Carbon fiber integrated laying device

A technology of integrated paving and carbon fiber, which is applied in the field of composite material molding, can solve the problems of poor reliability and stability, achieve fast response speed, realize control requirements, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

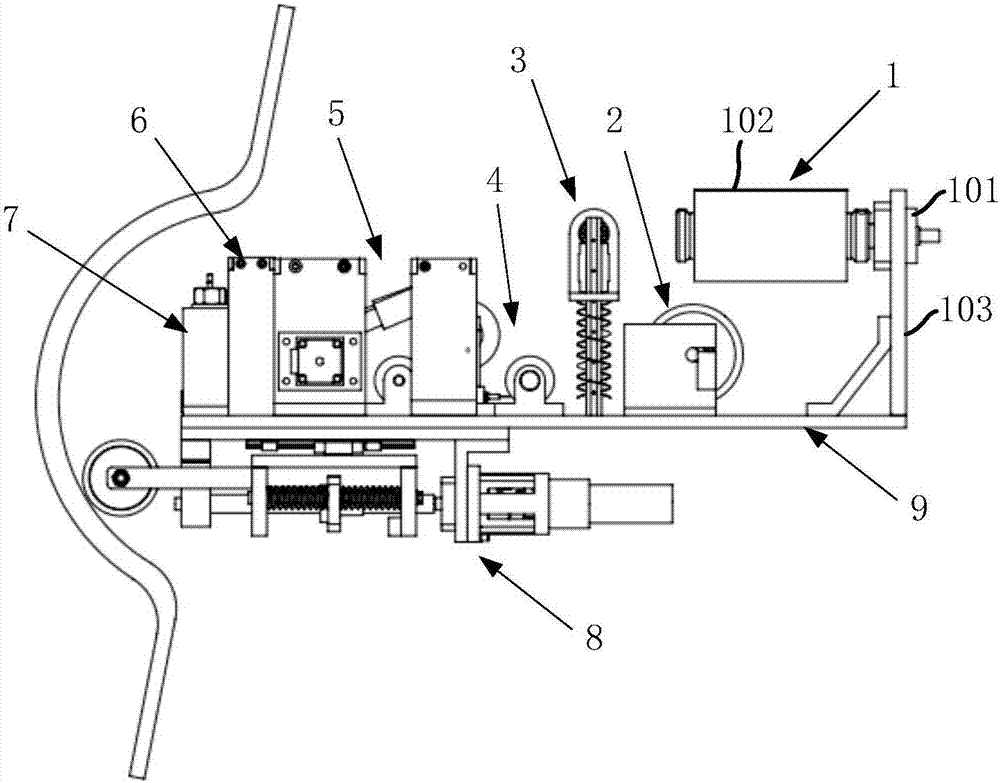

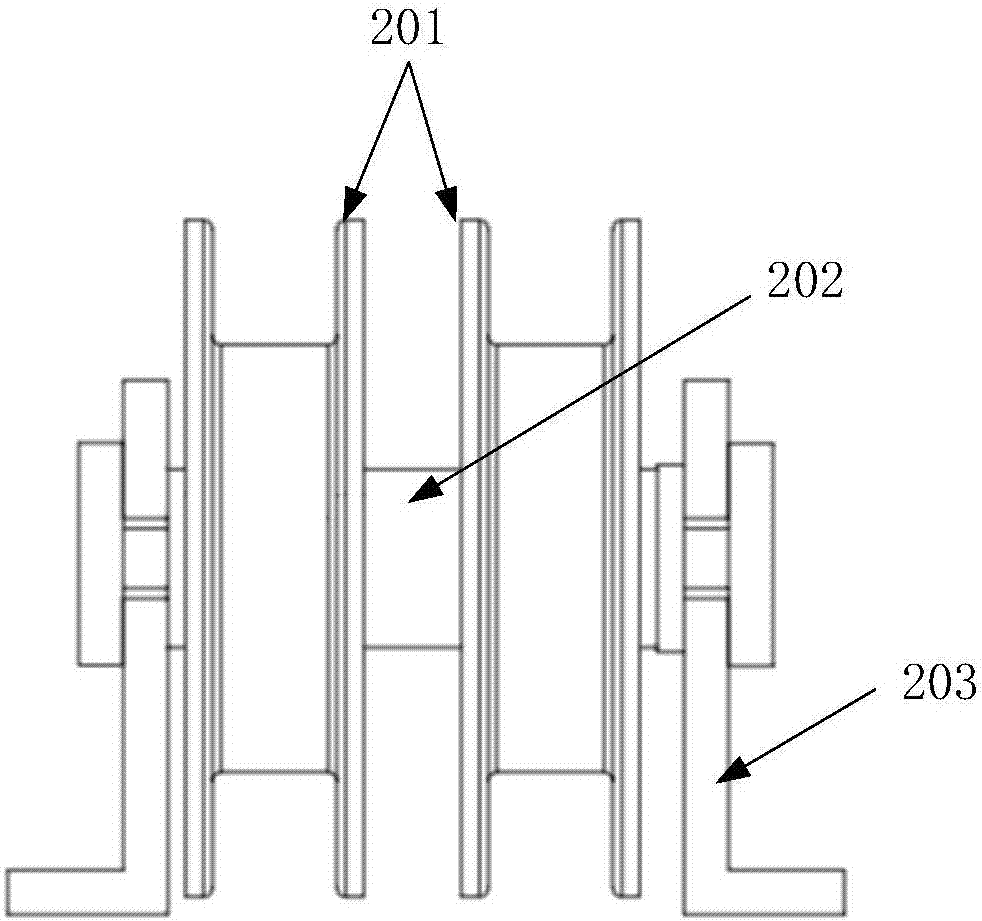

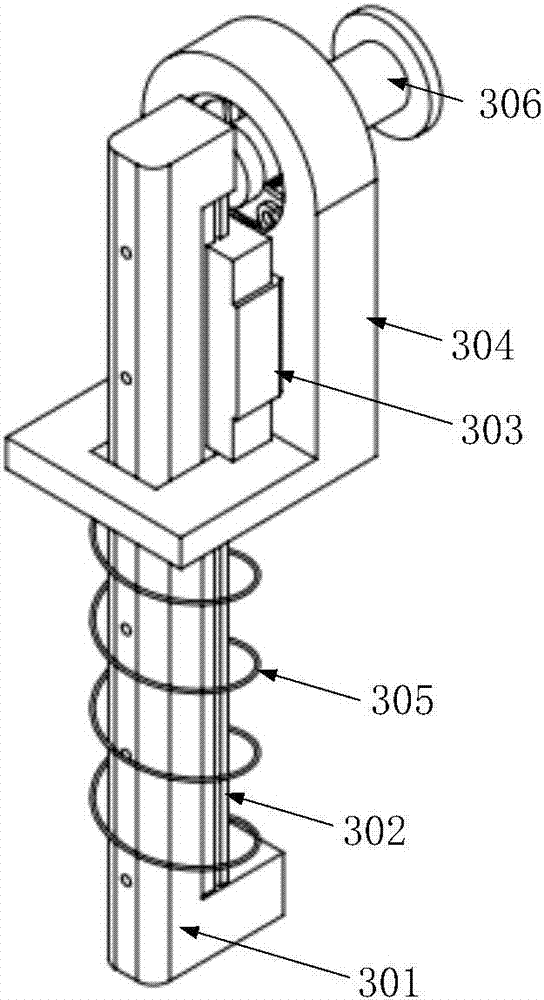

[0049] The carbon fiber integrated laying device of the present invention includes a feeding and unwinding mechanism 1, a guiding mechanism 2, a tension adjusting mechanism 3, a tension measuring mechanism 4, a refeeding mechanism 5, a clamping mechanism 6, a shearing mechanism 7 and a compacting mechanism 8, like figure 1 As shown, each of the above mechanisms is fixed on the bottom plate 9, and each mechanism cooperates with each other to complete the functions of transmission, curing and compaction of the carbon fiber prepreg. The above-mentioned feeding and unwinding mechanism 1, guiding mechanism 2, tension regulating mechanism 3, tension measuring mechanism 4, re-feeding mechanism 5, clamping mechanism 6, and shearing mechanism 7 are installed on one side of the bottom plate 9, and the compacting mechanism 8 is installed on the On the other side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com