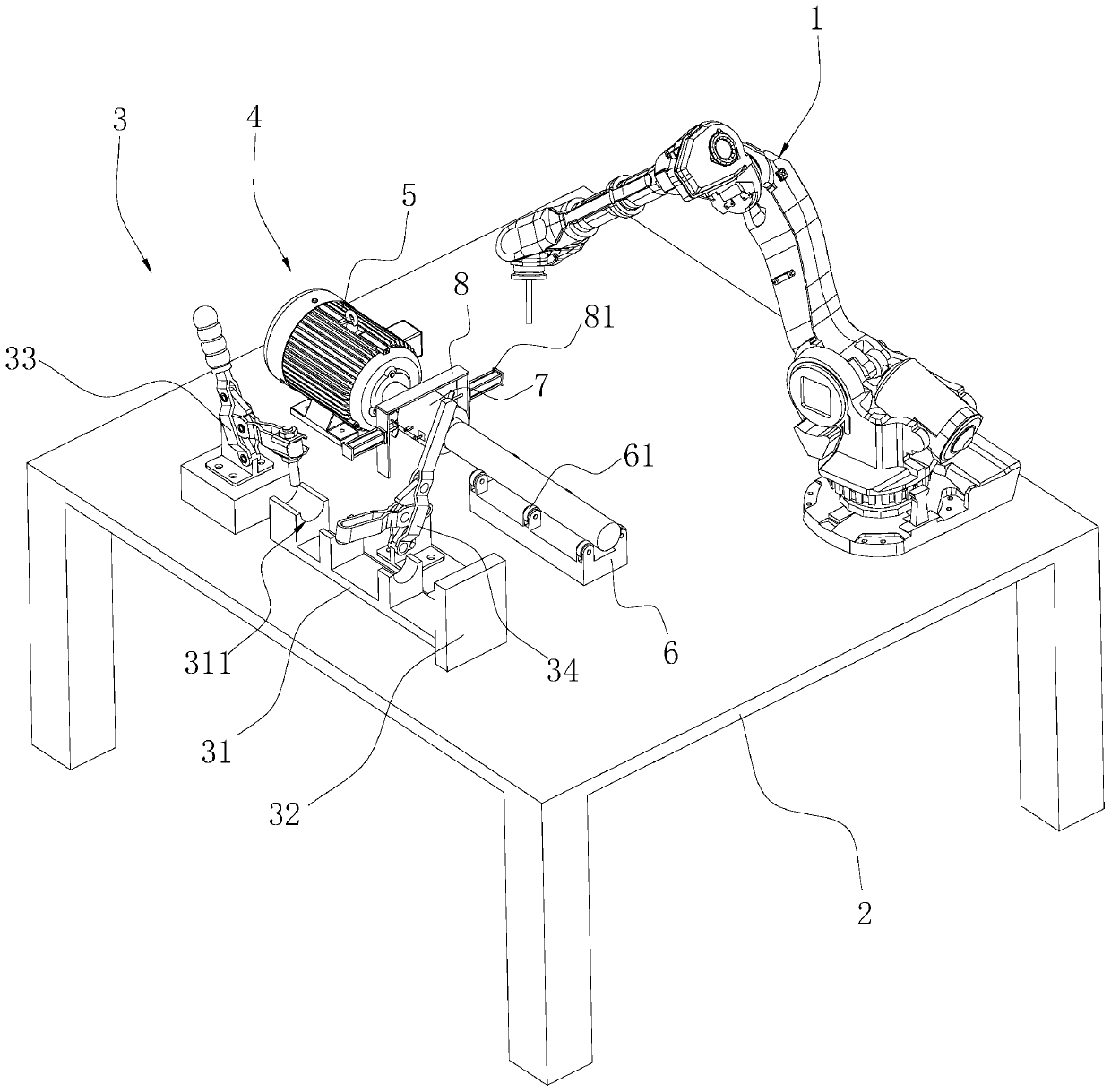

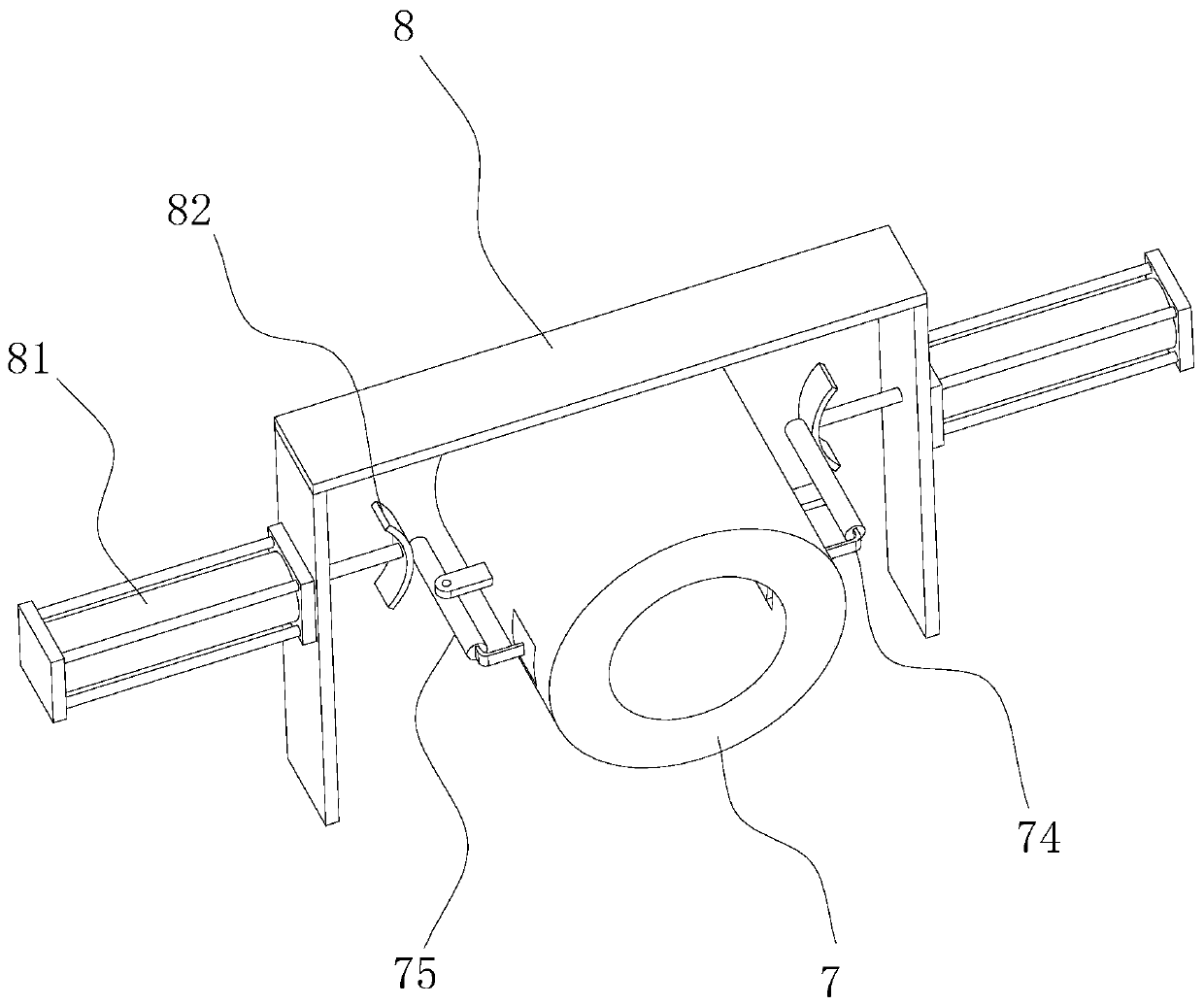

[0039] Such as figure 1 As shown, an arc automatic welding machine includes a welding robot arm 1 and a tooling unit, wherein the tooling unit includes a processing table 2, and the processing table 2 is sequentially provided with a preliminary tooling 3 and a secondary tooling 4, and the preliminary tooling 3 is used for positioning Fix the coaxial alignment of two equal-diameter round pipes and abut them, and then start the welding robot 1 to move to the joint between the round pipes for spot welding once, so that the round pipes are fixedly connected to form a semi-finished product; and then transfer the semi-finished product In the second step tooling 4, start the welding end of the welding robot 1 to align with the weld seam of the semi-finished product, and at the same time, the second step tooling 4 drives the semi-finished product to rotate around its axis, and the welding robot 1 keeps still and continues to weld the semi-finished product to form a weld finished produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com