Patents

Literature

55results about How to "Realize controllability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

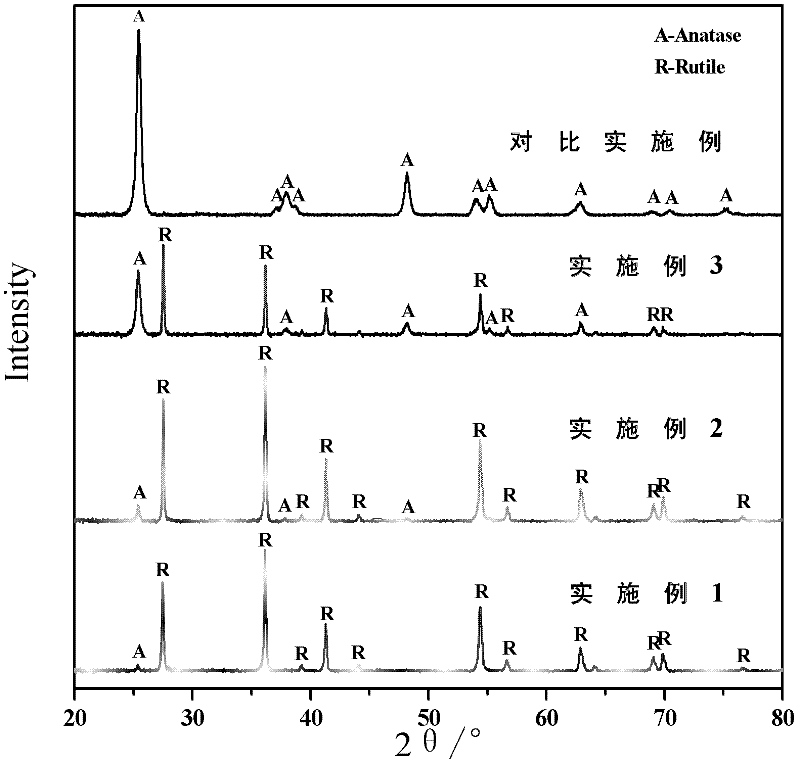

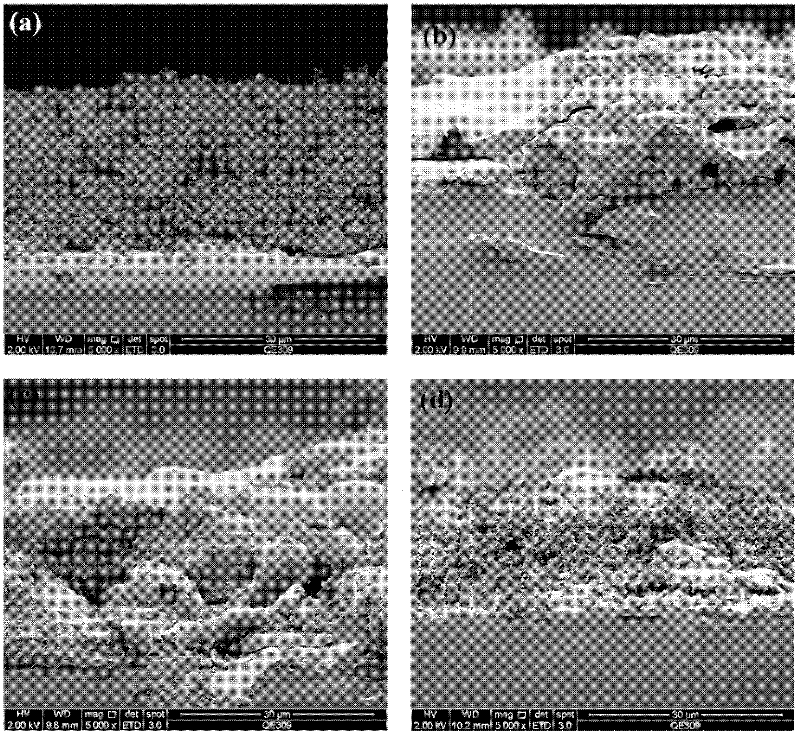

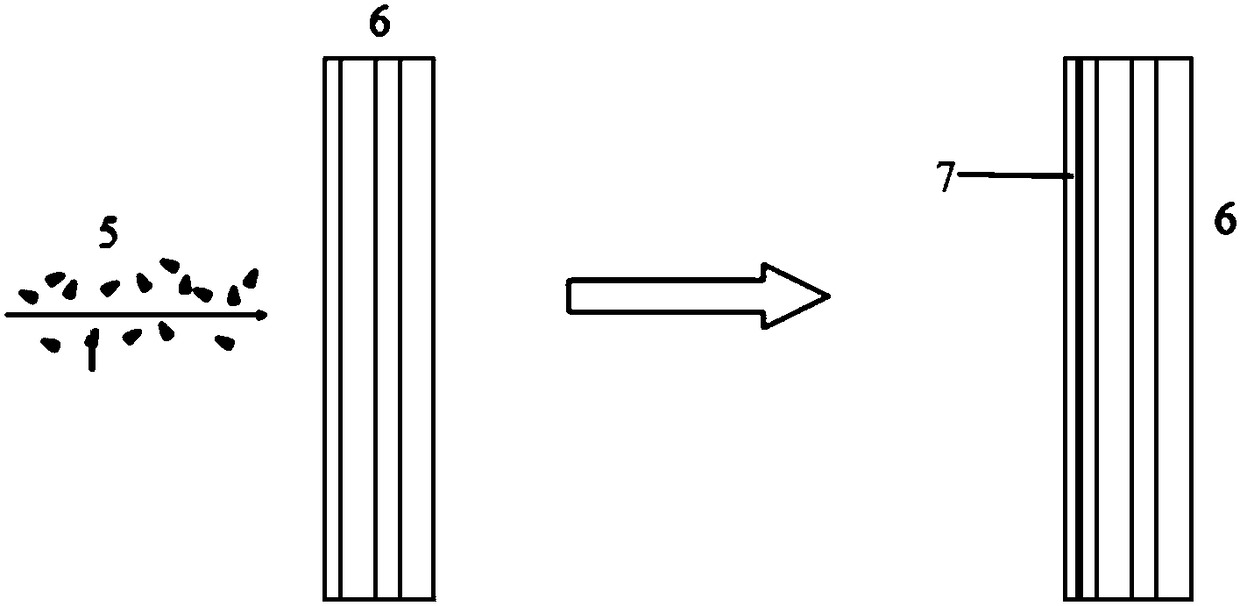

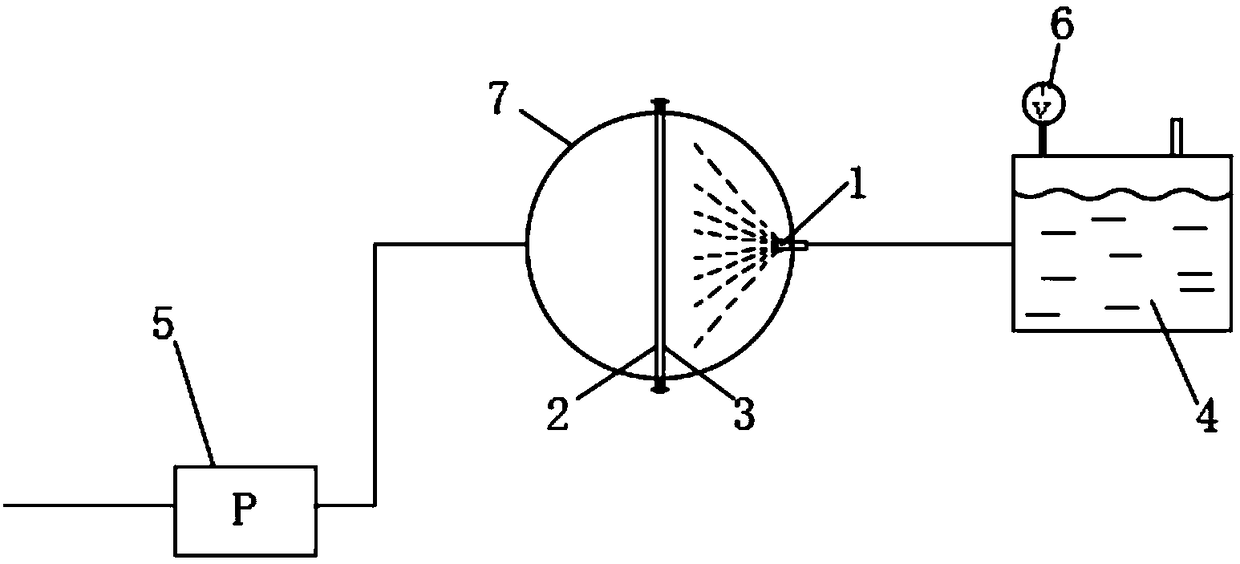

Micro-nanometer structure TiO2 coating with high hardness and high adhesion force as well as preparation method thereof

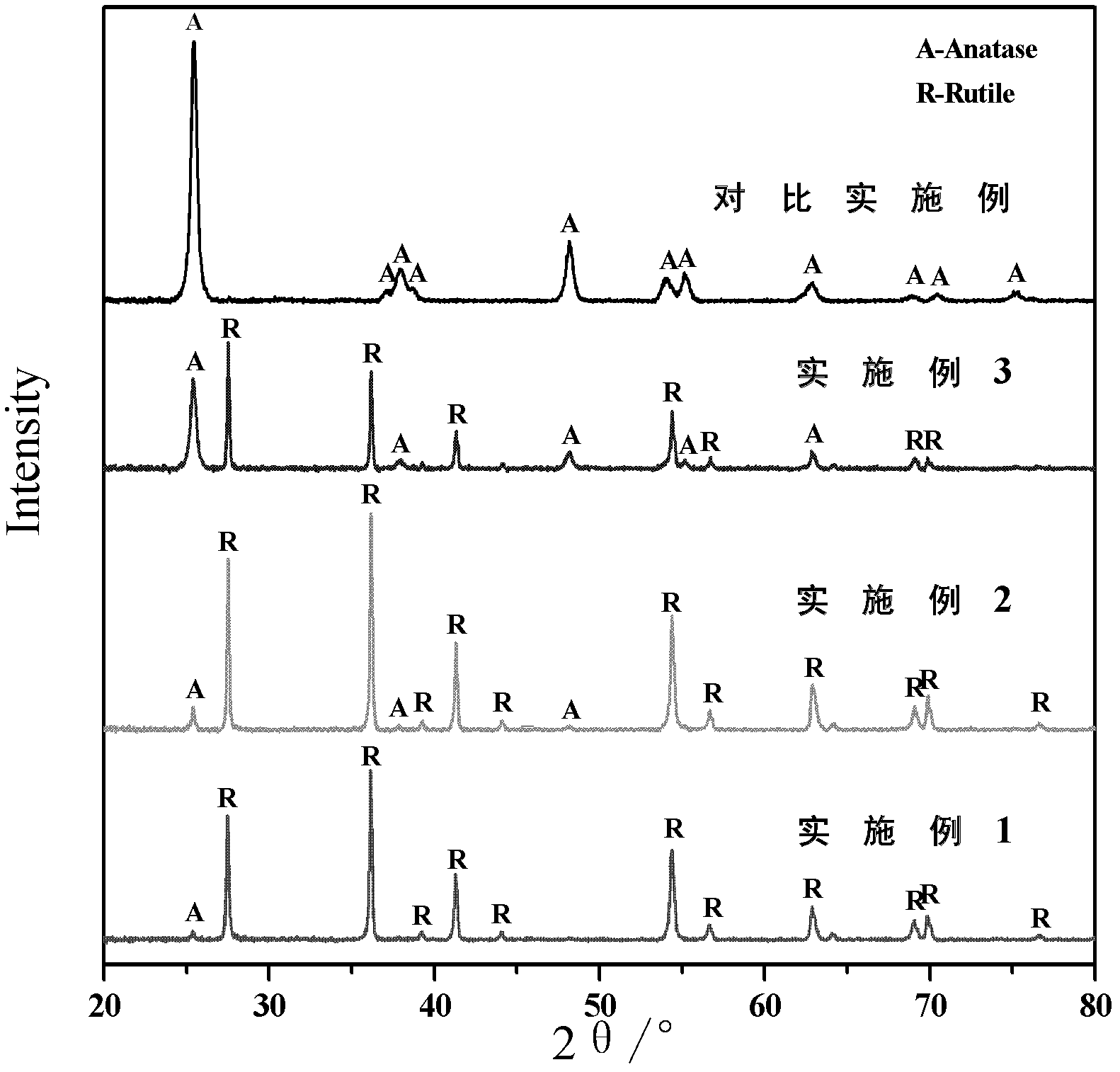

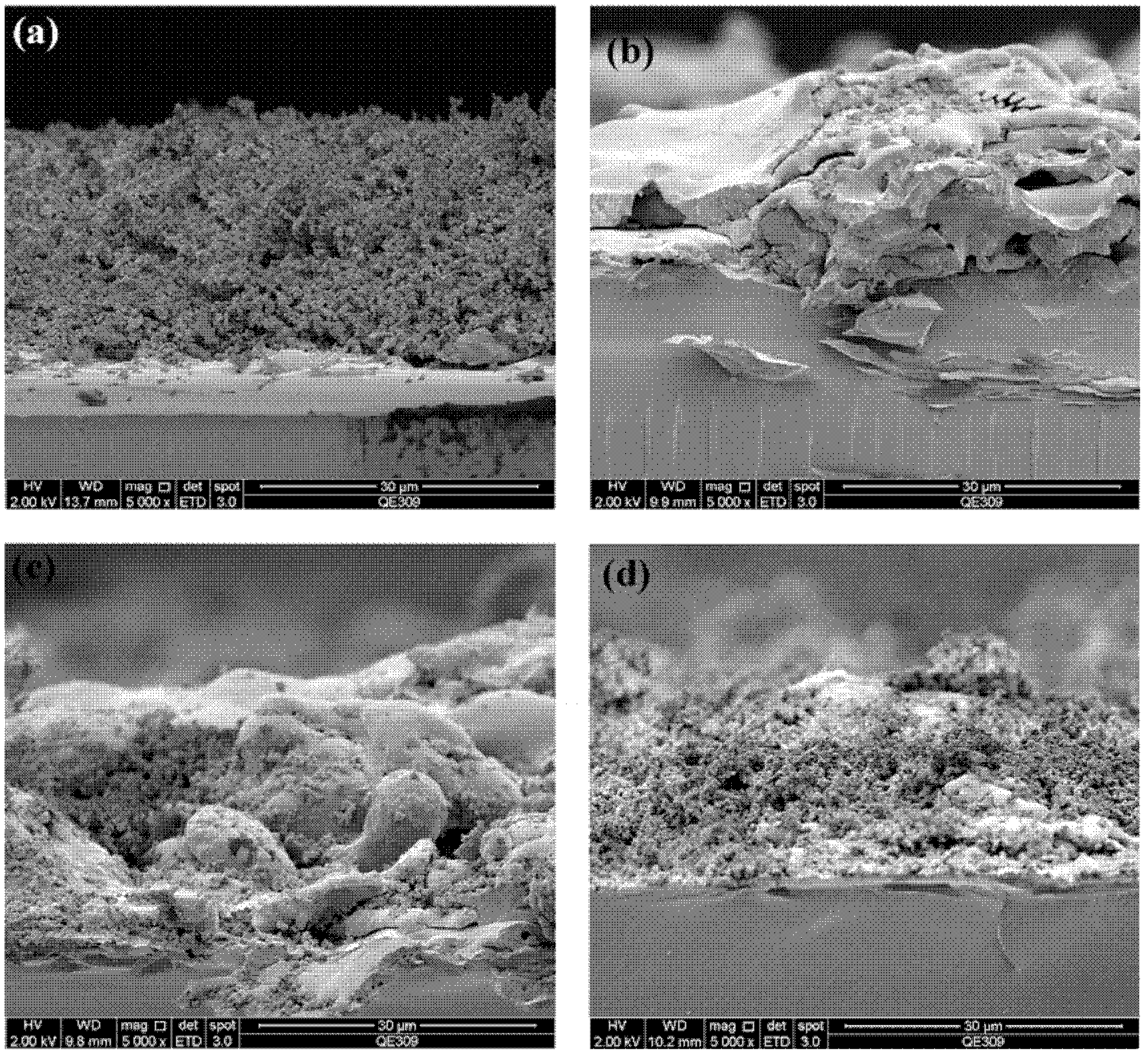

ActiveCN102373397AImprove adhesionHigh anatase phase contentMolten spray coatingAnatasePhase composition

The invention discloses a micro-nanometer structure TiO2 coating with high hardness and high adhesion force and a preparation method thereof. The thickness of the TiO2 coating is 10mum to 100mum, the crystal phase compositions of TiO2 in the coating are anatase phase and rutile phase, and in addition, the anatase TiO2 accounts for 3 percent to 35 percent of the mass percent of the TiO2 coating. The liquid phase hot spraying coating method and the traditional hot spraying coating method are adopted and are combined, TiO2 liquid materials and powder are simultaneously sent into hot spraying coating flame, compared with the TiO2 coating obtained by the liquid phase hot spraying coating method, the prepared TiO2 coating has the advantages that the microhardness is improved by nearly 10 times,the adhesion force is improved nearly 3 times, the photocatalysis function of the TiO2 coating is favorably realized, important application values are realized, and the micro-nanometer structure TiO2coating is hopeful to generate huge social and economic benefits.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

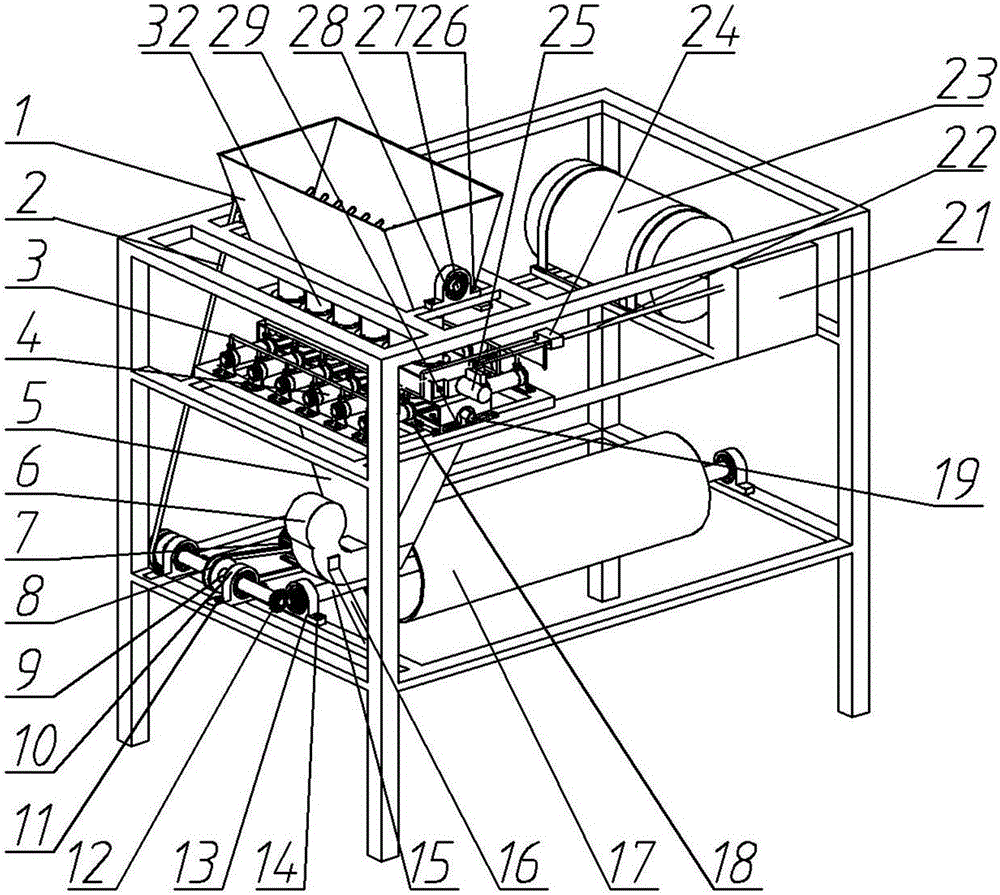

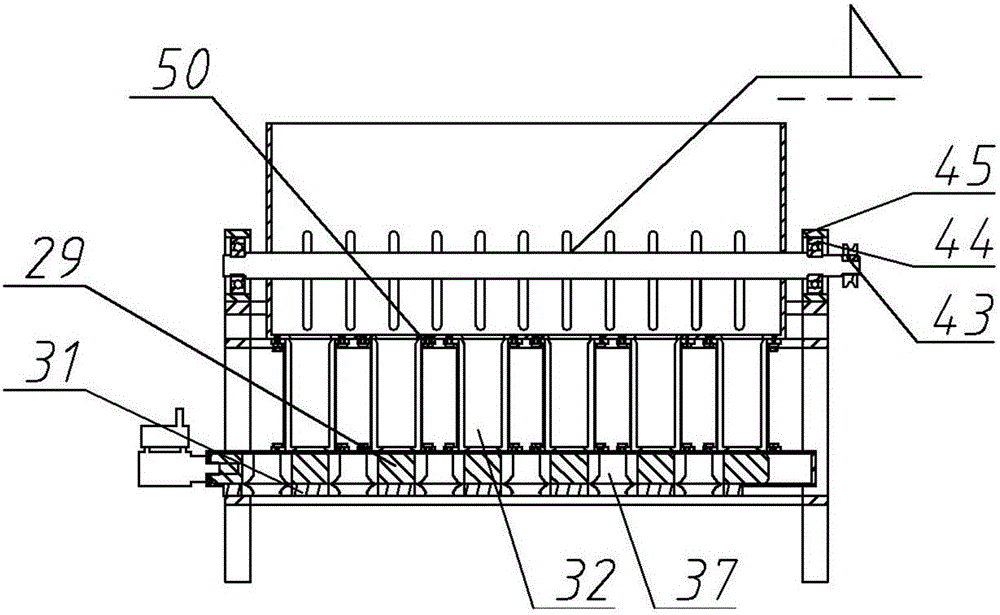

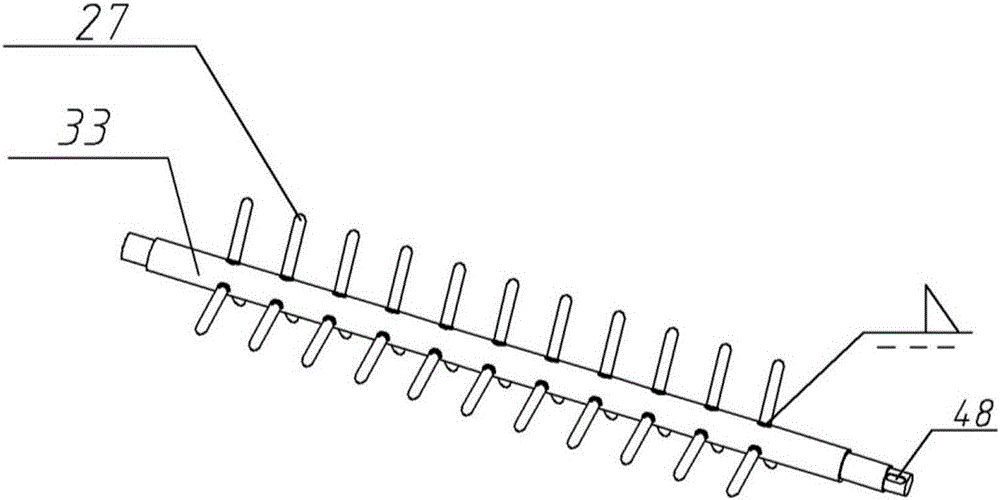

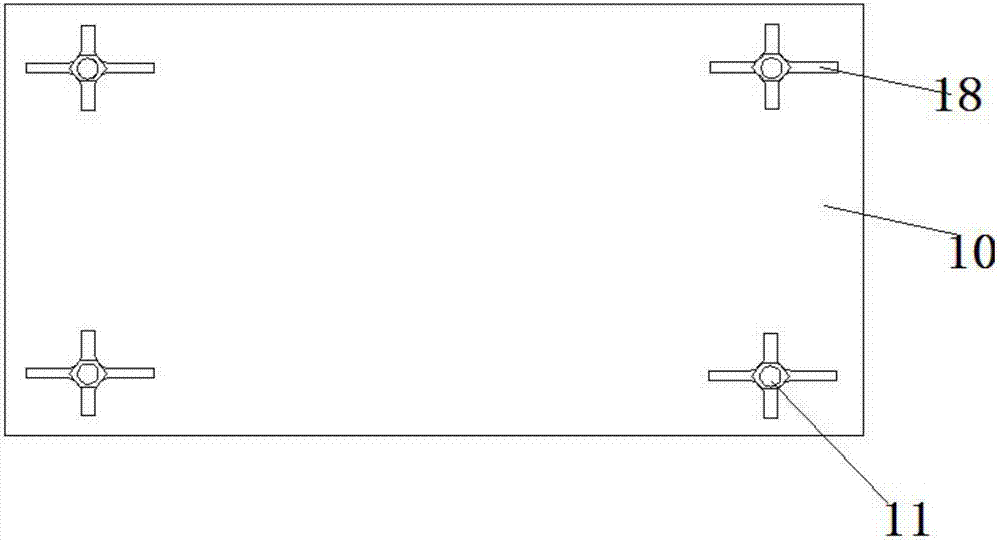

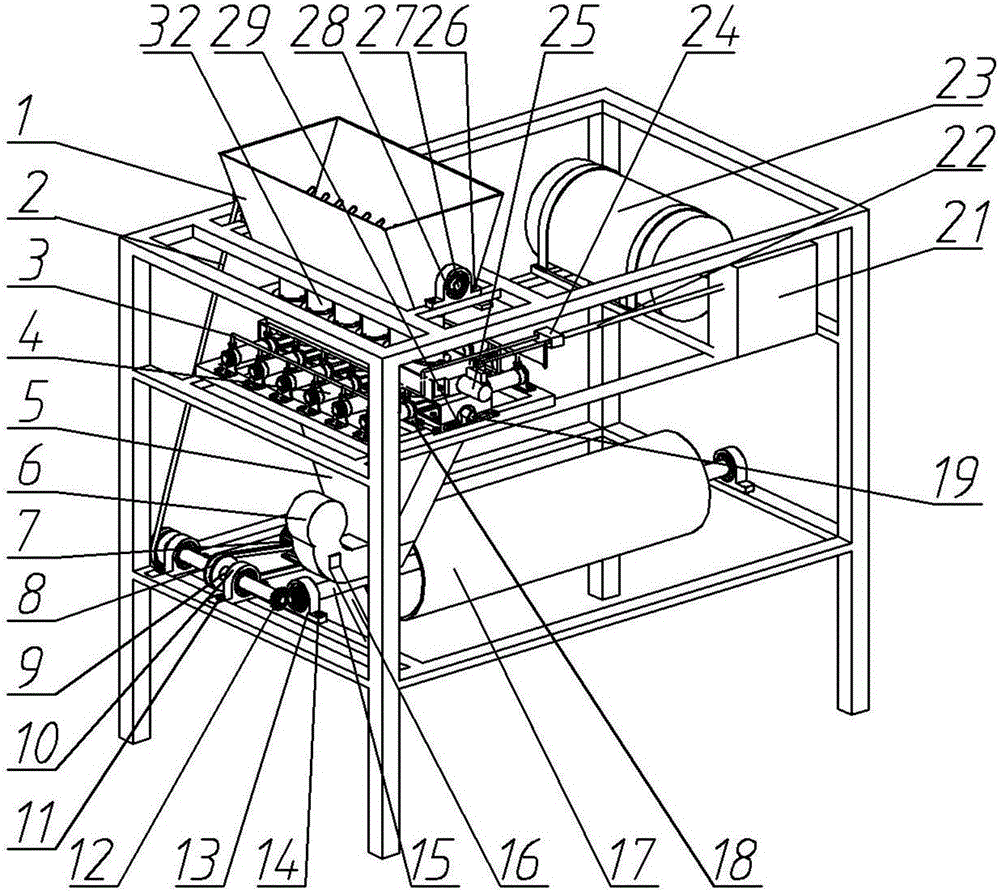

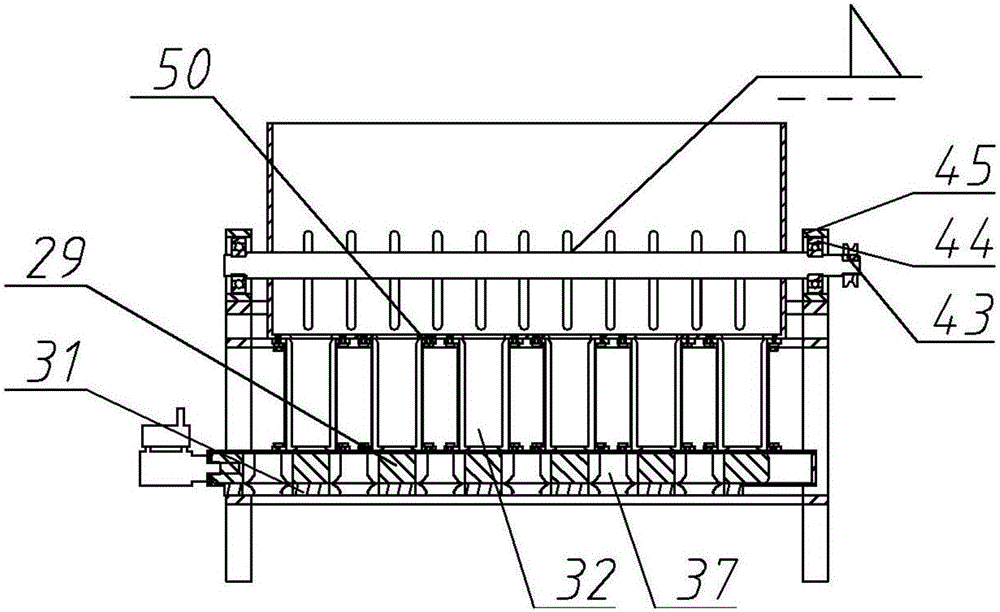

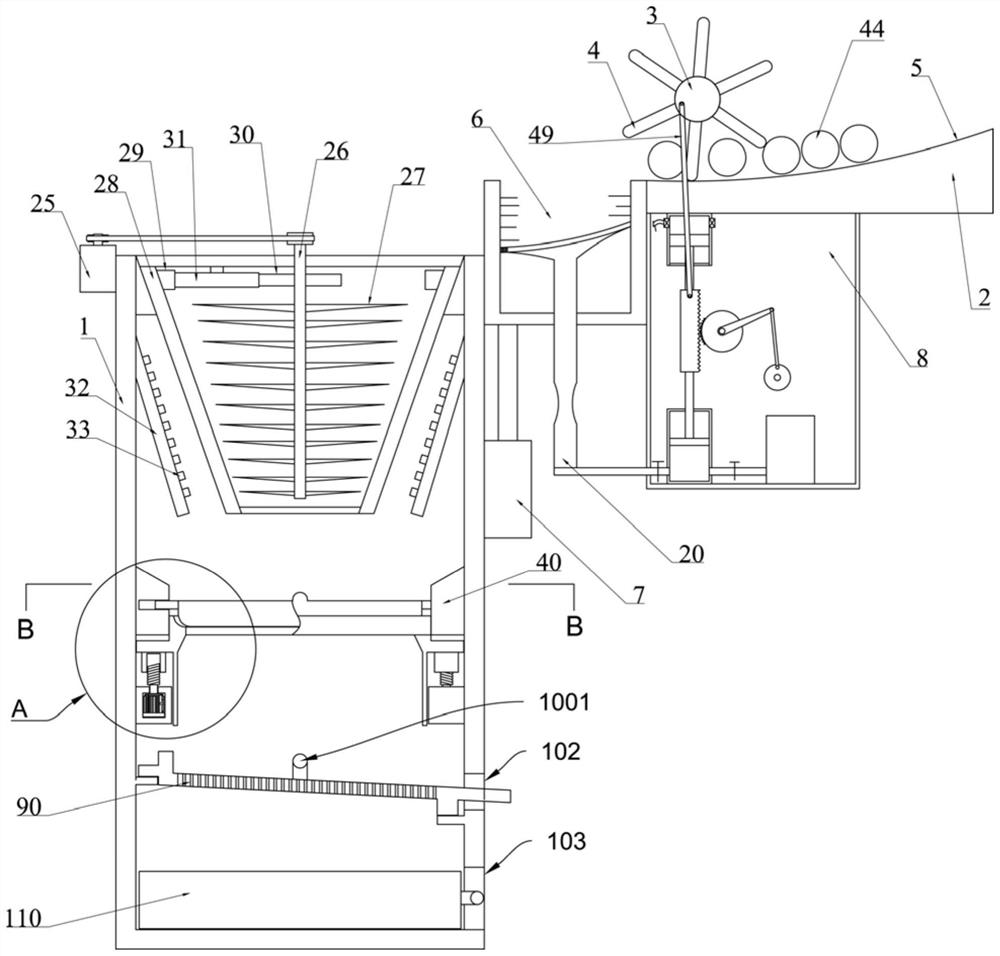

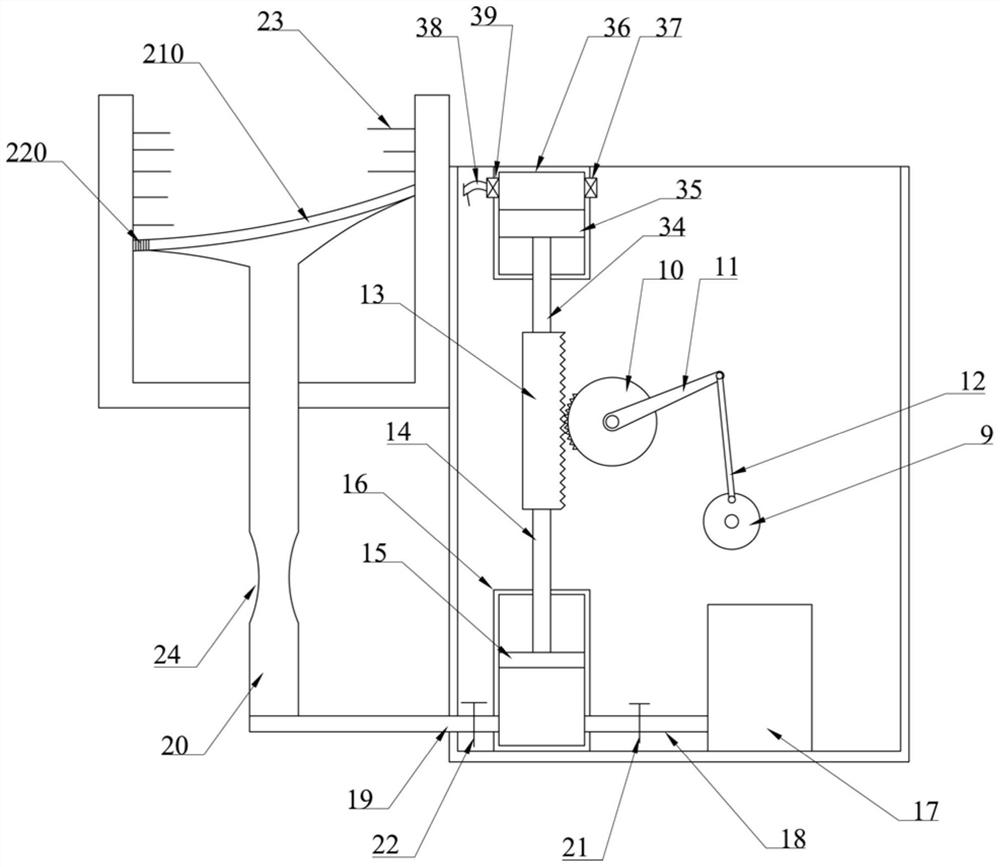

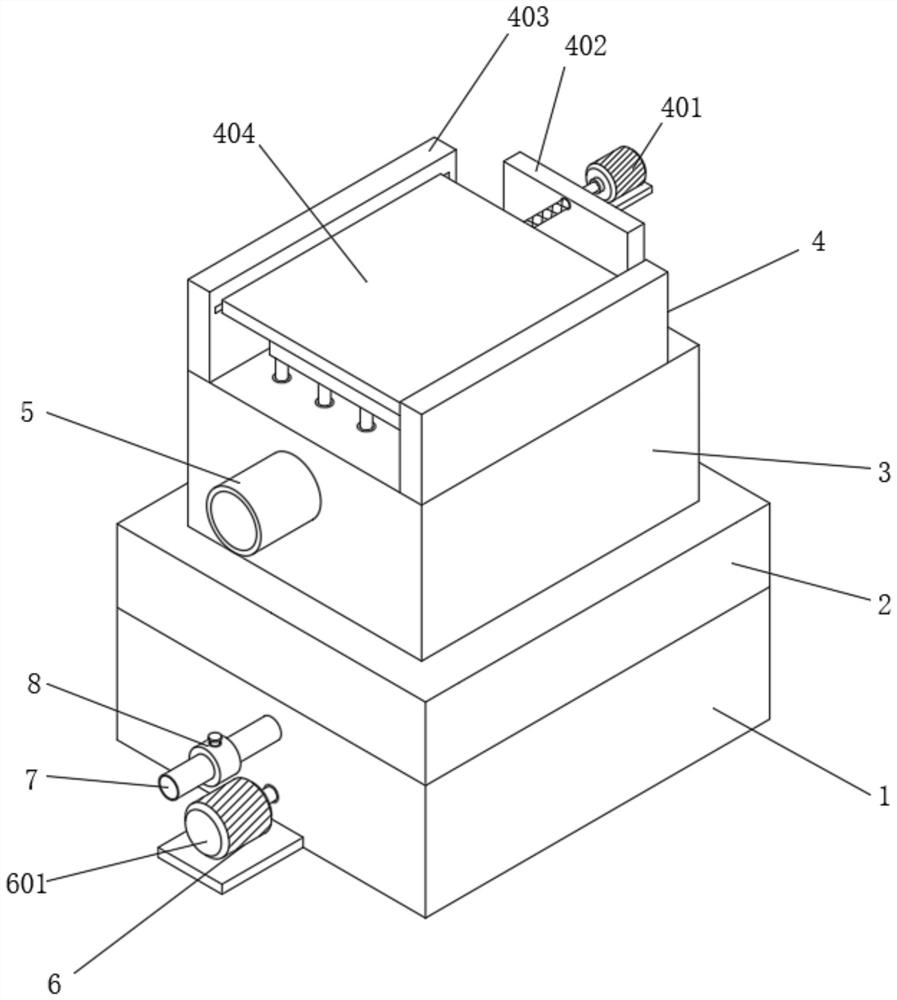

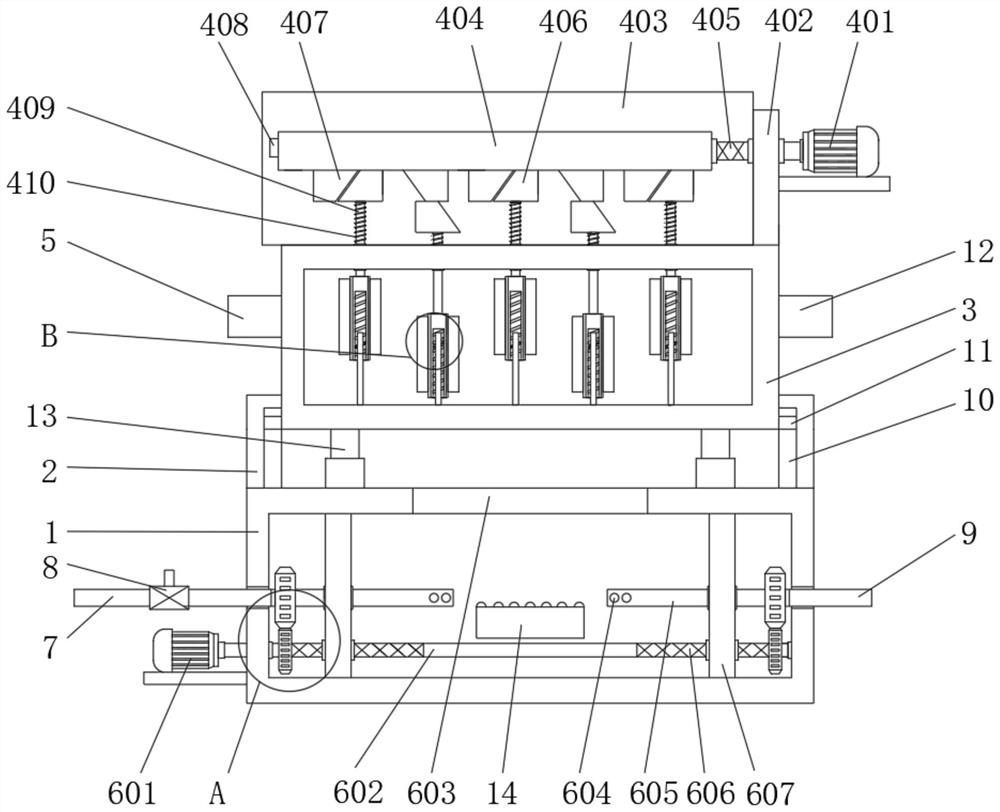

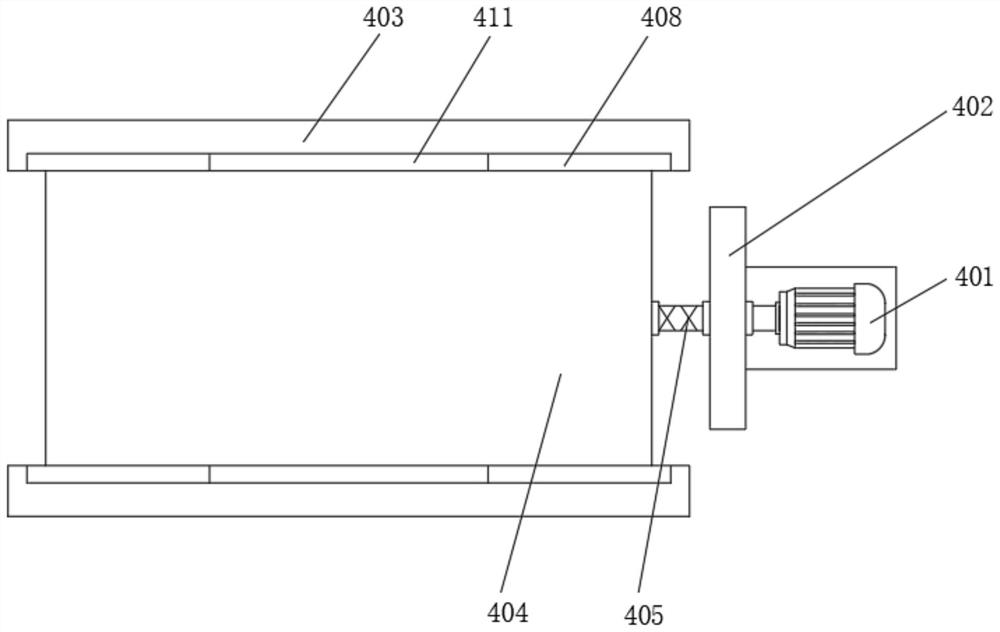

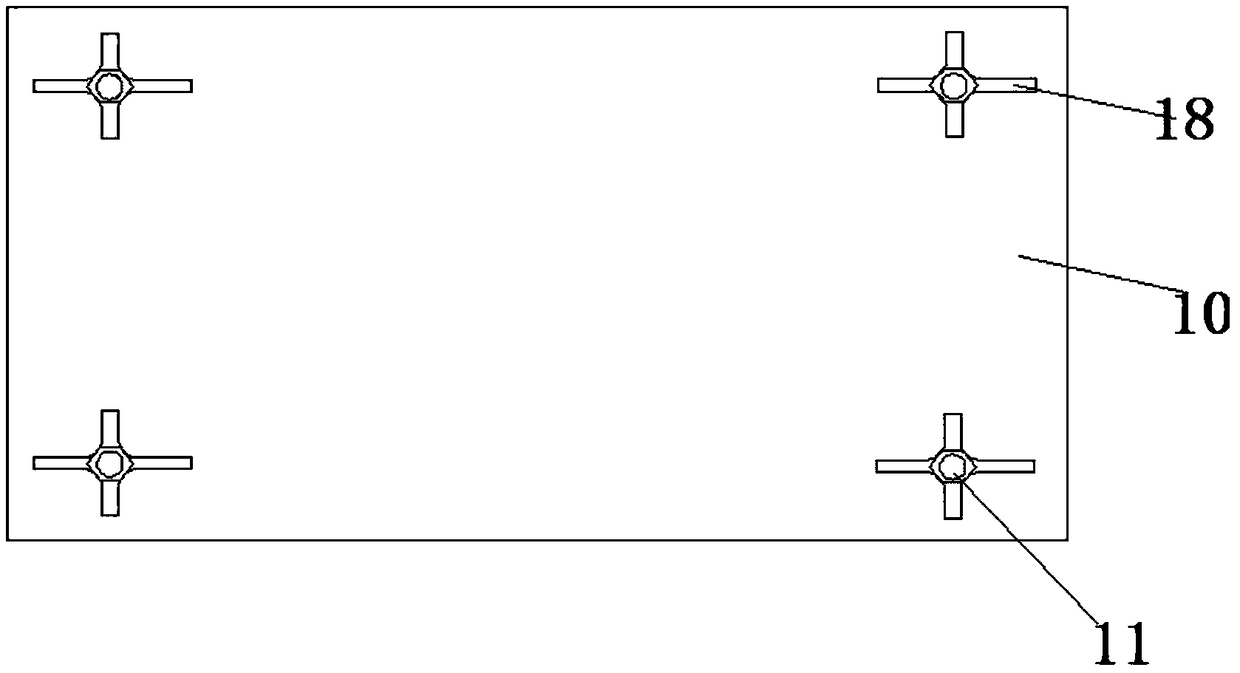

Walnut shell smashing device with automatic conveying and positioning functions and method for applying walnut shell smashing device

The invention discloses a walnut shell smashing device with automatic conveying and positioning functions and a method for applying the walnut shell smashing device. The walnut shell smashing device comprises at least one walnut fixing mechanism and at least two knocking rods. The walnut fixing mechanisms and the knocking rods are arranged on a framework, a walnut feeding hopper is arranged above the walnut fixing mechanisms, walnut positioning holes are formed in walnut shell smashing molds, positioning quantitative conveying sliders are respectively arranged on two sides of each walnut positioning hole and are for covering the walnut positioning hole, at least two open holes which are communicated with the corresponding walnut positioning hole are formed in the side walls of each walnut shell smashing mold, and the multiple knocking rods can be driven by moving mechanisms to penetrate the open holes corresponding to the knocking rods to knock walnuts arranged in the walnut positioning holes. The walnut shell smashing device and the method have the advantages that the walnuts can be conveyed by a stirring device, and the walnut shell smashing device is exquisite in structure, high in efficiency and extremely low in failure rate; a discharge hole of the feeding hopper and through holes in positioning and conveying mechanisms are in the shapes of walnut positioning sections, so that stable and invariable positioning results can be guaranteed in a series of walnut falling procedures; the walnuts are in accurate and controllable gestures, and accordingly the walnuts can be automatically and controllably fed.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

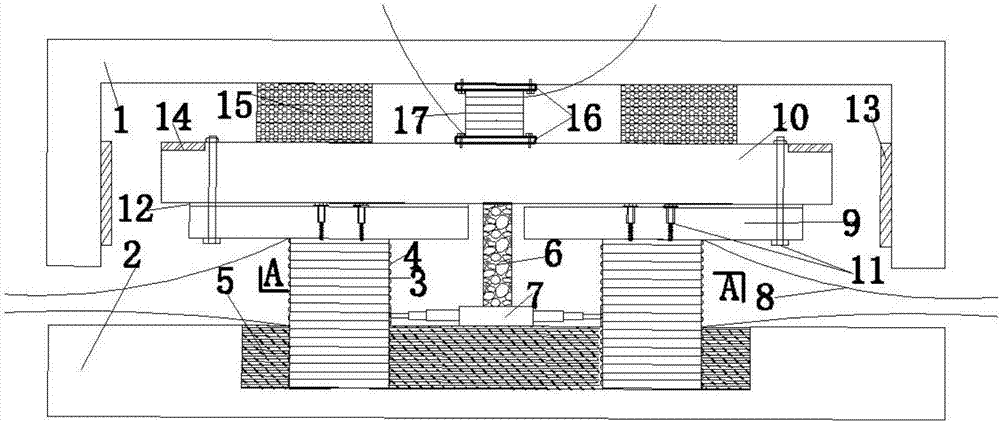

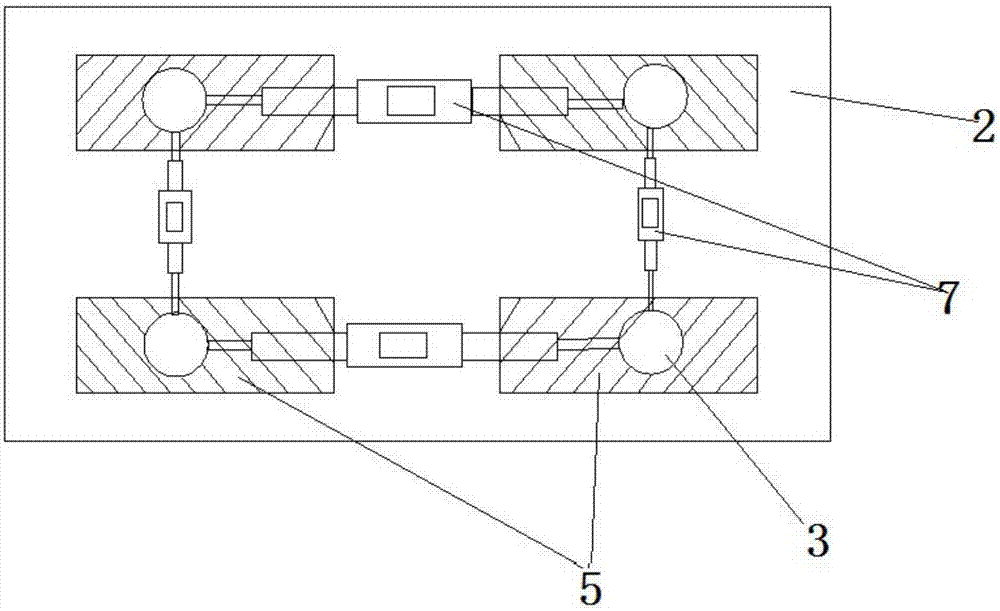

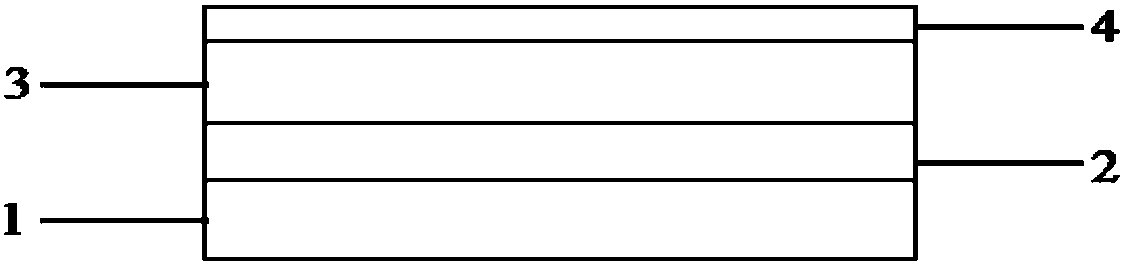

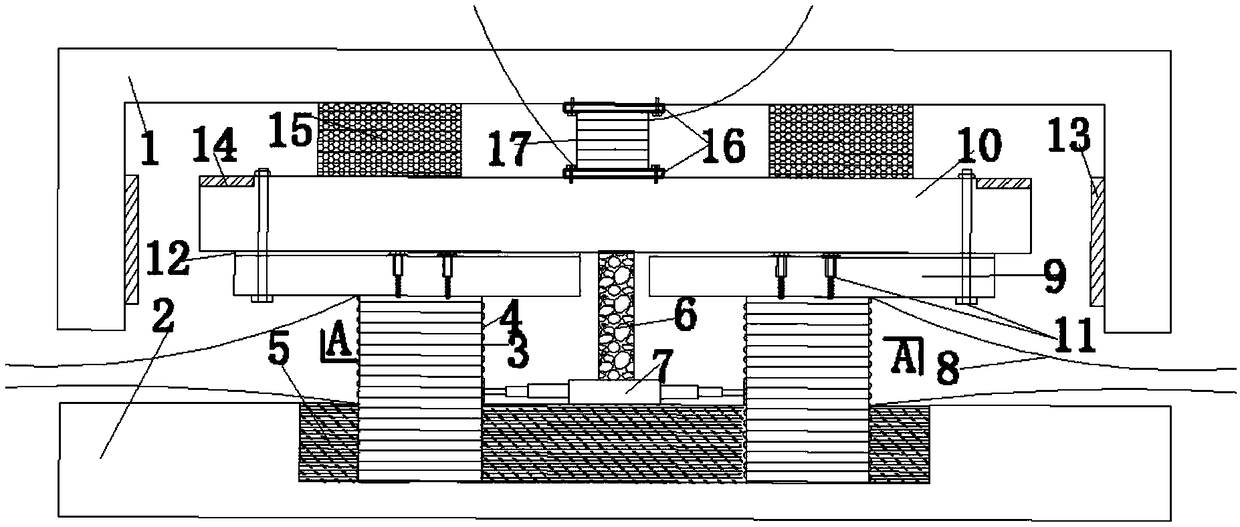

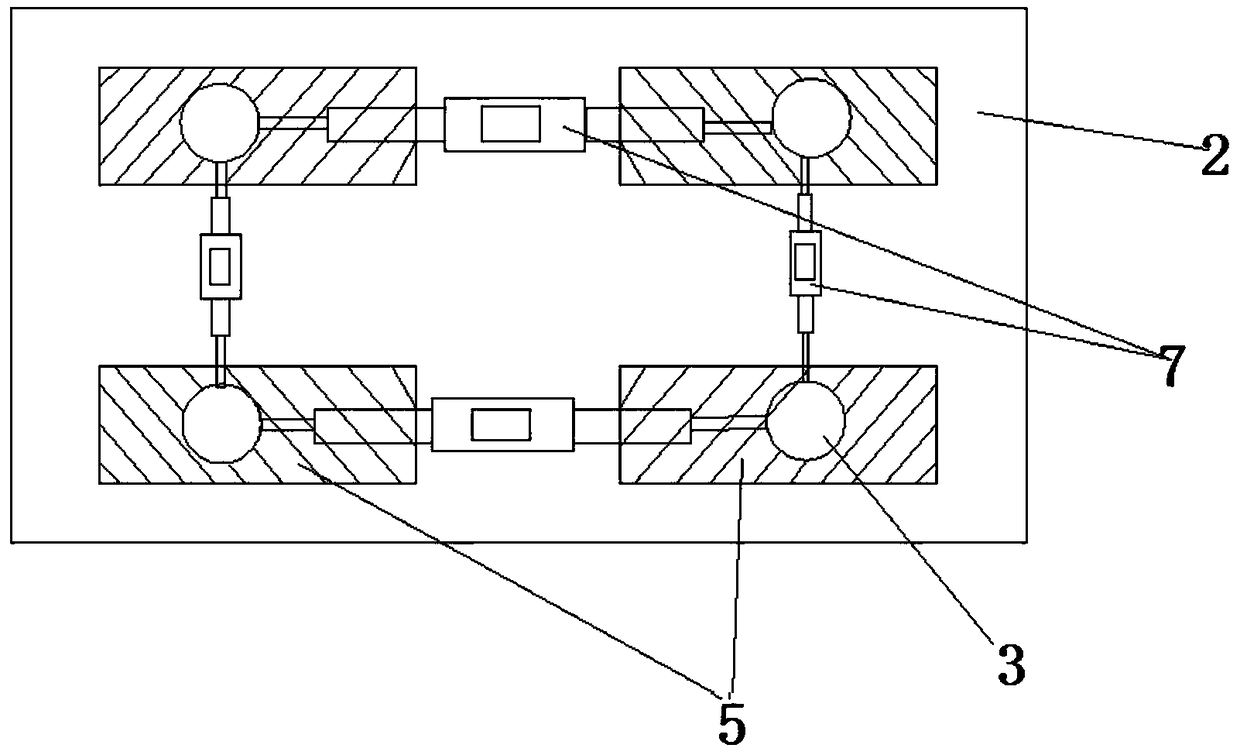

Controllable intelligent magnetorheological piezoelectric vibration isolation support

InactiveCN107165301ARealize controllabilityReal-time damping controlProtective buildings/sheltersShock proofingWireless transmissionEngineering

A controllable intelligent magnetorheological piezoelectric vibration isolation support comprises a lower steel plate and an upper cover plate. Magnetorheological liquid is arranged in four grooves inside the lower steel plate. High-magnetic sliding columns are arranged in the grooves. Excitation coils encircle the high-magnetic sliding columns. Meanwhile, a hydraulic telescopic rod is arranged between every two adjacent high-magnetic sliding columns. The tops of the high-magnetic sliding columns are connected with small friction plates. The small friction plates are connected with a large friction plate. The upper portion of a rubber body filled with magnetorheological gels is connected with the large friction plate, and the lower portion of the rubber body is directly connected with the lower steel plate. The upper portion of the large friction plate is connected with the upper cover plate through four rubber laminates. The large friction plate and the upper cover plate bear force stably through an upper force transmission cushion plate, a lower force transmission cushion plate and a supporting steel body filled with piezoelectric stacks. Rubber cushion layers are stuck to the interiors of the two side walls of the upper cover plate. Pressure sensor modules arranged inside the rubber cushion layers are matched with wireless transmission modules arranged on the two sides of the large friction plate. According to the controllable intelligent magnetorheological piezoelectric vibration isolation support, real-time monitoring is achieved, and the vibration isolation support is controlled actively to reset and has the advantages of quick response and high sensitivity.

Owner:XIJING UNIV

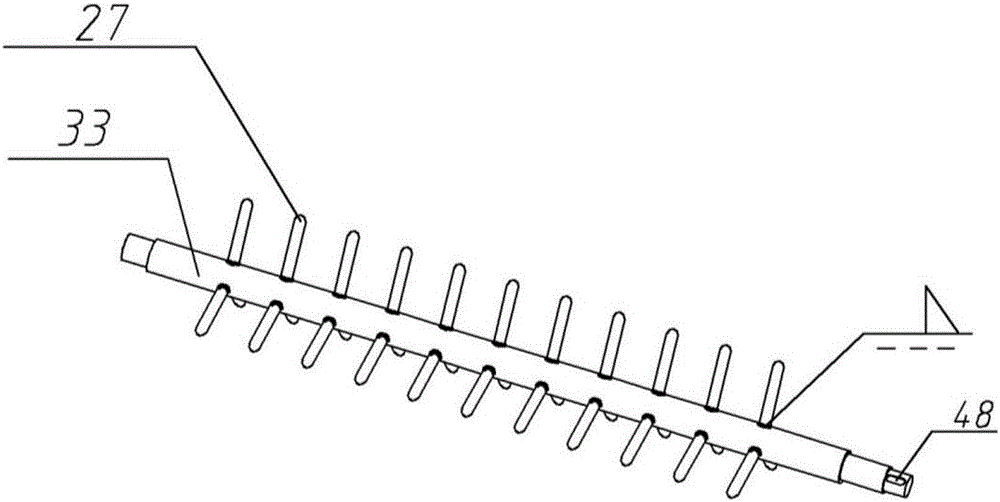

Walnut shell breaking, kernel taking and separating device and application method thereof

The invention discloses a walnut shell breaking, kernel taking and separating device and an application method thereof. The walnut shell breaking, kernel taking and separating device comprises at least one walnut fixing mechanism and at least two impact rods which are arranged on a rack as well as locating and quantitative feeding sliding blocks which are arranged at the two sides of walnut locating holes and are respectively used for covering the walnut locating holes, wherein the walnut locating holes are formed in a walnut shell breaking mould, at least two open pores communicated with the walnut locating holes are formed in the side wall of the walnut shell breaking mould, multiple impact rods penetrate through the open pores corresponding to each impact rod when being driven by a moving mechanism to impact walnuts arranged in the walnut locating holes, a collecting device is arranged below the locating and quantitative feeding sliding blocks at one side of the walnut locating holes, and the collecting device is connected with an air blower. The walnut shell breaking, kernel taking and separating device has the advantages that a stirring device is adopted for feeding, structure is delicate, efficiency is high, and failure rate is extremely low; and shape of a discharging hole of a feeding hopper and a through hole in a locating and conveying mechanism adopt a walnut locating cross-section shape, and automatic and controllable walnut feeding is realized.

Owner:广州华大生物科技有限公司 +1

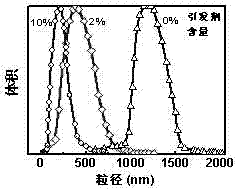

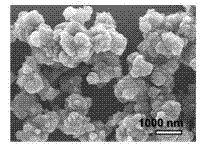

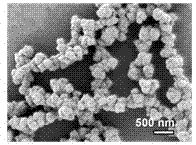

Size-controllable polypyrrole nano particle and preparation method thereof

The invention discloses a size-controllable polypyrrole nano particle and a preparation method thereof. The preparation method comprises the following steps of: dissolving pyrrole and an initiator into a first solvent to form blended solution of pyrrole monomer and the initiator; dissolving an oxidant into a second solvent to form oxidant solution; then mixing the blended solution of the pyrrole monomer and the initiator with the oxidant solution, swaying violently, standing, and after reaction is complete, carrying out centrifugation, washing, drying and the like; and finally, obtaining the size-controllable polypyrrole nano particle. According to the size-controllable polypyrrole nano particle and the preparation method thereof, the preparation step is simple, high in efficiency and high in controllability; the particle size of the obtained size-controllable polypyrrole nano particle is 80-600nm, and the electric conductivity of the obtained size-controllable polypyrrole nano particle is 10<-2>-10<-7>S / cm. The size-controllable polypyrrole nano particle and the preparation method thereof can be used for the application fields such as sensors, actuating devices, artificial muscles, overpotential containers, electrochromic color-changing windows, fuel cells, functional coatings and ultrafiltration membranes.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Filter bag for filtering and recovering nonferrous metal dust and preparation method thereof

ActiveCN108071020AHD Gray EffectivenessPrevent resorptionDispersed particle filtrationMembrane filtersEmulsionNonferrous metal

The invention discloses a filter bag for filtering and recovering nonferrous metal dust and a preparation method thereof. The filter bag comprises the following components in percentage by weight: 85-95% of a micro-porous composite filter material and 5-15% of an adsorption layer supported onto the micro-porous composite filter material, wherein the adsorption layer is a mixture obtained by blending magnetic nanocrystalline iron oxide, a polytetrafluoroethylene dispersion emulsion and a dispersing agent emulsion and performing curing treatment; the mixture comprises the following components inpercentage by weight: 3-25% of the magnetic nanocrystalline iron oxide, 55-70% of the polytetrafluoroethylene and the balance of a cured dispersing agent emulsion. The filter bag prepared by the invention has high adsorption capacity on the metal dust, the formation time of a pressed powder layer is effectively shortened, and the nonferrous metal recovery rate and ash removal effectiveness are improved. The filter bag disclosed by the invention is high in filtering precision, the conductivity is obviously improved, and excellent antistatic and explosion-proof properties are obtained.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

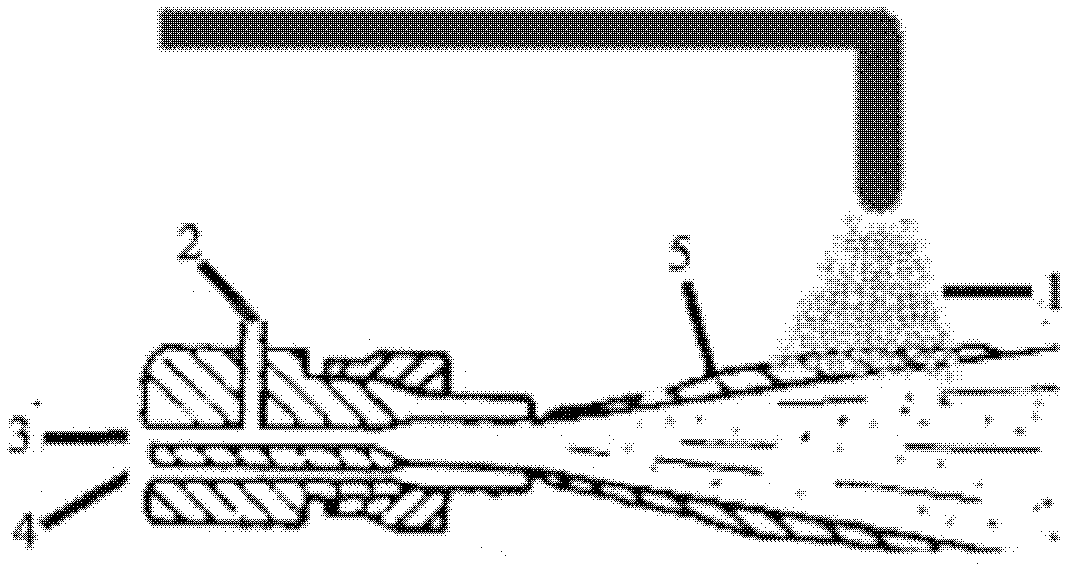

Chestnut sheller with positioned conveying and usage thereof

ActiveCN105852149AExquisite structureImprove efficiencyHuskingHullingMechanical engineeringEngineering

The invention discloses a chestnut sheller with positioned conveying and usage thereof. The chestnut sheller comprises at least one chestnut fixator and at least two impact rods both arranged on a frame, a chestnut shelling die is provided with a chestnut positioning hole, the sidewall of the chestnut shelling die is provided with at least two holes in communication with the chestnut positioning hole, the multiple impact rods are driven by a moving mechanism to pass through the holes corresponding to the impact rods, impacting on chestnuts placed in the chestnut positioning hole, the chestnut sheller also comprises positioning quantitative feeding sliders disposed on two sides of the chestnut positioning hole to cover the chestnut positioning hole, a positioned conveying mechanism is arranged above the positioning quantitative feeding slider at the inlet side of the chestnut positioning hole, and an inner passage of the positioned conveying mechanism is as shaped as maximum cross section of a chestnut; the positioned conveying mechanism and the positioning quantitative feeding sliders cooperate to store chestnuts in the inner passage of the positioned conveying mechanism before the chestnuts enter the chestnut positioning hole, and operation in the chestnut positioning hole is guaranteed effectively.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

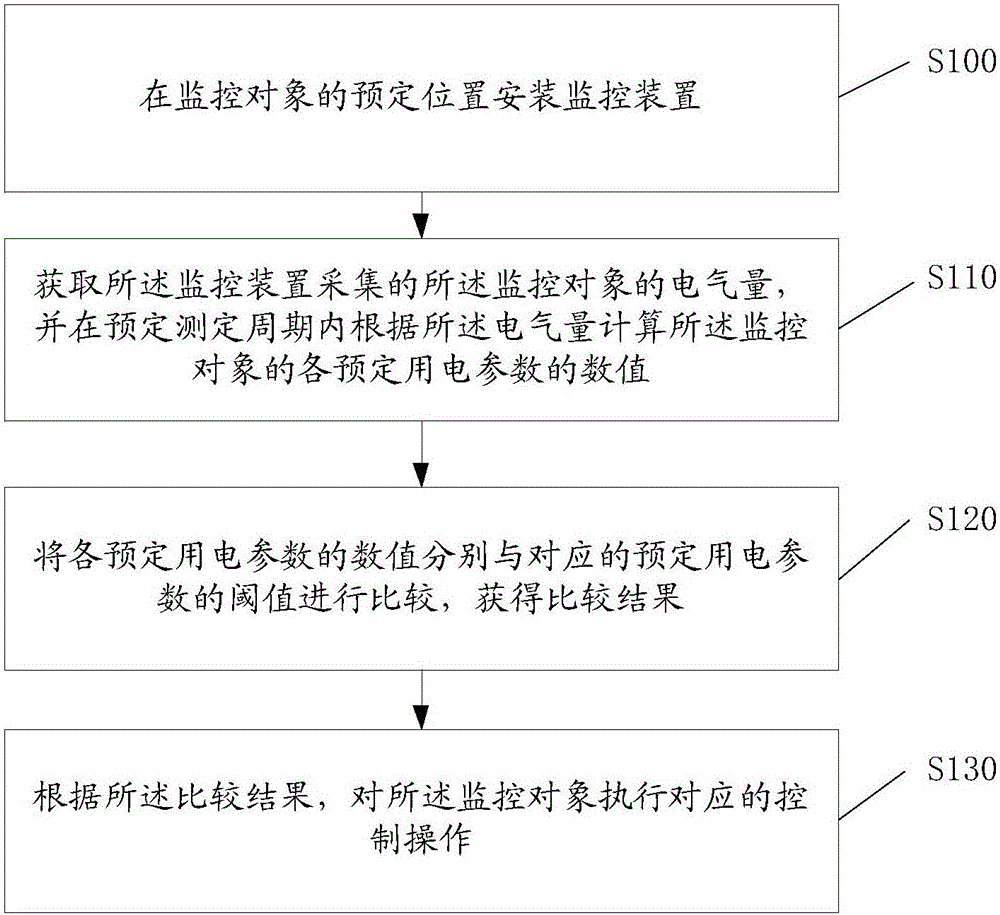

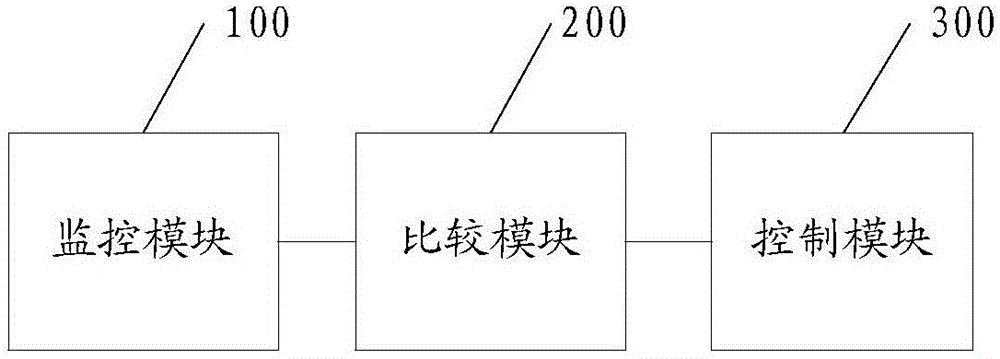

Power consumption condition monitoring method and system

ActiveCN106199172ARealize informatizationImprove efficiencyElectric devicesElectrical testingObject basedEngineering

The invention discloses a power consumption condition monitoring method. The power consumption condition monitoring method includes installing a monitoring device at the predetermined position of a monitored object; acquiring the electric quantity of the monitored object acquired by the monitoring device, and calculating the value of each predetermined power consumption parameter of the monitored object in the measuring period based on the electric quantity; comparing the value of each predetermined power consumption parameter with the corresponding threshold of the predetermined power consumption parameter to obtain a comparison result; and executing the corresponding control operation on the monitored object based on the comparison result. By installing the monitoring device at the predetermined position of the monitored object, the electric quantity of the monitored object can be obtained in real time; the informationization, visualization and controllability of the dynamic process of energy consumption can be realized, the energy consumption structure, process, and elements during the enterprise production process can be managed, controlled and optimized, and the energy use efficiency is improved. The invention further discloses a power consumption condition monitoring system.

Owner:GUANGDONG POWER GRID CO LTD

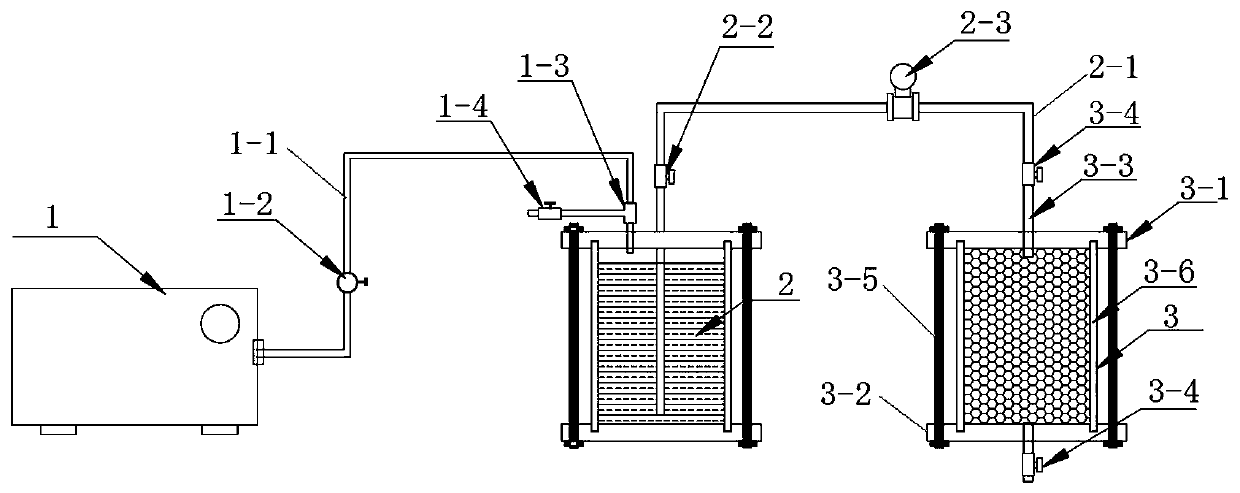

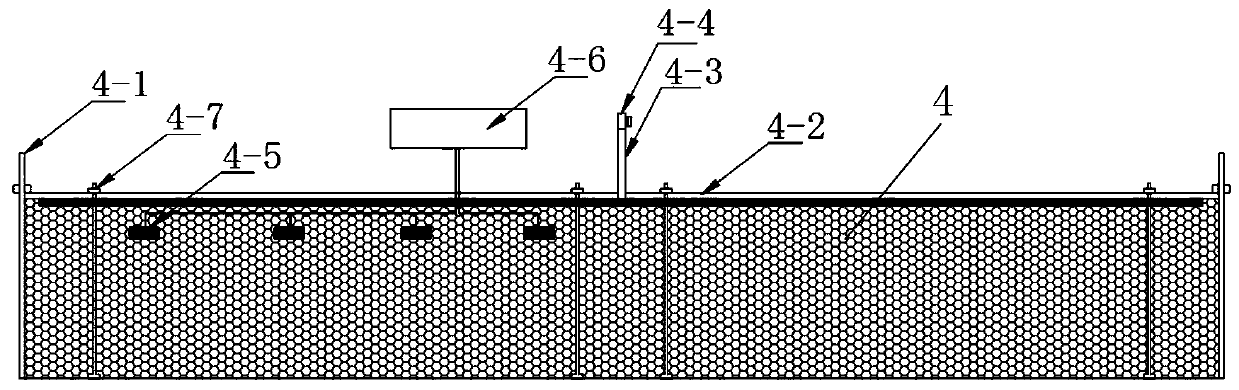

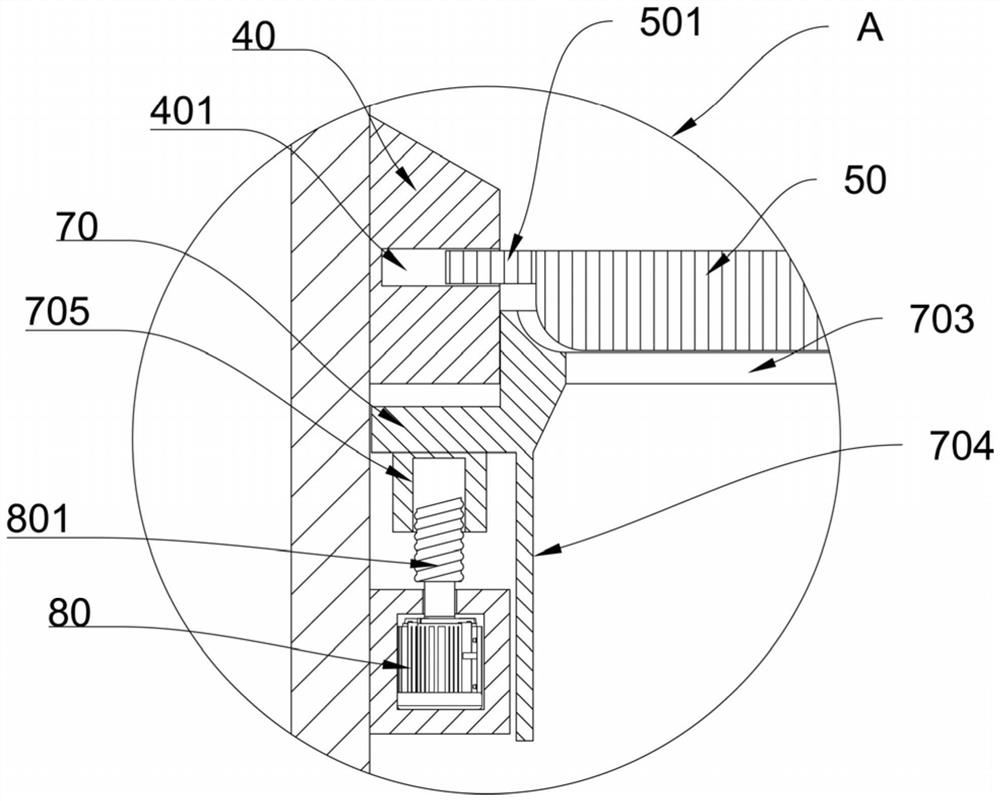

Pressure-stabilized simulated grouting test device and application method thereof

PendingCN109959775AReal-time monitoring of pressure changesRealize controllabilityEarth material testingTest roomEngineering

The invention discloses a pressure-stabilized simulated grouting test device and an application method thereof. The technical problems that the existing grouting test cannot repeatedly simulate a plurality of working conditions and the grouting pressure is difficult to control are solved. The device provided by the invention comprises a slurry grouting tank which is connected with an air compressor through a first conduit. A pressure regulating valve is arranged on the first conduit. The slurry grouting tank is connected with a sample mold through a second conduit. The second conduit is provided with a slurry outlet valve. The sample mold is a visualized pressure infiltration sample mold or a visualized slurry diffusion radius and real-time medium pressure detection sample mold. The methodcan realize the grouting process of a grouted medium in a test room from compaction to split grouting, and can monitor the variation law of the top pressure and the diffusion radius between structural layers, and realizes the visualization of the grouting process and the controllability of the grouting pressure and the grout amount. The operation is simple, and the test results are easy to quantify.

Owner:ZHENGZHOU UNIV

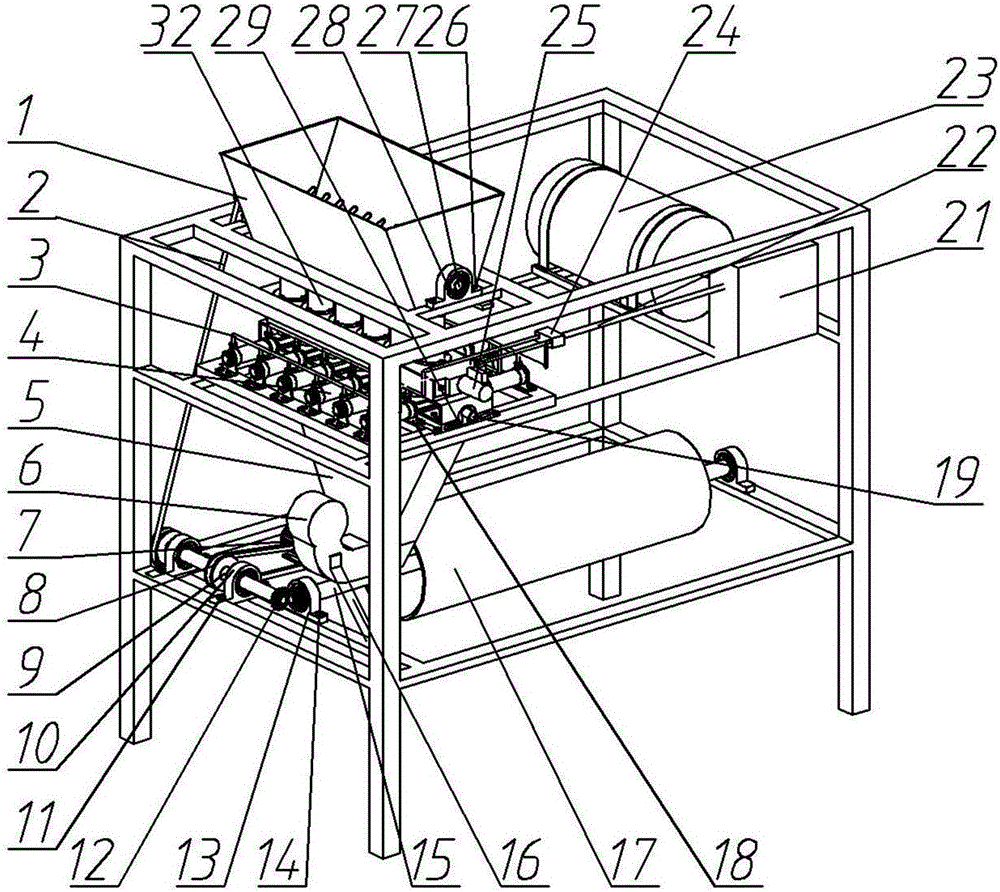

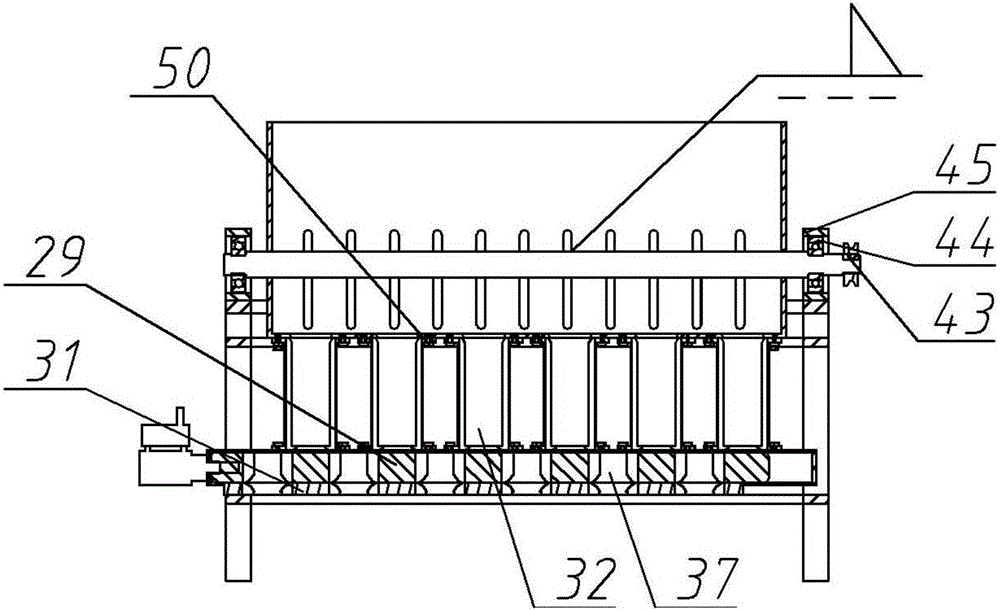

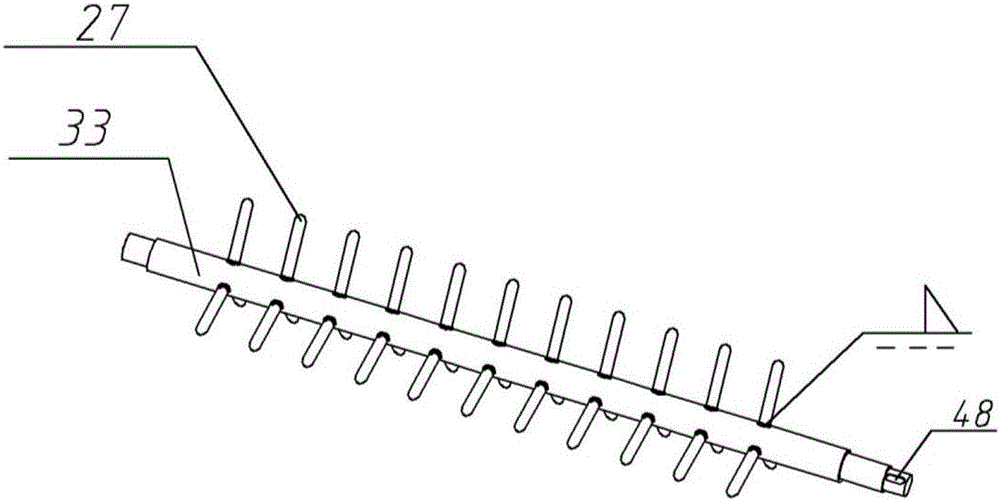

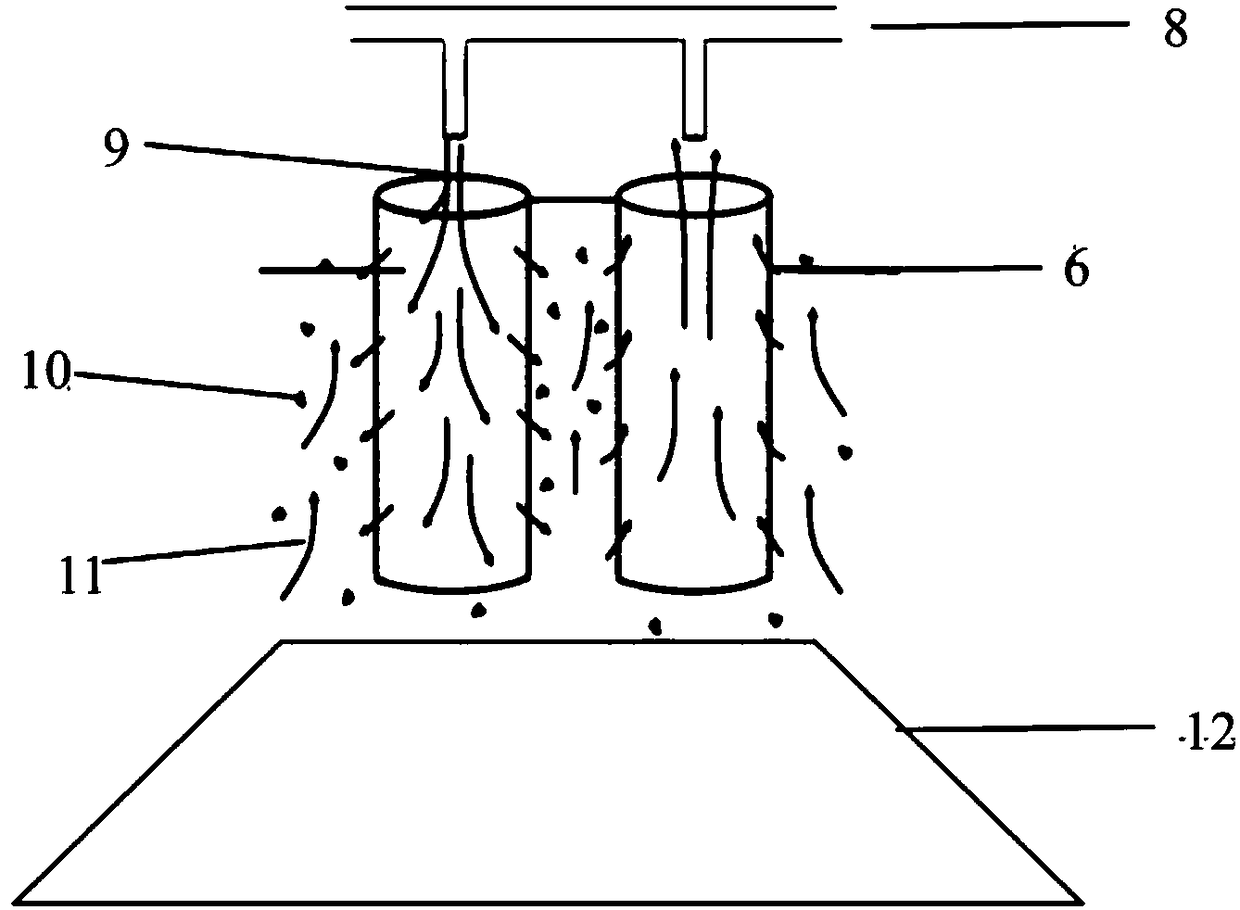

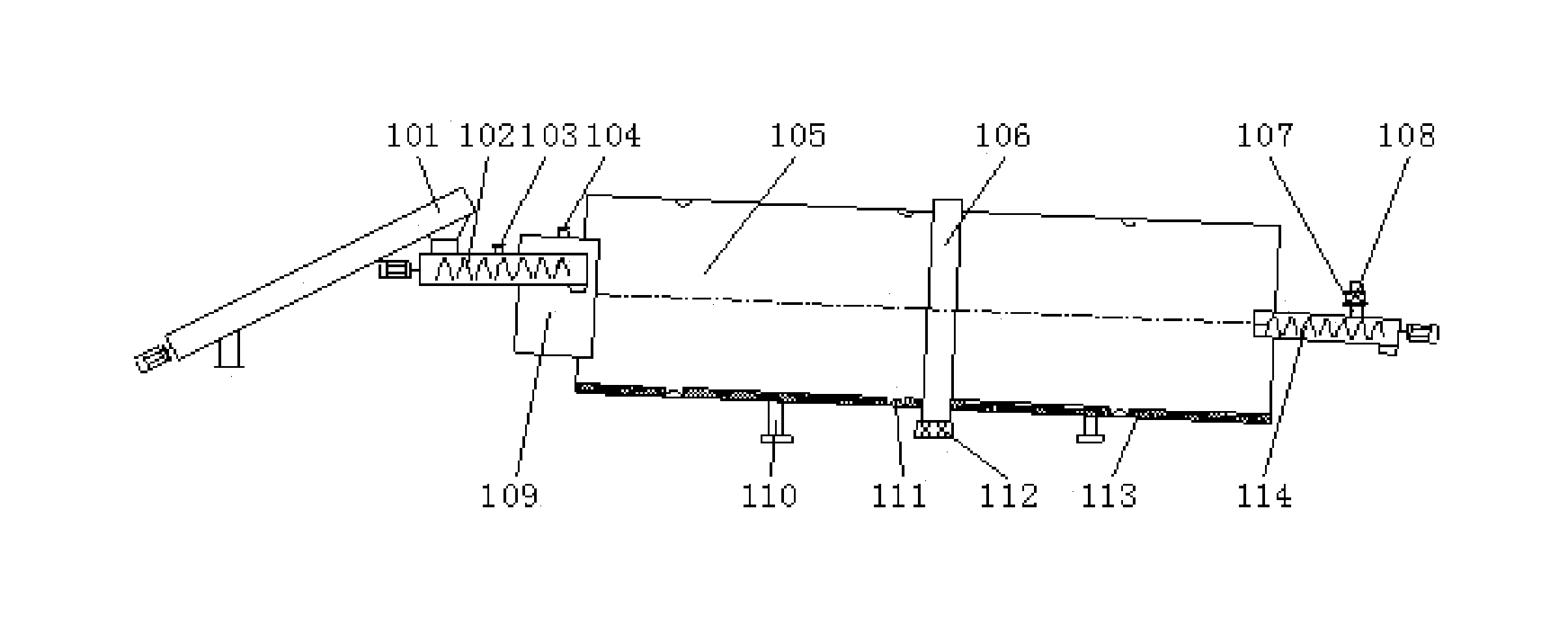

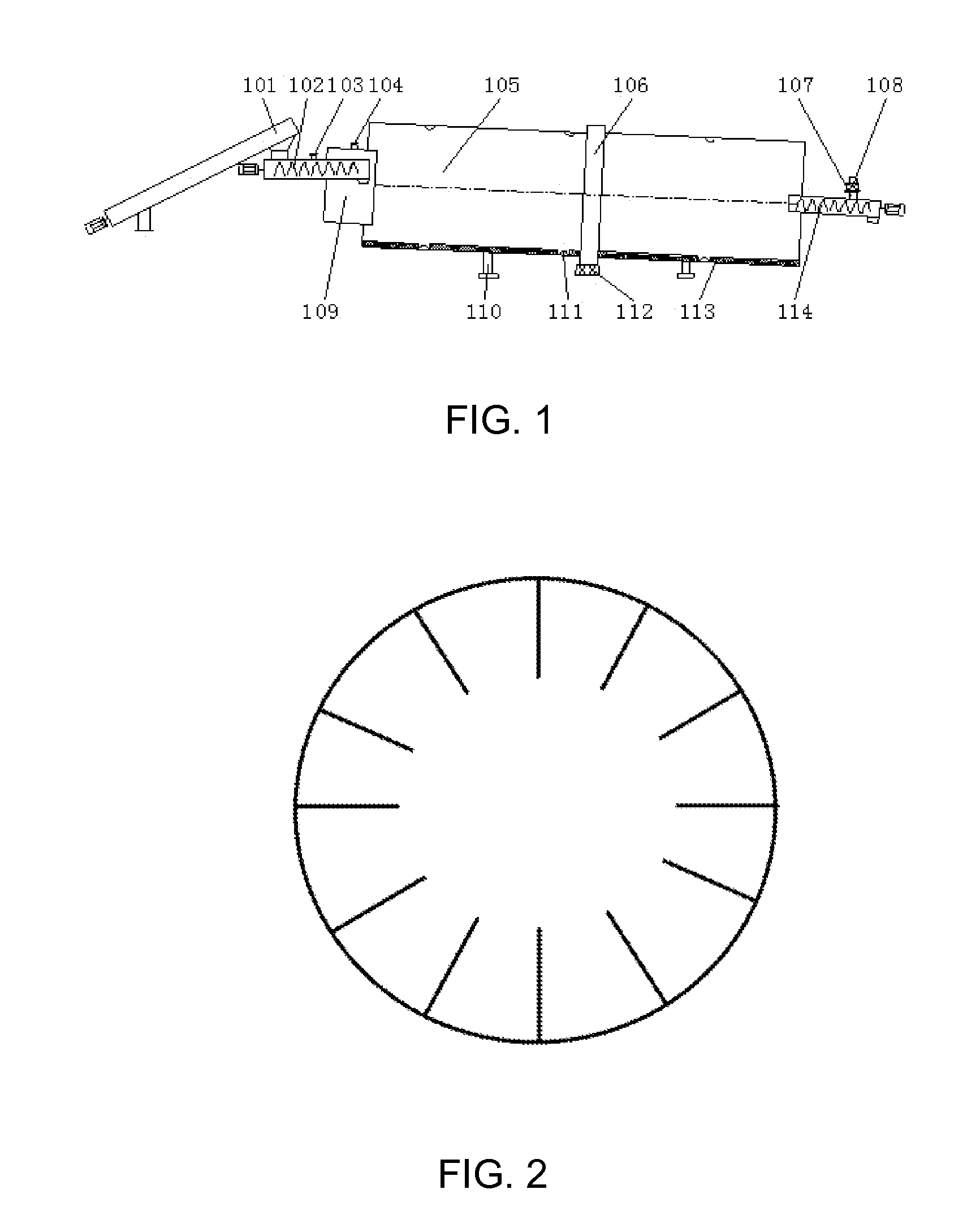

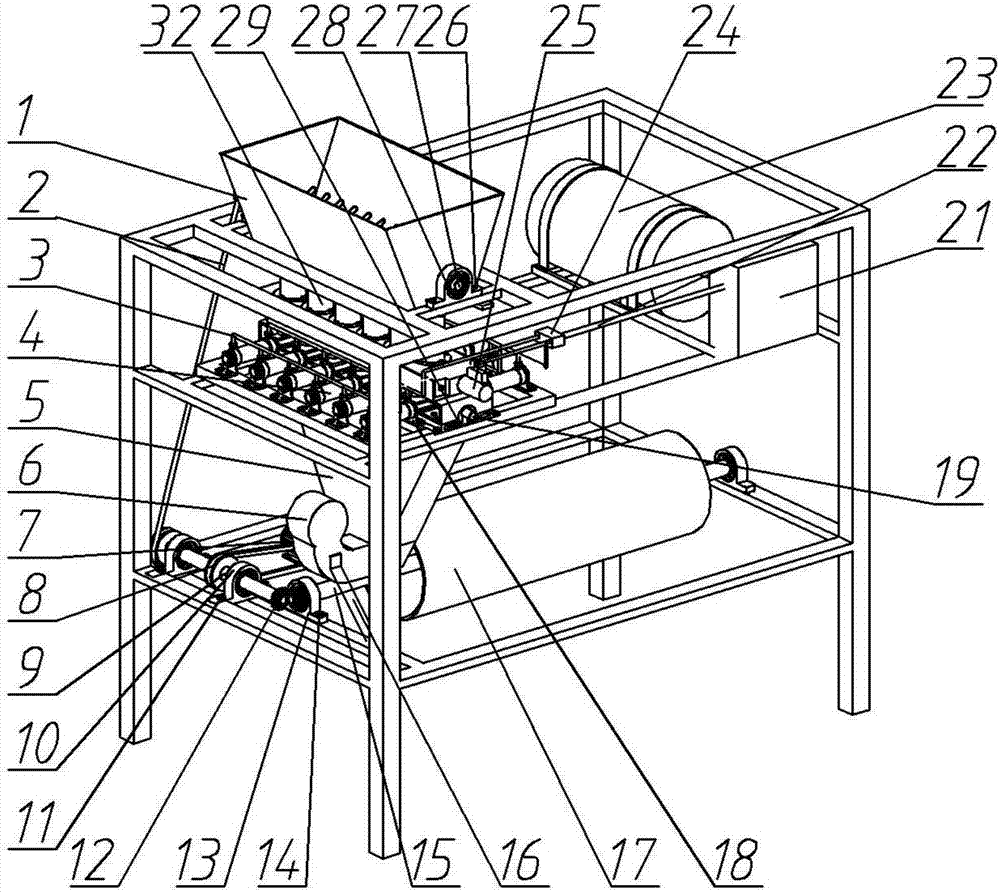

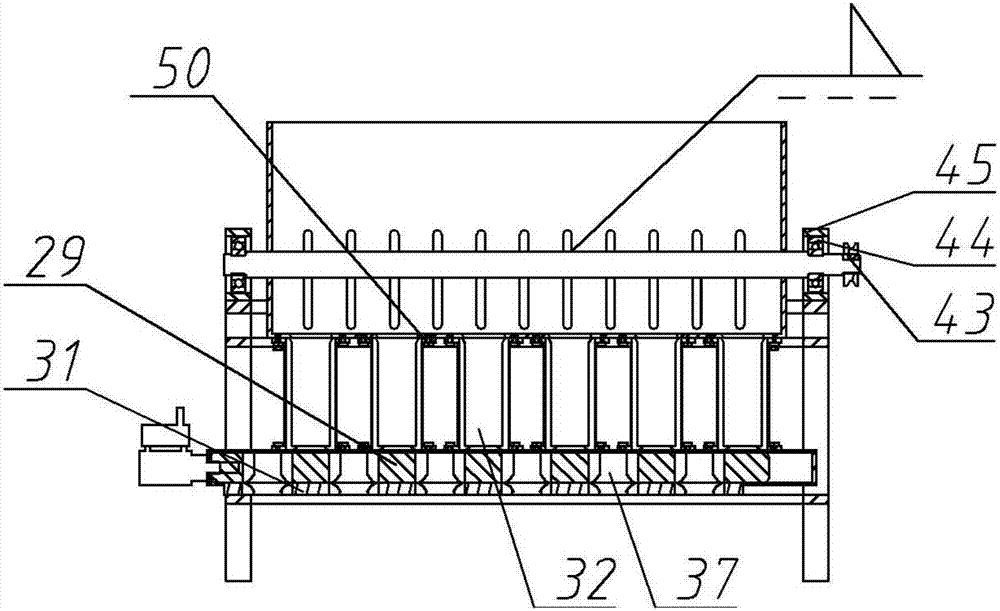

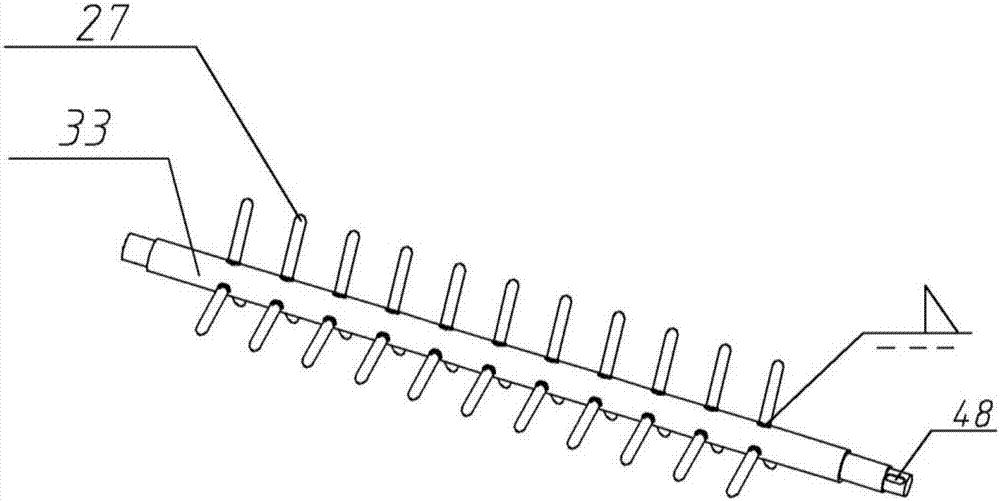

Ethanol production device and process through continuous solid-state fermentation and having self-control system

InactiveUS20160083684A1Flexible adjustmentMeet needsBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The present invention belongs to the technology field of microbial fermentation for producing fuel ethanol. It specifically relates to a device and process having self-control system for producing fuel ethanol. The process mainly comprises the two steps of strain addition and continuous solid-state fermentation, that is, adding the fermentation bacterial strains into crushed raw materials before the crushed materials entering into the continuous solid-state fermentation tank and then the above materials mixed with bacteria are fermented in the continuous solid-state fermentation tank, making the fermentable sugars into ethanol.

Owner:TSINGHUA UNIV

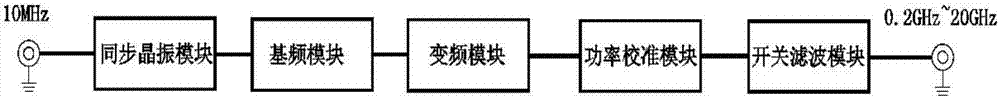

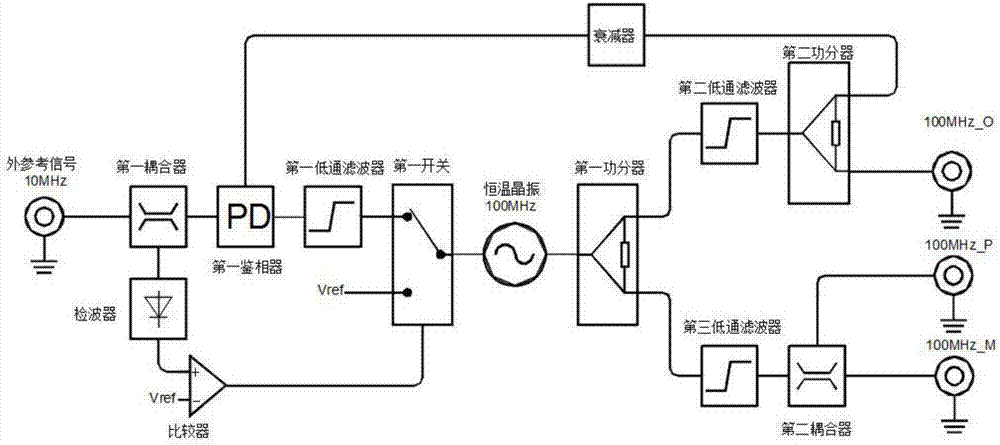

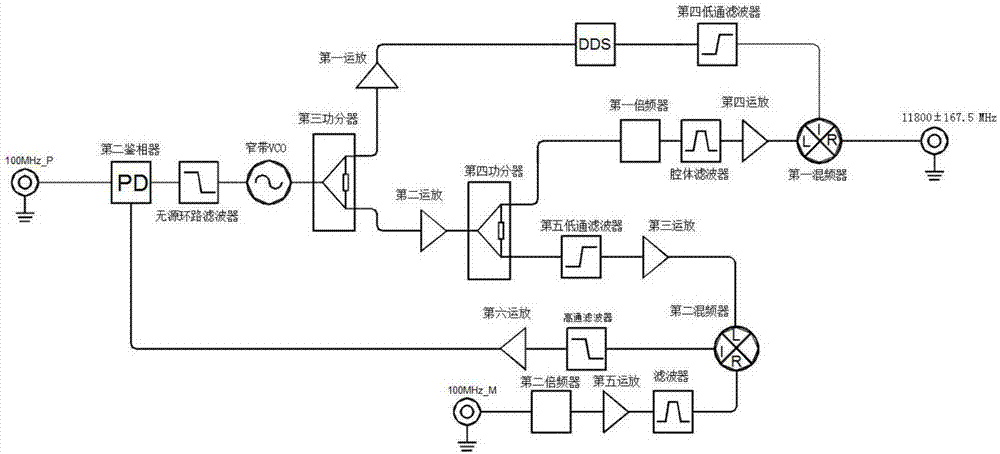

Wideband frequency-agile frequency source

ActiveCN107483049AImprove spurious indicatorsShorten the frequency conversion timePulse automatic controlHigh level techniquesUltra-widebandFrequency conversion

The invention relates to a wideband frequency-agile frequency source. The frequency source comprises a synchronous crystal oscillation module, a fundamental frequency module, a frequency conversion module, a power calibration module, and a switch filtering module which are connected in sequence. The frequency source has the advantages that continuous frequency-dividing harmonic wave extraction is carried out on a fundamental frequency to achieve the purposes of ultra-wideband, small frequency steps and high frequency agility, stray indicators are improved, the system frequency conversion time is shortened, and the system reliability is improved.

Owner:CHENGDU PHASE LOCK ELECTRONICS TECH

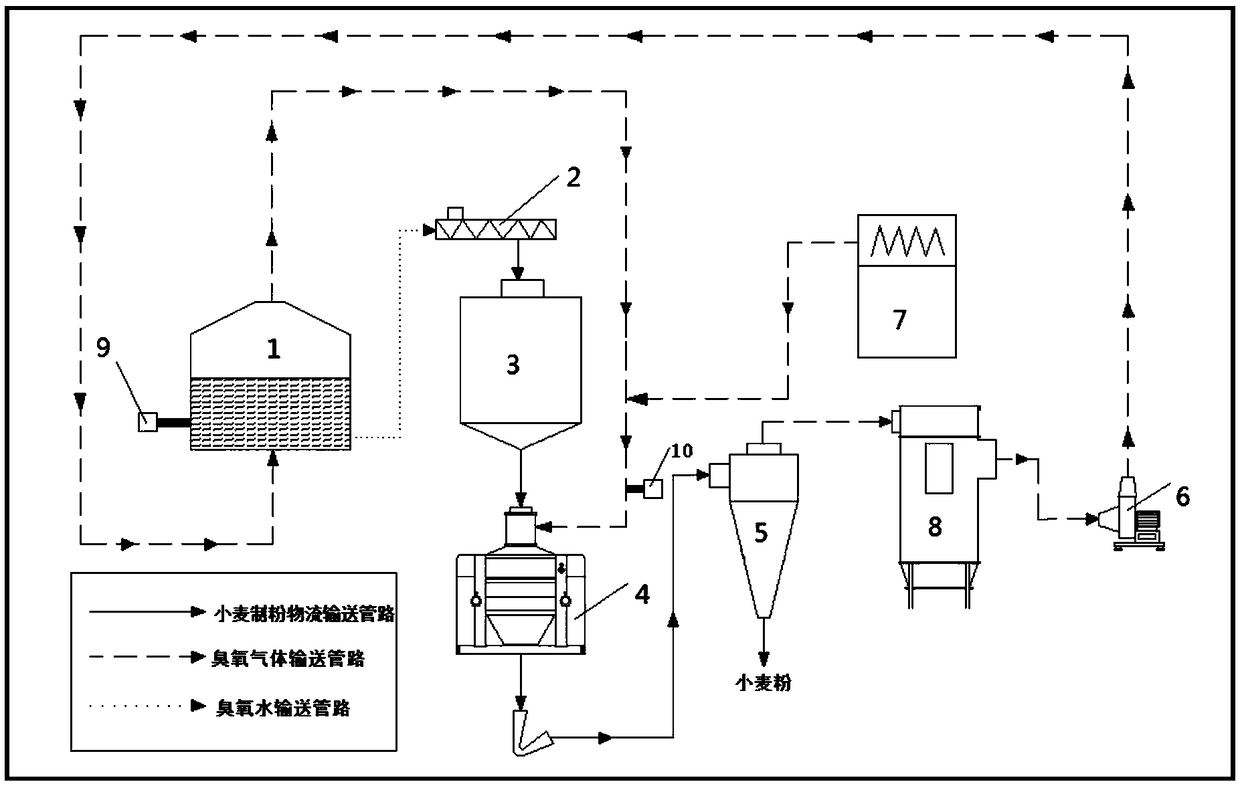

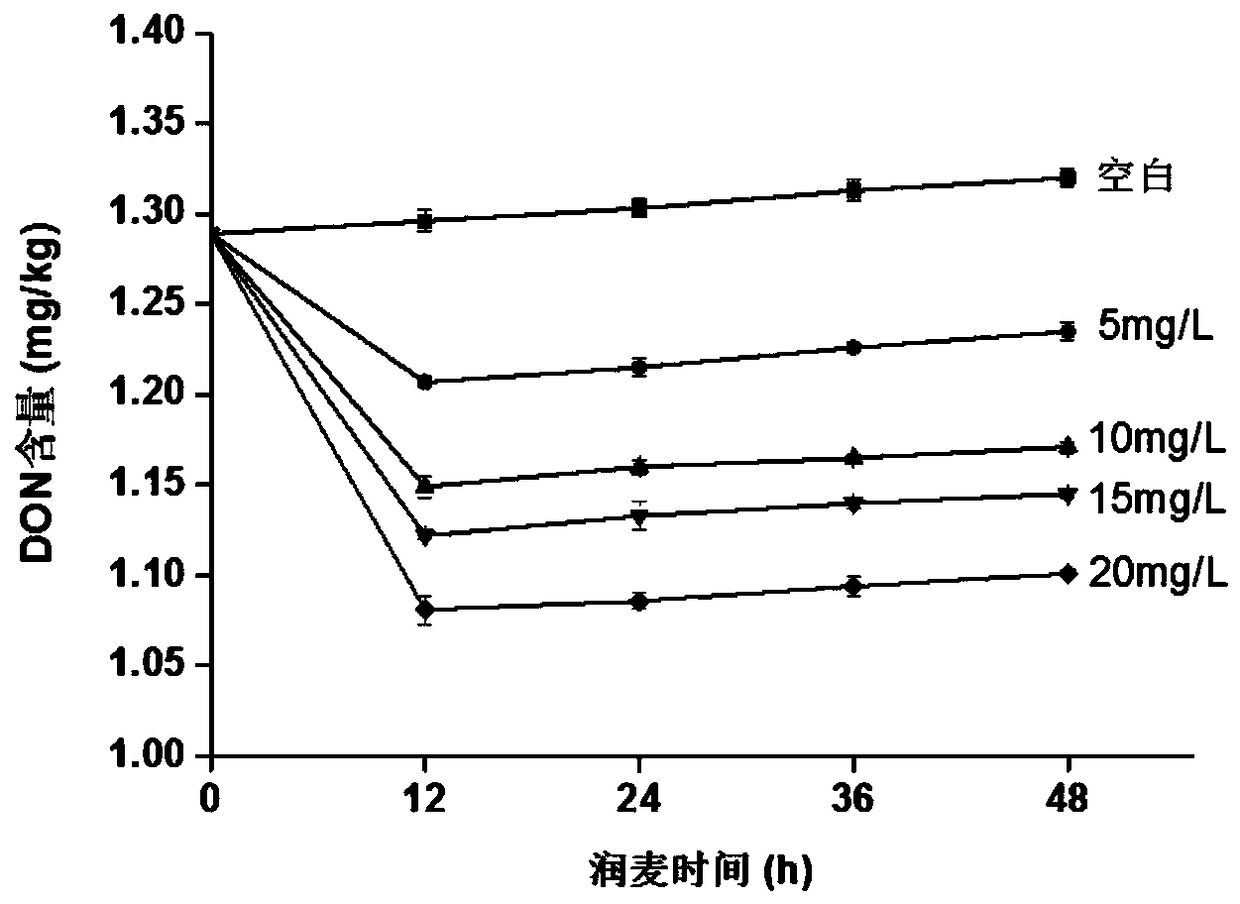

Ozone treatment system and method for degrading deoxynivalenol in wheat

PendingCN109497398AReduce exhaust emissionsRealize controllabilityFood scienceChemistryClean technology

Owner:WUHAN POLYTECHNIC UNIVERSITY

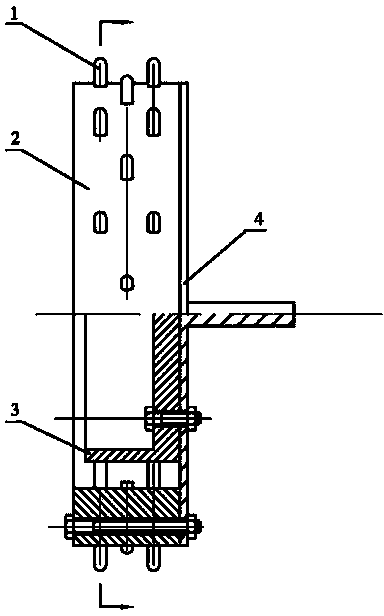

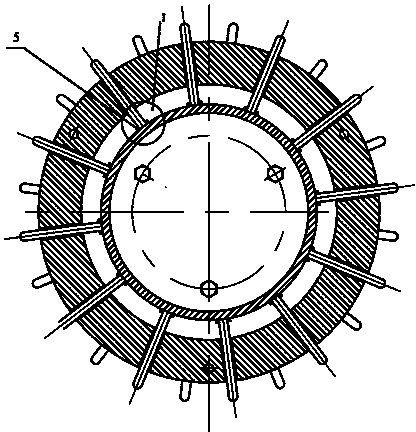

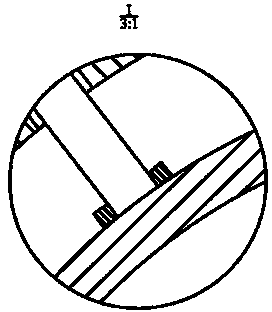

Flexible finishing machining device for hole surfaces

ActiveCN103612194ASolve not easy to movePrevent movementHoning toolsHoning machinesMechanical componentsElectric machinery

The invention discloses a flexible finishing machining device for hole surfaces, and belongs to the technical field of finishing machining of mechanical part surfaces. The flexible finishing machining device for the hole surfaces is characterized in that on the basis of the centrifugal principle, machining parameters are controlled externally in real time, the flexibility, automation and controllability of machining are achieved, and the flexible finishing machining device can automatically machine the surfaces of holes such as bent holes, stepped holes and irregularly-shaped holes; according to the flexible finishing machining device for the hole surfaces, the acting force between an oilstone stick and the hole surfaces is adjusted By externally controlling the rotary speed of a motor, so that constant-pressure machining is achieved, and uniformity of machining is guaranteed; a flexible finishing head has certain flexibility, can pass through the bent holes and the irregularly-shaped holes with certain size such as a pipeline with the elliptic cross section, and can pass through the pipeline and achieve finishing machining on the inner surface of the pipeline within the flexible range of the device. The whole flexible finishing machining device for the hole surfaces is simple in structure, small in floor area, convenient to control, and capable of achieving automation easily.

Owner:TAIYUAN UNIV OF TECH

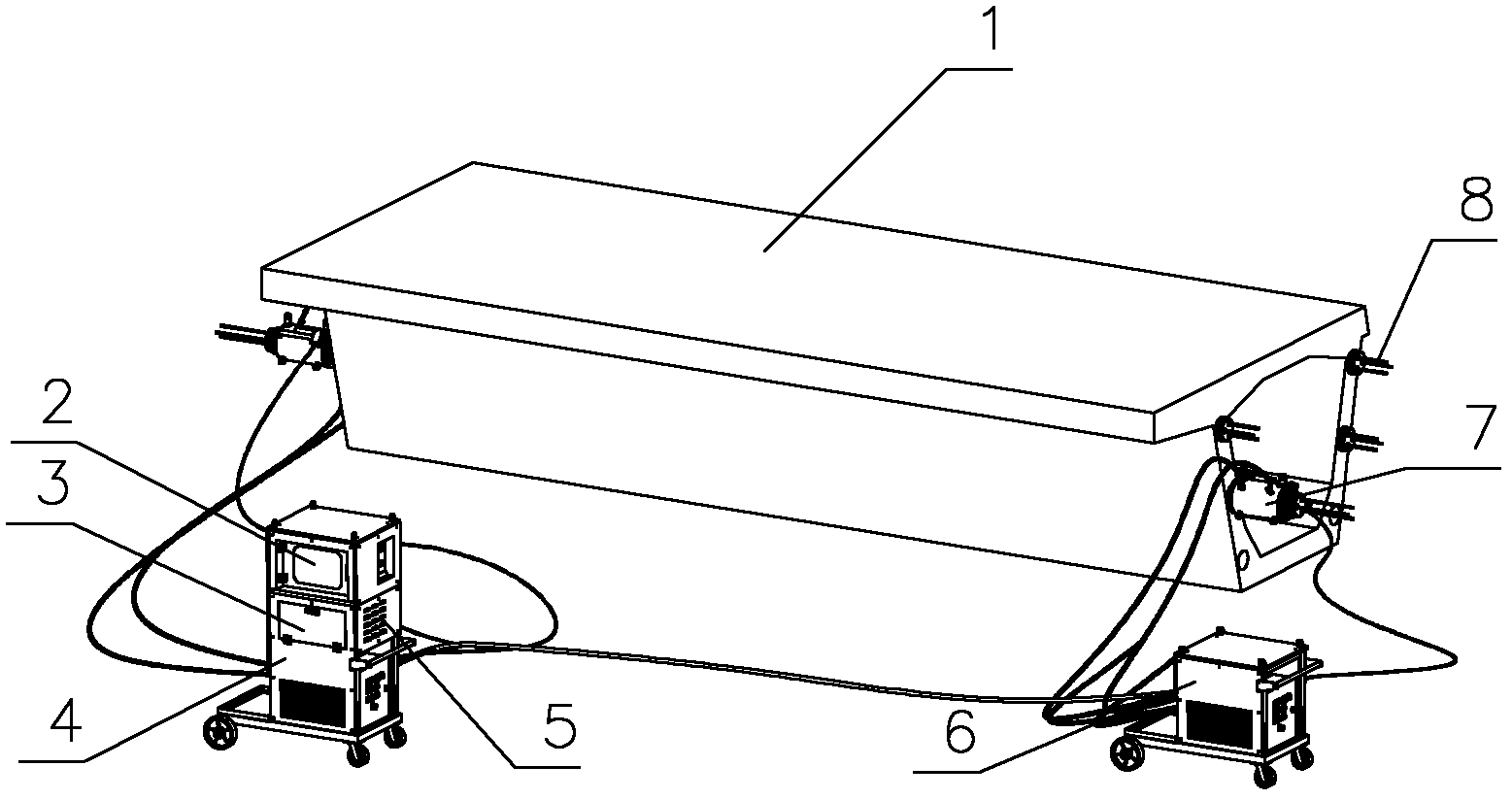

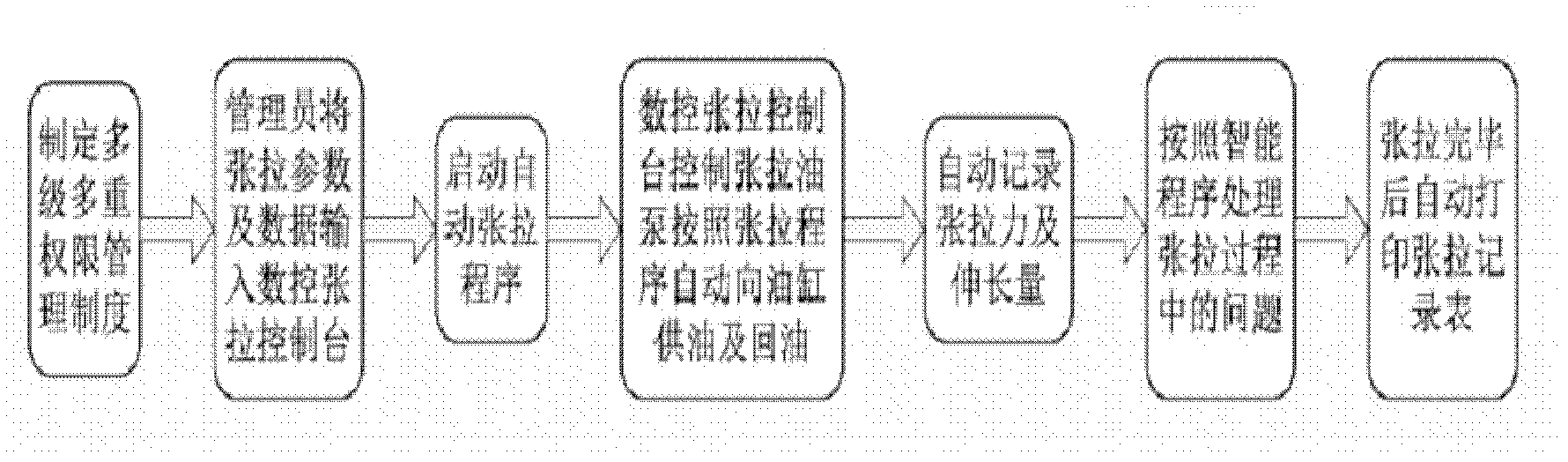

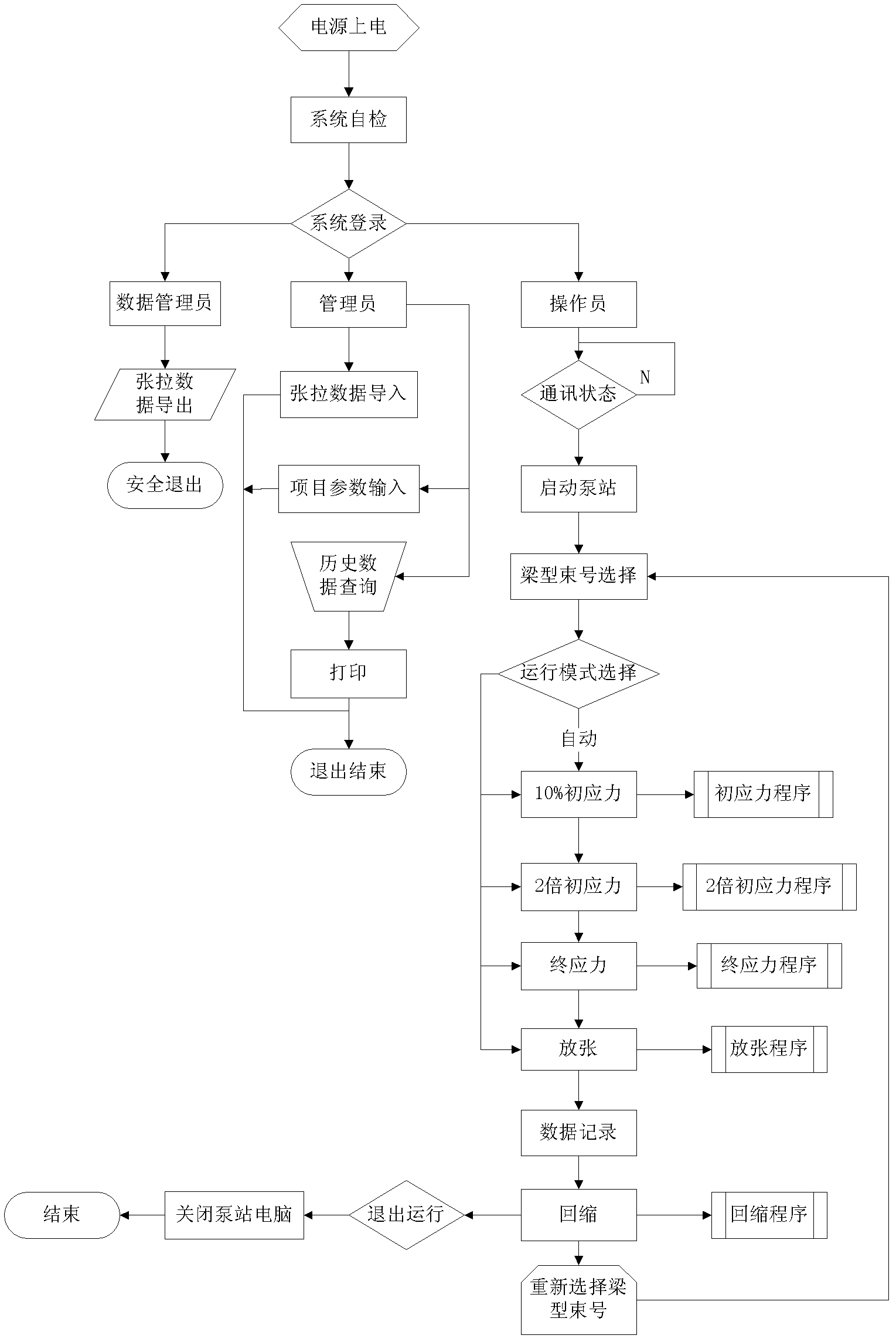

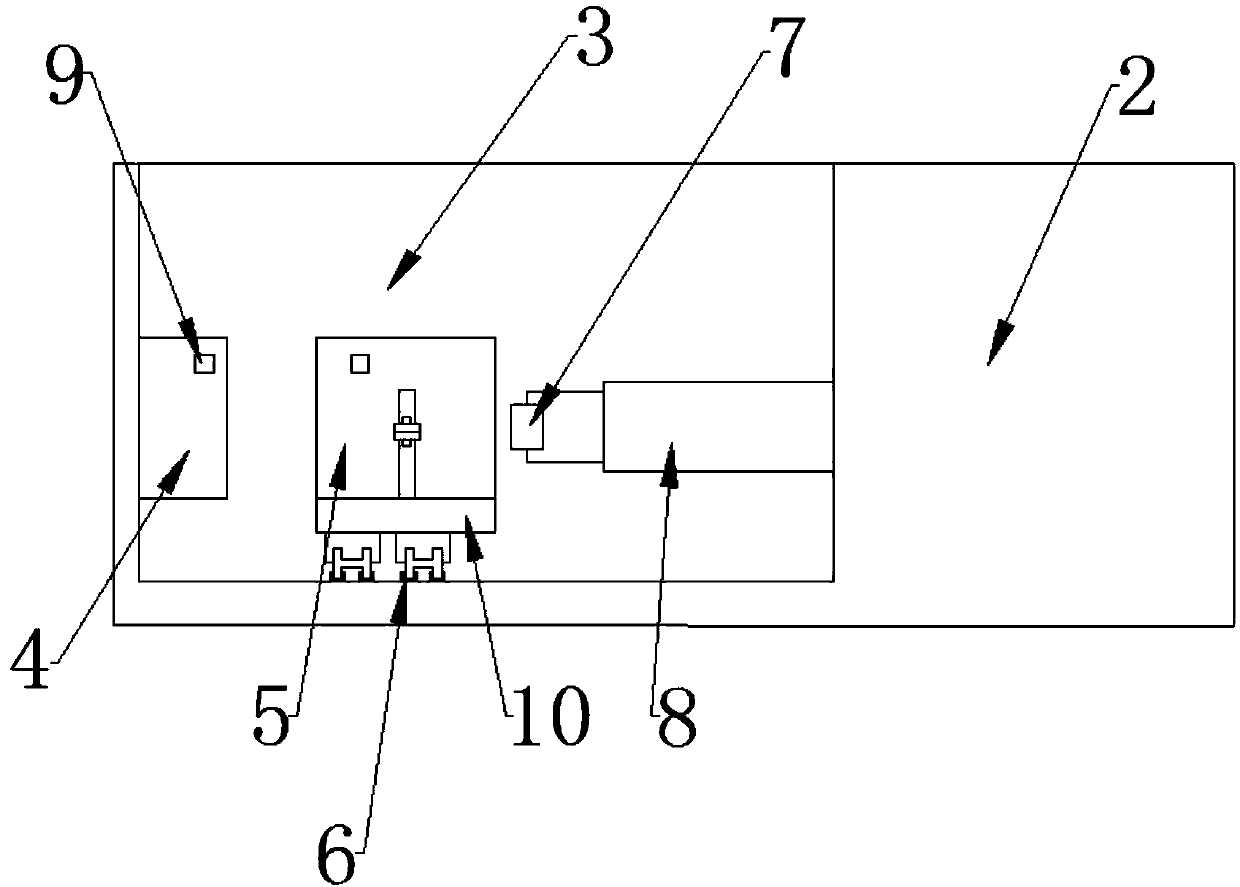

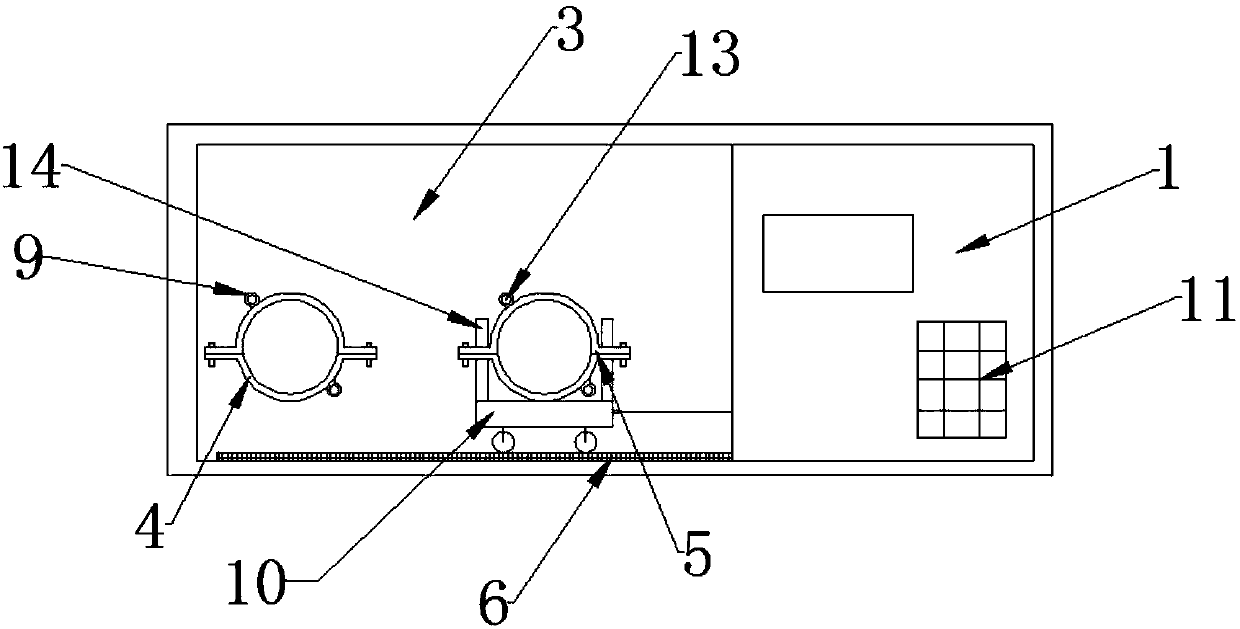

Pre-stress full automatic intelligent tensioning device and operation method thereof

InactiveCN103161317APrecise tensionPrecise measurement of precise elongationBridge erection/assemblyBuilding material handlingNumerical controlPrimary station

The invention provides a pre-stress full automatic intelligent tensioning device which is characterized by being formed by connecting an integrated intelligent tensioning main station, an intelligent tensioning auxiliary pump station and an intelligent tensioning oil cylinder through cables. The intelligent tensioning main station integrates a tensioning control table, a numerical control tensioning pump station and a printing machine. Wheel-type structures are adopted in the intelligent tensioning main station and the intelligent tensioning auxiliary station. The intelligent tensioning oil cylinder integrates a pressure and displacement sensor and a force measuring unit independent from the oil cylinder. The operation method includes the following steps of formulating limits of authority, inputting tensioning parameters and data, starting tensioning programs, controlling the numerical tensioning pump station, supplying oil to the intelligent tensioning oil cylinder and returning the oil, recording tensioning force and extension quantity of a pre-stress rib, solving the problems in the tensioning process, and printing tension records. The pre-stress full automatic intelligent tensioning device has the advantages of being high in measurement precision, accurate to control, convenient and fast to control and manage and the like. Moreover, pre-stress tensioning work procedures can be controlled, pre-stress force is loaded, the extension quantity is automatic and precise to measure, and the tensioning data are actualized.

Owner:上海耐斯特液压设备有限公司

Traditional Chinese medicinal material conveying, grinding and crushing device

ActiveCN112844670AEfficient grindingGrinding degree controlCocoaCleaning using liquidsDrive wheelReciprocating motion

The invention discloses a traditional Chinese medicine material conveying, grinding and crushing device which comprises a shell, a conveying assembly, a crushing assembly and a grinding assembly, the conveying assembly is arranged at the outer side of the shell and comprises a workbench and a stirring rotating disc rotatably arranged above the workbench, stirring rollers are uniformly distributed on the stirring rotating disc in the circumferential direction, an inclined plate is fixed to a feeding end of the conveying assembly, a cleaning box is arranged at a discharging end of the conveying assembly, the cleaning box is arranged between the workbench and the shell in a sliding mode, the bottom of the cleaning box is connected with an output end of a first air cylinder, the first air cylinder is fixed to a sidewall of the shell, a working box is arranged below the workbench, a driving wheel and an incomplete gear are rotatably arranged in the working box, the driving wheel is driven by a stepping motor, and a first connecting rod is fixed to the center of the incomplete gear. According to the device, through up-and-down reciprocating movement of a first rack, spaced and ordered discharging, spraying of cleaning water in the cleaning box and anti-blocking air spraying of the crushing box can be achieved, the structure is compact, and the design is reasonable.

Owner:JIANGZHONG PHARMA

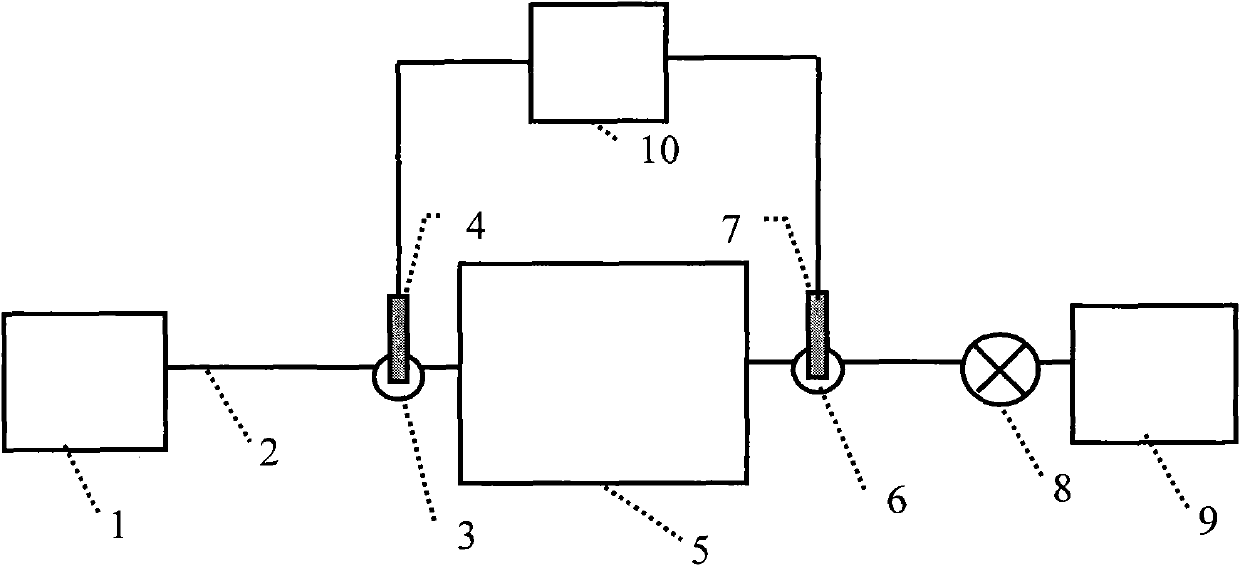

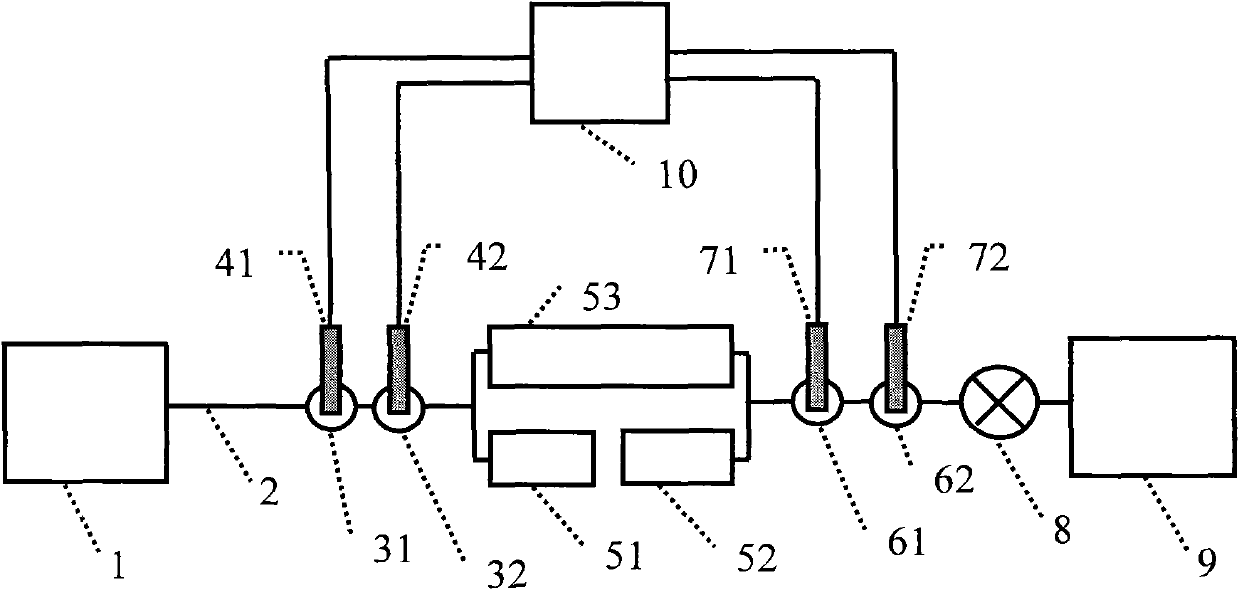

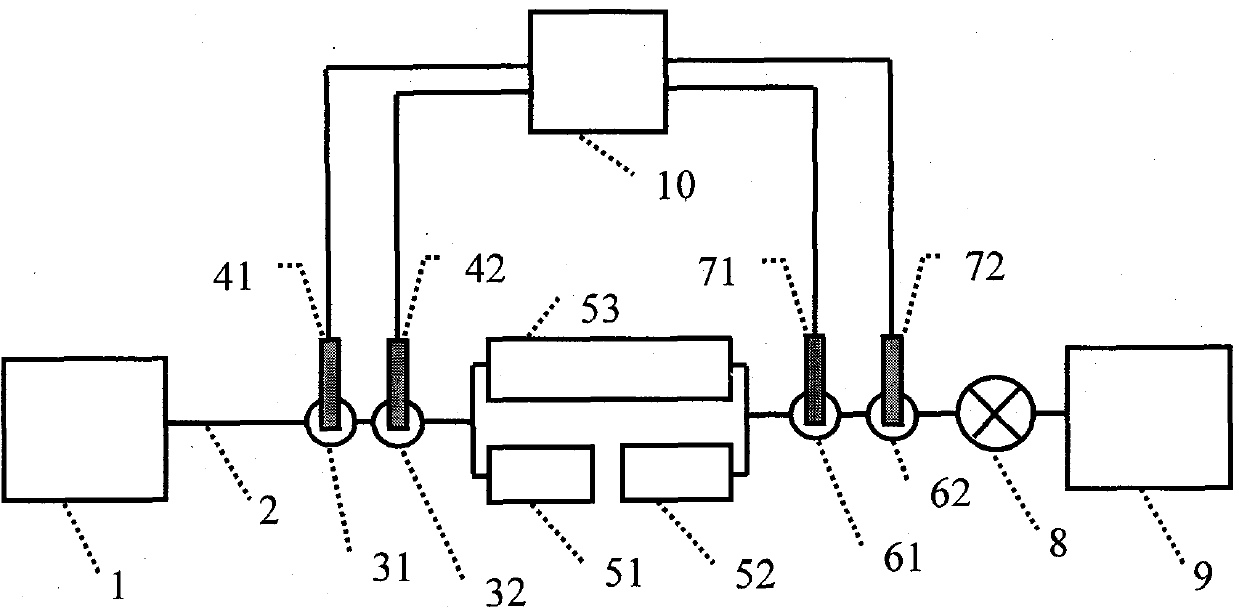

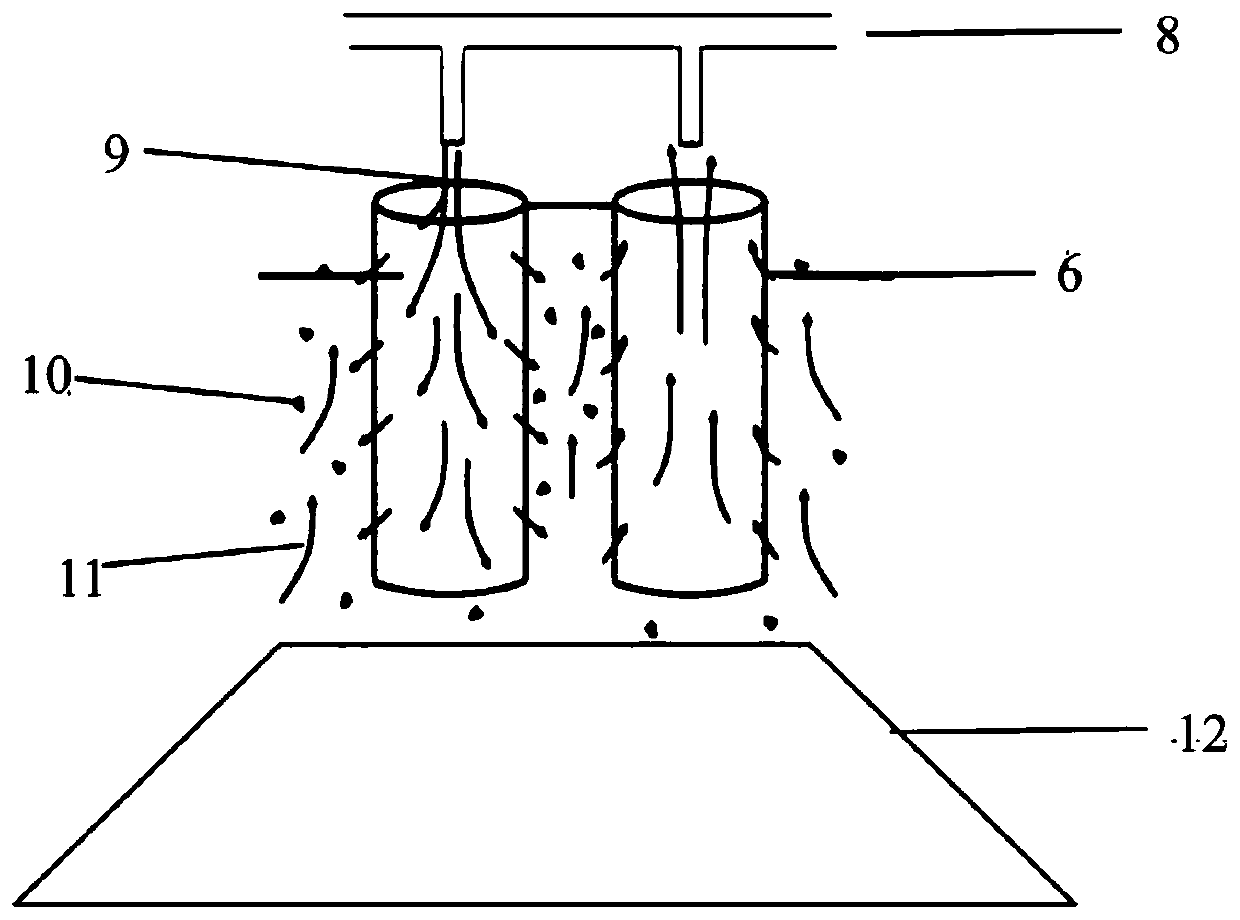

Apparatus and method for monitoring cell quantity or cell proportion during dynamic stem cell differentiation

InactiveCN102199536ARealize controllabilityBioreactor/fermenter combinationsBiological substance pretreatmentsMetaboliteStem cell culture

The invention discloses an apparatus and a method for monitoring cell quantities or cell proportions during dynamic stem cell differentiation. The invention relates to the field of bioengineering, and especially relates to apparatuses and methods for the on-line or off-line monitoring of cell numbers or other relative information of dynamic cellular differentiation during the cultivation, amplification, and differentiation processes of stem cells. The apparatus comprises: an upstream cell culture solution supplying system or an upstream differentiation solution supplying system; upstream physiological and biochemical index detecting head chambers; detecting heads or connecting heads arranged in the upstream detecting head chambers with an aseptic and sealed condition; cell cultivating apparatuses, downstream physiological and biochemical index detecting head chambers; detecting heads or connecting heads arranged in the downstream detecting head chambers with an aseptic and sealed condition; a fluid speed controlling aseptic pusher; a downstream waste liquid or obtained solution system; and speed-controlling liquid-conveying tubing systems for connecting the above components. According to the method, on-line or off-line monitoring is carried out upon the gas / liquid phase of upstream / downstream cell cultivating system, for monitoring nutrients, metabolites, production concentrations, total quantities, or quantity differences of target cells. Quantities or other relative information of functioning cells or functioning precursor cells differentiated during stem cell differentiation processes can be dynamically obtained.

Owner:SHANGHAI KUNJU TECH DEV

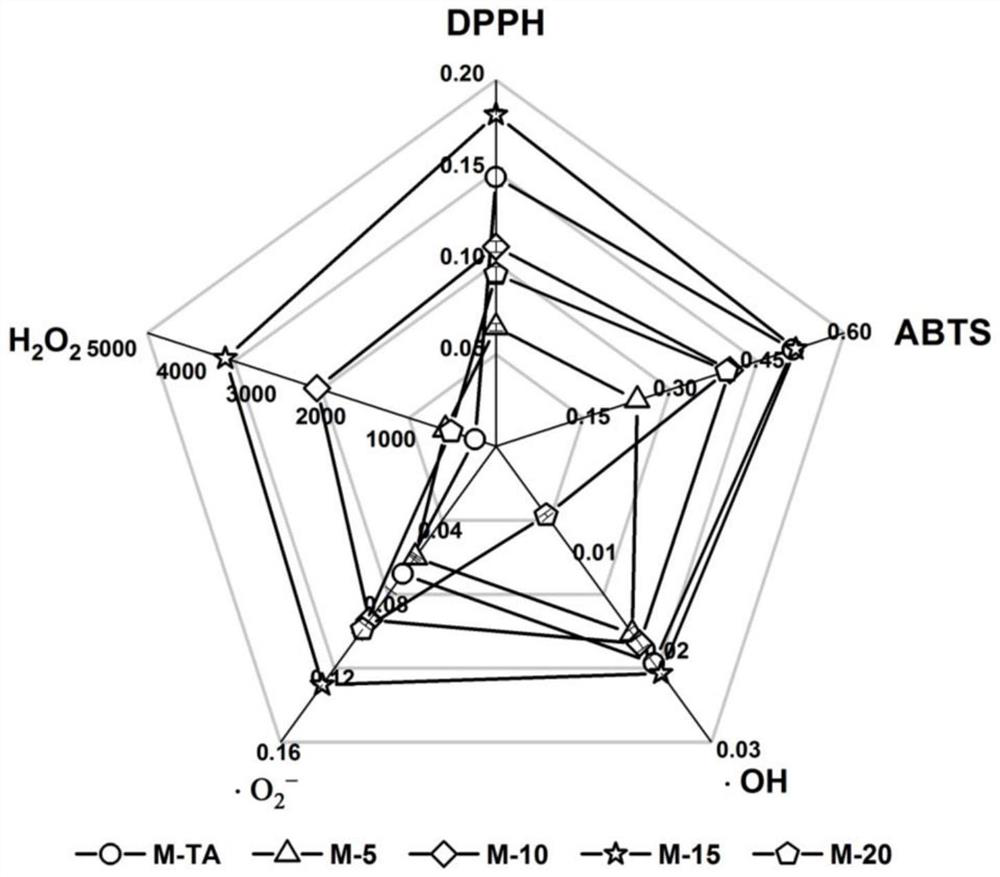

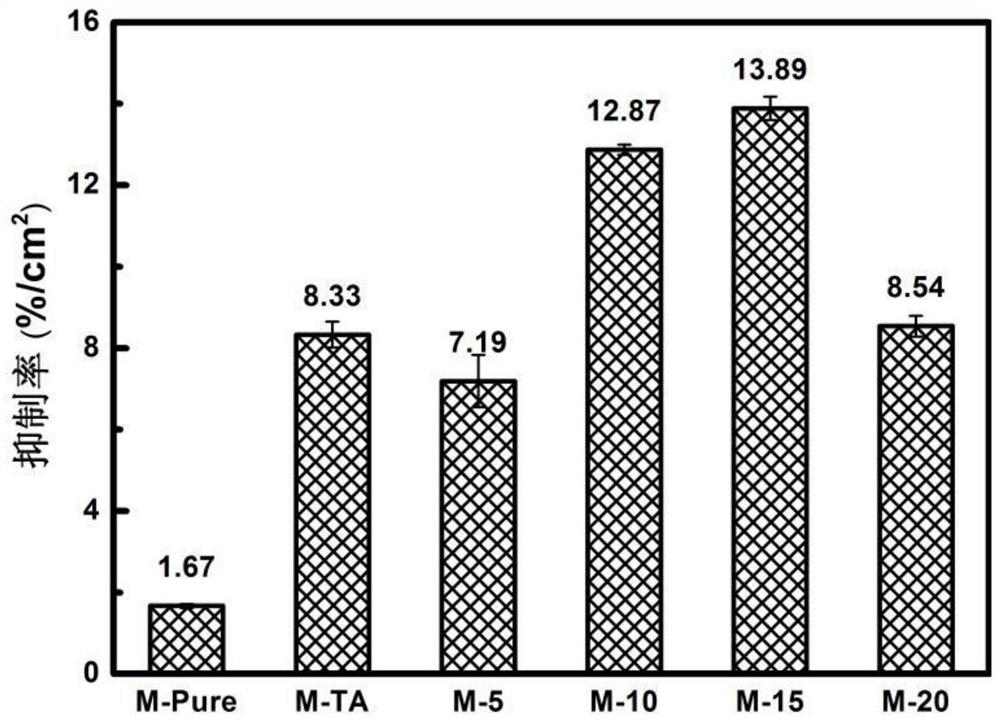

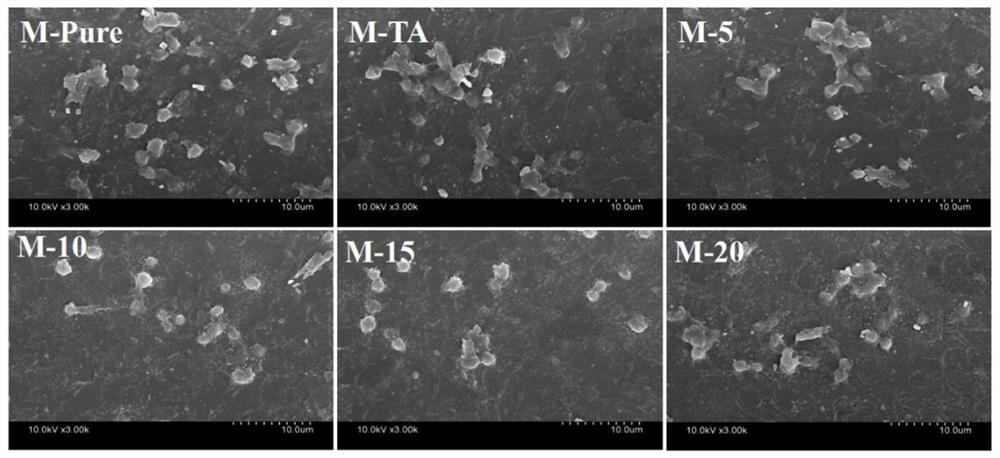

A plant polyphenol-polyacryloylmorpholine composite modified hemodialysis membrane and its preparation method and application

ActiveCN111013397BIntervene in oxidative stressIntervention of oxidative stress achievedSemi-permeable membranesDialysis membranesMorpholine

Owner:TIANJIN POLYTECHNIC UNIV

Amorphous high-conductivity quaternary metal nitride and preparation method thereof

ActiveCN111807418AImprove conductivityHigh electrocatalytic oxygen evolution capacityPhysical/chemical process catalystsNitrogen compoundsMicrostructureHigh conductivity

The invention relates to the field of new materials, and aims to provide an amorphous high-conductivity quaternary metal nitride and a preparation method thereof. The product comprises four metal elements of Co, Cu, Ce and Mo, wherein the molar ratio of Co to Cu to Ce to Mo is 1: 1: (0.2-0.4): (0.8-1.2); the product is powdery, and the microstructure of the product is an amorphous sheet-shaped structure or an olive-shaped structure. The method has the advantages that by strictly controlling the preparation process of parameters, non-crystallization and microstructure controllability can be achieved according to the requirements of application in different fields; and the prepared amorphous high-conductivity quaternary metal nitride has high conductivity, high electrocatalytic oxygen evolution capacity and good interface affinity with metal silver. More high-valence active sites can be formed on the surface of the catalyst, so that the electro-catalytic performance is improved. Good interface bonding with a metal substrate is facilitated, the conductivity of the metal composite material is improved due to the high conductivity characteristic of the metal composite material, and excessive reduction of the conductivity due to addition of a reinforcing phase is avoided.

Owner:ZHEJIANG UNIV

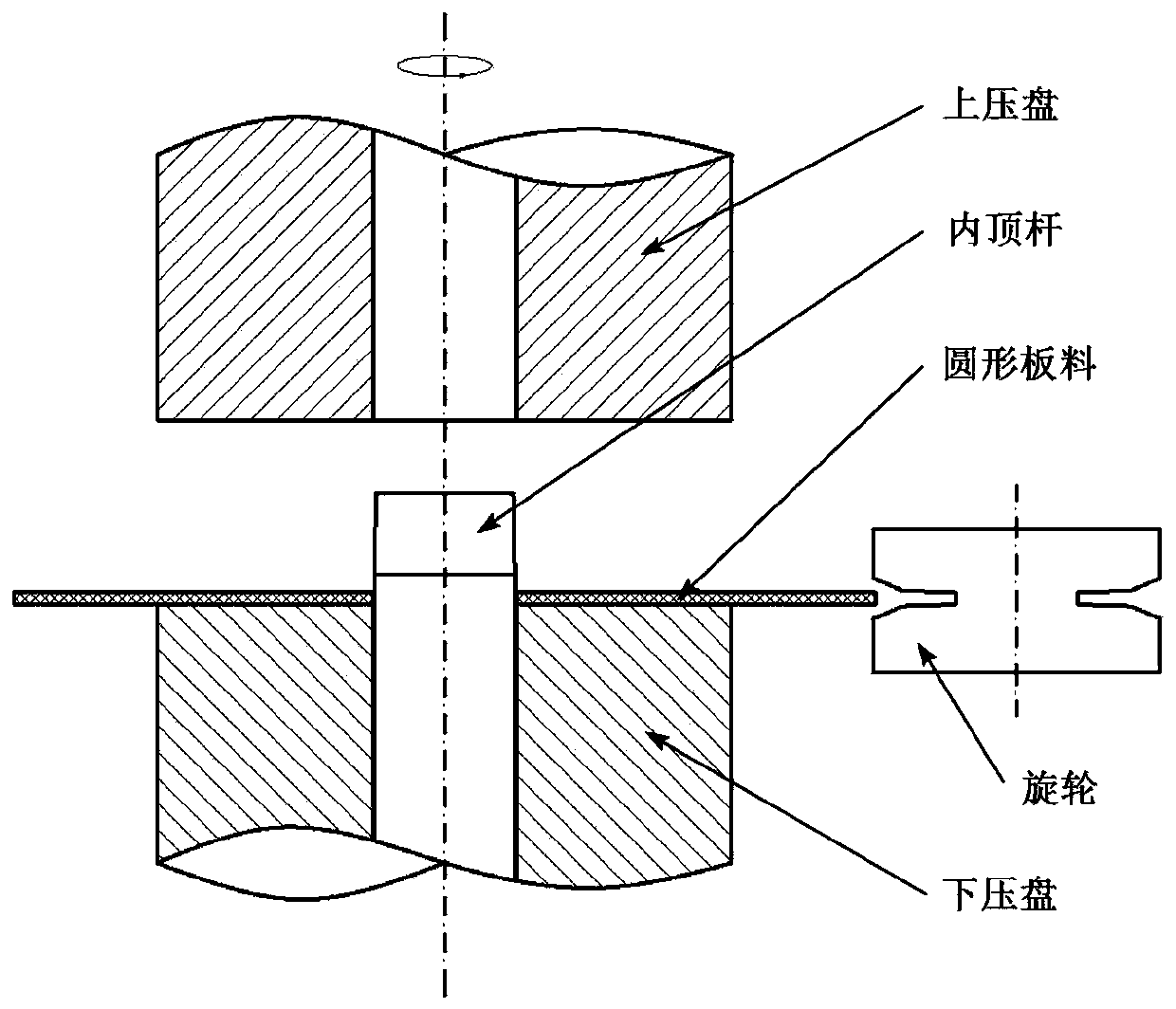

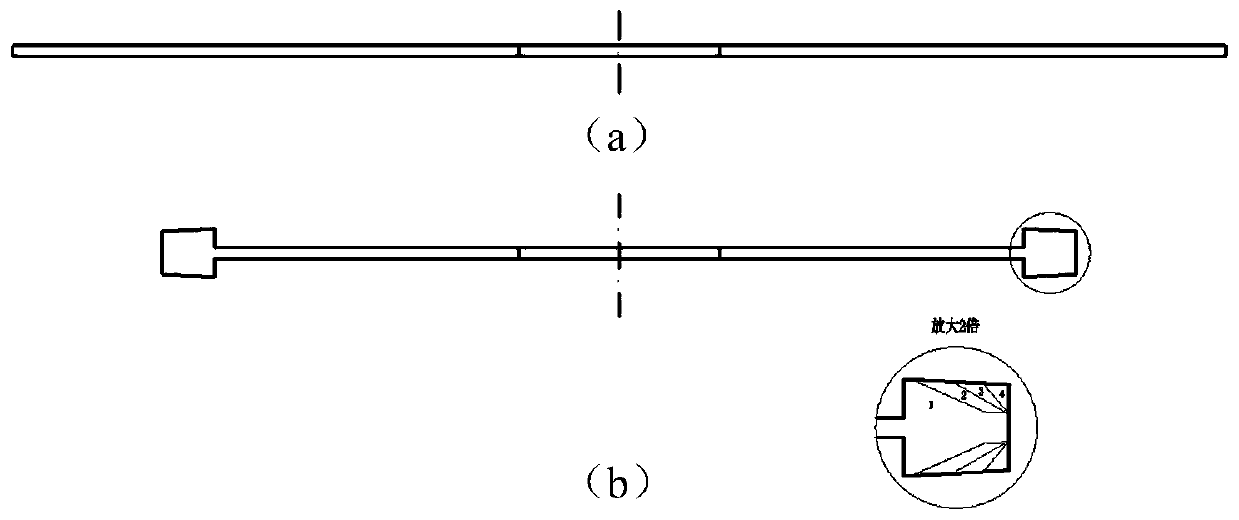

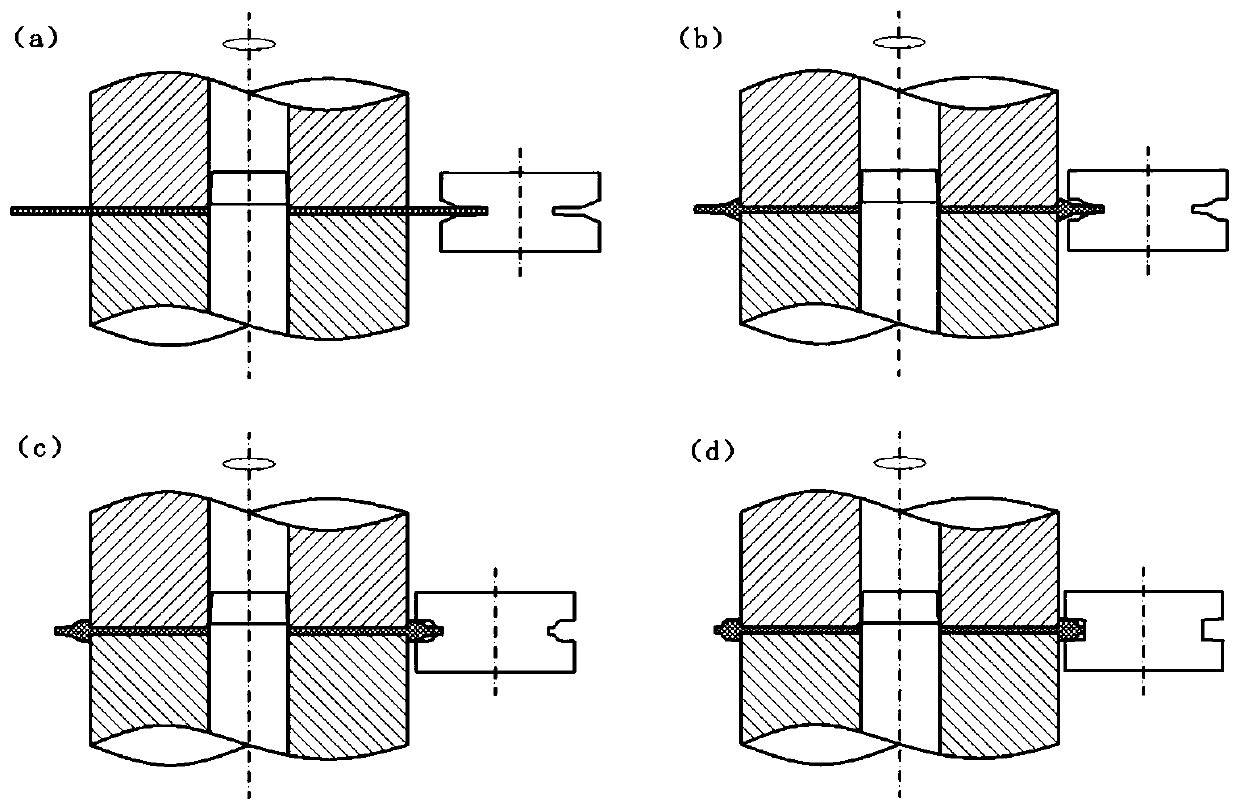

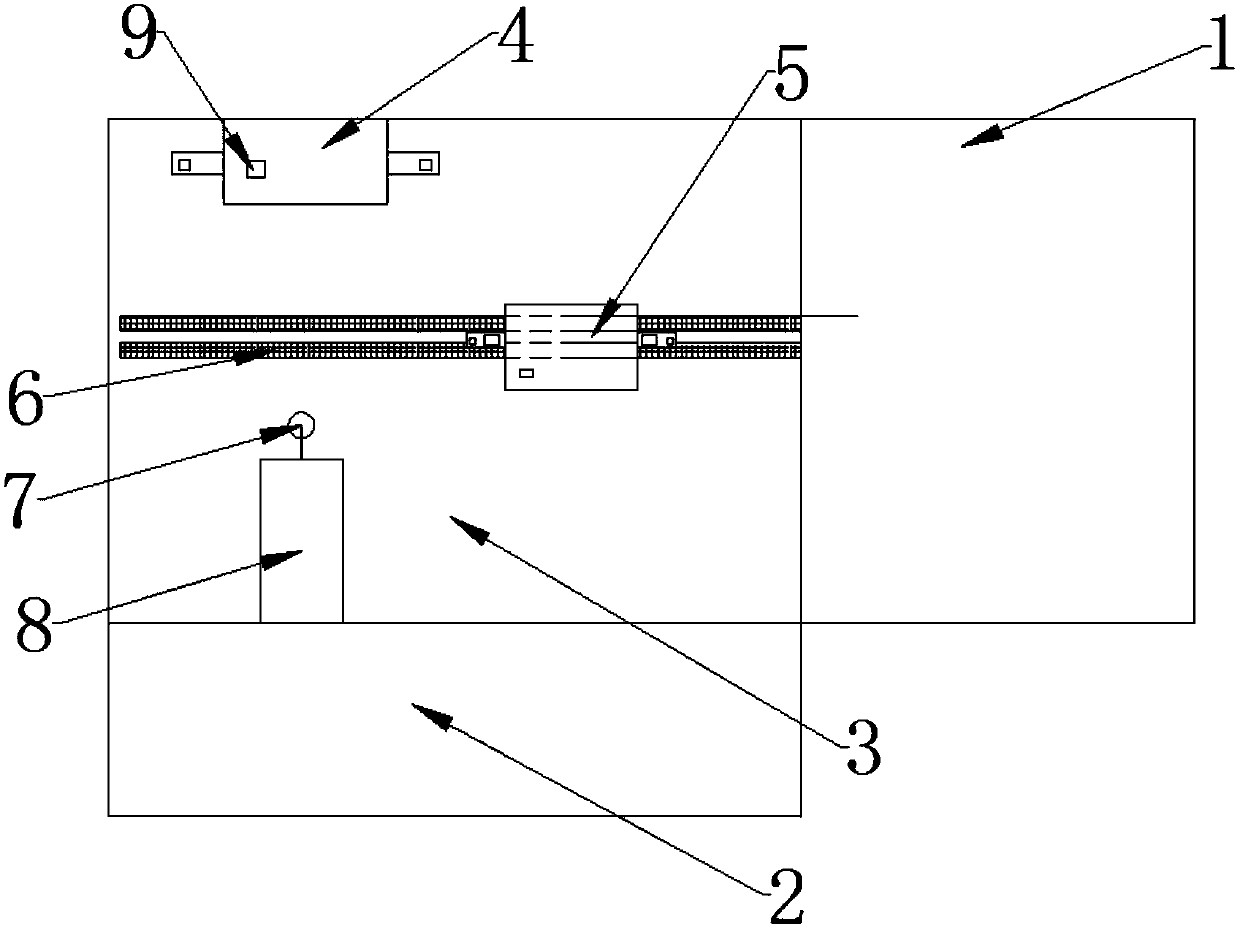

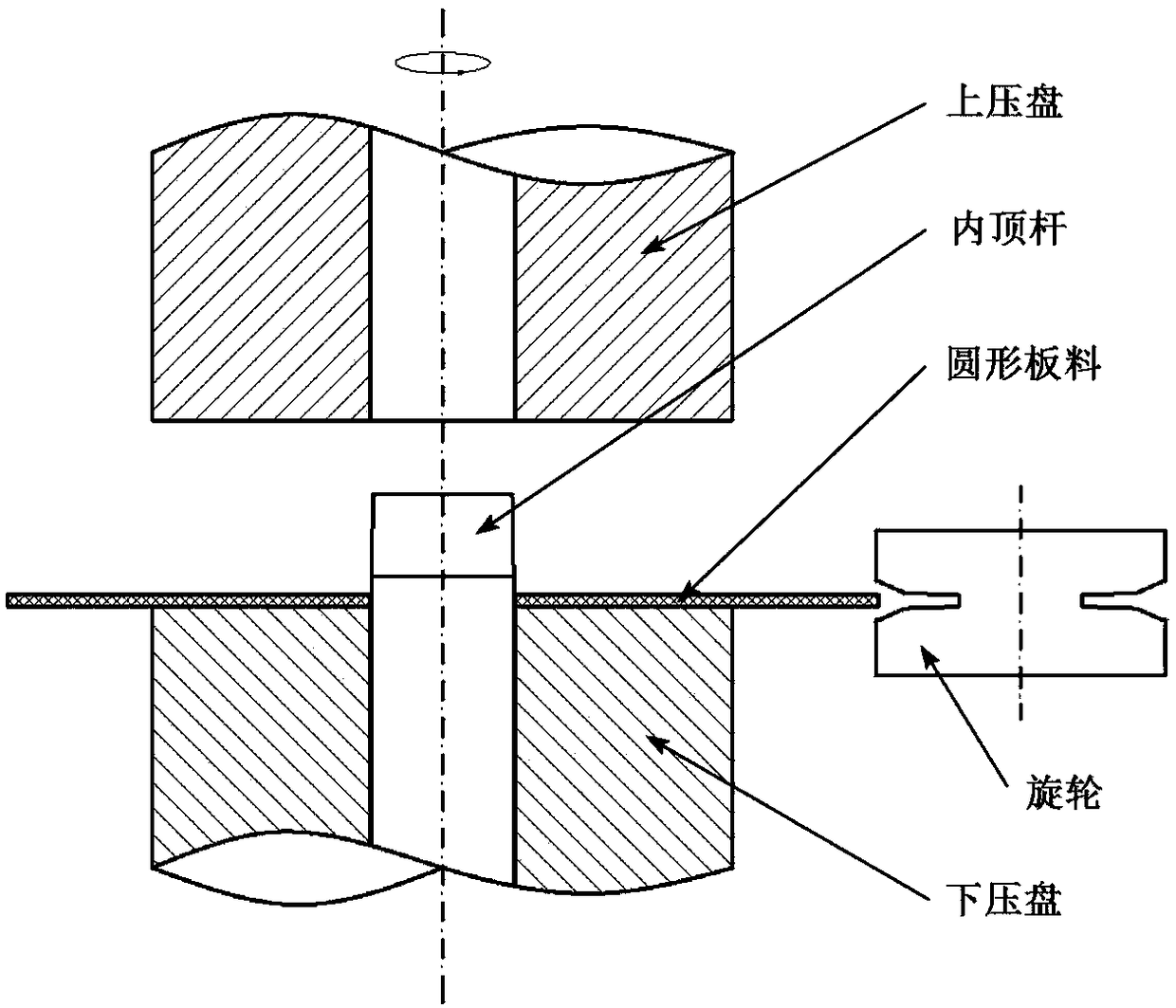

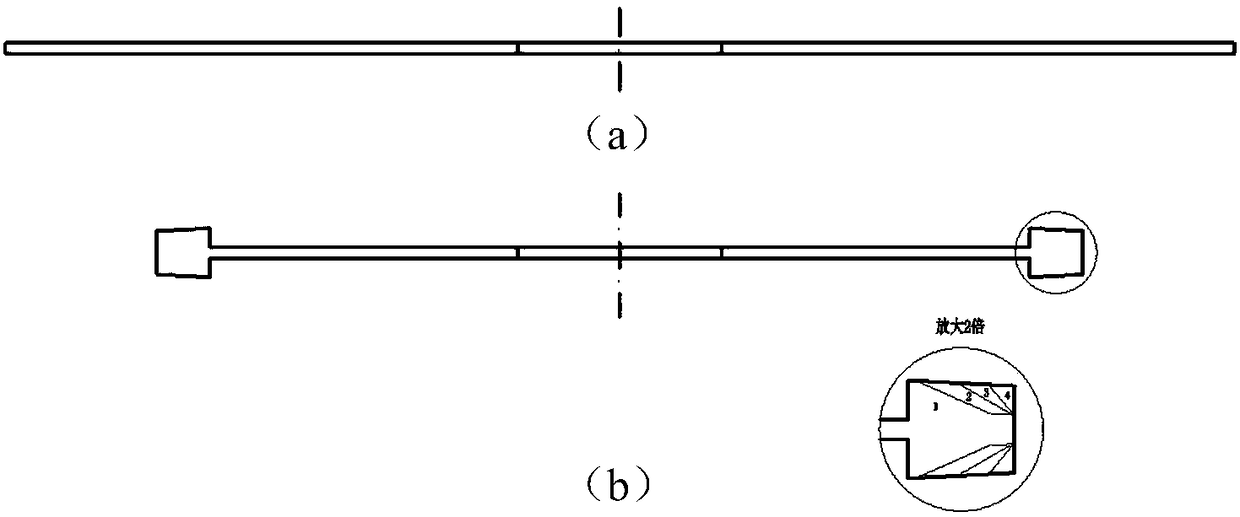

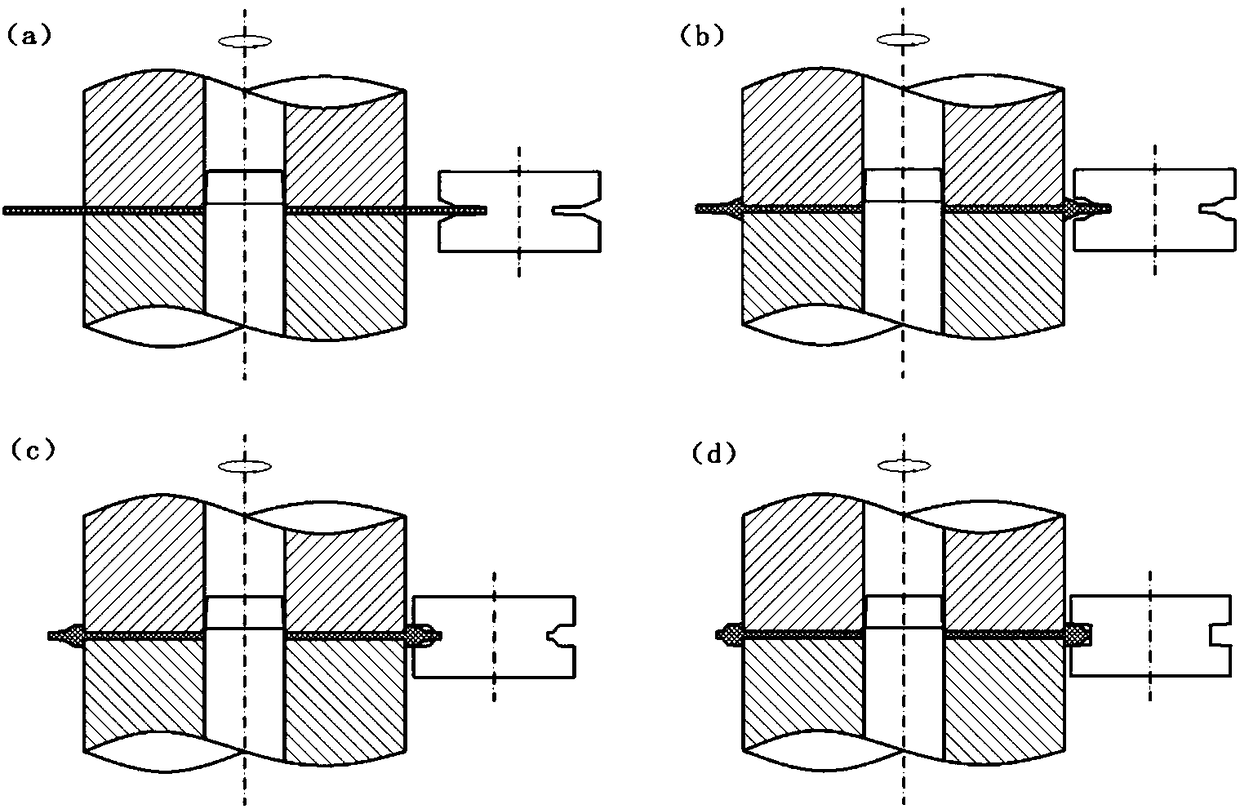

A multi-pass spinning stacking thickening forming method

The invention belongs to the field of machining methods for disk-shaped parts with thin radial plates and thick wheel flanges, and discloses a multi-pass spinning accumulation thickening forming method. The thickening process of the forming method includes multiple passes, and the slot shapes of spinning rollers of different passes are different; the slot of the spinning roller of each pass can bedivided into three parts, and the section of each part is trapezoidal; the second part is located between the first part of the top surface and the second part, and the thickness of the third trapezoid bottom surface of the section of the third part is the finally required thickness of a plate to be machined; the thickness of the first trapezoid top surface of the section of the first part is theinitial thickness of the plate to be machined, and the volumes of the second part and the first part are gradually decreased by increasing the volume of the third part gradually, till the volumes ofthe first part and the second part are decreased to zero; and thus, the process of gradually thickening the plate from inside to outside through the multiple passes is achieved. Through the forming method, the controllable thickening process of the plate is achieved, and the formed plate is uniform in thickness; and the forming quality is high, and the forming process is stable.

Owner:HUAZHONG UNIV OF SCI & TECH

A contact strength shear test device for asphalt mixture aggregates and a test method thereof

PendingCN107782636AAvoid frictionReduce experimental errorMaterial strength using steady shearing forcesAsphaltPitch blende

Owner:GUANGZHOU UNIVERSITY

A filter bag for filtering and recovering non-ferrous metal dust and its preparation method

ActiveCN108071020BHD Gray EffectivenessPrevent resorptionDispersed particle filtrationMembrane filtersEmulsionPhysical chemistry

The invention discloses a filter bag for filtering and recovering non-ferrous metal dust and a preparation method thereof. The filter bag contains 85% to 95% by weight of microporous composite filter material and the weight loaded on the microporous composite filter material. The adsorption layer with a percentage of 5%-15%, the adsorption layer is a mixture obtained by blending magnetic nano iron oxide, polytetrafluoroethylene dispersion emulsion and dispersant emulsion after curing treatment, and the weight percentage of magnetic nano iron oxide in the mixture is 3%-25%, the weight percentage of polytetrafluoroethylene is 55%-70%, and the balance is the cured product of the dispersant emulsion. The filter bag prepared by the invention has stronger adsorption force for metal dust, effectively shortens the formation time of the powder cake layer, and improves the recovery rate of non-ferrous metals and the effectiveness of cleaning dust; the filter bag of the invention has higher filtration precision and electrical conductivity. It will be significantly improved to obtain excellent anti-static and explosion-proof capabilities.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Gas hot blast stove for heating by burning liquefied gas or natural gas

PendingCN114739001AWell mixedEvenly filledAir heatersGaseous fuel burnerCombustion chamberEngineering

The invention discloses a gas hot blast stove utilizing liquefied gas or natural gas combustion for heating, and belongs to the technical field of hot blast stoves, the gas hot blast stove comprises a combustion box, an ignition device is fixedly connected in the combustion box, one side of the combustion box is fixedly connected with a natural gas inlet pipe, and one side of the natural gas inlet pipe is fixedly connected with a valve; the side, away from the natural gas inlet pipe, of the combustion box is fixedly connected with an air inlet pipe, and the natural gas inlet pipe and the air inlet pipe both extend to one end of the combustion box and are both movably connected with a gas mixing assembly. According to the device, by arranging a gas mixing assembly, air and natural gas enter a combustion box through a gas conveying pipe, a second motor drives two second gears to rotate through a rotating shaft, the two second gears drive two gas conveying pipes to rotate through two first gears, and the gas conveying pipes drive gas nozzles to rotate; and the combustion chamber can be uniformly filled with natural gas and air, so that the gas is more fully mixed, and the combustion efficiency is improved.

Owner:邵红瑞

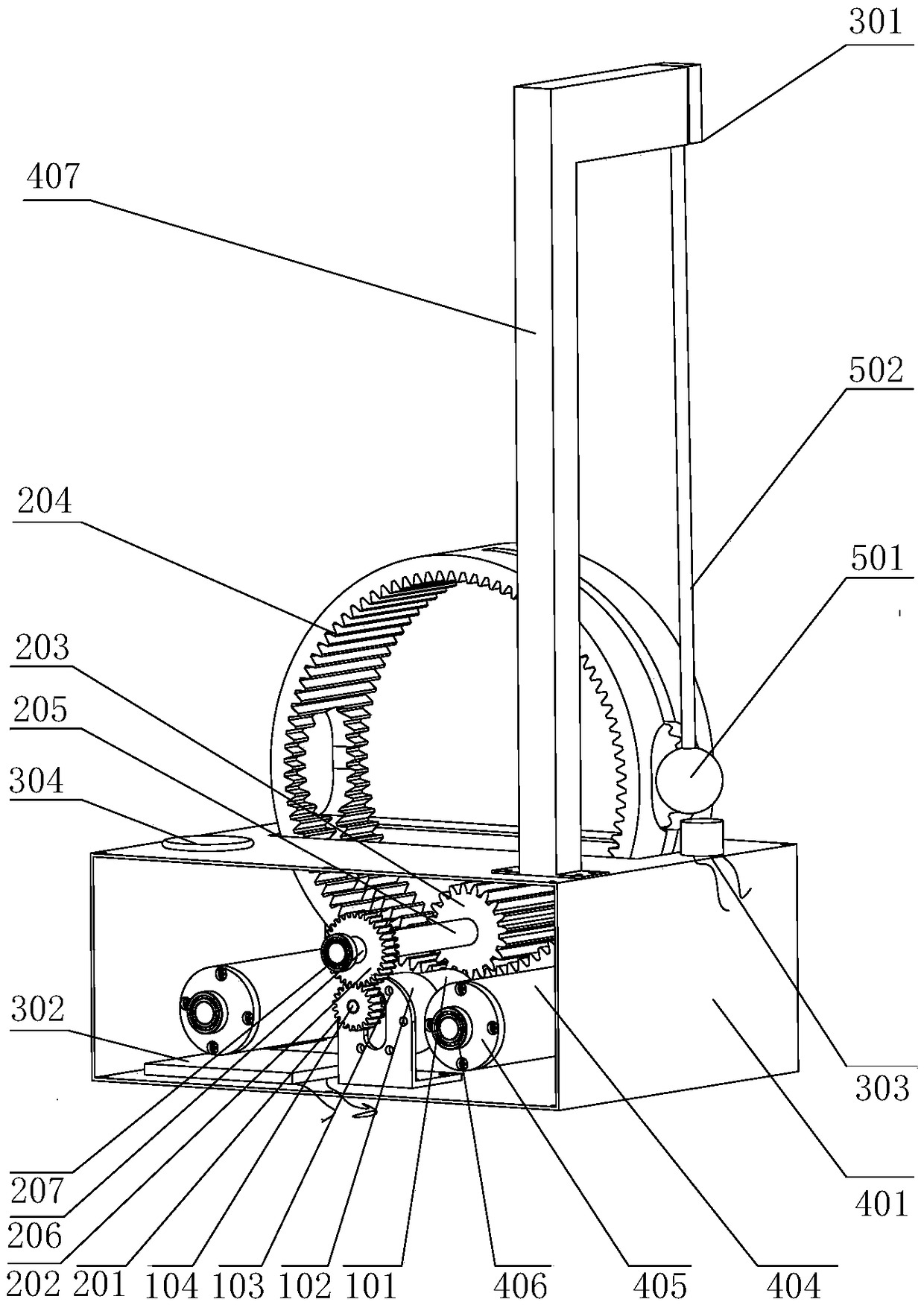

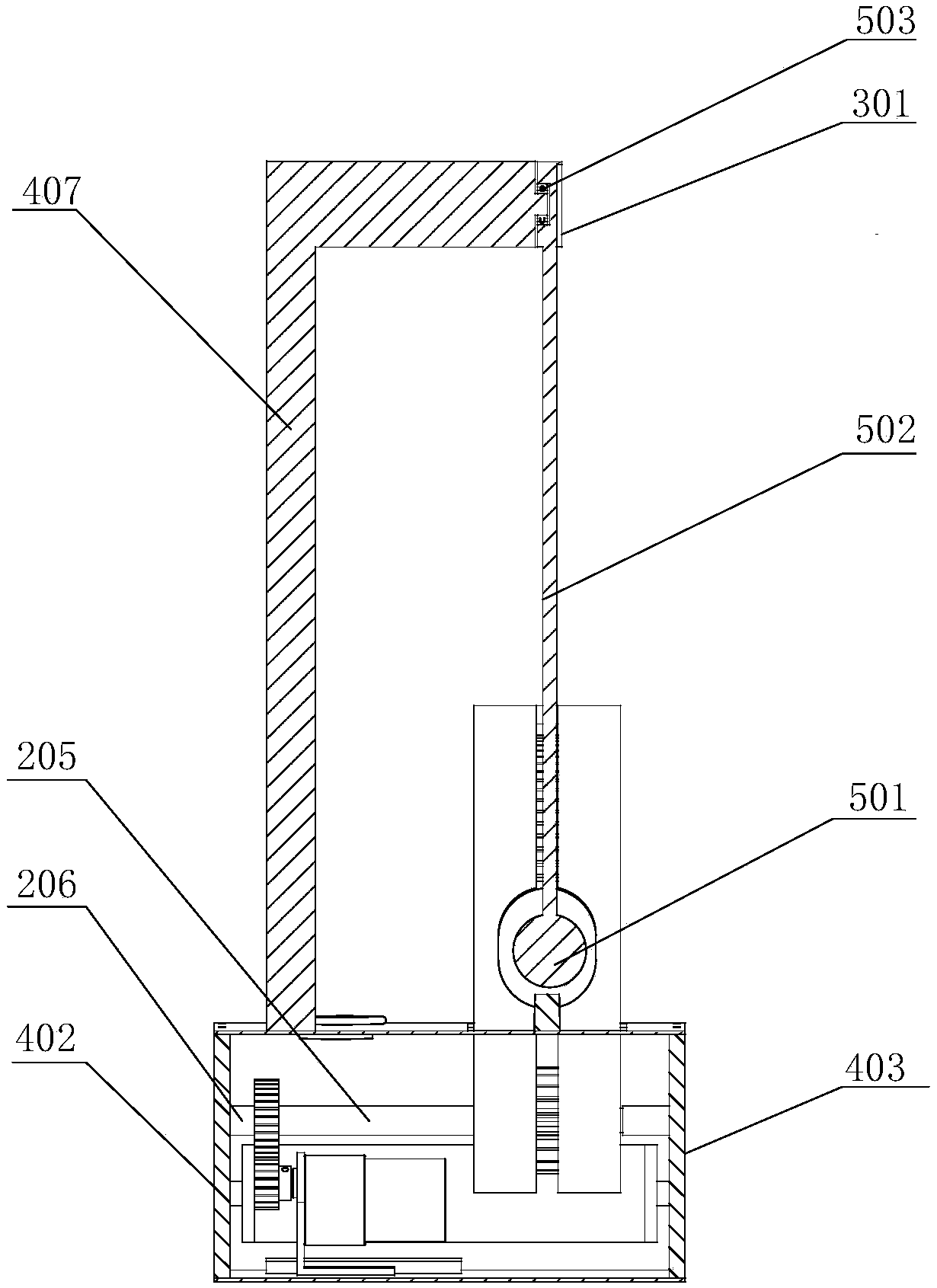

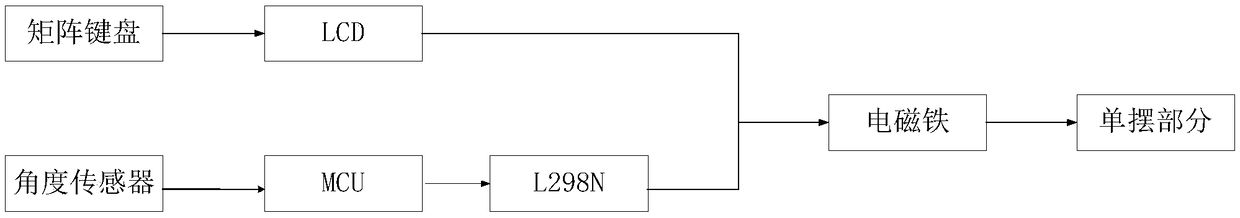

Electromagnetic control single pendulum and U-shaped groove gear rhythm matching device

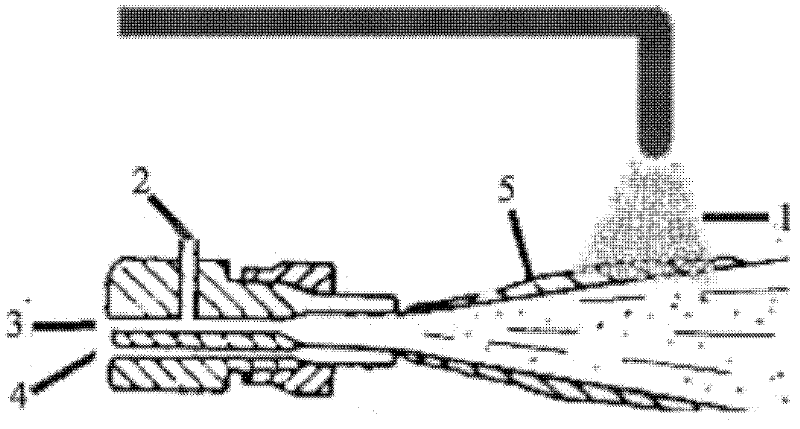

ActiveCN109116874AAchieve continuous swingAchieve rhythmToothed gearingsControl using feedbackReduction driveTransmitted power

The invention discloses an electromagnetic control single pendulum and U-shaped groove gear rhythm matching device that is a mechanized and controllable single-pendulum motion rhythm matching device.The device comprises a driving mechanism (1), a transmission mechanism (2), an electromagnetic controller (3), a supporting mechanism (4) and a single pendulum mechanism (5). A direct-current motor transmits power to a two-stage gear by a reducer so as to drive a U-shaped groove gear to rotate; the angle of single-pendulum swing is detected by an angle sensor and the detected angle is returned tothe controller; and the controller adjusts the current of an electromagnet to change the electromagnetic repulsive force to single pendulum by the electromagnet, so that the single-pendulum equal-amplitude swinging is realized and the motion rhythm matching with the U-shaped groove gear is realized. The device has characteristics of exquisite structure and reliable control.

Owner:ANHUI UNIVERSITY +1

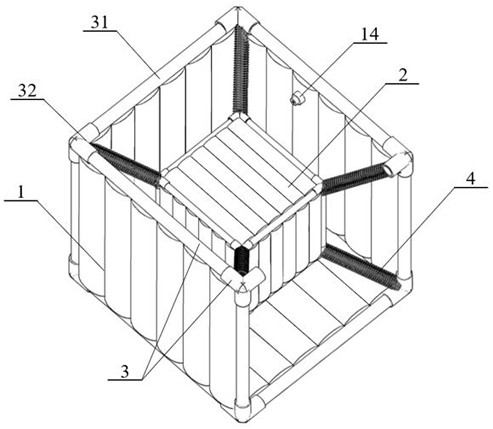

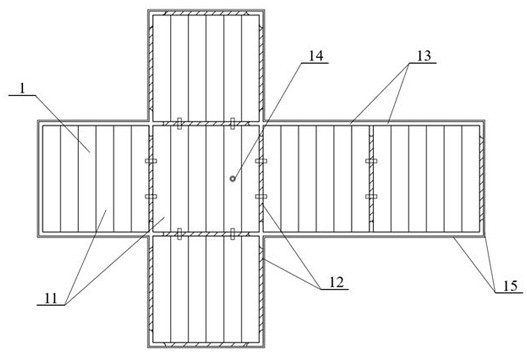

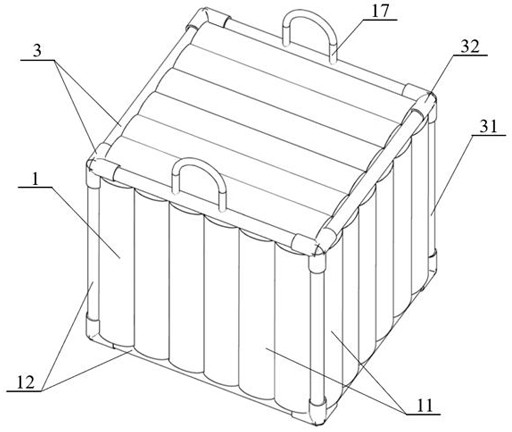

Expandable inflatable membrane structure air-drop device and operation method thereof

ActiveCN112811004AGuaranteed StrengthGuaranteed stiffnessAircraft componentsContainers to prevent mechanical damageClassical mechanicsAirbag

The invention relates to the field of air-drop packaging boxes, in particular to an expandable inflatable membrane structure air-drop device and an operation method thereof. The device comprises an outer airbag type expandable inflatable membrane structure box body, an inner airbag type expandable inflatable membrane structure box body, an outer cable rod framework, an inner cable rod framework and an elastic limiting mechanism. The outer cable rod framework is installed on the edge portion of the outer airbag type expandable inflatable membrane structure box body and connected with the outer airbag type expandable inflatable membrane structure box body. According to the expandable inflatable membrane structure air-drop device, multiple energy dissipation mechanisms of landing impact of an air-drop bag are achieved, and the air delivery time and space of materials are saved through quick inflation and assembly; and the problems that the parachute air-drop hit rate is poor and the landing time is long are solved, the device is suitable for delivering solid and liquid substances in different shapes, work is efficient, the structure is reasonable, cost is low, and industrialization is easy.

Owner:ARMY ENG UNIV OF PLA

Multi-pass spinning accumulation thickening forming method

The invention belongs to the field of machining methods for disk-shaped parts with thin radial plates and thick wheel flanges, and discloses a multi-pass spinning accumulation thickening forming method. The thickening process of the forming method includes multiple passes, and the slot shapes of spinning rollers of different passes are different; the slot of the spinning roller of each pass can bedivided into three parts, and the section of each part is trapezoidal; the second part is located between the first part of the top surface and the second part, and the thickness of the third trapezoid bottom surface of the section of the third part is the finally required thickness of a plate to be machined; the thickness of the first trapezoid top surface of the section of the first part is theinitial thickness of the plate to be machined, and the volumes of the second part and the first part are gradually decreased by increasing the volume of the third part gradually, till the volumes ofthe first part and the second part are decreased to zero; and thus, the process of gradually thickening the plate from inside to outside through the multiple passes is achieved. Through the forming method, the controllable thickening process of the plate is achieved, and the formed plate is uniform in thickness; and the forming quality is high, and the forming process is stable.

Owner:HUAZHONG UNIV OF SCI & TECH

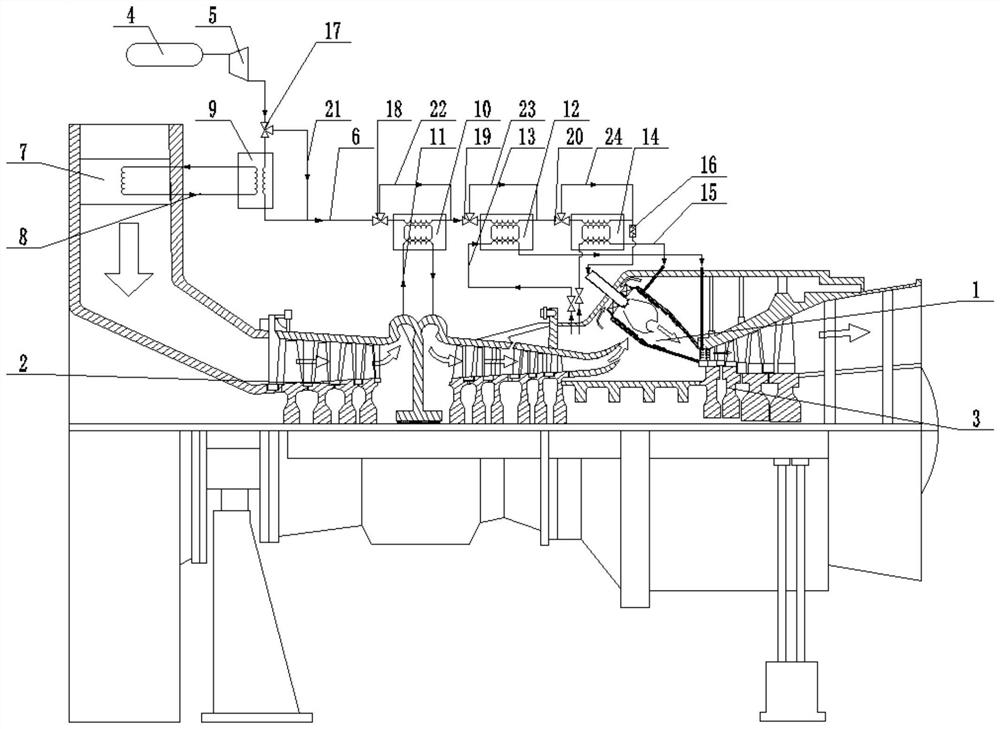

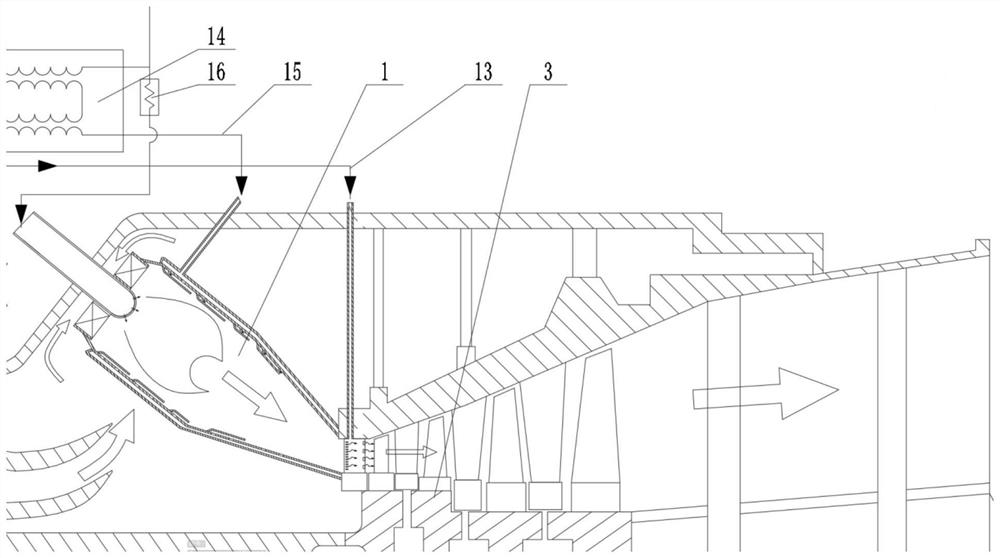

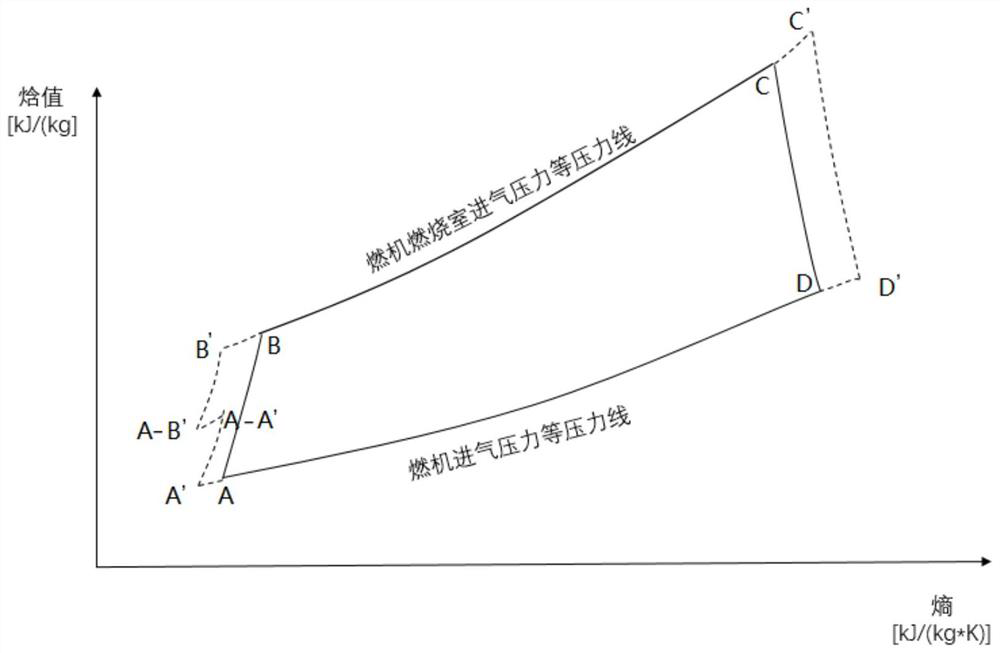

Efficiency improving system of hydrogen fuel gas turbine and control method

PendingCN114483307AImprove combustion efficiencyImprove overall efficiencyTurbine/propulsion engine coolingGas turbine plantsLiquid hydrogenAutomotive engineering

The invention discloses an efficiency improving system of a hydrogen fuel gas turbine and a control method, at least one heat exchange part is arranged, the heat exchange part is used for leading out cold energy in low-temperature hydrogen and cooling gas participating in acting in the gas turbine, and the cooled gas after heat exchange can improve the efficiency of the gas turbine; a straight-through assembly is further arranged, the low-temperature hydrogen can be controlled to circulate to exchange heat with the heat exchange part or bypass the heat exchange part to continue to circulate, and control over whether the low-temperature hydrogen exchanges heat or not is achieved; meanwhile, after the low-temperature hydrogen subjected to heat exchange absorbs heat, the temperature is increased, and when the low-temperature hydrogen enters a combustion chamber of the gas turbine, the combustion efficiency can be further improved, so that the overall efficiency of the gas turbine is improved, and the problems that the temperature of the provided hydrogen is low when high-pressure stored hydrogen or cryogenic liquid hydrogen is used as a hydrogen source; and a part of heat released by combustion needs to be absorbed when entering a combustion chamber of the gas turbine for combustion, so that the efficiency of the gas turbine is reduced.

Owner:上海慕帆动力科技有限公司

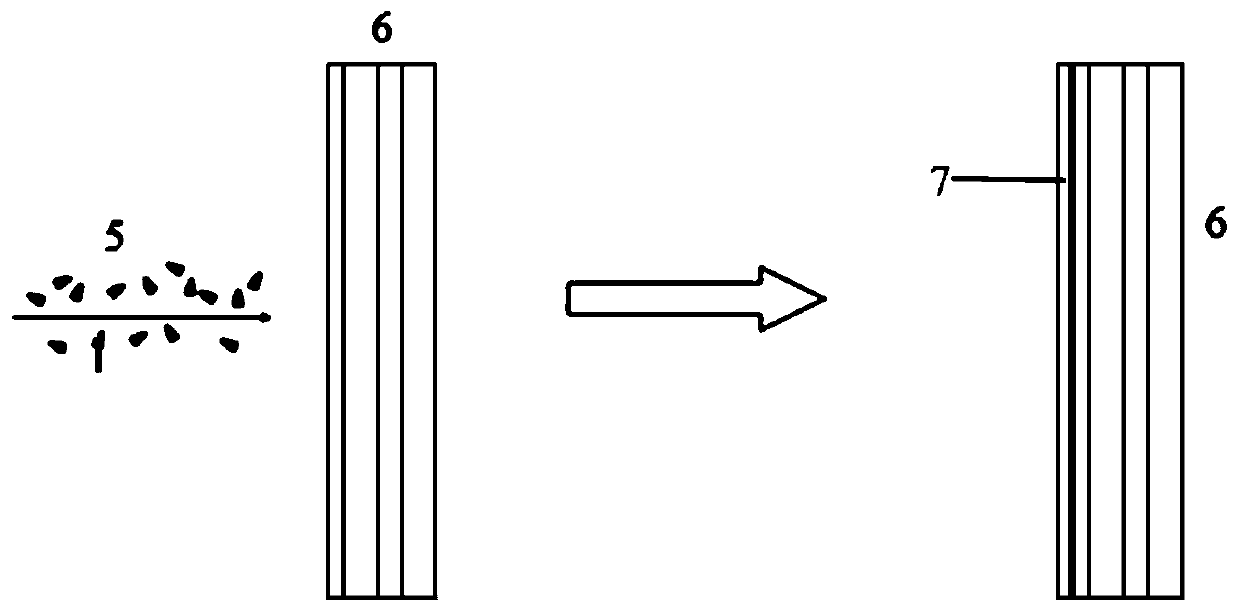

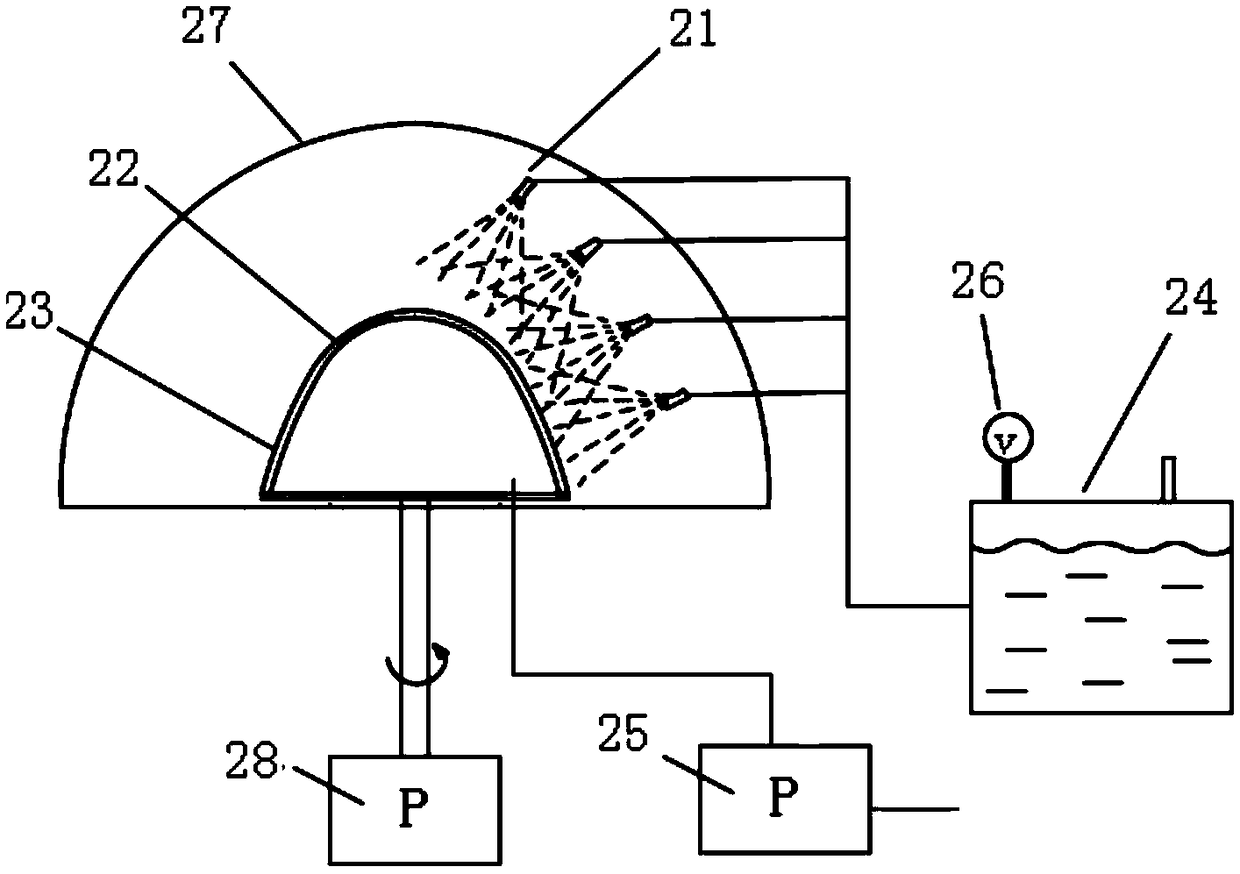

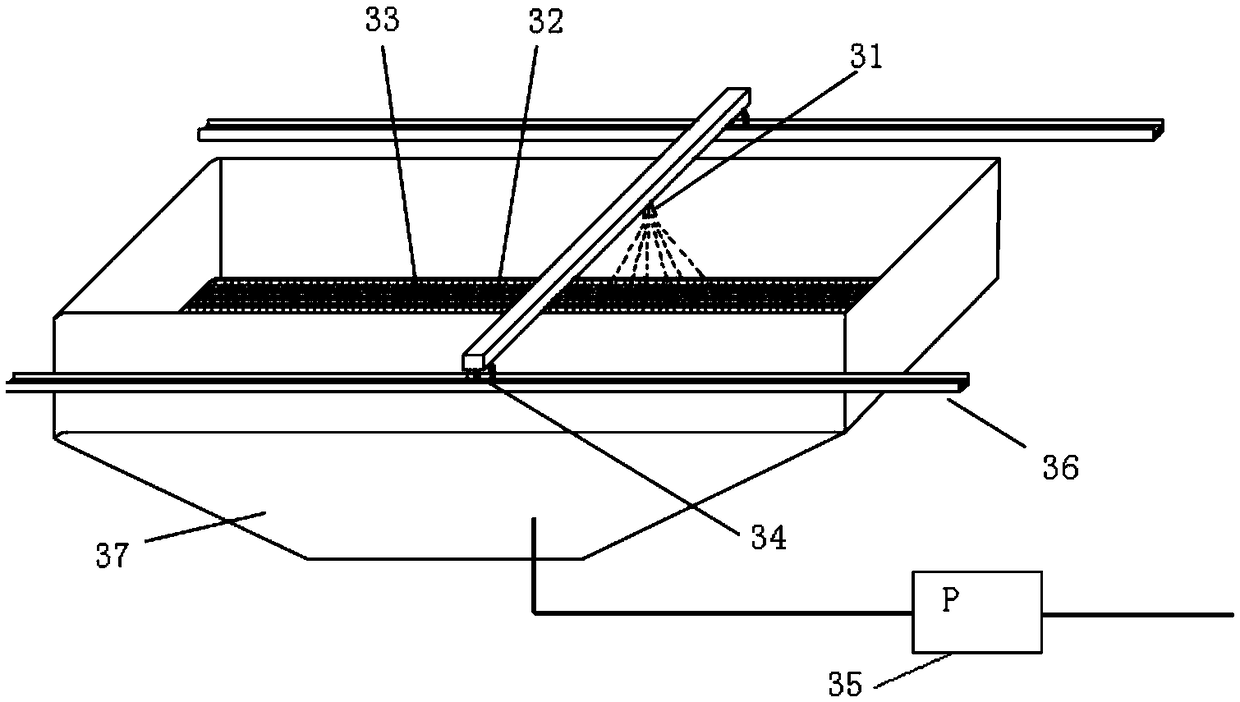

Method and device for manufacturing special inorganic thermal insulation felt

ActiveCN109385773AIncrease productivityUniform thicknessTextile treatment machine arrangementsTextile treatment by spraying/projectingThermal insulationSprayer

The invention discloses a method for manufacturing special inorganic thermal insulation felt. The method comprises the steps that firstly, slurry is conveyed into a pressure container, then the pressure container is connected with an atomizing nozzle, and finally, the slurry is atomized and sprayed to the surface of a filter screen through a sprayer to form a felt body; meanwhile, a vacuum suctiondevice is used at the bottom of the filter screen so as to strengthen the liquid and solid separation effect on the filter screen. In addition, according to the thermal insulation felt with differentshape characteristics, multiple sprayers can be used for mobile production. In order to improve the uniformity, the method that the sprayers can be used for alternate spraying and the slurry is stacked for covering can also be used. The method can be used for mechanically producing the felt and greatly improve the production efficiency. Besides, process parameters in the production process are reasonably controlled, thermal insulation felt products uniform in thickness, high in strength and good in performance can be obtained, and standardized, automatic and controllable production modes areachieved.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Micro-nanometer structure TiO2 coating with high hardness and high adhesion force as well as preparation method thereof

The invention discloses a micro-nanometer structure TiO2 coating with high hardness and high adhesion force and a preparation method thereof. The thickness of the TiO2 coating is 10mum to 100mum, the crystal phase compositions of TiO2 in the coating are anatase phase and rutile phase, and in addition, the anatase TiO2 accounts for 3 percent to 35 percent of the mass percent of the TiO2 coating. The liquid phase hot spraying coating method and the traditional hot spraying coating method are adopted and are combined, TiO2 liquid materials and powder are simultaneously sent into hot spraying coating flame, compared with the TiO2 coating obtained by the liquid phase hot spraying coating method, the prepared TiO2 coating has the advantages that the microhardness is improved by nearly 10 times, the adhesion force is improved nearly 3 times, the photocatalysis function of the TiO2 coating is favorably realized, important application values are realized, and the micro-nanometer structure TiO2 coating is hopeful to generate huge social and economic benefits.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A controllable and intelligent magnetorheological piezoelectric vibration isolation bearing

InactiveCN107165301BRealize controllabilityReal-time damping controlProtective buildings/sheltersShock proofingWireless transmissionComputer module

Owner:XIJING UNIV

Device for separating walnut shells and extracting kernels and using method thereof

The invention discloses a device for separating walnut shells and taking kernels and a method for using the same. The wall is provided with at least two openings communicating with the walnut positioning holes. Driven by the moving mechanism, multiple striking rods pass through the openings corresponding to each striking rod and strike the walnuts arranged in the walnut positioning holes. The two sides of the walnut positioning hole are respectively used to cover the positioning and quantitative feeding slider of the walnut positioning hole, and a collecting device is arranged below the positioning and quantitative feeding slider on one side of the walnut positioning hole, and the collecting device is connected with a blower; the present invention uses a stirring device to carry out Feeding, compact structure, high efficiency and extremely low failure rate. The shape of the discharge hole of the feeding hopper and the through hole in the positioning conveying mechanism adopt the shape of the walnut positioning section, which realizes the automation and controllability of walnut feeding.

Owner:广州华大生物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com