Rectangular concrete filled steel tubular column - steel beam connection node and construction methods thereof

A technology of concrete columns and rectangular steel pipes, which is applied in the direction of construction and building construction, can solve the problems of very high installation and positioning accuracy, the influence of welds on the development of plastic hinges, and the influence of concrete pouring in pipes, so as to reduce the inability of steel beams to be fixed The risk of bit, the avoidance of adverse effects, and the effect of reducing precision sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described below in conjunction with the embodiments of the accompanying drawings.

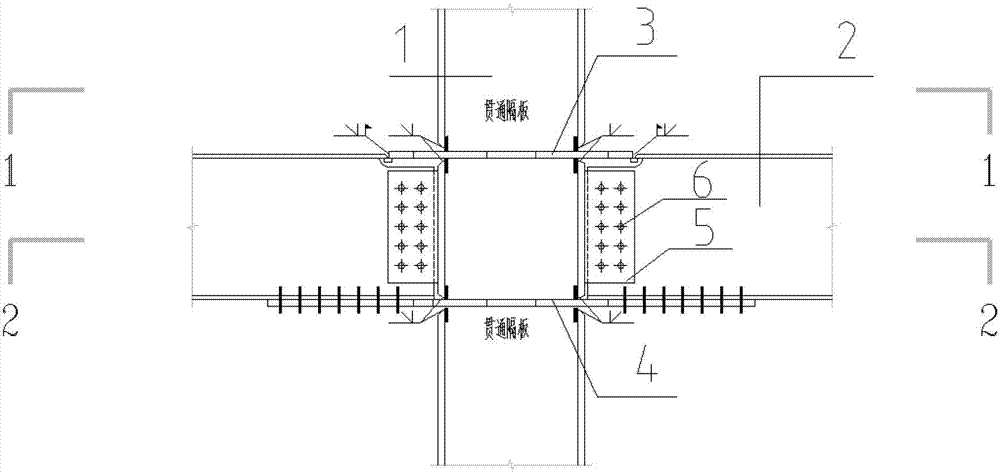

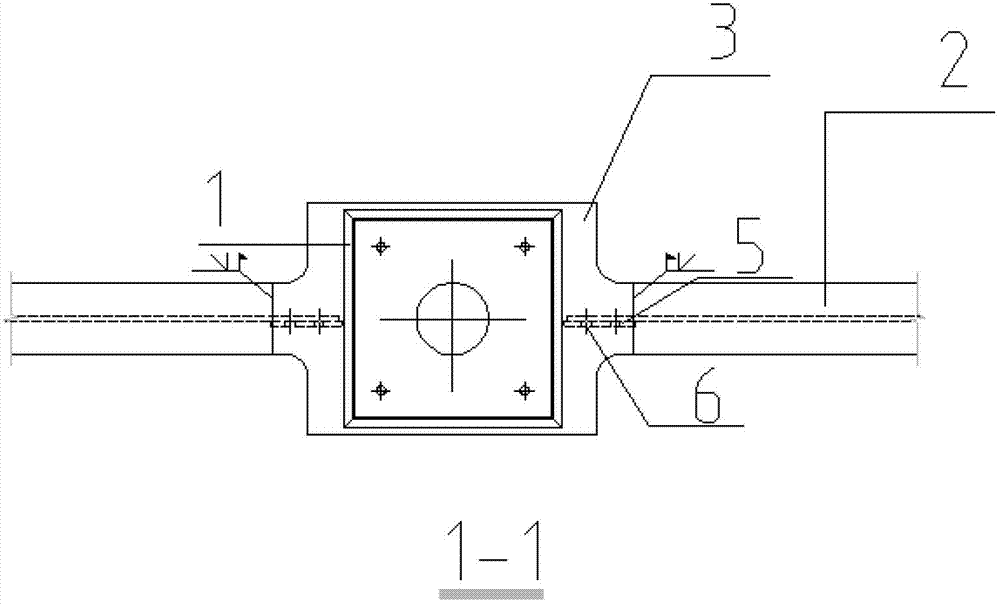

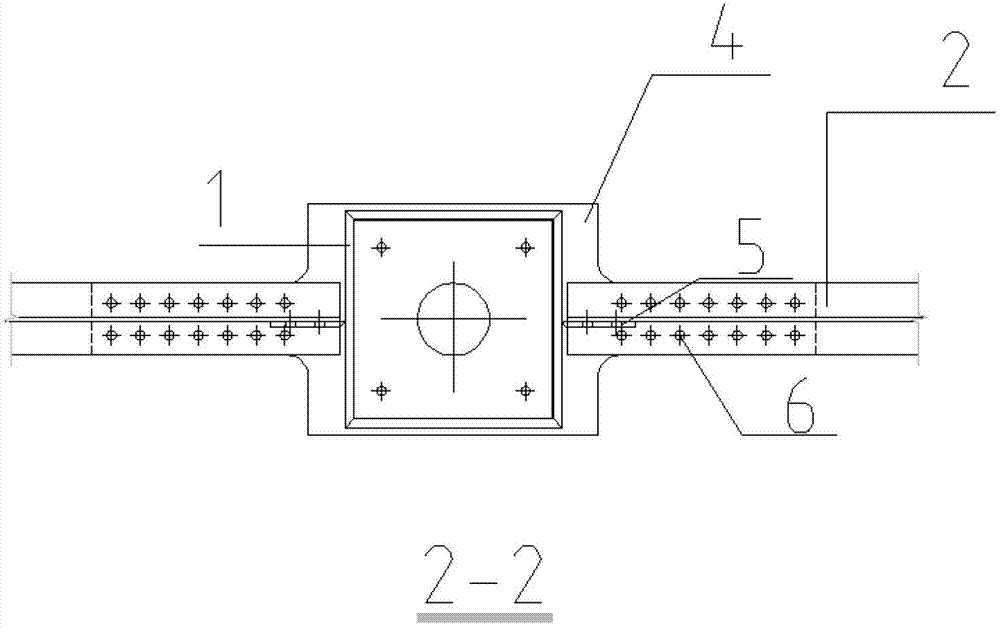

[0044] The present invention proposes a rectangular steel pipe concrete column-steel girder lower bolt and upper welded diaphragm connection joint, which is composed of the following parts: rectangular steel pipe concrete column, steel beam, upper through diaphragm, lower through diaphragm, connecting plate and high-strength bolt. The present invention has two main forms, and its realization method is as follows:

[0045] 1. For Example 1:

[0046] see figure 1 , figure 2 , image 3 , a rectangular concrete-filled steel pipe column 1, a steel beam 2, an upper through-wall partition 3, a lower through-wall partition 4, a connecting plate 5, and a high-strength bolt 6, wherein the upper through-wall partition 3 and the lower through-wall partition 4 run through the rectangular steel pipe concrete column 1 The column wall is connected with the surrounding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com