Micro-nanometer structure TiO2 coating with high hardness and high adhesion force as well as preparation method thereof

A micro-nano-structured, high-adhesion technology, applied in coatings, metal material coating processes, melt spraying, etc., to achieve high anatase phase content, excellent mechanical properties, and ensure the effect of photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

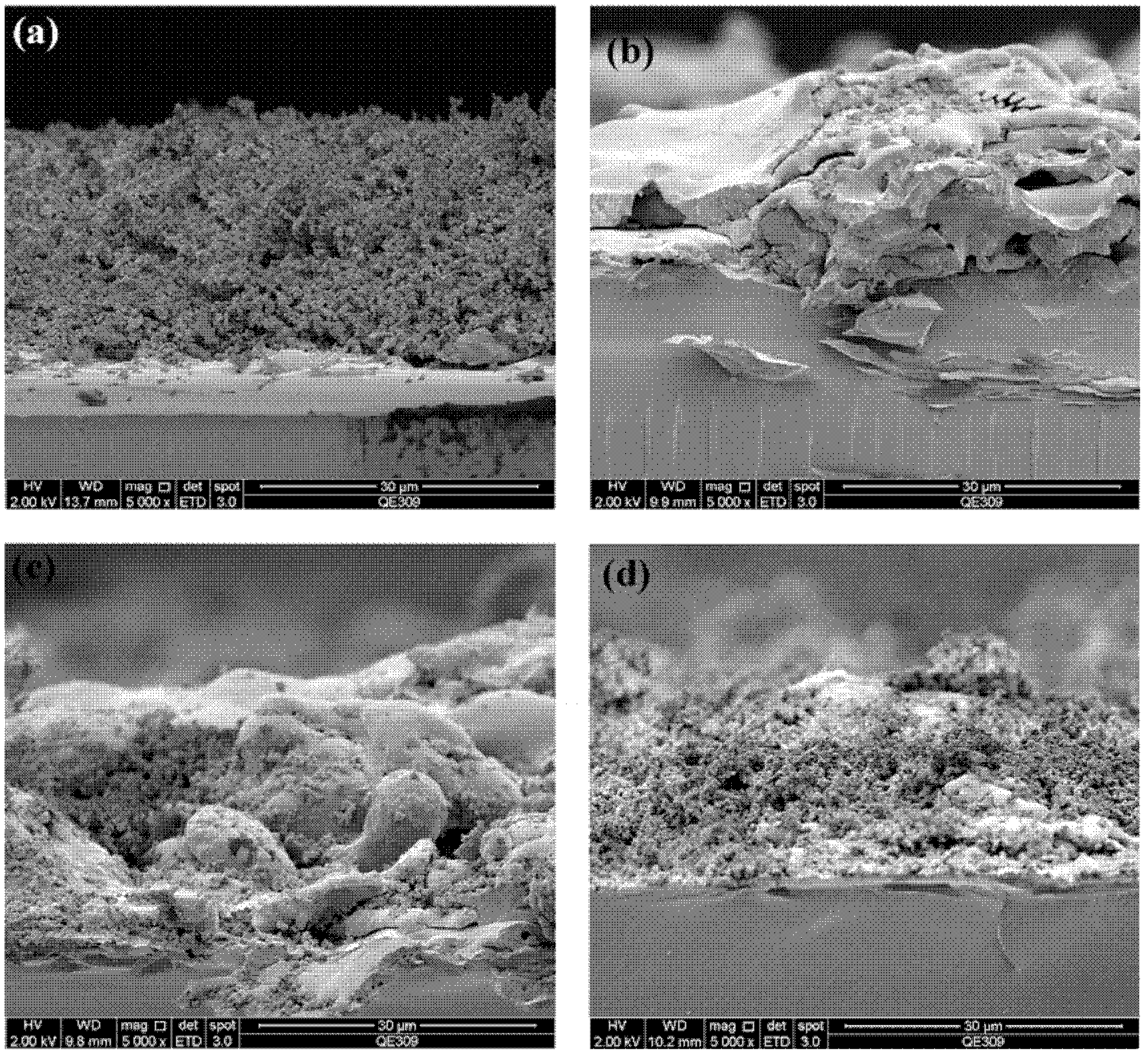

[0050] In this embodiment, the substrate is a 304 stainless steel sheet with a thickness of about 2mm, and the TiO on the surface of the substrate 2 coating thickness is 40µm, the TiO 2 TiO in coating 2 The crystal phase composition is anatase phase and rutile phase, according to the mass fraction, anatase TiO 2 Accounted for 3 to 35%. The TiO 2 The specific preparation method of the coating is as follows:

[0051] Mix deionized water and absolute ethanol at a volume ratio of 1:1 to make a solvent, and commercially available TiO with an average particle size of 10nm to 40nm and anatase crystal form 2 Add the powder into the prepared solvent above, and mix it uniformly by magnetic stirring to make TiO 2 Spray liquid material 1 with a solid content of 1 wt%. Spraying powder 2 is commercially available TiO with an average particle size of 10 μm to 40 μm and a crystal form of rutile 2 powder. The substrate used for spraying is a 304 stainless steel sheet with a thickness o...

Embodiment 2

[0056] The present embodiment is basically the same as embodiment 1, the difference is that the TiO of the spray liquid material in the present embodiment 2 The solid content is 4wt%, and other experimental conditions are the same.

[0057] Utilize coating microhardness test method to measure above-mentioned TiO 2 The microhardness of the coating is about 173.1HV, and the above-mentioned TiO is measured by the coating adhesion test method 2 The critical load of the coating is about 17.7N.

[0058] Compared with the comparative example, the TiO prepared by composite flame spraying method in this example 2 The mechanical properties of the coating are significantly improved.

Embodiment 3

[0060] The present embodiment is basically the same as embodiment 1, the difference is that the TiO of the spray liquid material in the present embodiment 2 The solid content was 7wt%, and other experimental conditions were the same.

[0061] Utilize coating microhardness test method to measure above-mentioned TiO 2 The microhardness of the coating is about 534.1HV, and the above-mentioned TiO 2 The critical load of the coating is about 25.5N.

[0062] Compared with the comparative example, the TiO prepared by composite flame spraying method in this example 2 The mechanical properties of the coating are significantly improved.

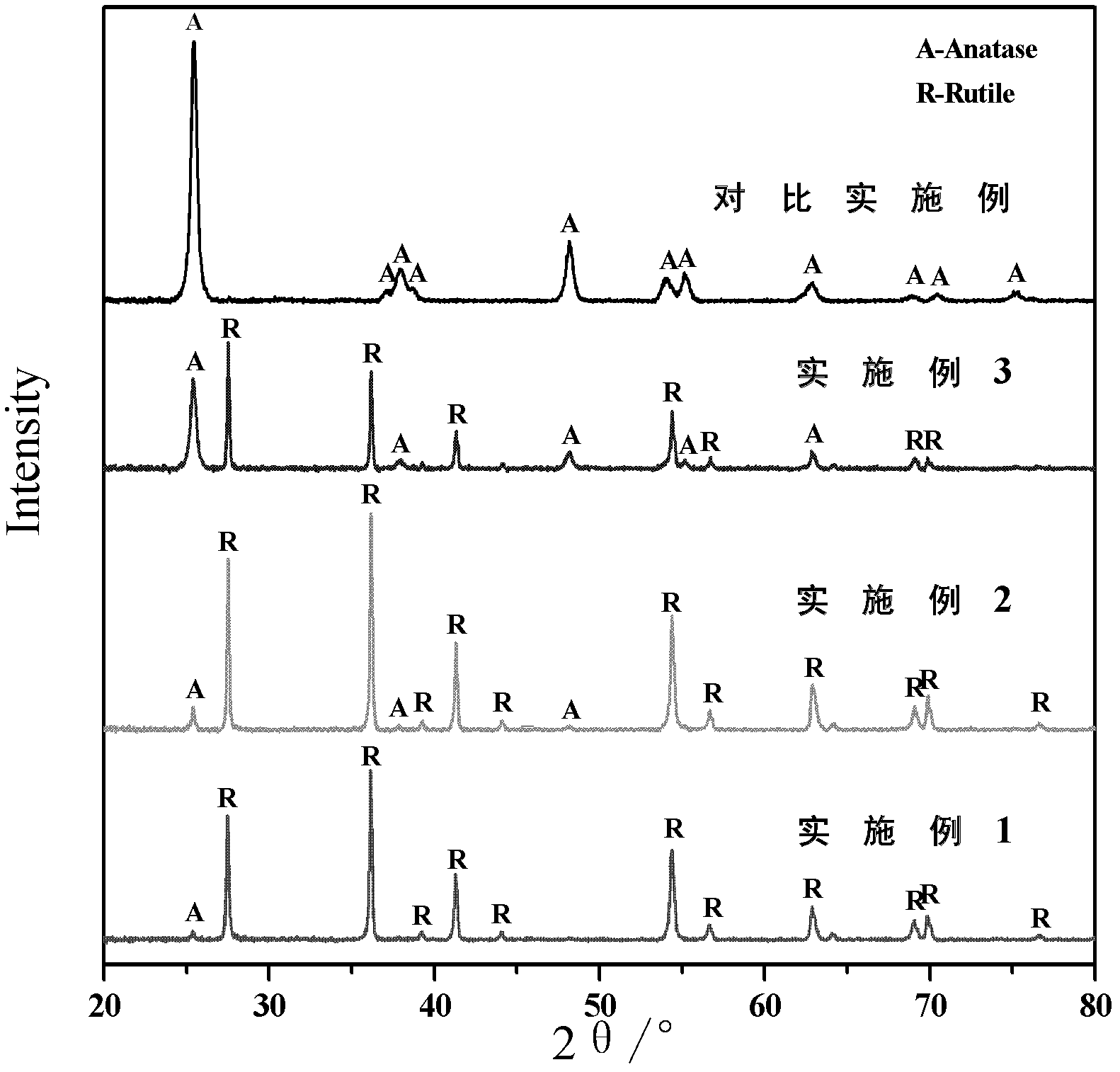

[0063] figure 2 It is the TiO prepared in comparative example, embodiment 1, embodiment 2, embodiment 3 2 XRD pattern of the coating. The results show that the TiO prepared by flame spraying method using liquid material and micron powder as spraying raw materials 2 Both coatings contain two crystal phases of anatase and rutile, and with the inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com