Technique and device for coproducing carbide slag cement in a dry-method acetylene process

A dry-process acetylene and calcium carbide slag technology, applied in cement production, chemical instruments and methods, hydrocarbons, etc., can solve the problems of waste of calcium carbide resources, complex process, low acetylene yield, etc., to reduce operating requirements and prevent clogging. , The effect of smooth feeding

Active Publication Date: 2012-10-24

XINJIANG TIANYE GRP +3

View PDF10 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

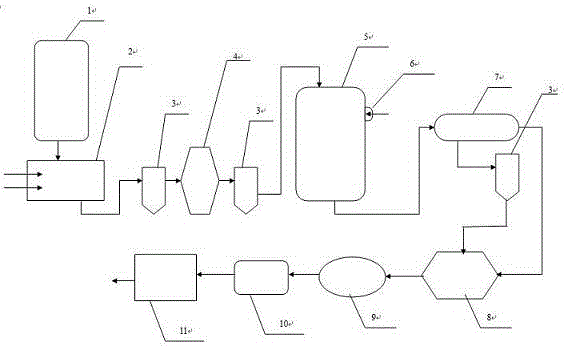

[0006] The purpose of the present invention is to solve the problems in the prior art such as high cost of calcium carbide crushing, incomplete reaction of calcium carbide in the dry acetylene section, waste of calcium carbide resources, low yield of acetylene, easy blockage of the reactor, complicated process, etc., and further provides a process Simple, complete calcium carbide reaction, high acetylene yield, continuous and stable dry process acetylene co-production calcium carbide slag cement process and device for cement production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

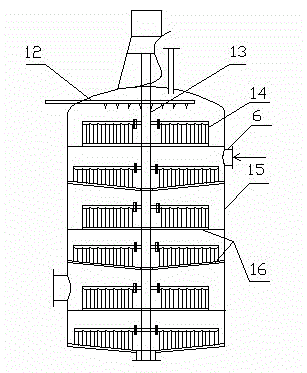

[0025] The difference between Example 2 and Example 1 is that the opening 6 is provided at the shell 15 of the third or fourth section of the partition plate 16 of the dry-process acetylene reactor 5 .

Embodiment 3

[0026] The difference between embodiment 3 and embodiment 1 or 2 is that the calcium carbide crushing system is placed in a calcium carbide pot with the same volume and then crushed after cooling.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a technique and device for coproducing carbide slag cement in a dry-method acetylene process. The device comprises a carbide crushing system, a dry-method acetylene reaction system and a cement production system. The technique is implemented in a way that: liquid carbide from a carbide furnace is sent to a seal device under the action of gravity; the seal device is provided with an air flow nozzle; pressurized carbon dioxide is introduced to crush the liquid carbide; the crushed carbide is subjected to iron removal, crushing and iron removal, and sent to a dry-method acetylene reactor again; the metered carbide with small particle sizes falls into the dry-method acetylene reactor; the second section of the partition of the dry-method acetylene reactor is provided with an opening; eolian sand or furnace slag is added; and under the action of a stirring device, the eolian sand or furnace slag and the carbide slag are discharged out of the dry-method acetylene reaction system through the outlet of the dry-method reactor, and are sent to the cement production system. The invention solves the problems of high carbide crushing cost, incomplete reaction of carbide at the dry-method acetylene station, waste of carbide resources, low acetylene yield, high blockage tendency of the reactor, complex technique and the like.

Description

technical field [0001] The invention belongs to the field of chemical industry, and relates to a process and a device for dry-process acetylene co-production of carbide slag cement. Background technique [0002] There are two methods for industrial production of acetylene, namely calcium carbide method and hydrocarbon cracking method. Foreign countries have basically turned to the hydrocarbon cracking method in the 1970s. The dry-process acetylene involved in the calcium carbide method has attracted widespread attention at home and abroad due to its small water consumption, low consumption of calcium carbide, low water content in carbide slag, and obvious comprehensive utilization benefits. Putting it into industrial application, it is characterized by using small calcium carbide (particle size less than 3mm) as raw material, spraying water slightly larger than the theoretical water amount, and obtaining the by-product calcium hydroxide with a water content of about 10% and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C11/24C07C1/00C04B7/24B02C19/06

CPCY02P40/10

Inventor 郭庆人张新力吴彬熊新阳李朝阳

Owner XINJIANG TIANYE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com