Pre-stress full automatic intelligent tensioning device and operation method thereof

An intelligent tensioning and fully automatic technology, which is applied in bridge construction, erection/assembly of bridges, bridge materials, etc., can solve the problems of prestressed tensioning quality, etc., and achieve the effect of realizing loading and realizing controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

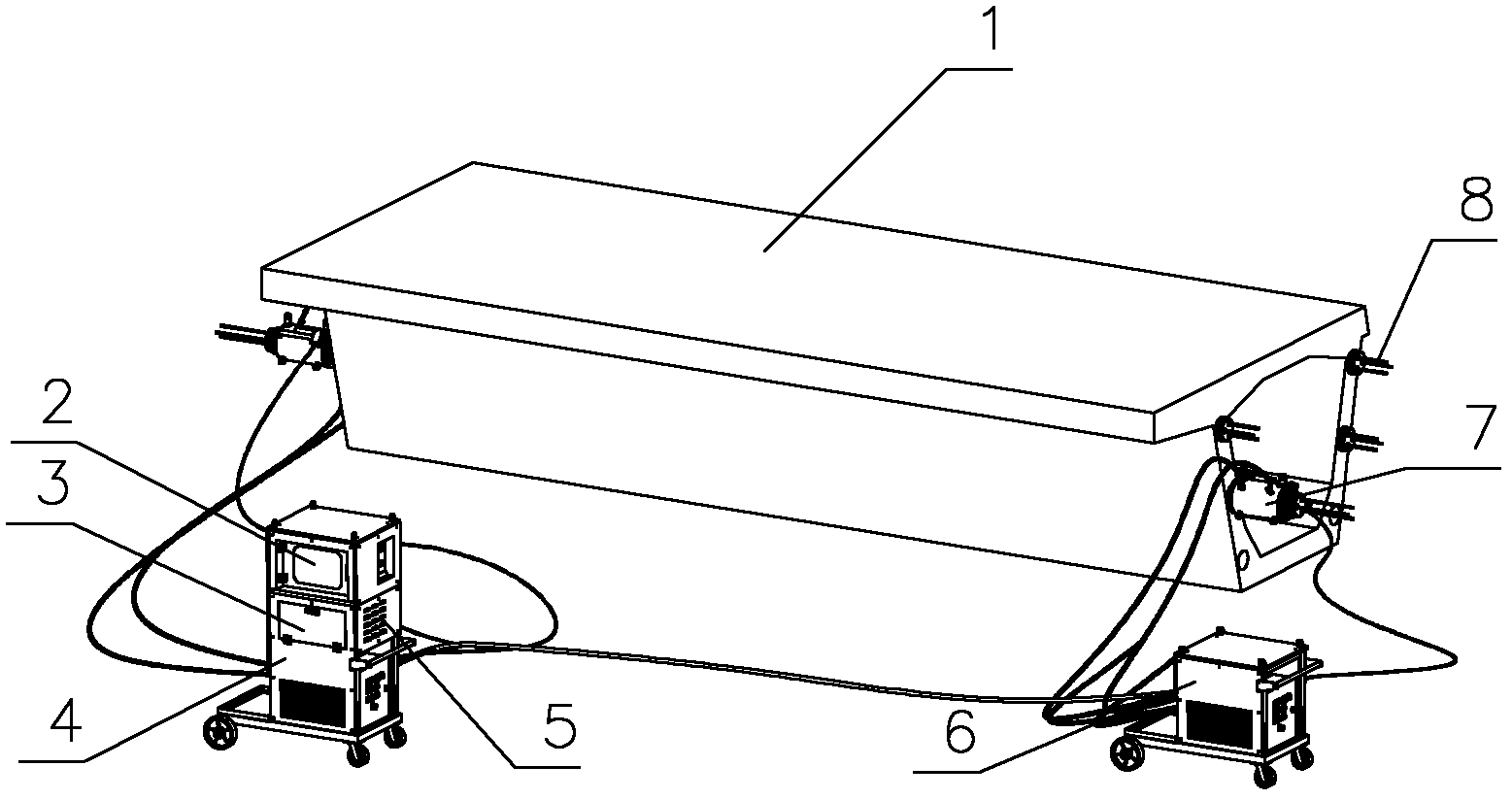

[0038] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

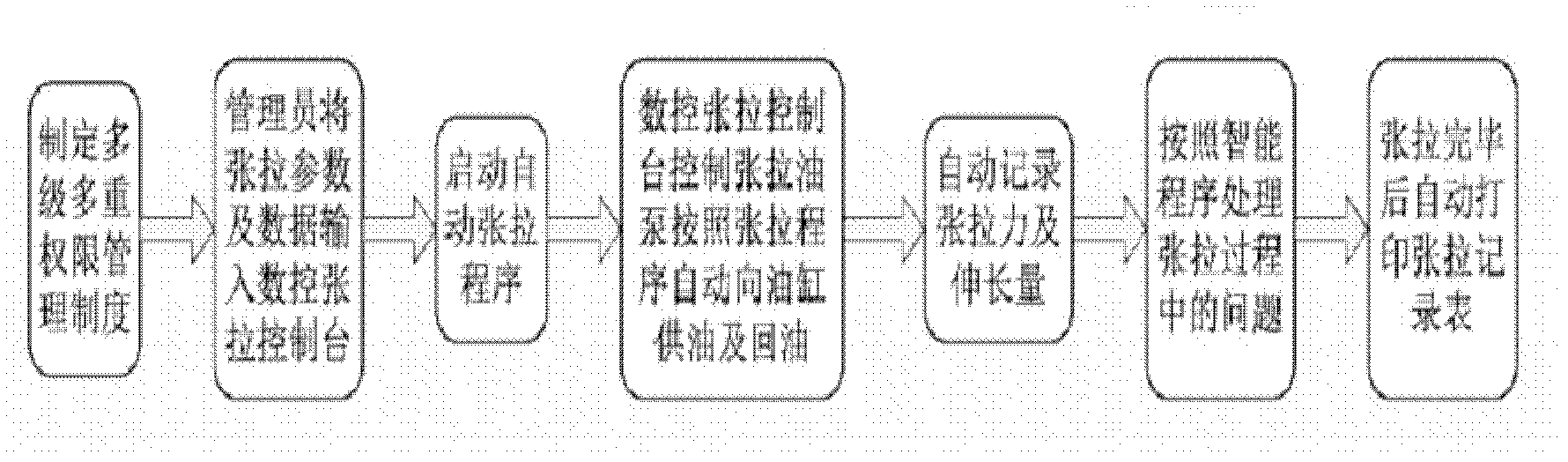

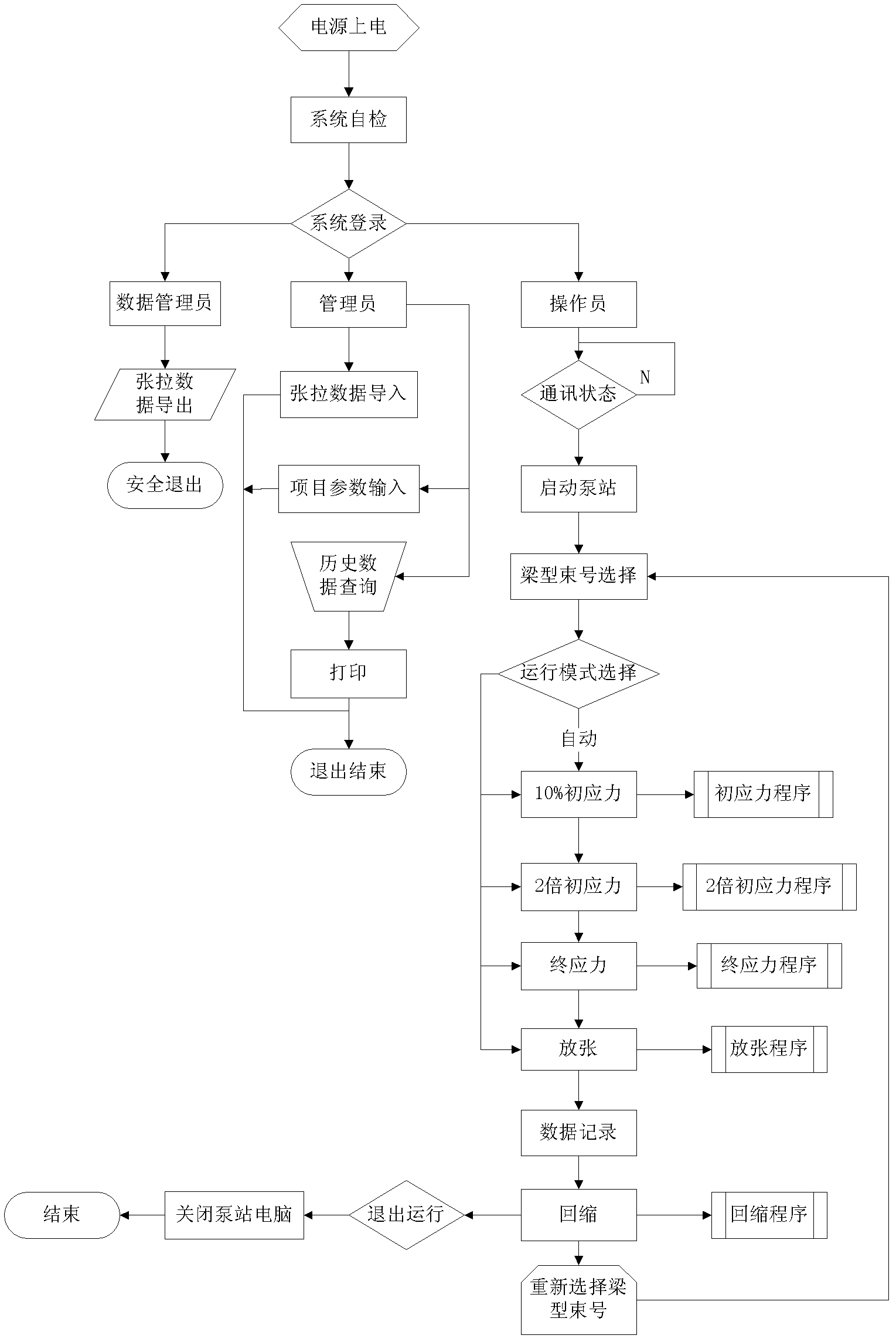

[0039] A prestressed fully automatic intelligent tensioning equipment, characterized by comprising: an integrated intelligent tensioning master station, an intelligent tensioning slave pump station, and an intelligent tensioning oil cylinder connected by cables; the integrated intelligent tensioning master station , using an integrated design, integrating the tensioning console, intelligent tensioning pump station and printer; the tensioning console uses a 10-inch touch screen, an industrial-grade computer and is equipped with WINDOWS system and interface, which can be easily operated; the intelligent The working pressure of the pumping stations of the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com