Patents

Literature

165results about How to "Precise tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Height-and angle-adjustable motion disc implant

Owner:DEPUY SPINE INC (US)

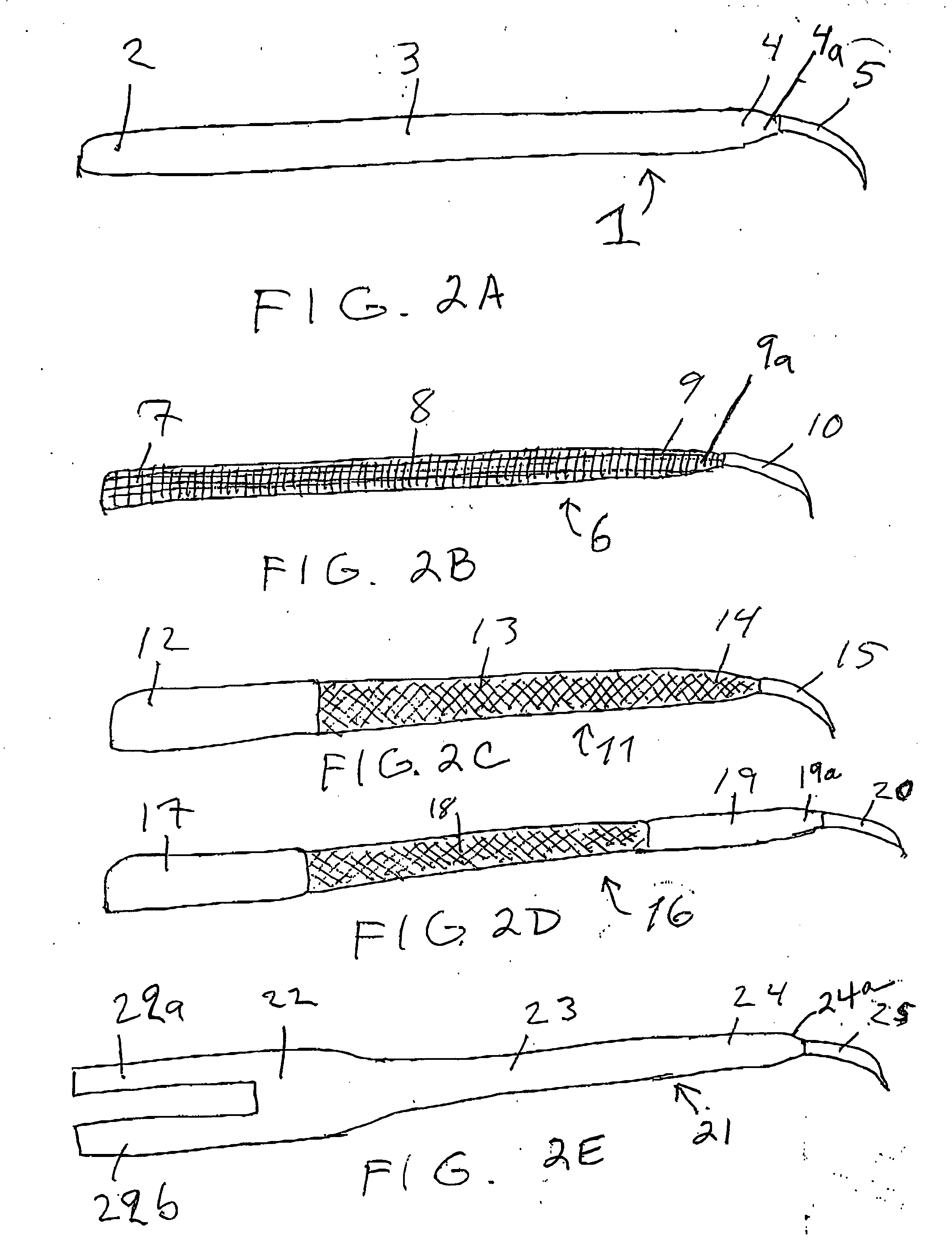

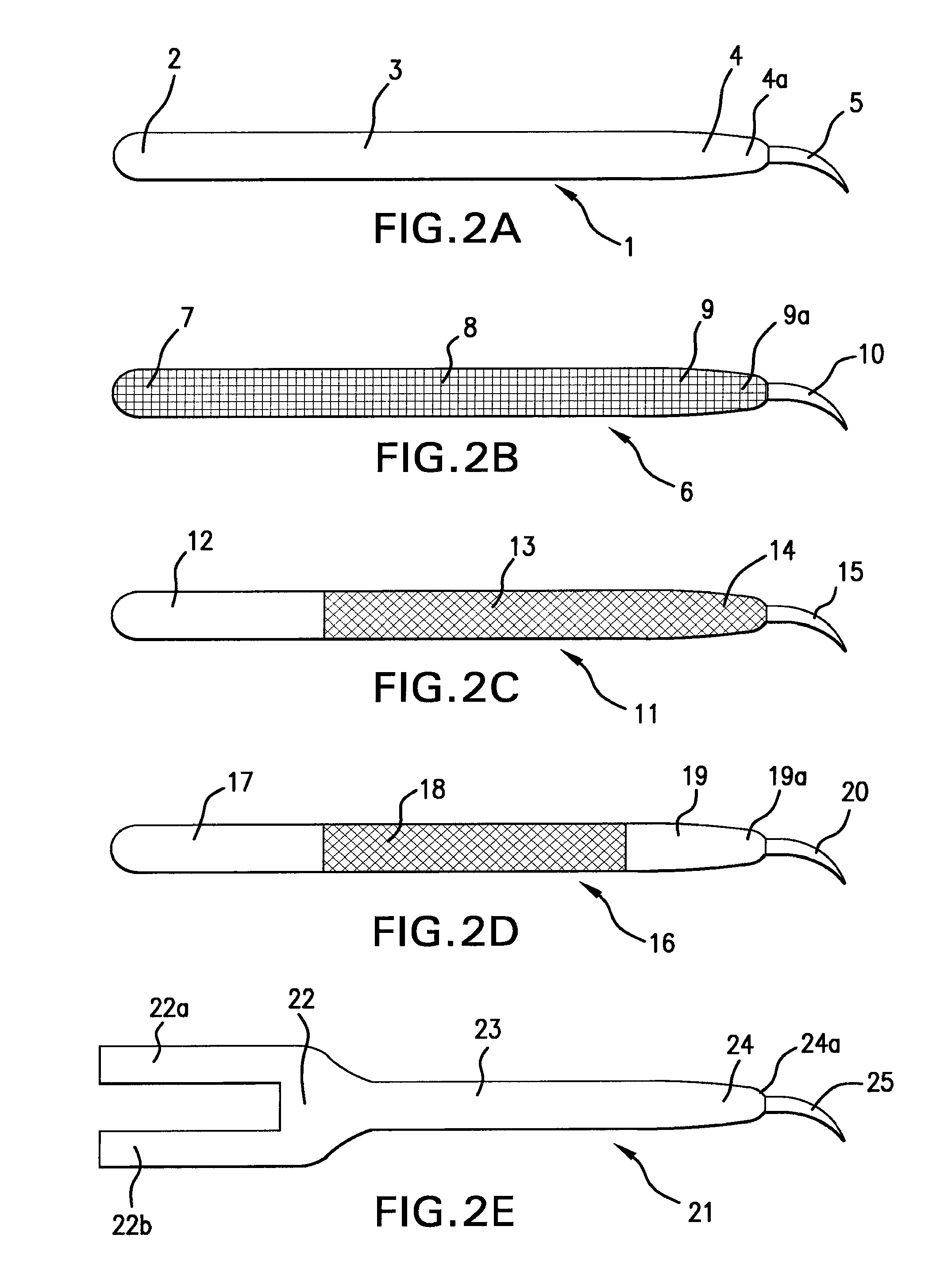

Bioabsorbable band system

InactiveUS20050070928A1Precise tensionLocking is particularly safeSuture equipmentsInternal osteosythesisEngineeringOsteotomy

Owner:BIORETEC

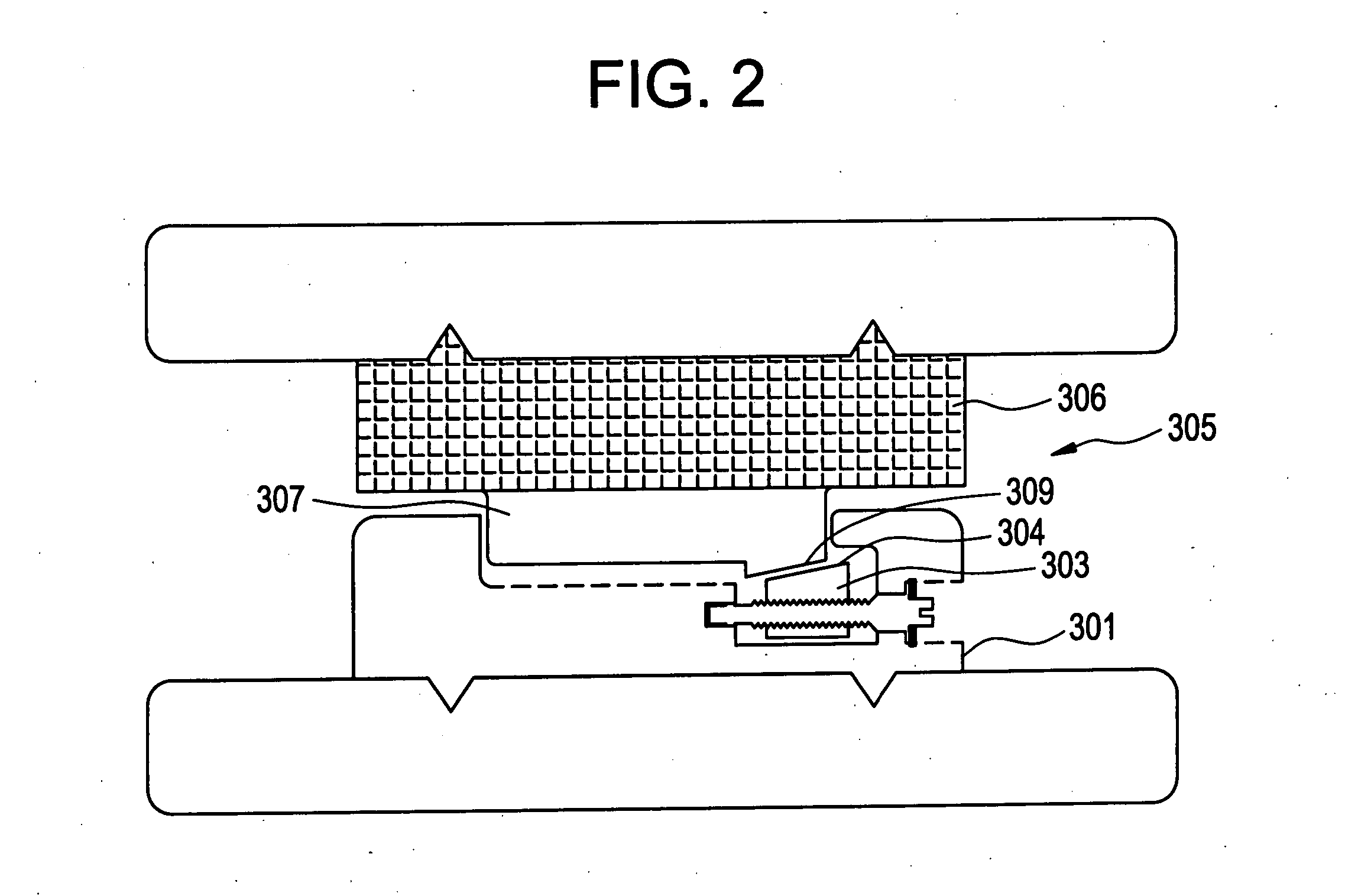

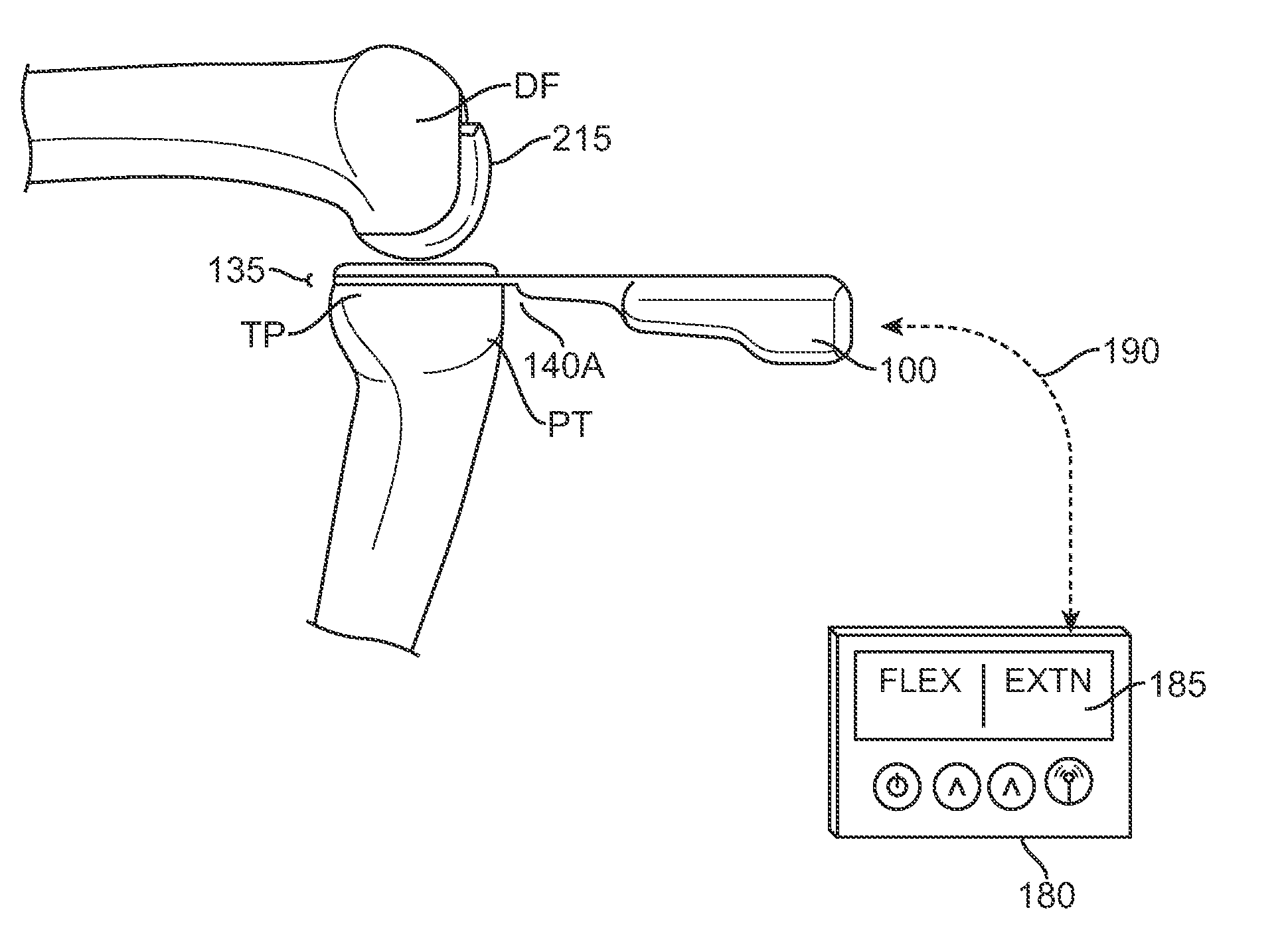

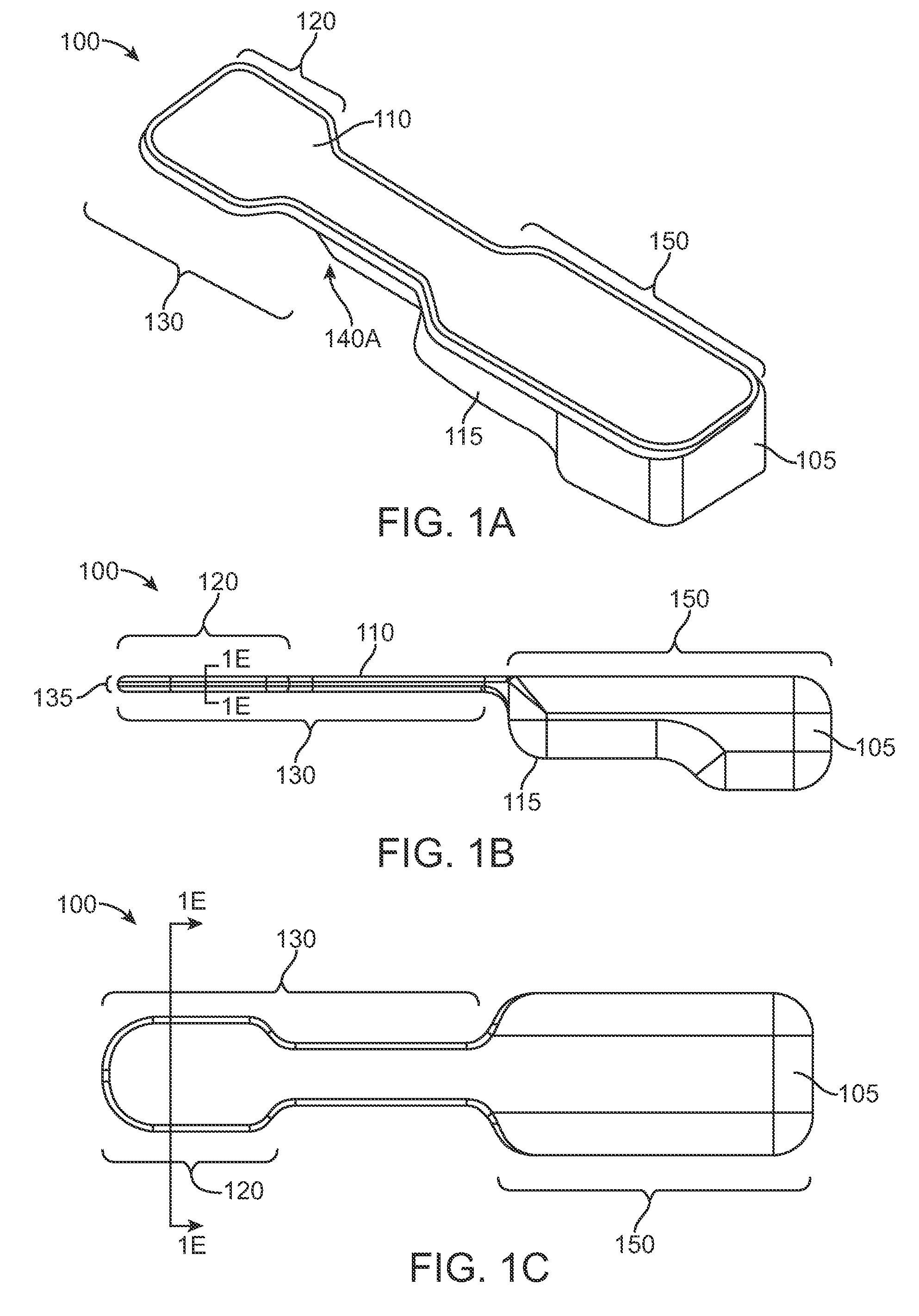

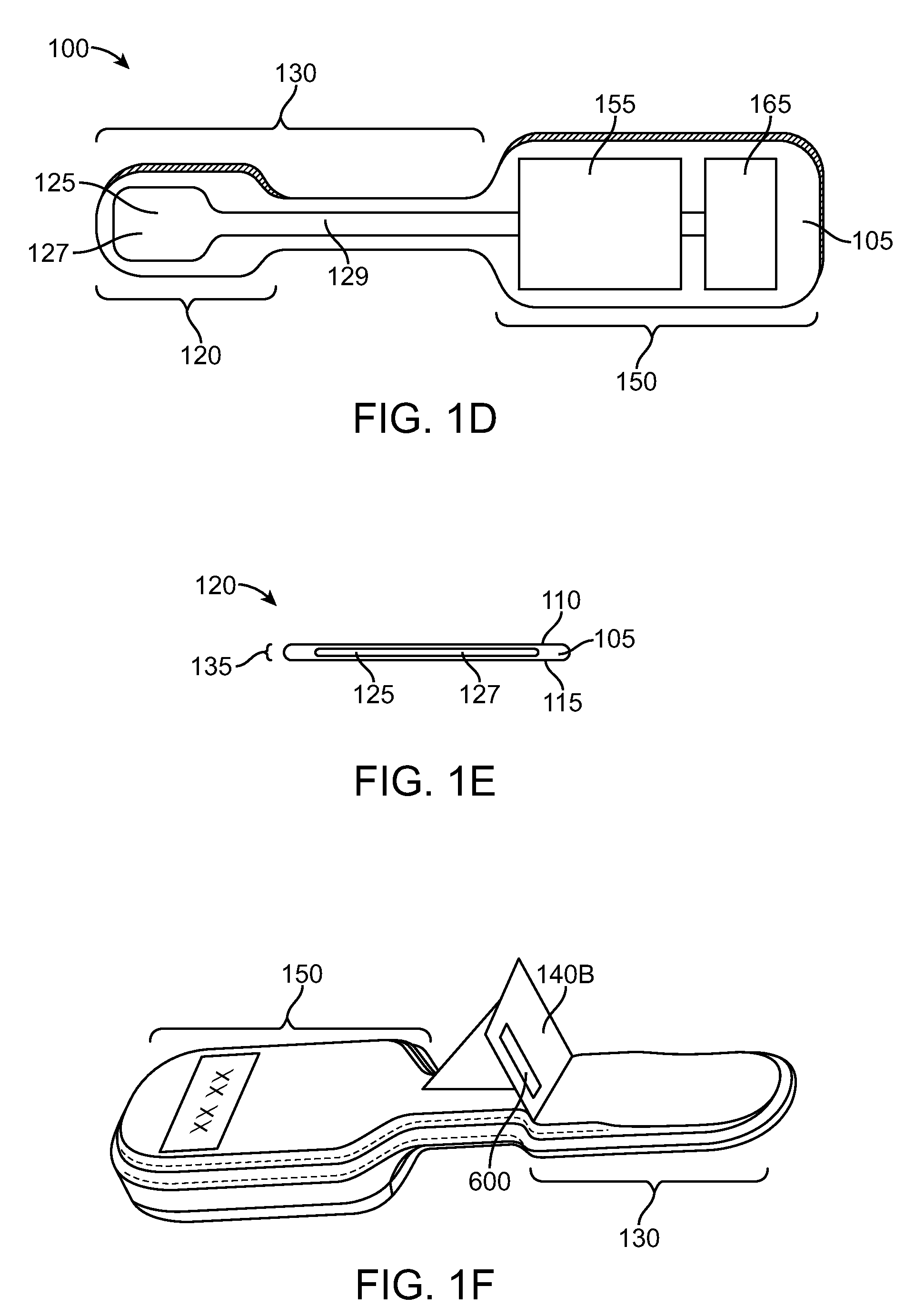

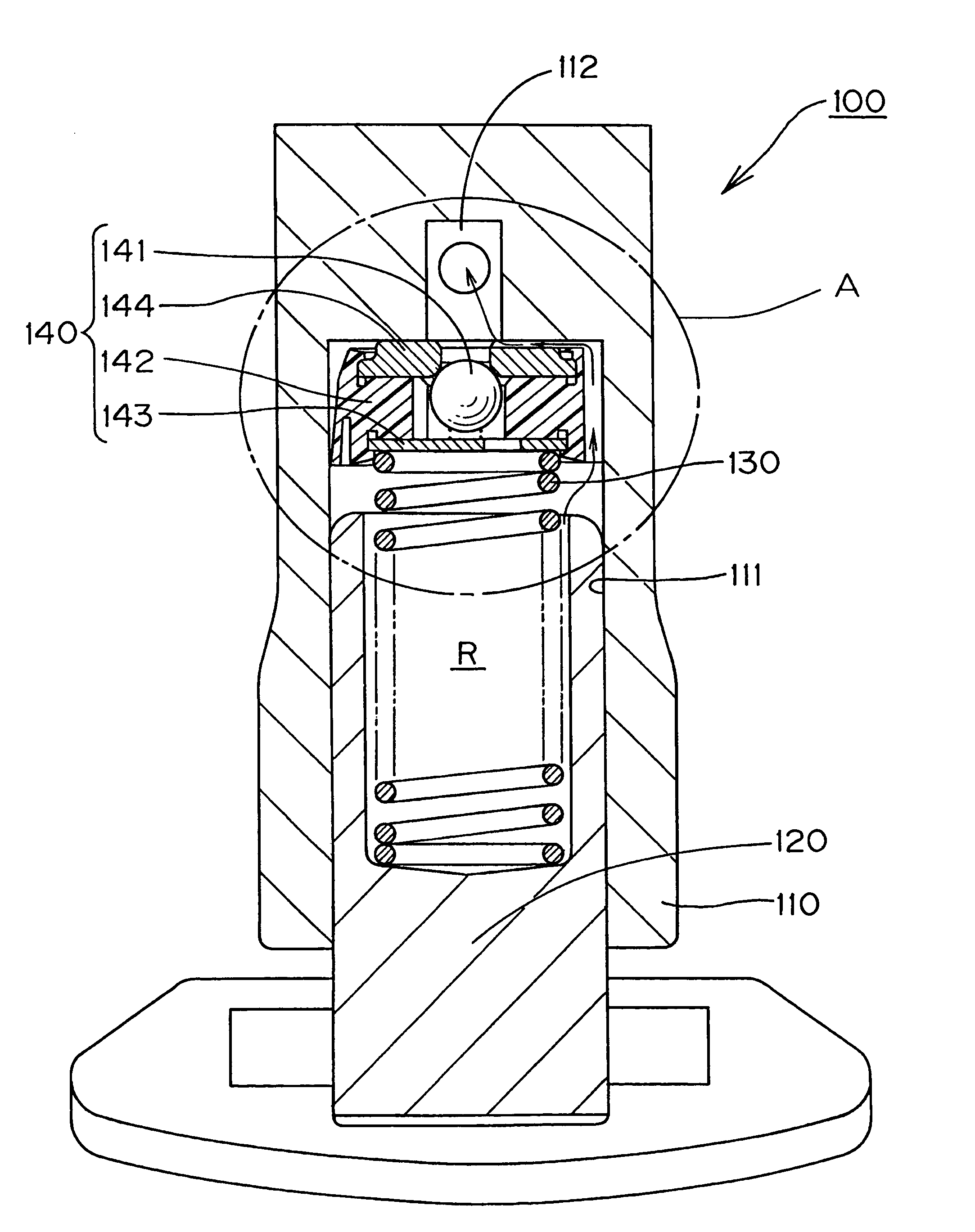

Sensing force during partial and total knee replacement surgery

ActiveUS8211041B2Accurate and quantifiable measurementPrecise tensionAnkle jointsPerson identificationTibiaTotal knee replacement surgery

Systems, devices, and methods are provided for measuring forces in the space of a knee during surgery. Such forces can be caused by tension in the ligaments of the knee. A femoral member is engaged with a distal femur. While the knee is flexed, partially extended, or fully extended, a force sensor and a gauge shim can be placed in the gap between the femoral member and the tibial plateau to measure the forces therebetween. The force sensor provides an accurate and quantifiable measurement of force, making knee replacement surgery and ligament tension balancing more accurate, standardized and repeatable. The force sensor comprises an elongate housing which comprises a thin force sensing distal portion and a proximal handle portion.

Owner:SYNVASIVE TECH

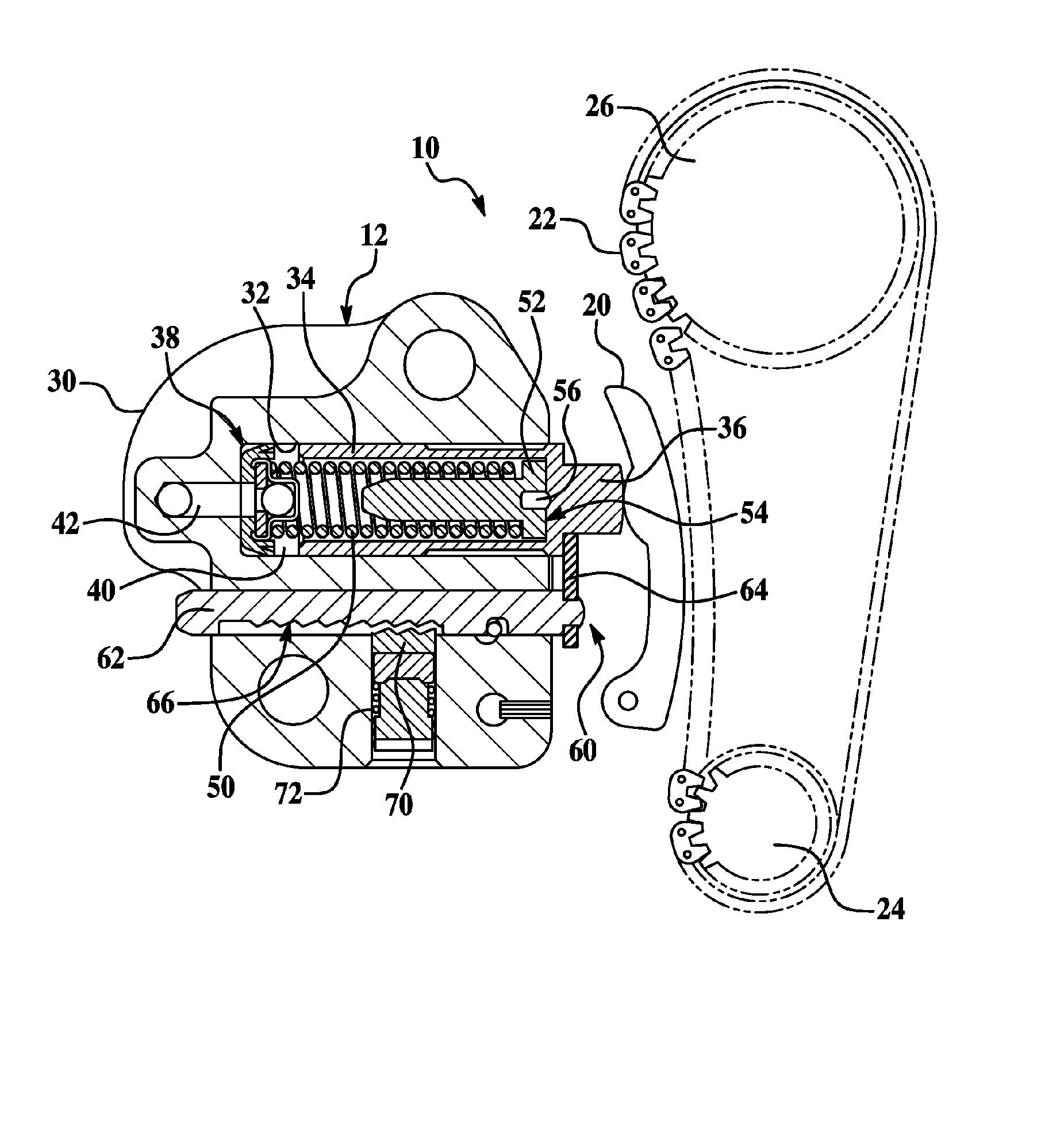

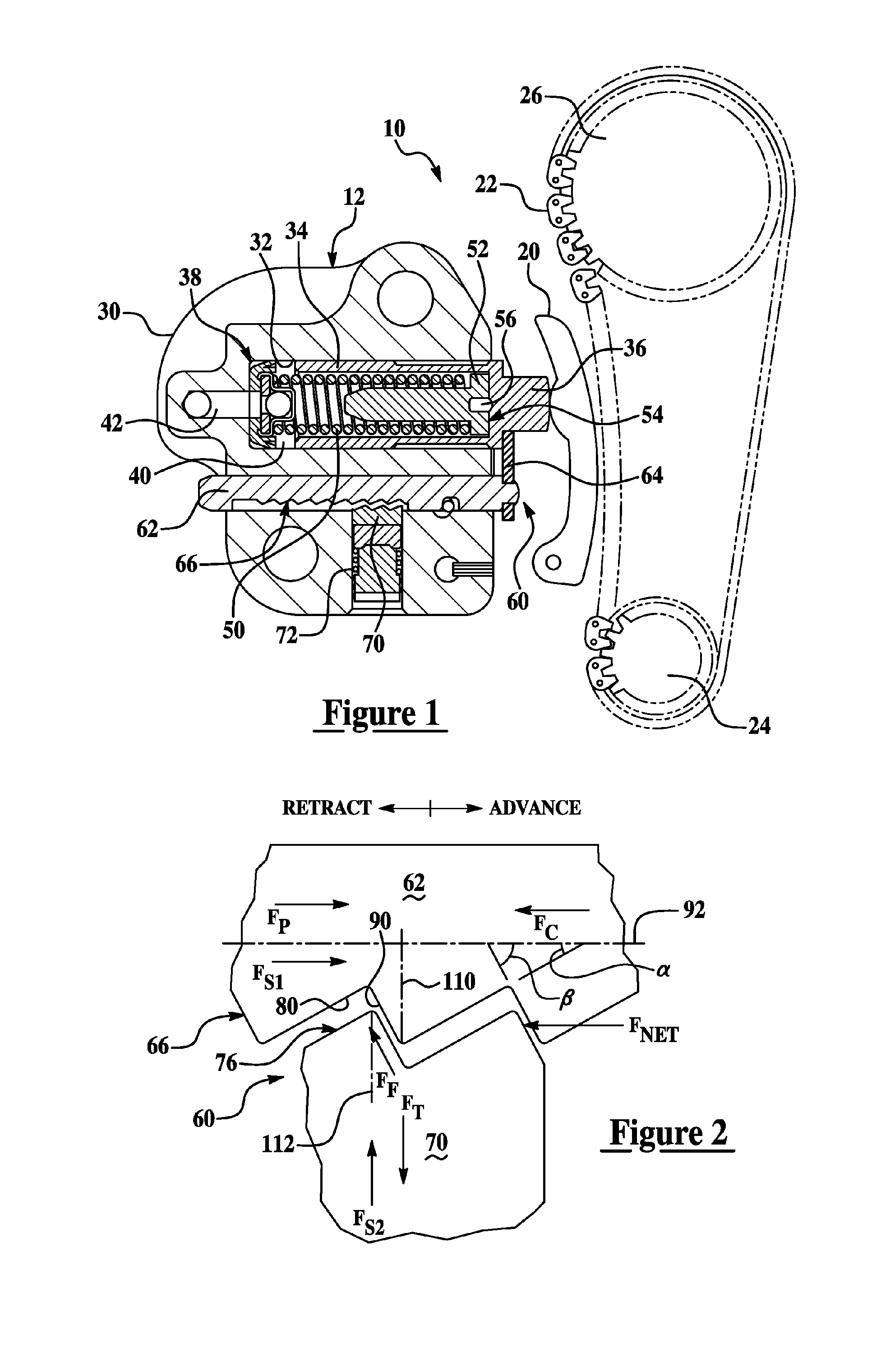

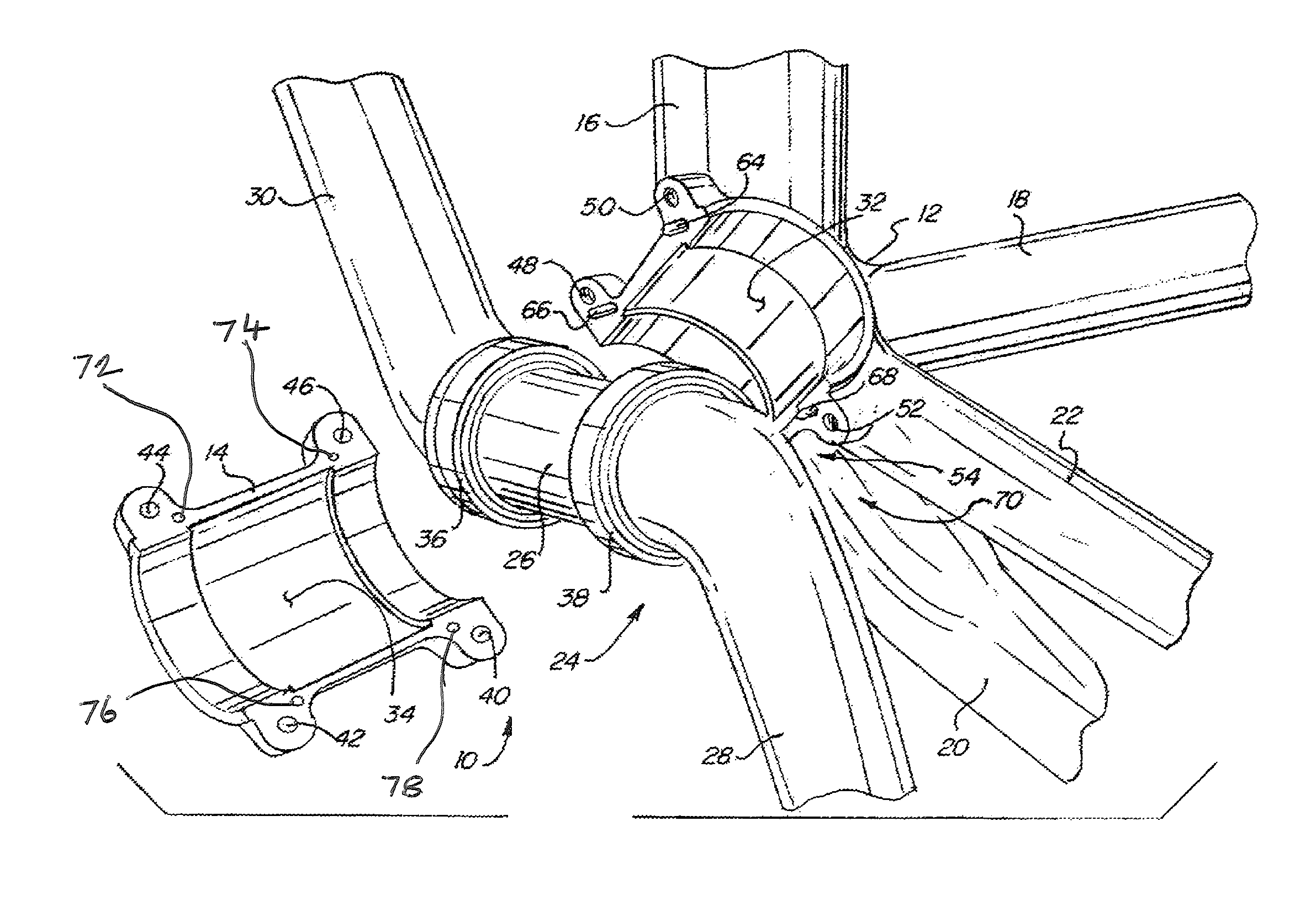

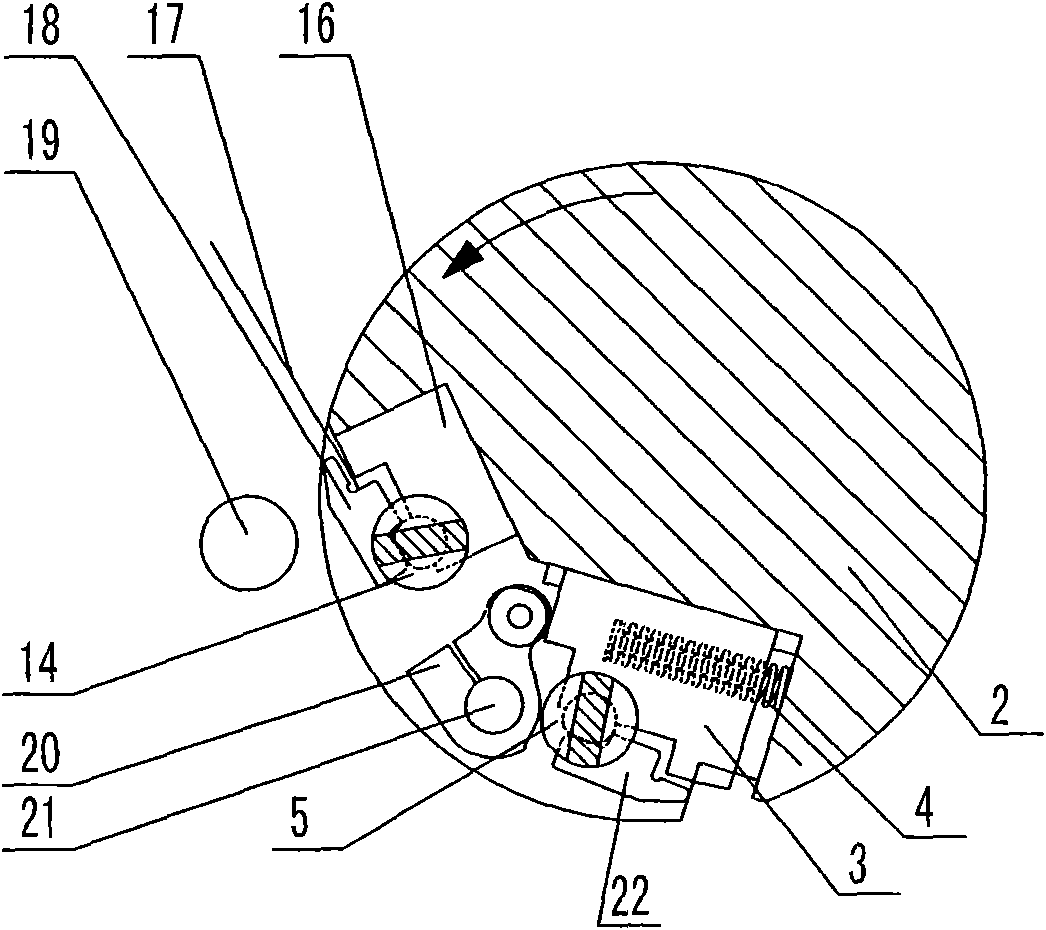

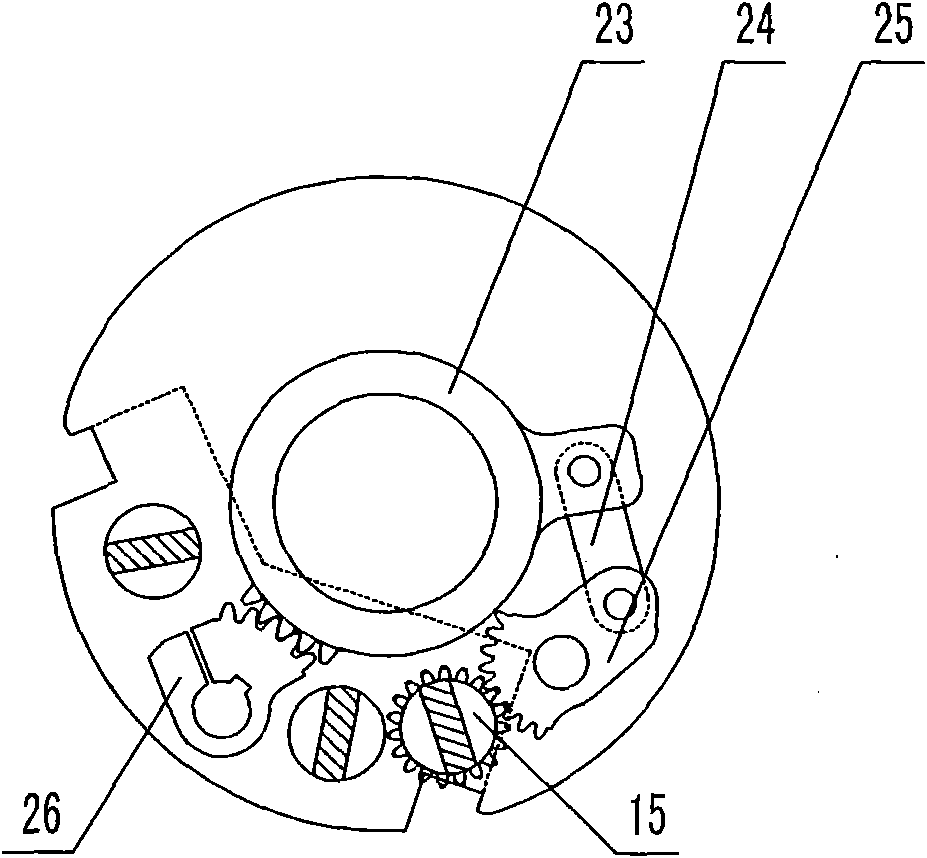

Ratcheting tensioner with override

InactiveUS20070243961A1Reduce over tensioning forceEliminates sustain over tensioningGearingPistonEngineering

Sustained over-tensioning of a power transmission device, such as a chain drive in an internal combustion engine, is prevented by overriding a tensioner ratchet mechanism to permit retraction of a tensioner. Tooth angle of the ratchet mechanism and pawl spring rate and preload are selected so that a sufficient axial force generated by chain / belt tension will produce a transverse force that overrides a biasing force acting on a pawl engaging a rack of the ratchet mechanism to retract a tensioning piston against hydraulic pressure and spring pressure by at least one tooth to reduce the sustained tensioning force applied to the chain / belt, while not adversely affecting the rack extension function. The tooth geometry of the pawl and / or rack of the ratcheting mechanism may have an angle chosen to be slightly less than the self-locking friction angle to permit retraction.

Owner:FORD GLOBAL TECH LLC

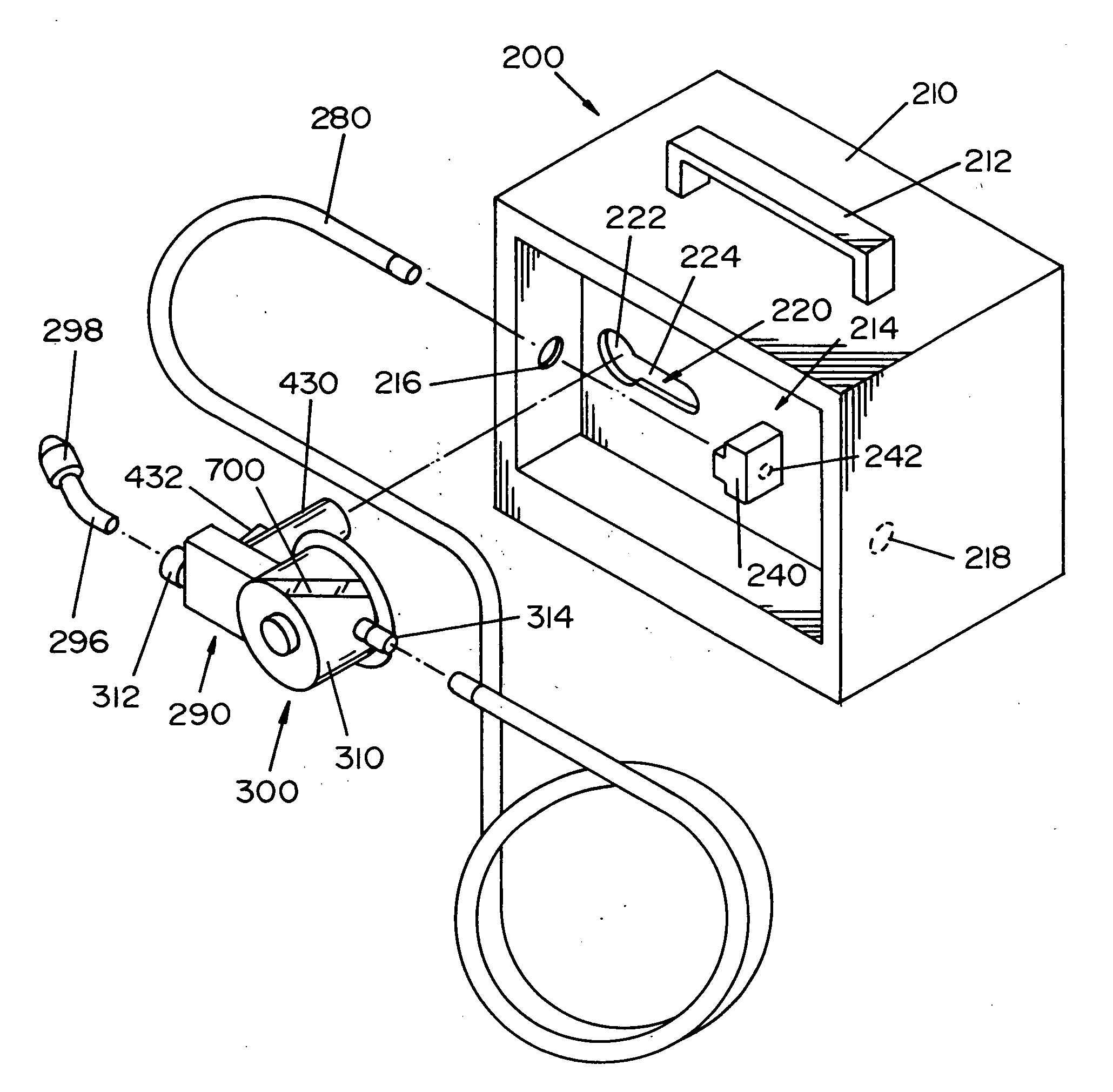

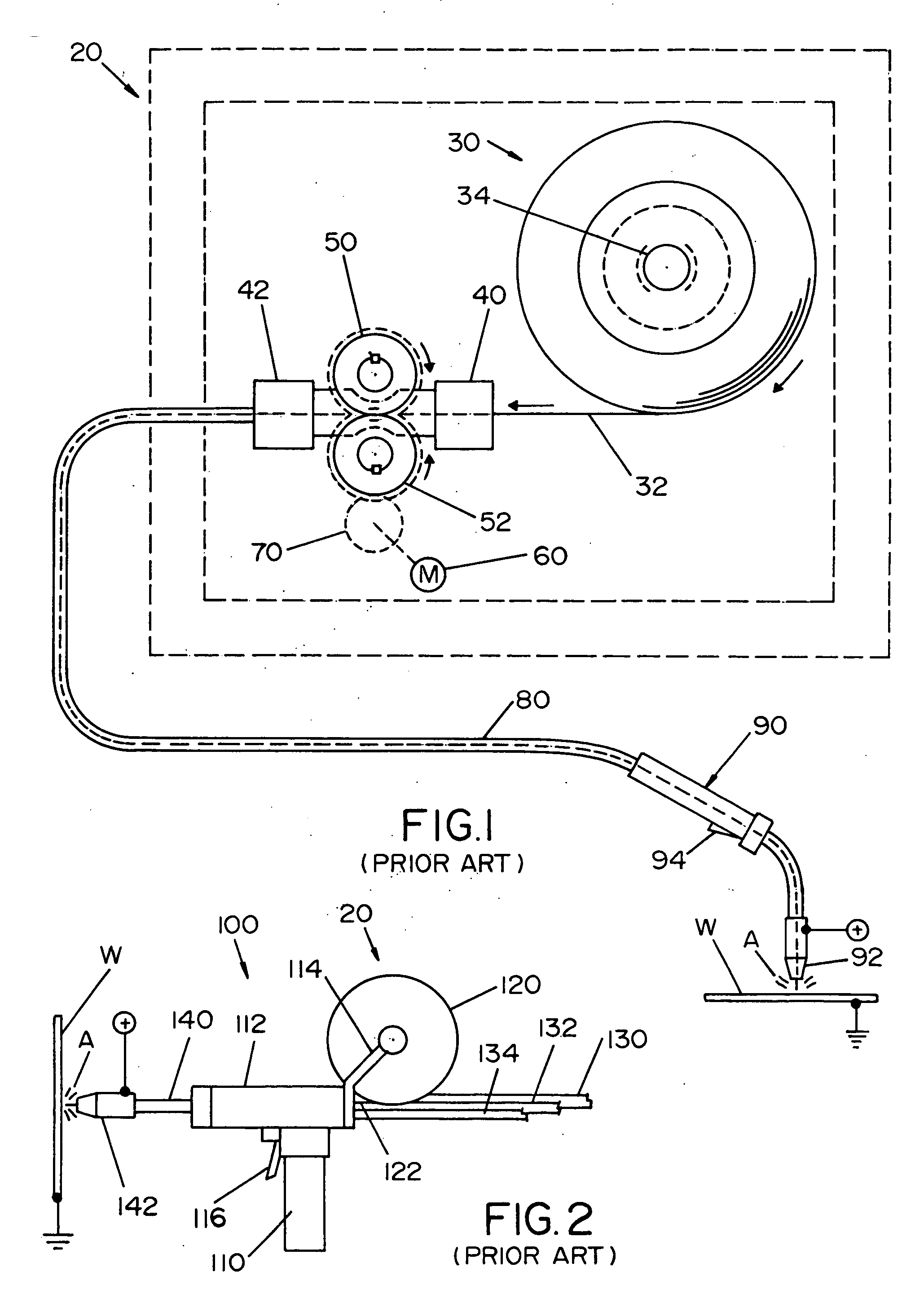

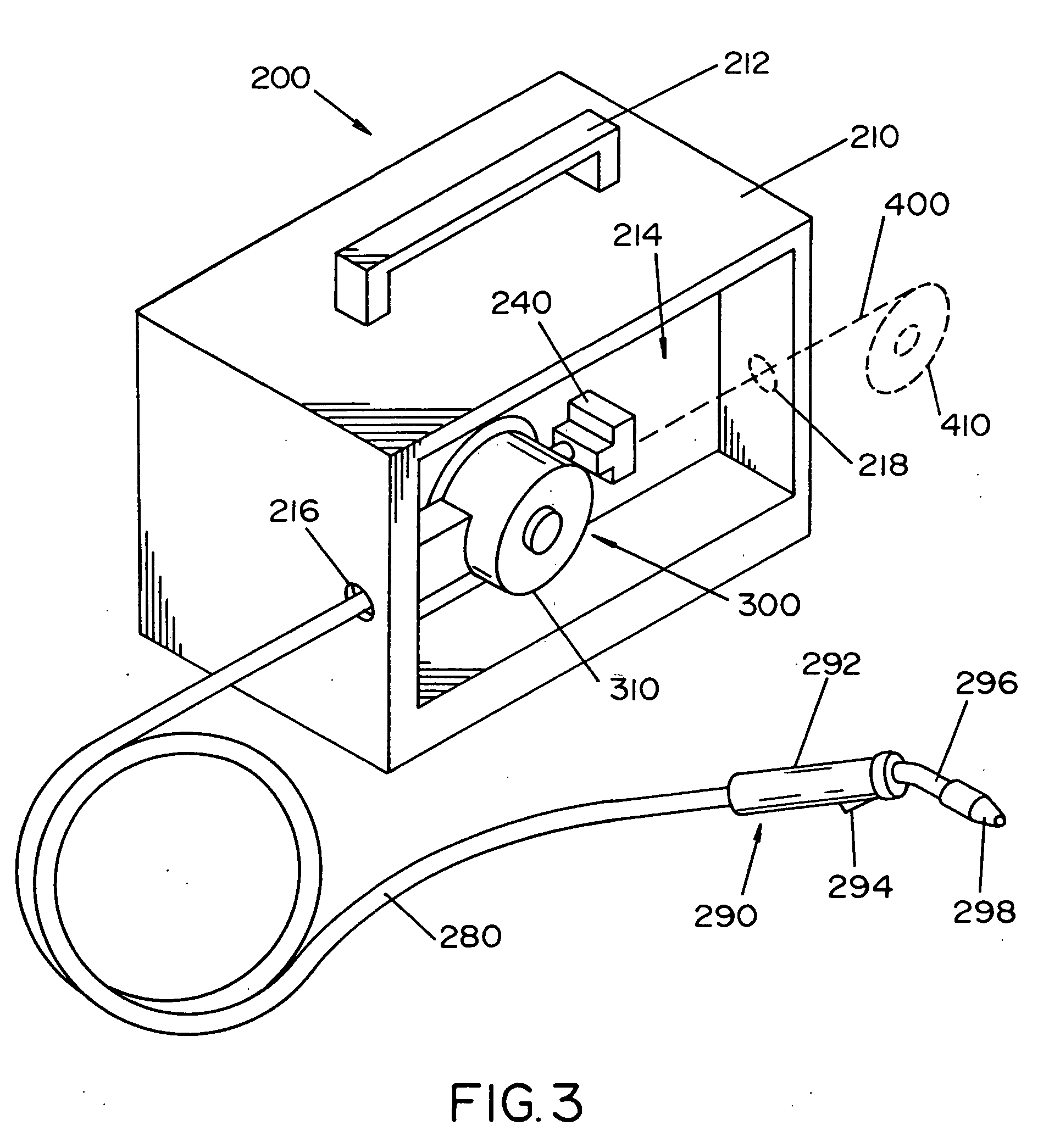

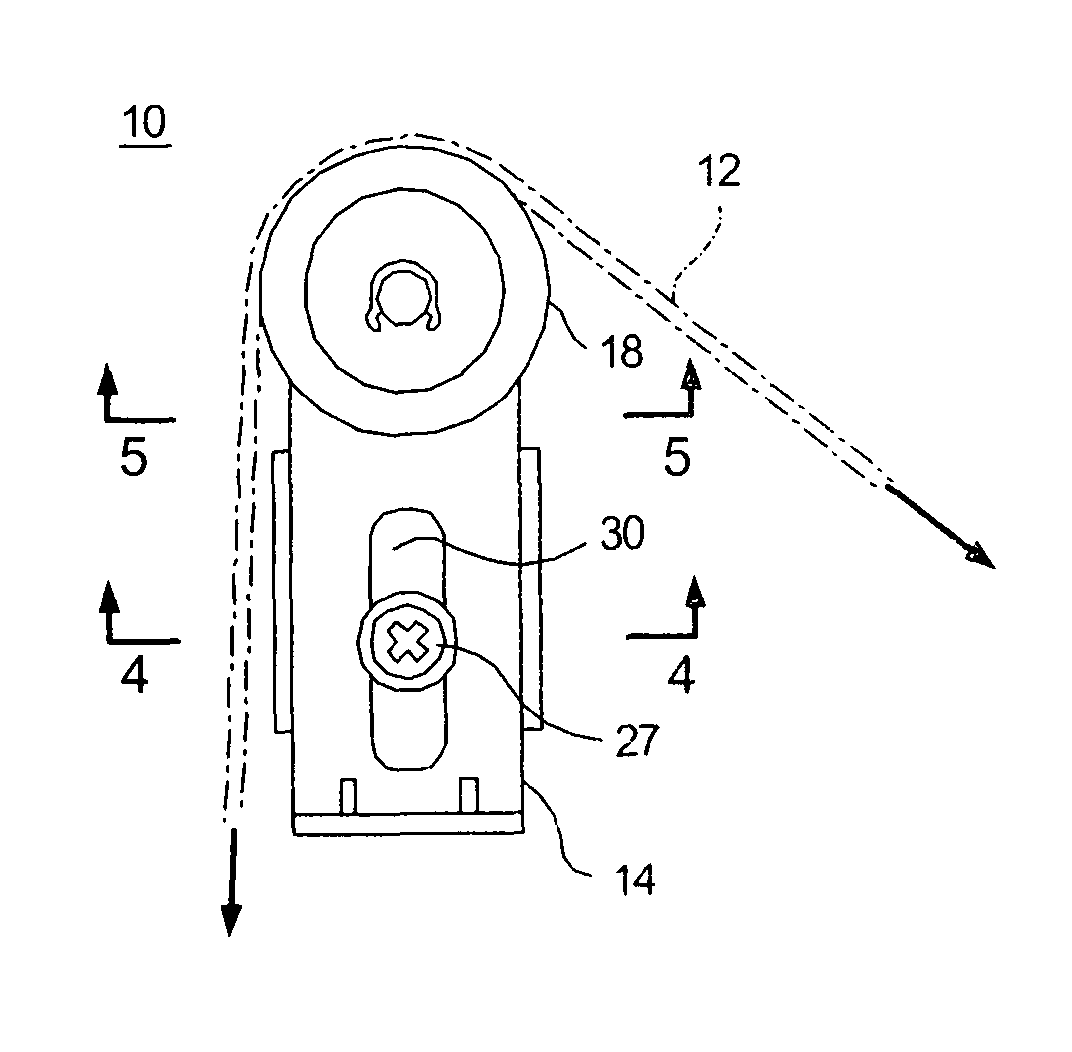

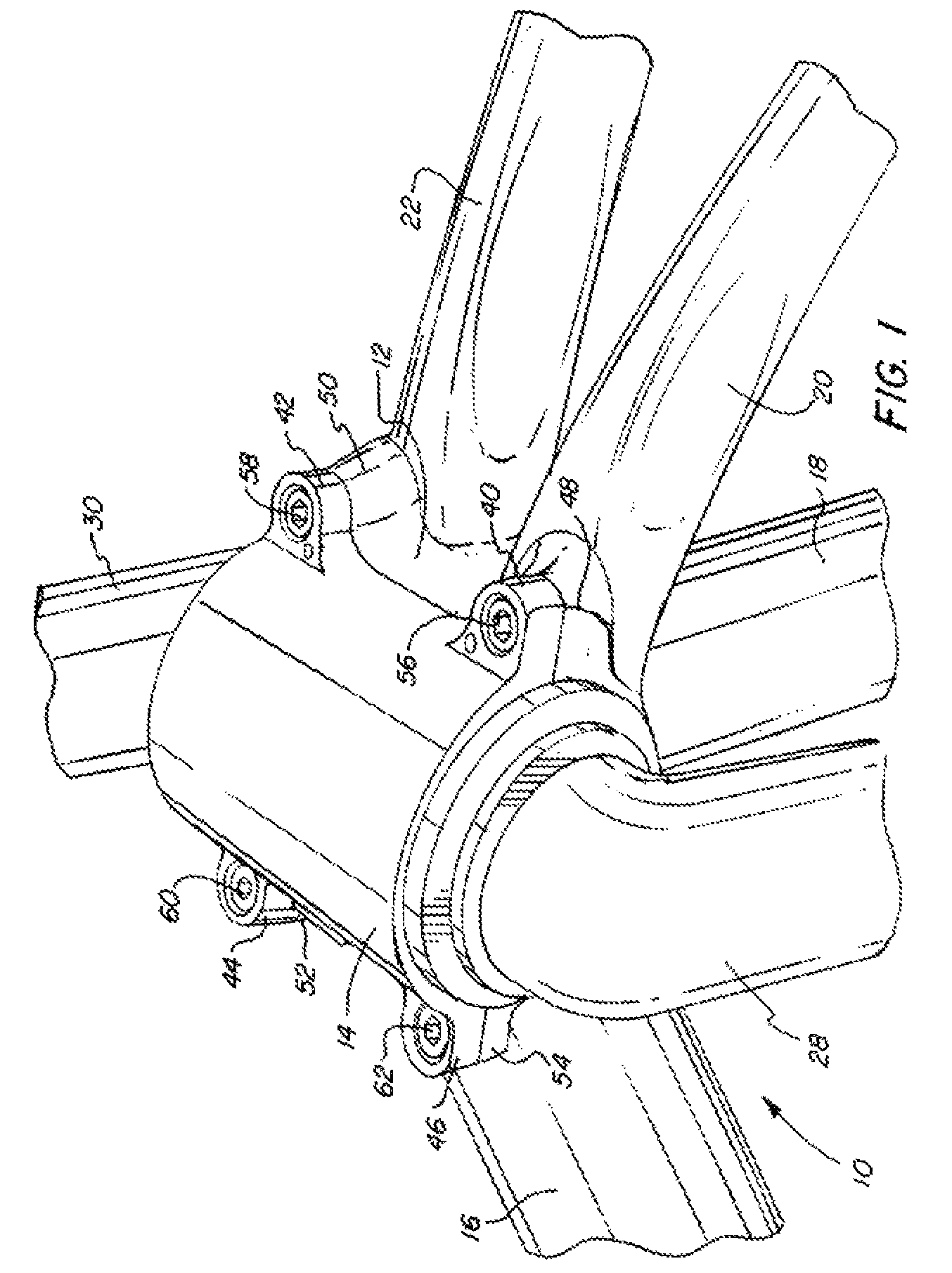

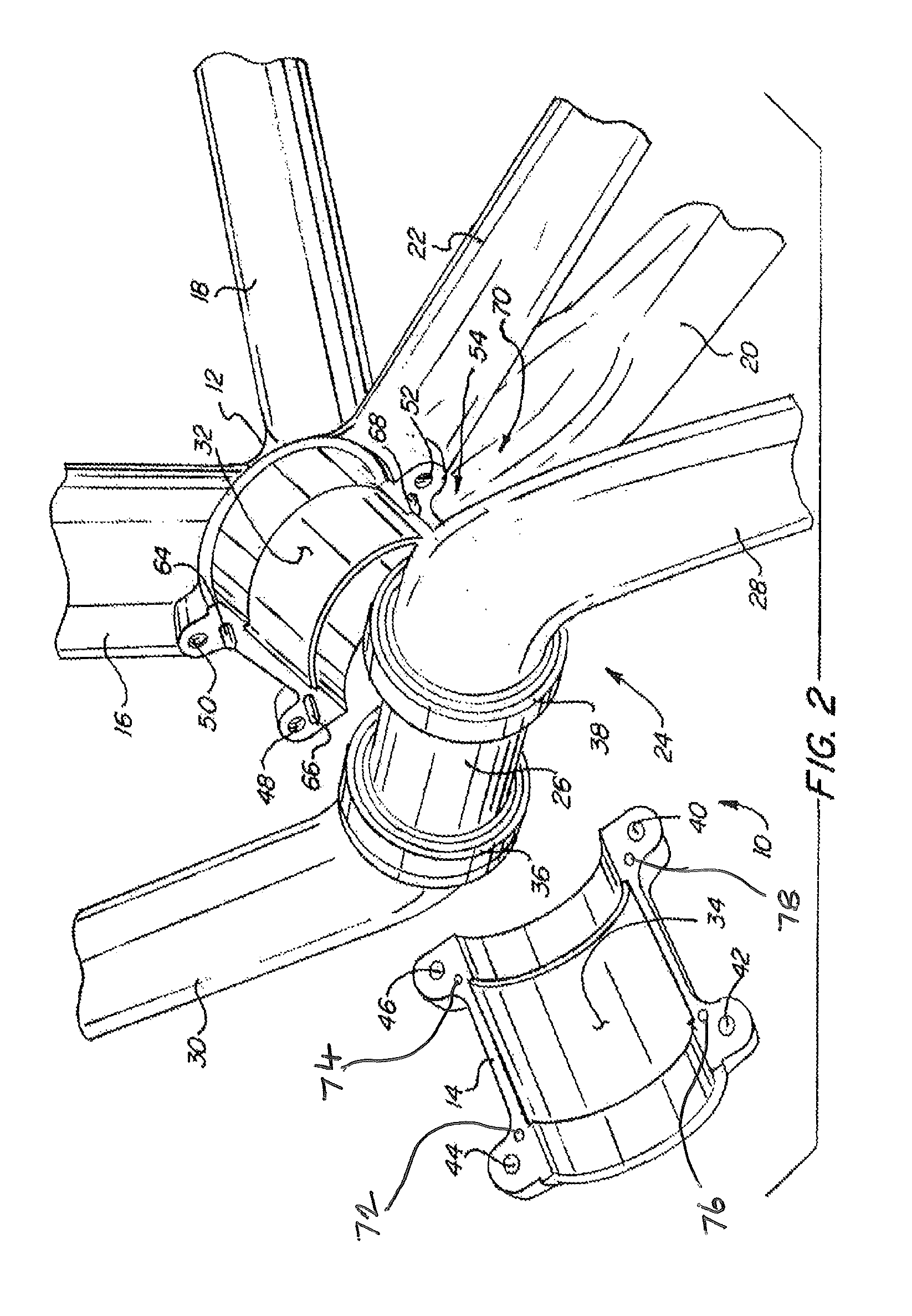

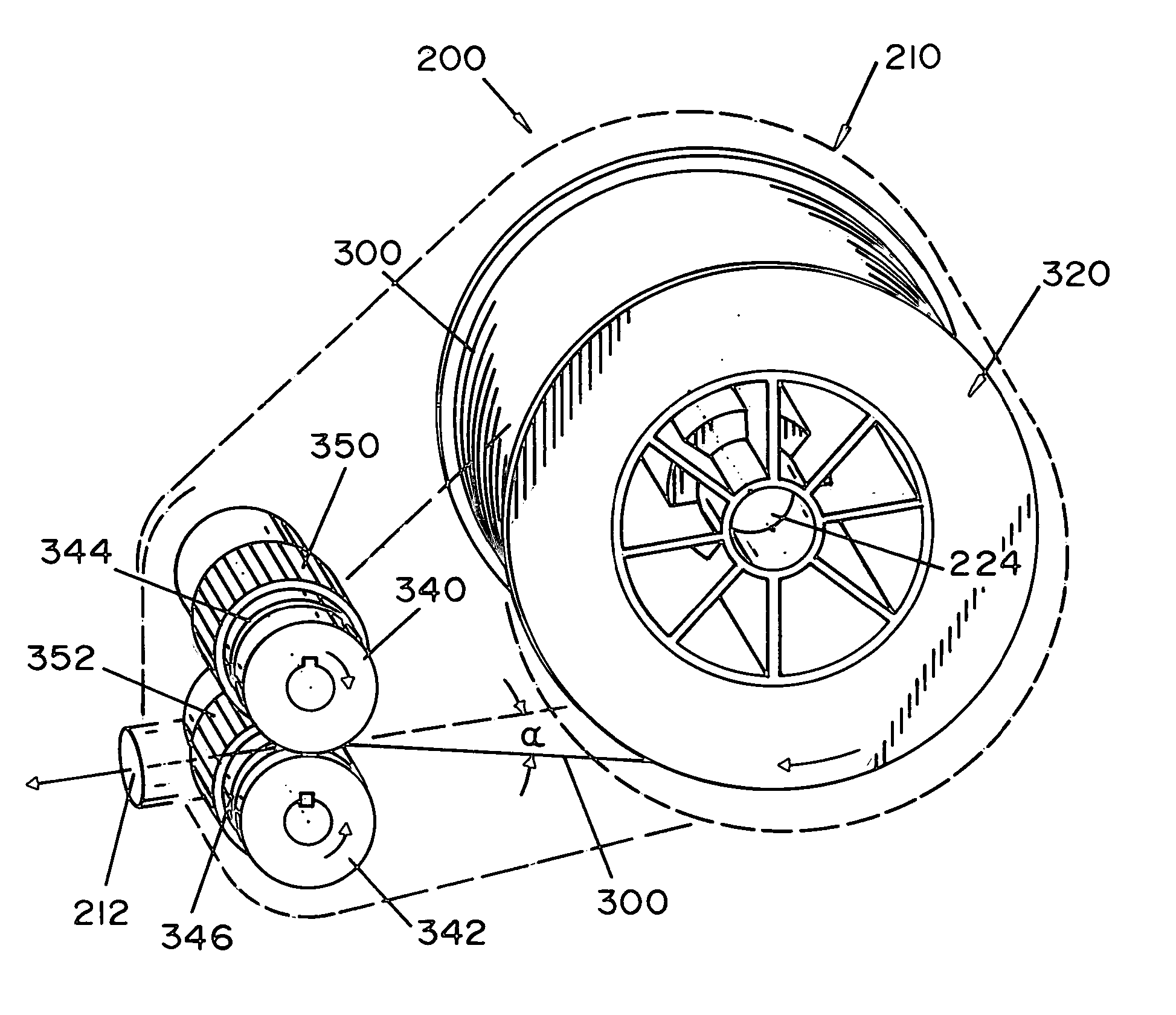

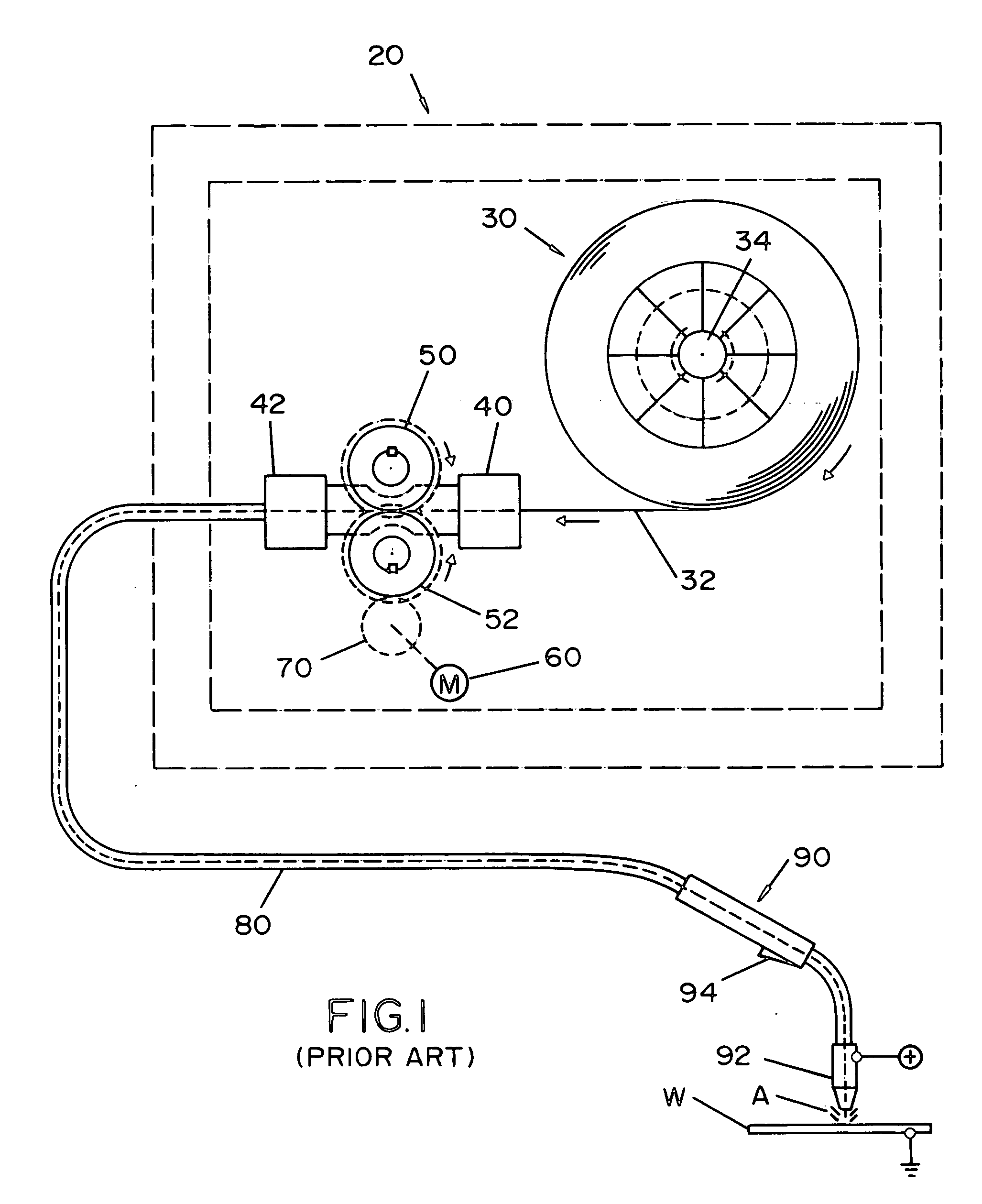

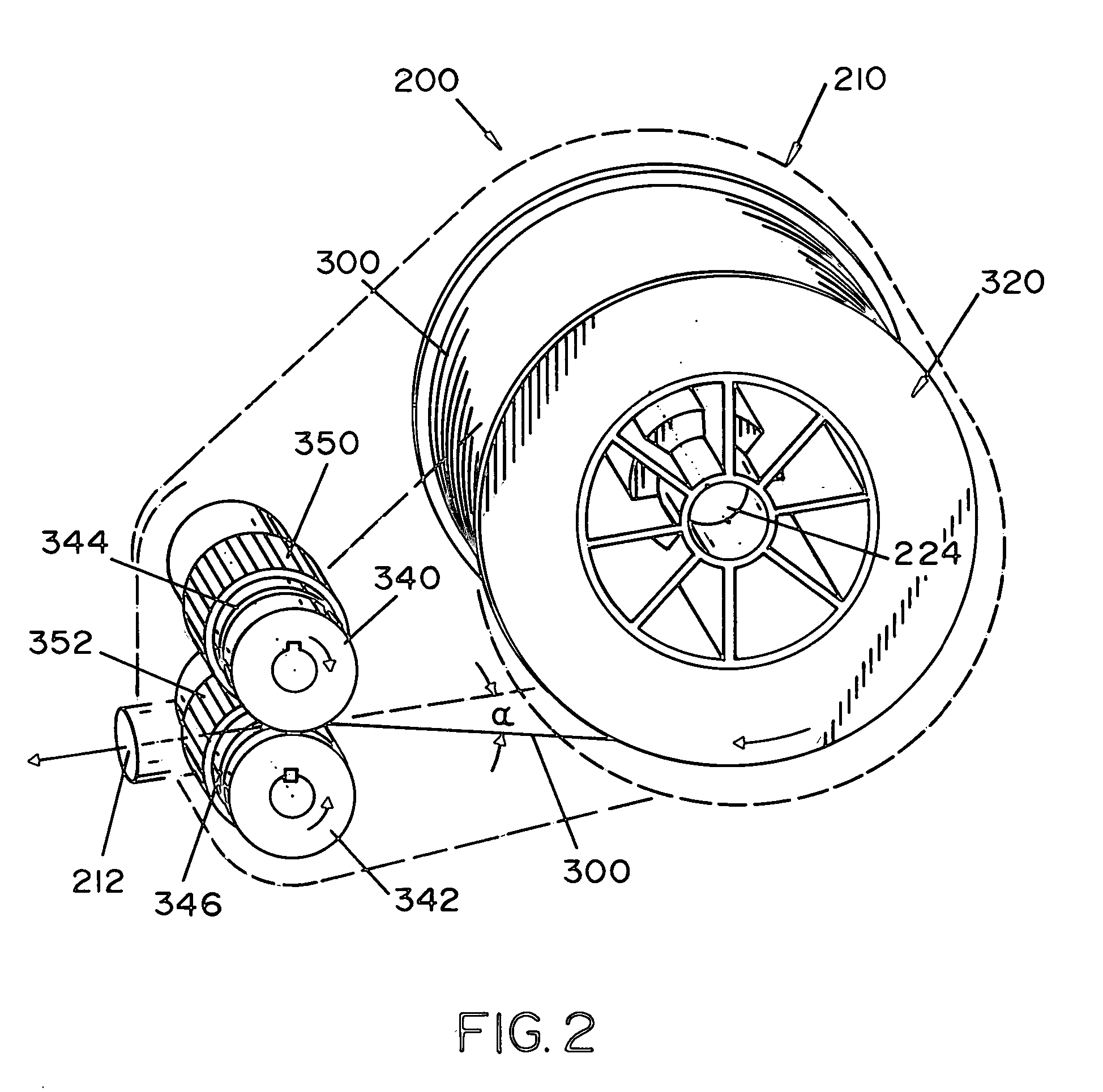

Interchangeable wire drive for wire feeder and spool gun

InactiveUS20060207981A1Reduce the amount requiredReduce equipment costsElectrode supporting devicesDrive motorHousing design

A modular welding wire feed drive for use in a welding system. The welding wire feed drive is designed to be detachably connected to the welding wire feed system of the welding system. The welding wire feed drive includes a drive housing designed to be detachably connectable to the welding wire feed system, a wire contact arrangement designed to controllably feed welding wire through the welding wire feed drive, and a drive motor that is connected to or interconnected to the wire contact arrangement to at least partially drive the wire contact arrangement.

Owner:LINCOLN GLOBAL INC

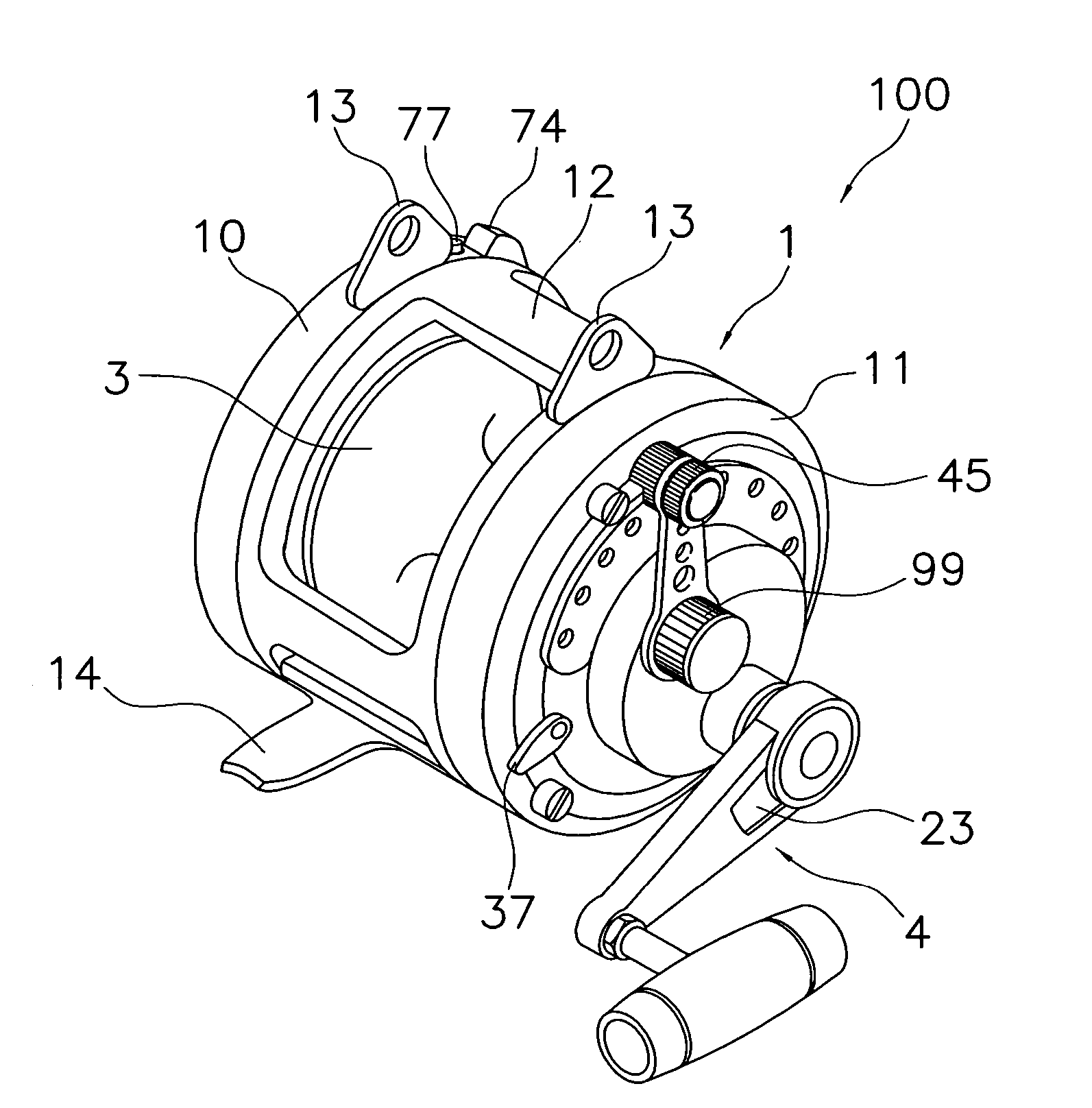

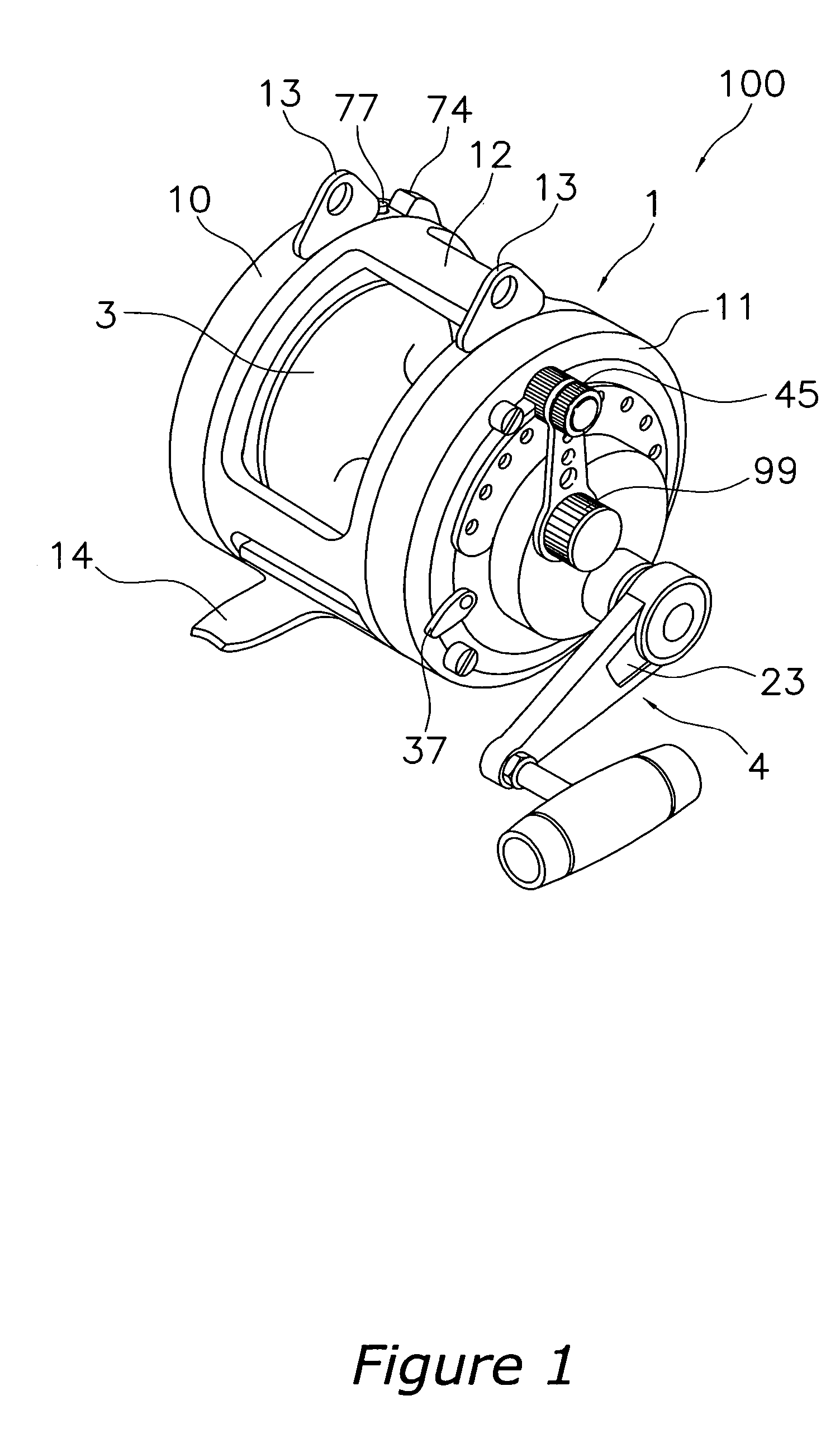

Fishing reel, fishing informatiom display apparatus, and fishing information display system

ActiveUS20050211812A1Easy to detectAccurate detectionWork measurementSemiconductor/solid-state device manufacturingInformation display systemsDisplay device

A fishing reel has a reel unit that is mounted on the fishing rod, a spool that is rotatably attached to the reel unit, a tension detector that detects tension applied to the said fishing line, and a communication portion that transmits to a fishing information display apparatus data of the tension applied to the fishing line detected by the tension detector. The fishing information display apparatus is provided externally of a fishing reel, and receives data communicated from the fishing reel. The fishing information display apparatus includes a body member, a display portion provided in the body member, a communication portion that receives from the fishing reel data of the tension applied to the fishing line, and a controller that is displays on the display portion the data of tension received from the fishing reel. A navigator away from an angler can certainly have information of the fishing situation.

Owner:SHIMANO INC

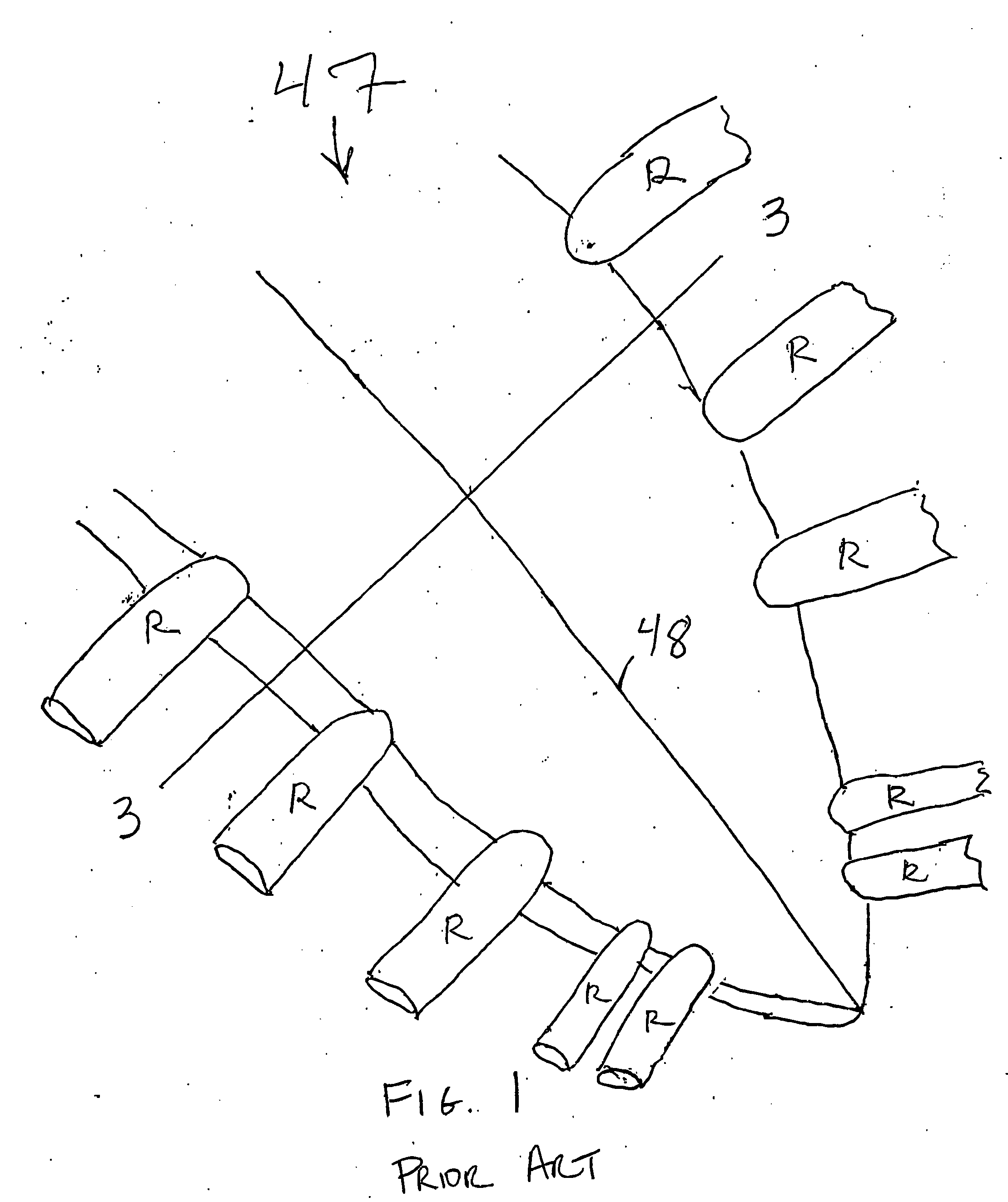

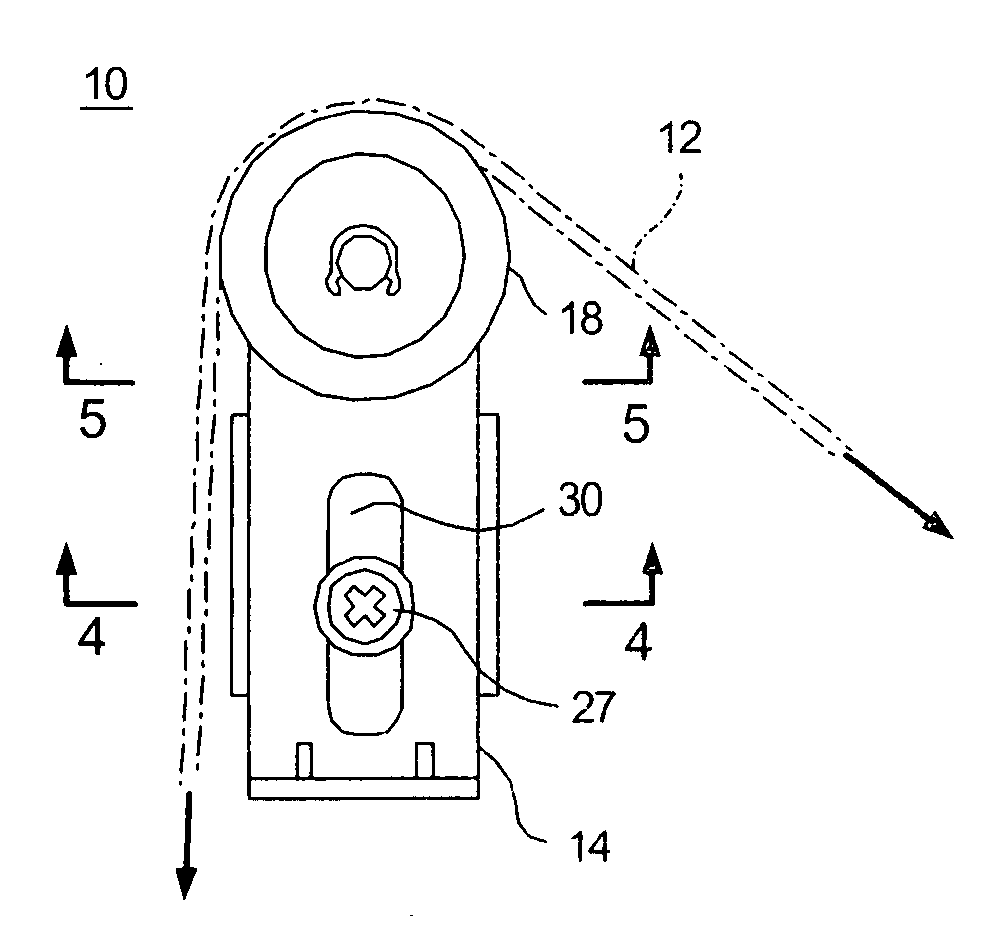

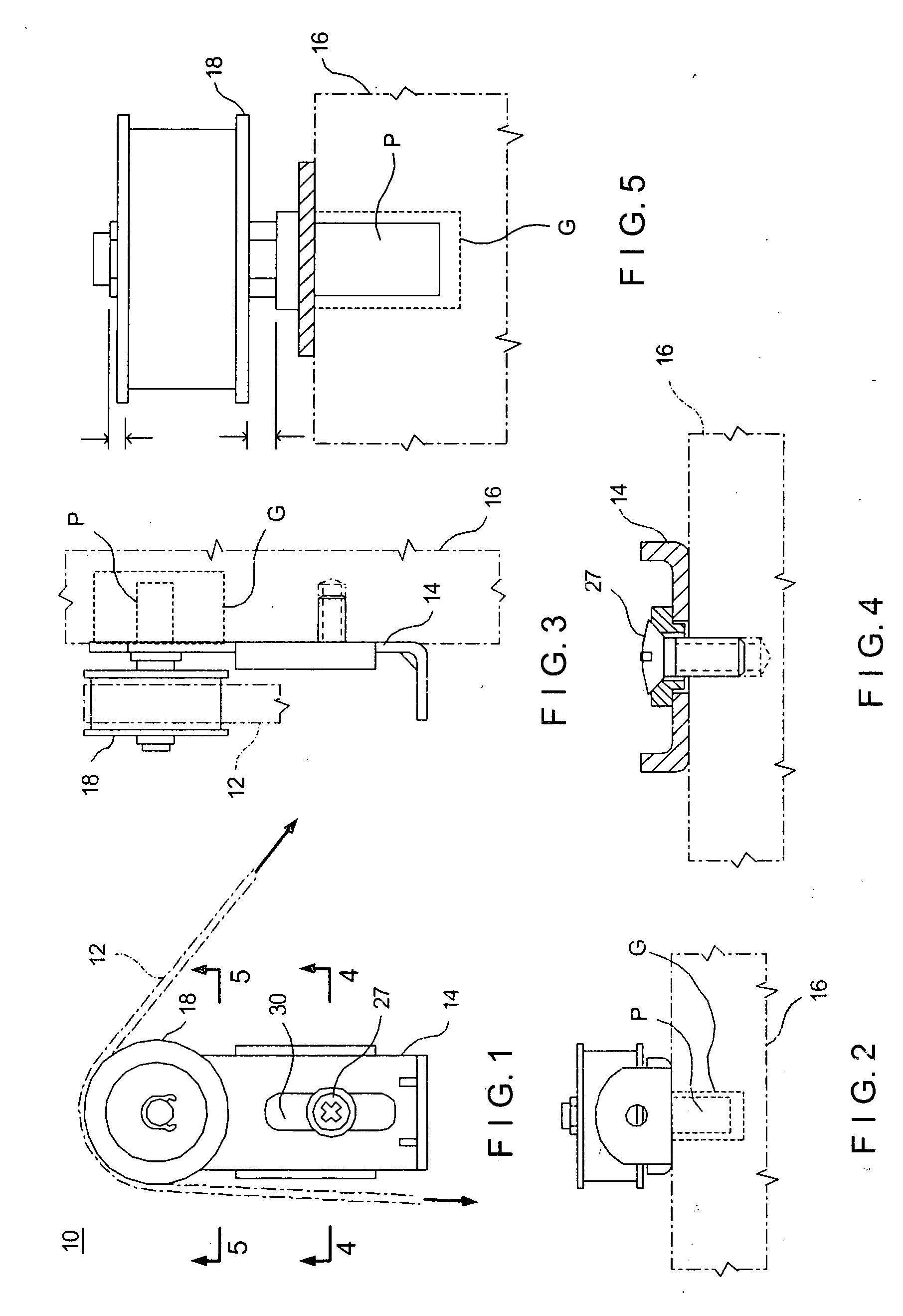

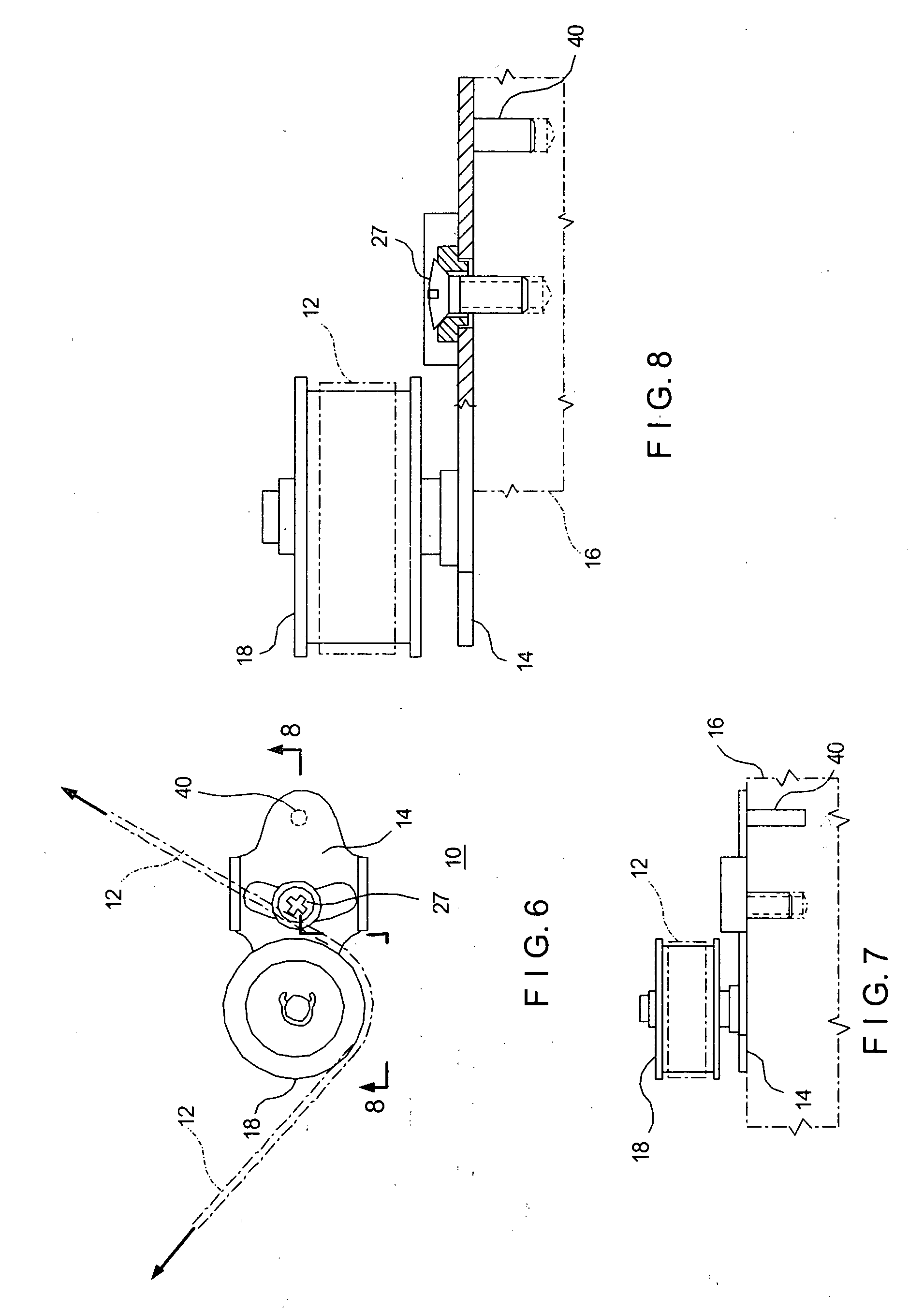

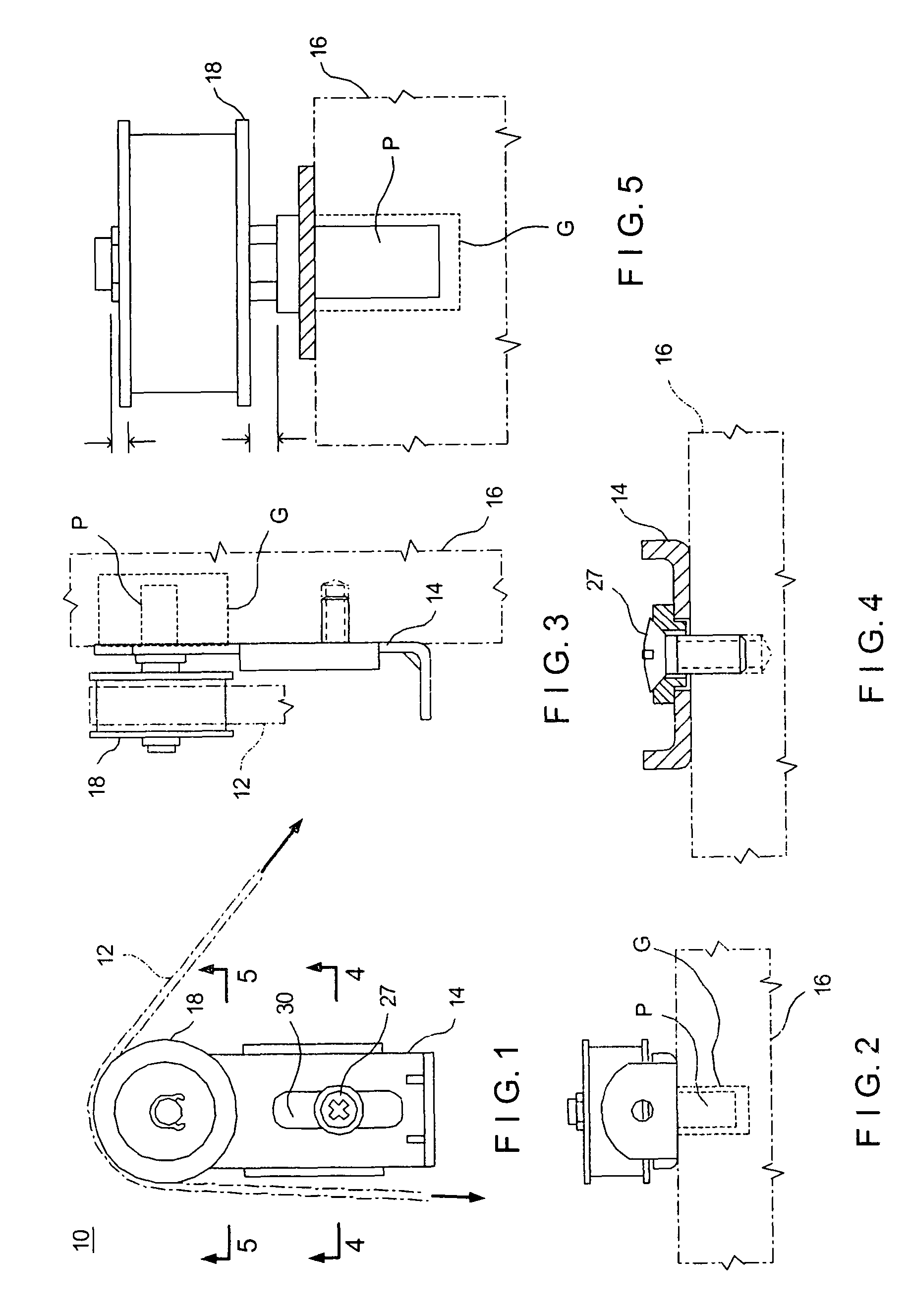

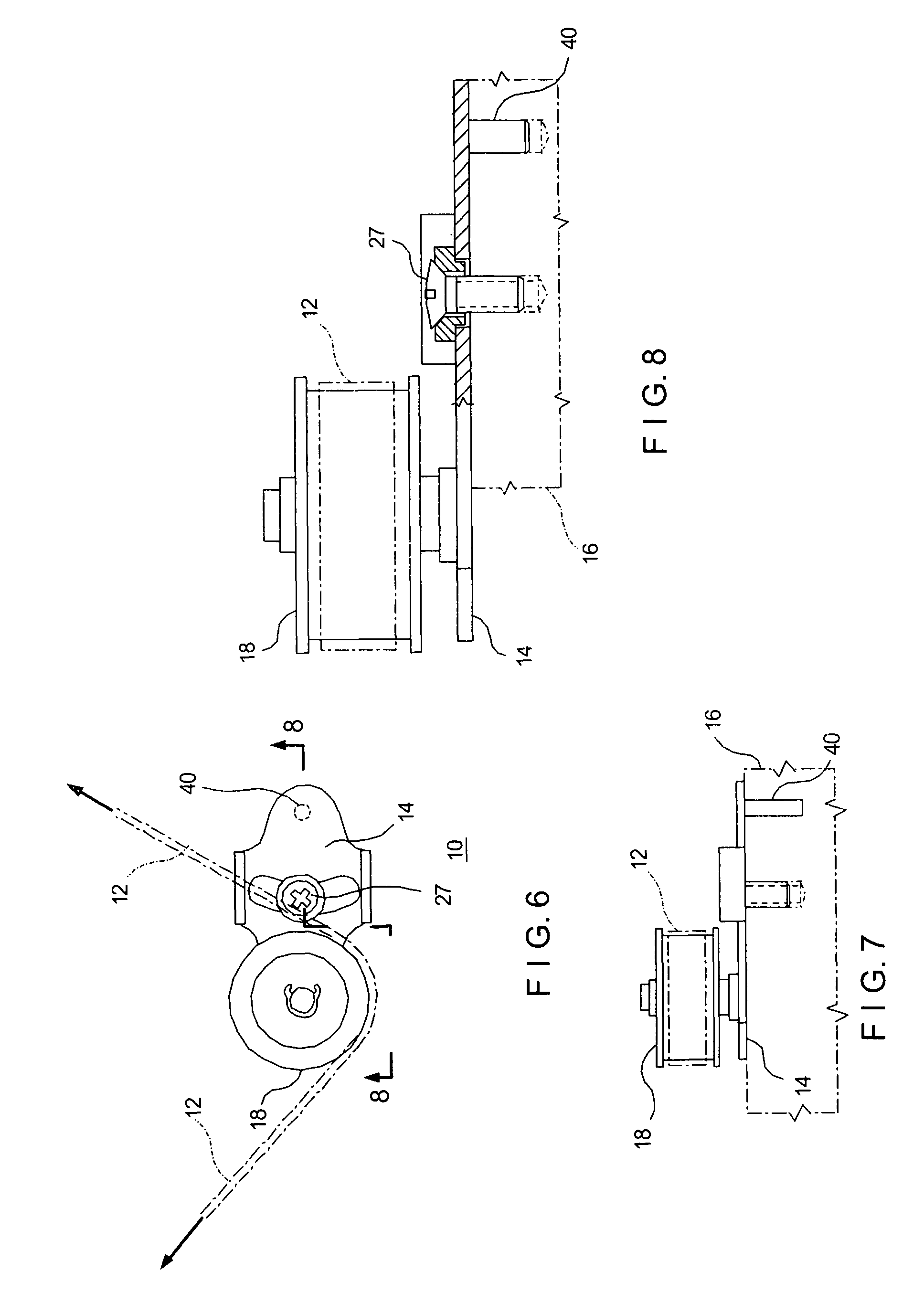

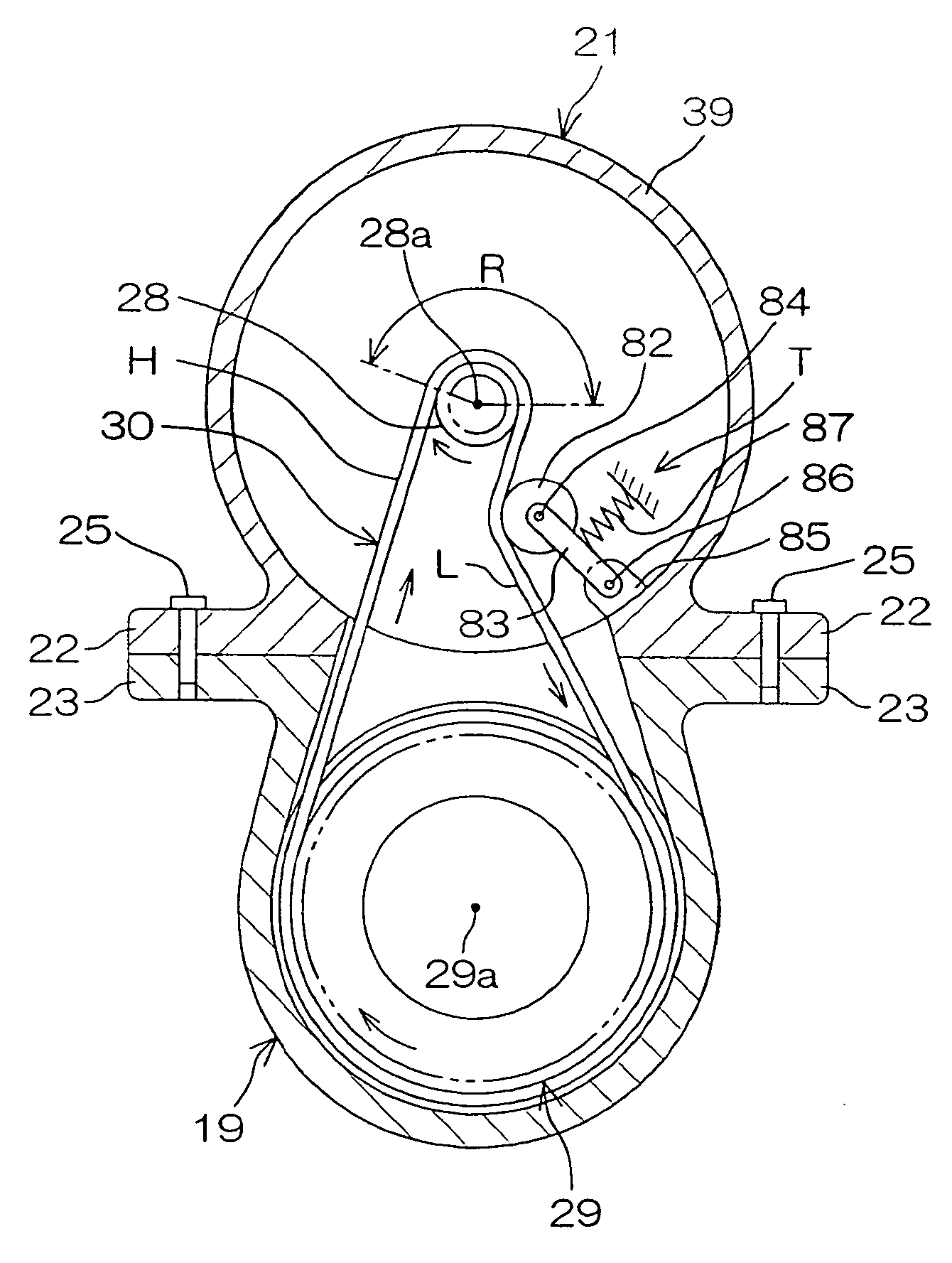

Device for placing a looped belt under tension

A tensioning device has a tension arm mounted on a base. A pulley is mounted on the tension arm for engaging a looped belt. By changing mounting bushings, one can select either a static mode wherein the tension arm is held stationary relative to the base, or a dynamic mode wherein, in response to a changing force applied between the pulley and the belt (due to vibrations or load changes, for example), the tension arm moves relative to the base in such a manner as to maintain the force substantially constant. Several such devices can be employed in a system for controlling the tension of a looped belt, one or more of the devices being in the static mode and one or more being in the dynamic mode. Several such systems can be employed in a complex machine such as a photocopier or medical apparatus for controlling the tension in a number of different belts.

Owner:YORK IND

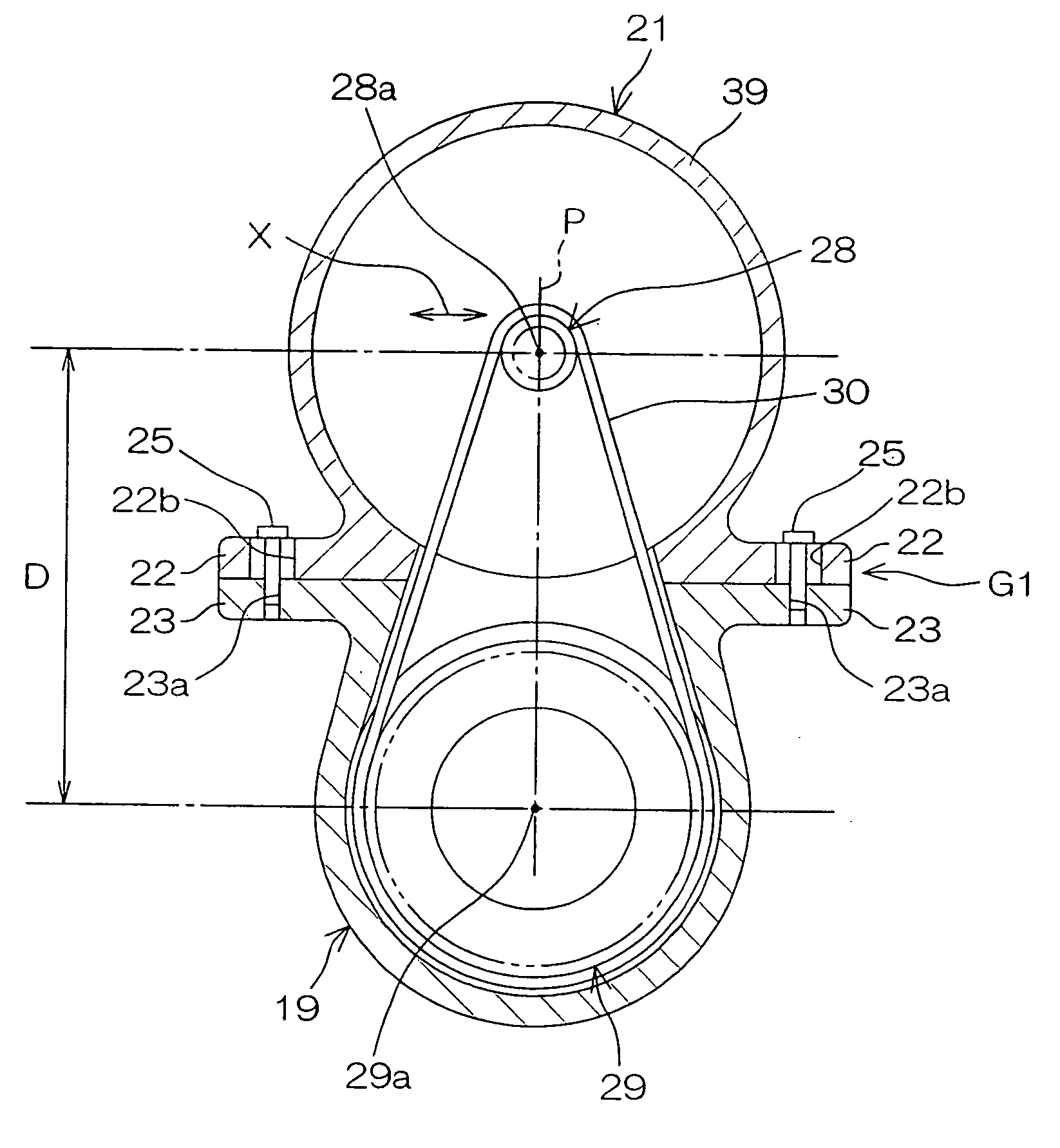

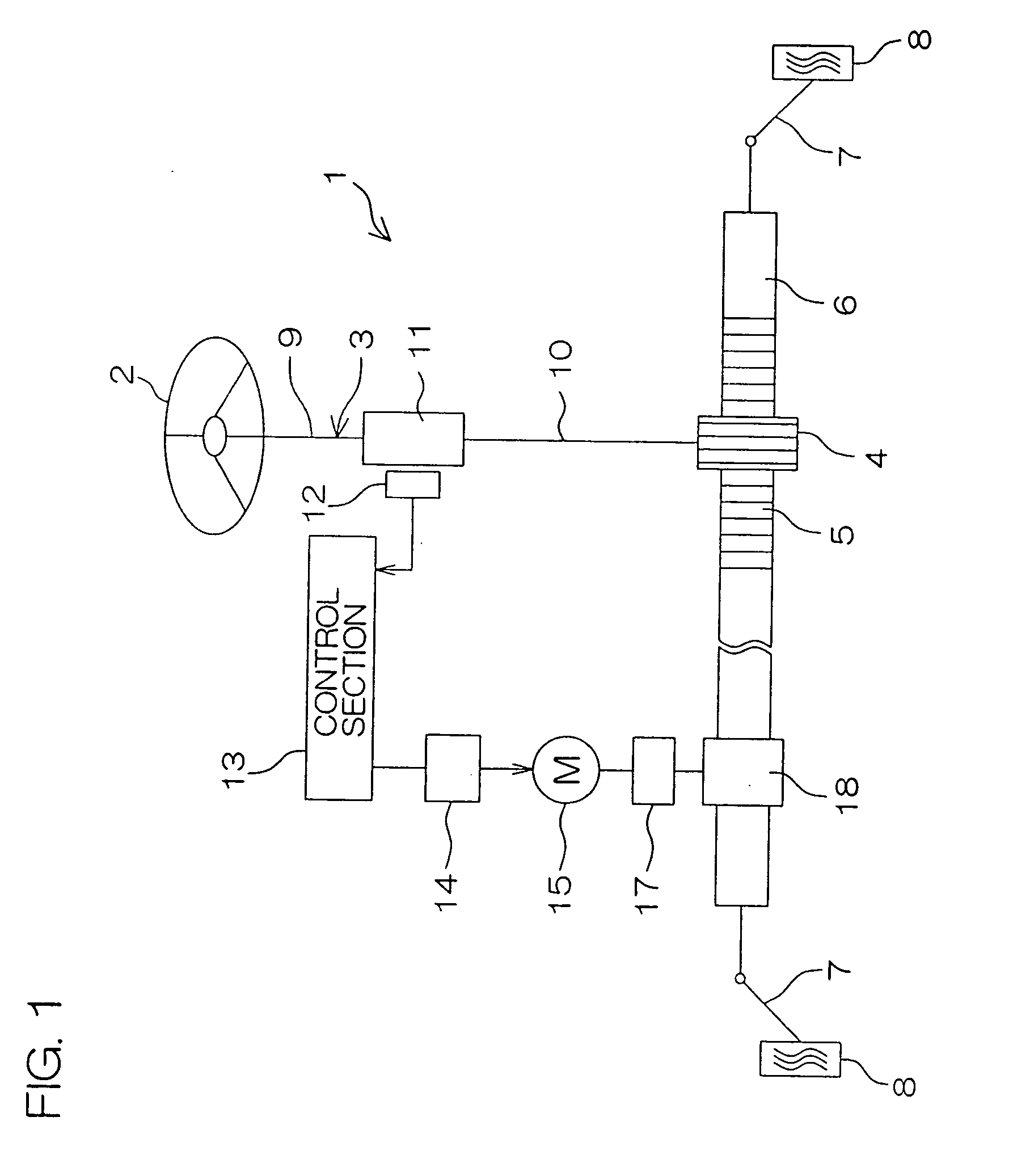

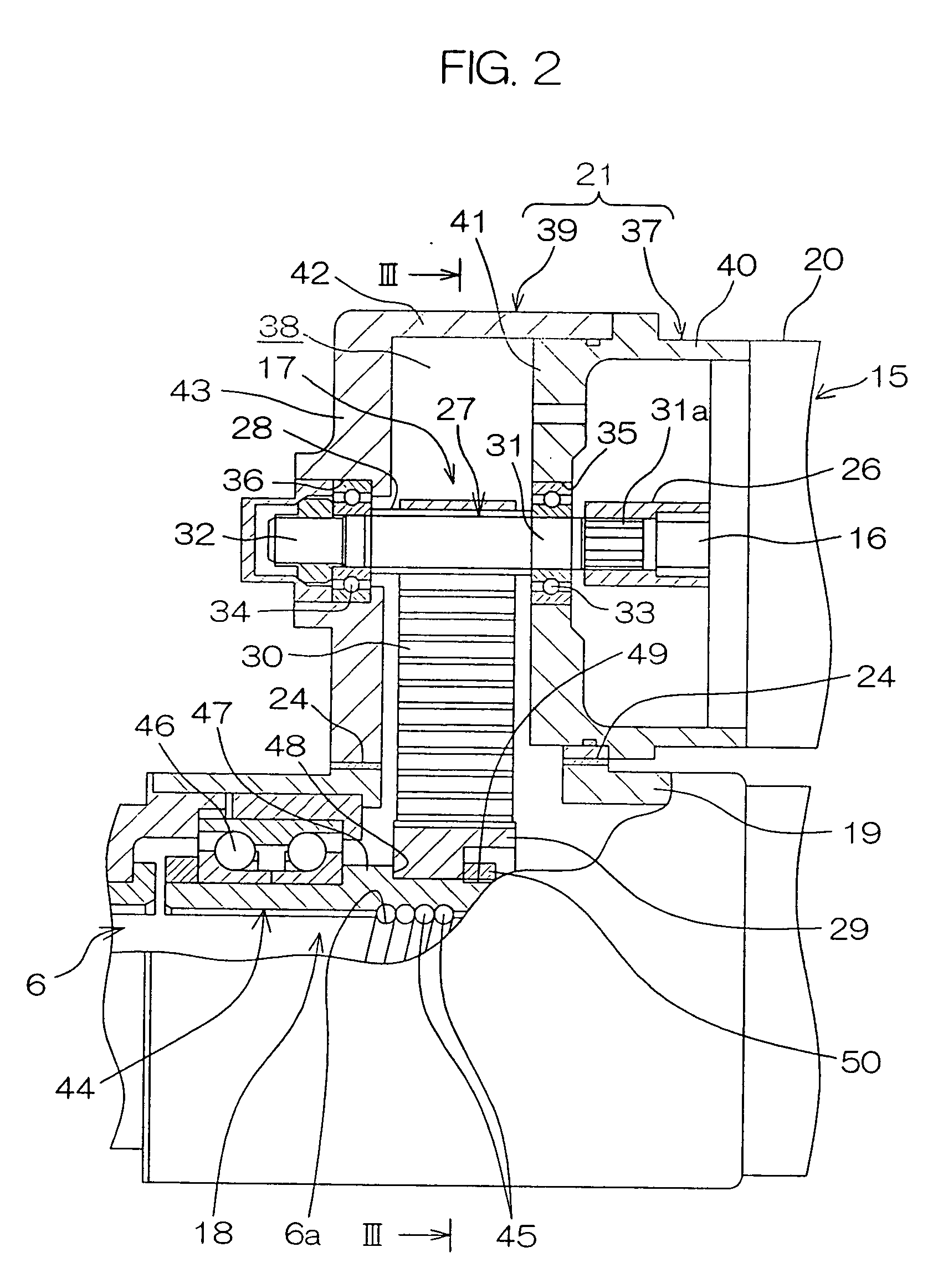

Electric power steering apparatus

InactiveUS6938722B2Reducing vibration and noiseInferior noiseGearingElectrical steeringElectric power steeringEngineering

Owner:KOYO SEIKO CO LTD +1

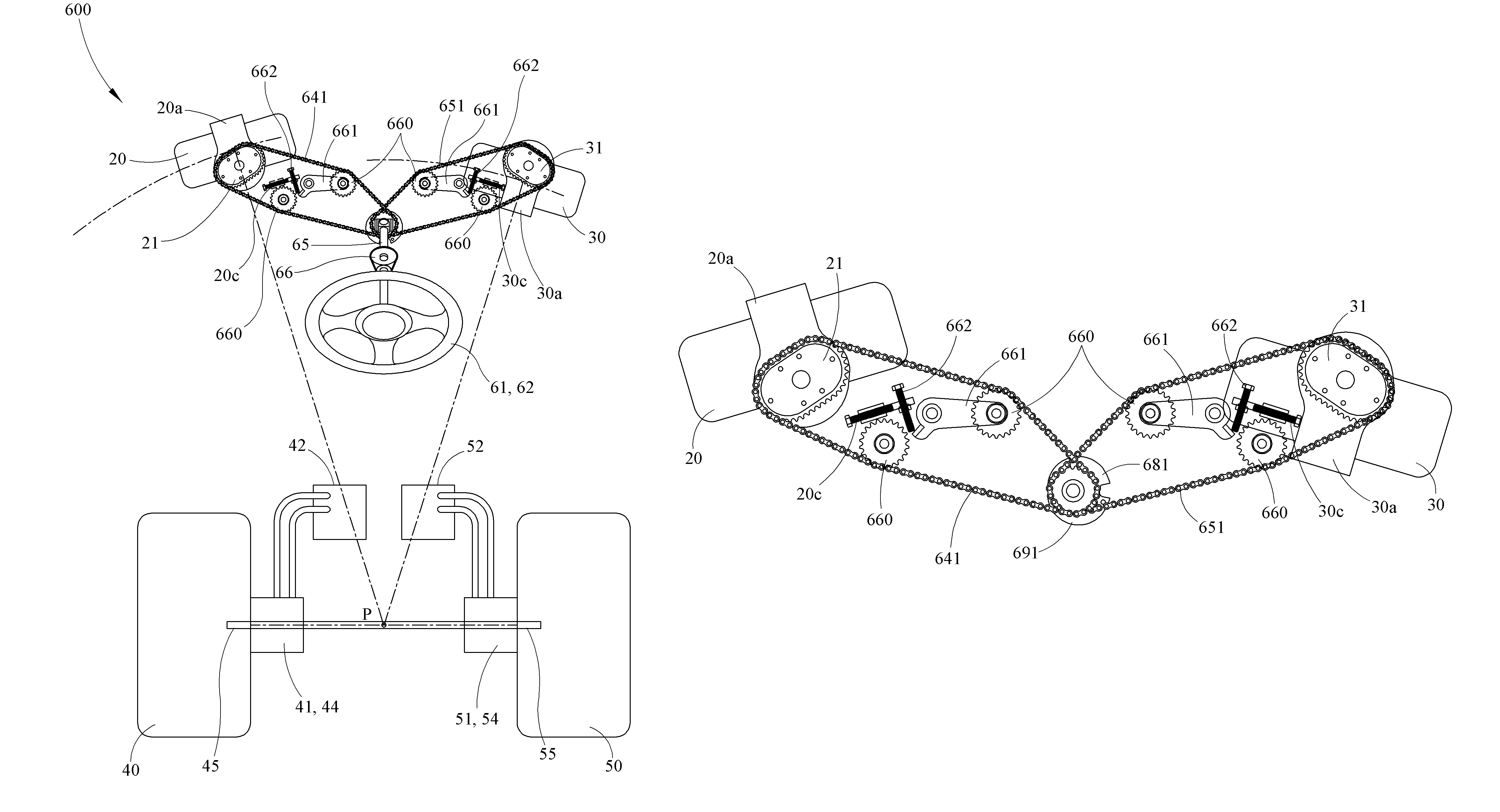

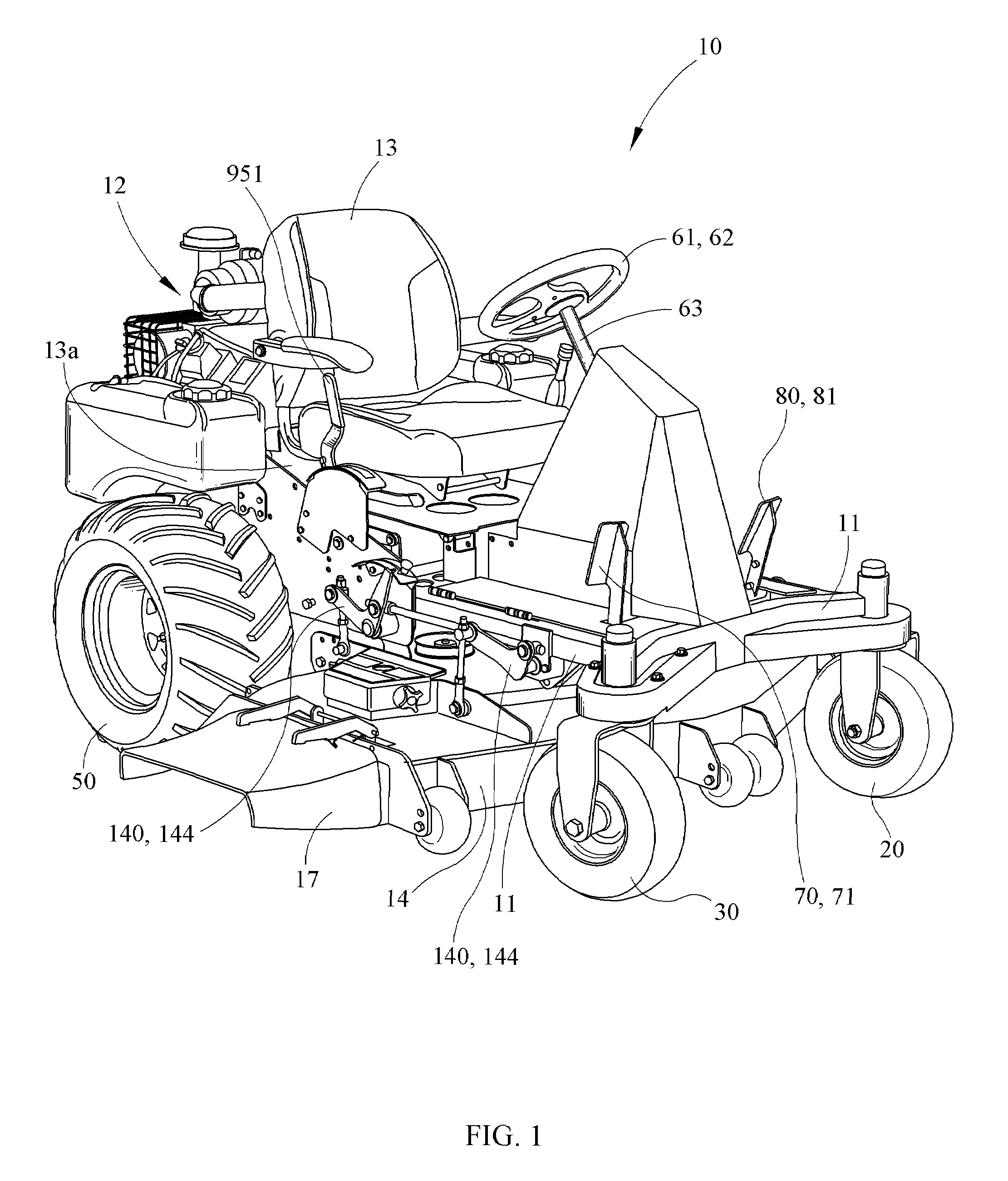

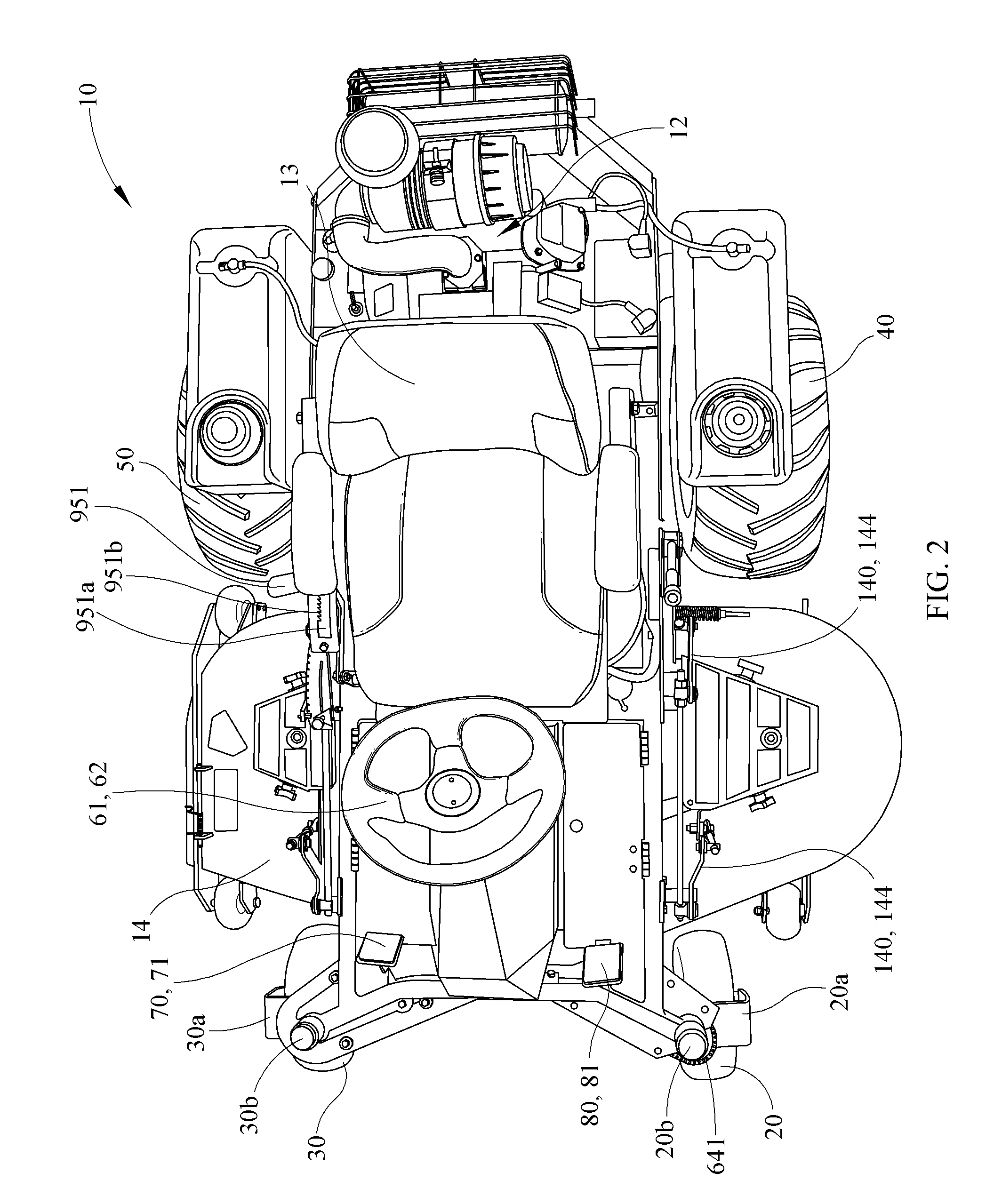

Zero-turn radius vehicle with steerable front wheels

InactiveUS7686107B1Precise tensionImprove security featuresMowersSteering linkagesDrive wheelSteering wheel

The present invention relates to a zero turning radius vehicle having at least one steerable front wheel and a multistage steering input system separately capable of steering the at least one front wheel and selectively driving the drive wheels. A front wheel steering system comprises at least one oblongated sprocket meshingly connected to a steering shaft. An engagement cam system provides the ability to selectively, independently couple the steering wheel to pump arms driving a first and second drive wheel. A steering cam shaft comprises at least one steering cam that acts on at least one bearing. Once the engagement cam system rotates the at least one bearing into place to receive the at least one steering cam, rotation of the steering cam independently alters the speed of one drive wheel in relation to the other drive wheel in response to steering input provided by the operator.

Owner:GIZMOW

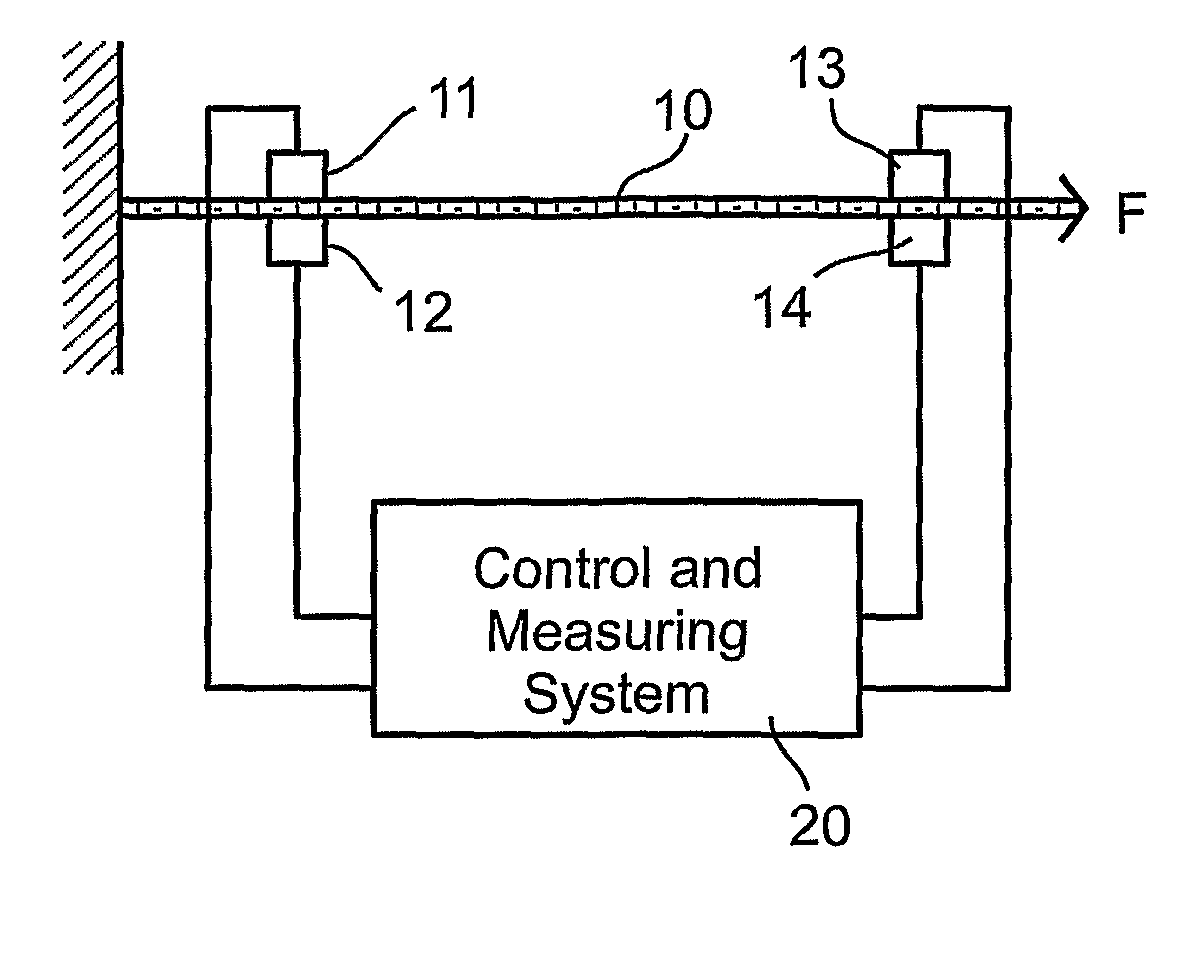

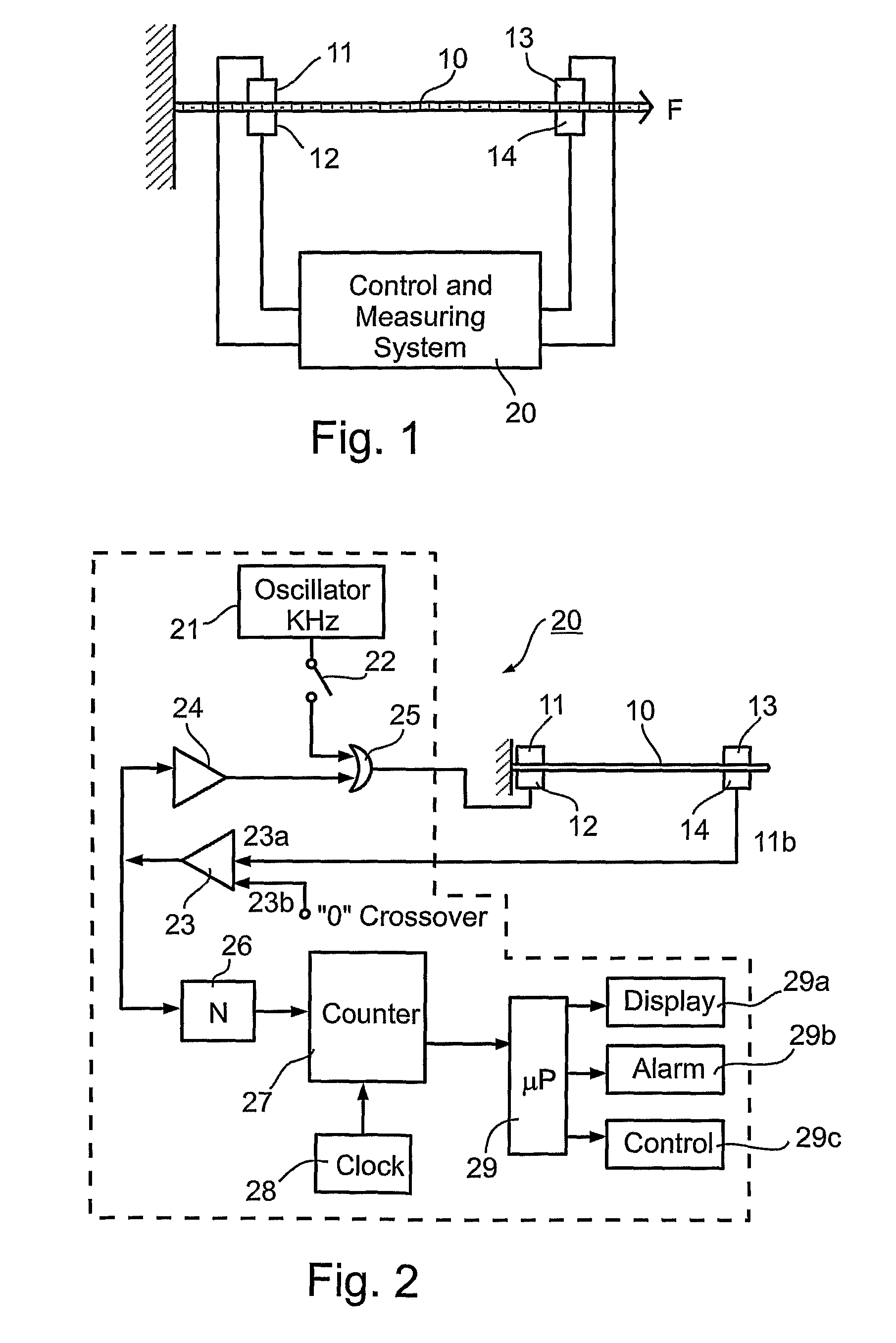

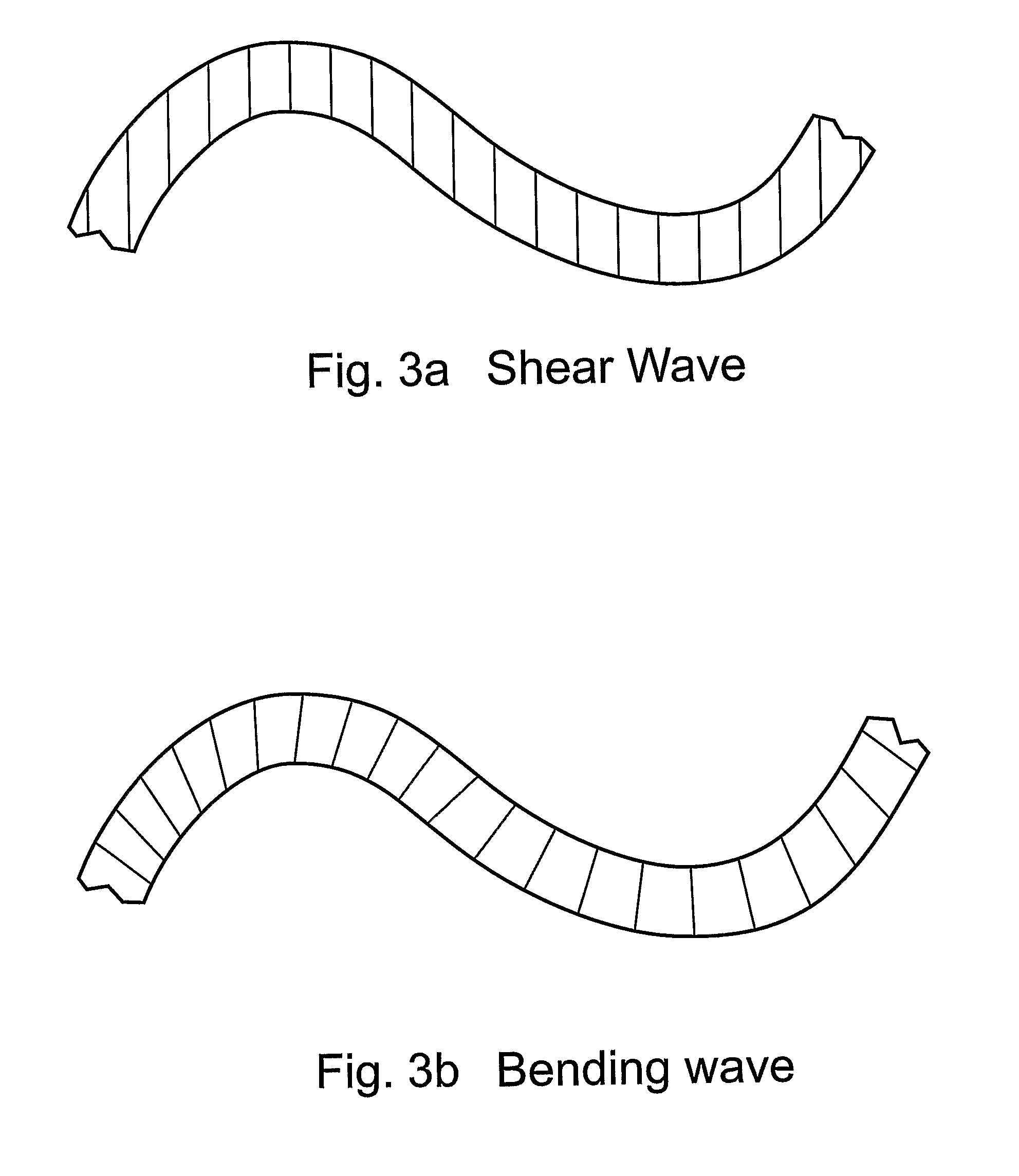

Method and Apparatus for Precisely Measuring Wire Tension and Other Conditions, and High-Sensitivity Vibration Sensor Constructed in Accordance Therewith

InactiveUS20080307885A1High sensitivityHigh precisionAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesContinuous measurementTransport time

A method and apparatus for monitoring a predetermined condition of a medium by; transmitting acoustical waves through the medium, continuously measuring changes in the transit time of the acoustical waves resulting from changes in the monitored condition; and utilizing the changes in transit time to provide a continuous measurement of the changes in the monitored condition. The acoustical waves are bending waves wherein cross-sections of the medium have a rotational movement orthogonally to the axis of propagation of the waves through the acoustical channel. Several examples of such method and apparatus are described, including a highly sensitive pressure sensor for sensing changes in pressure applied to a displaceable membrane, and a highly-sensitive vibration sensor for sensing earth or other vibrations.

Owner:NEXENSE

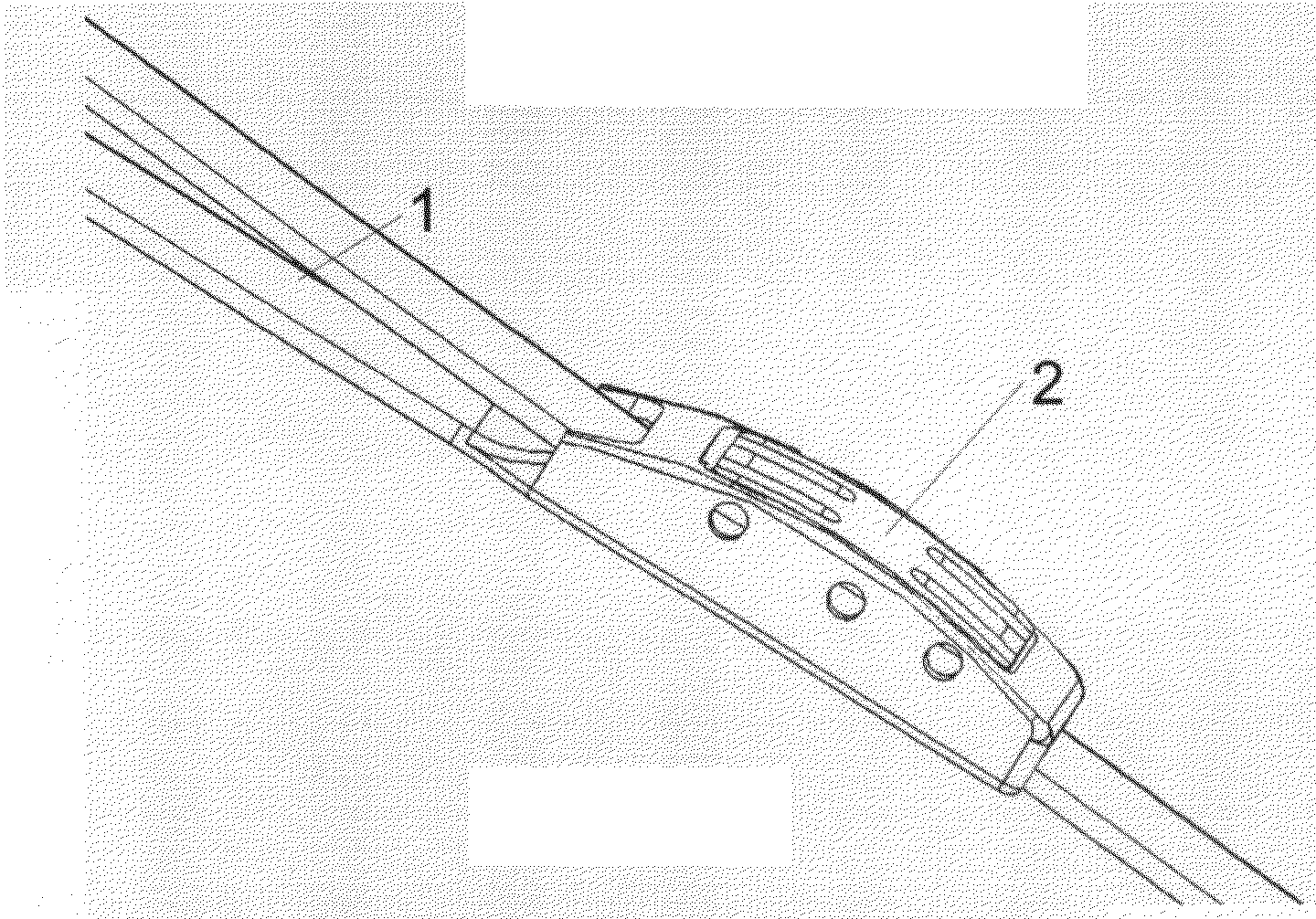

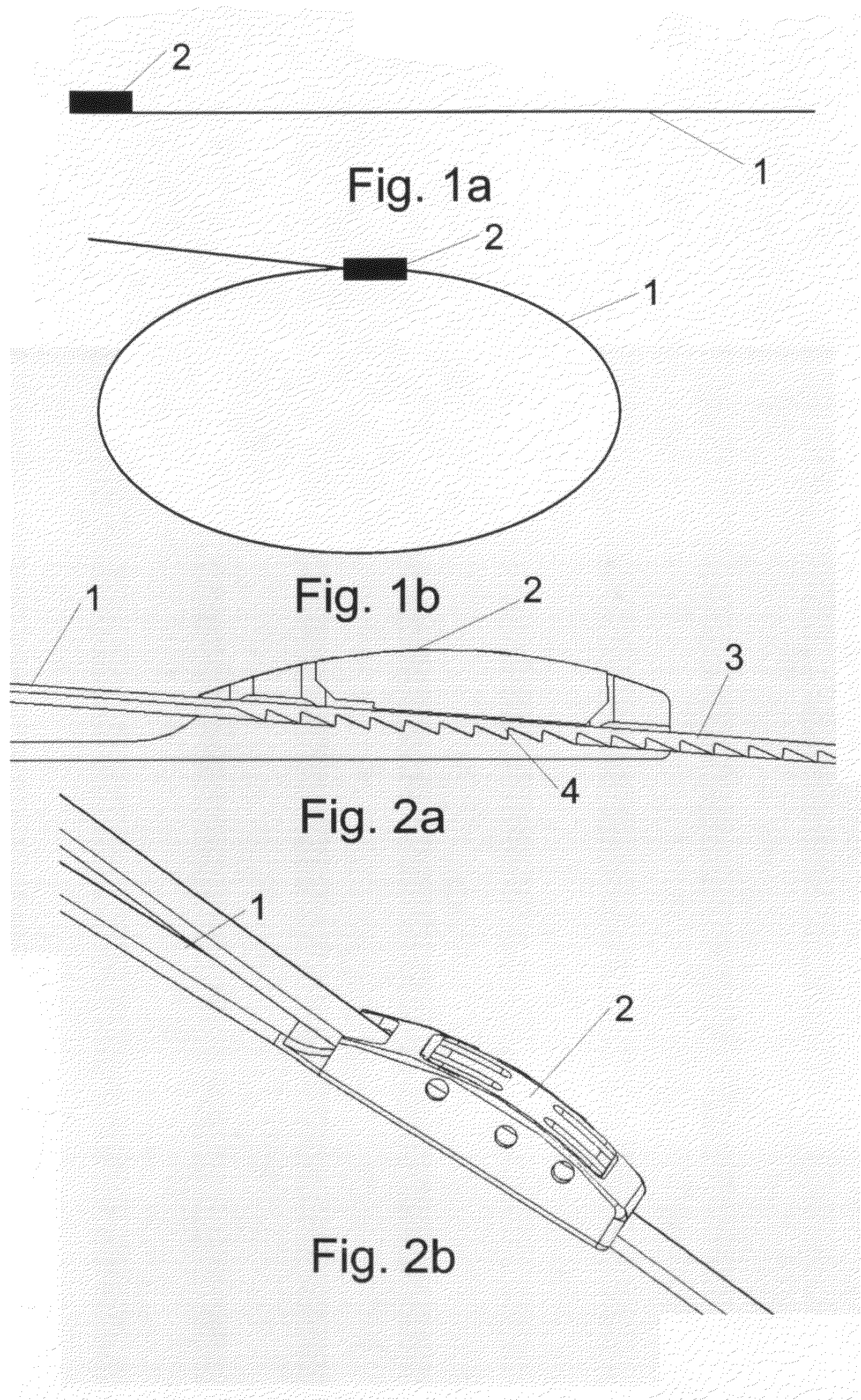

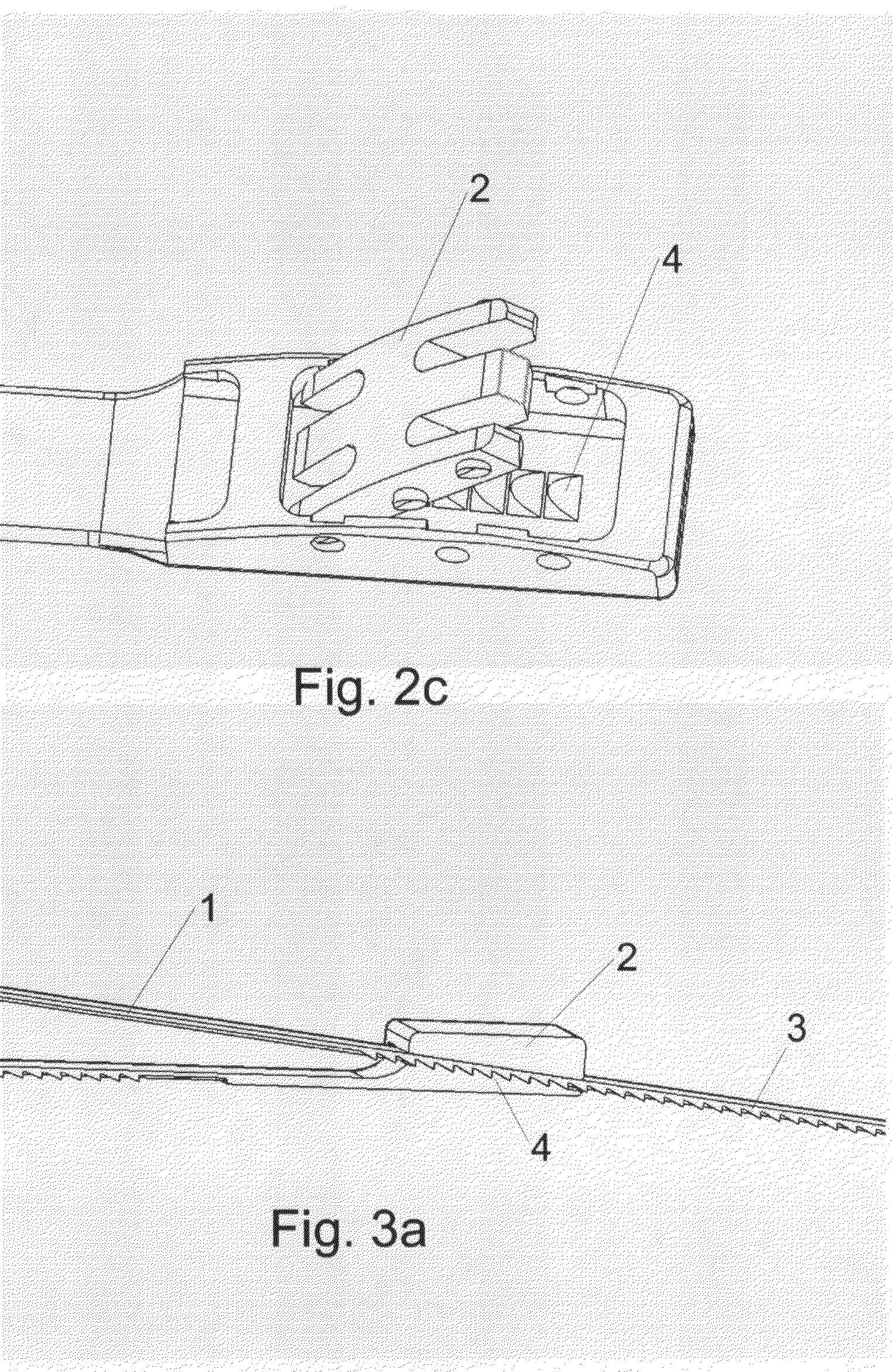

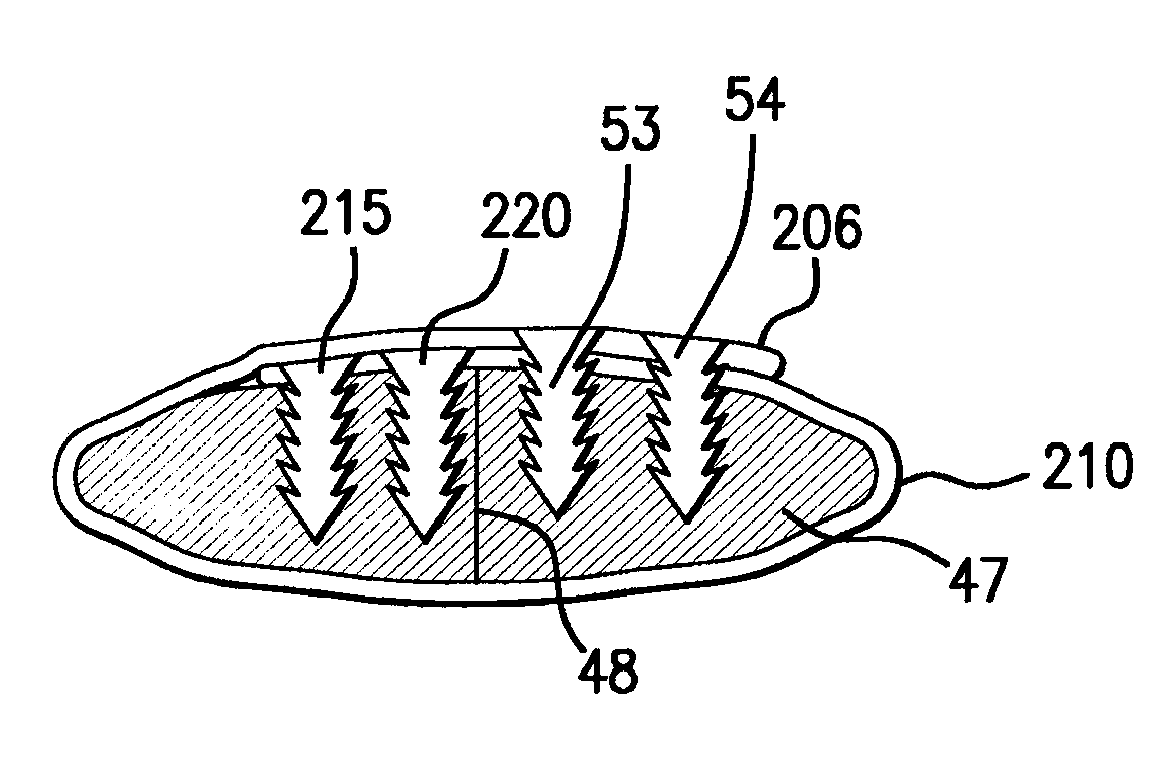

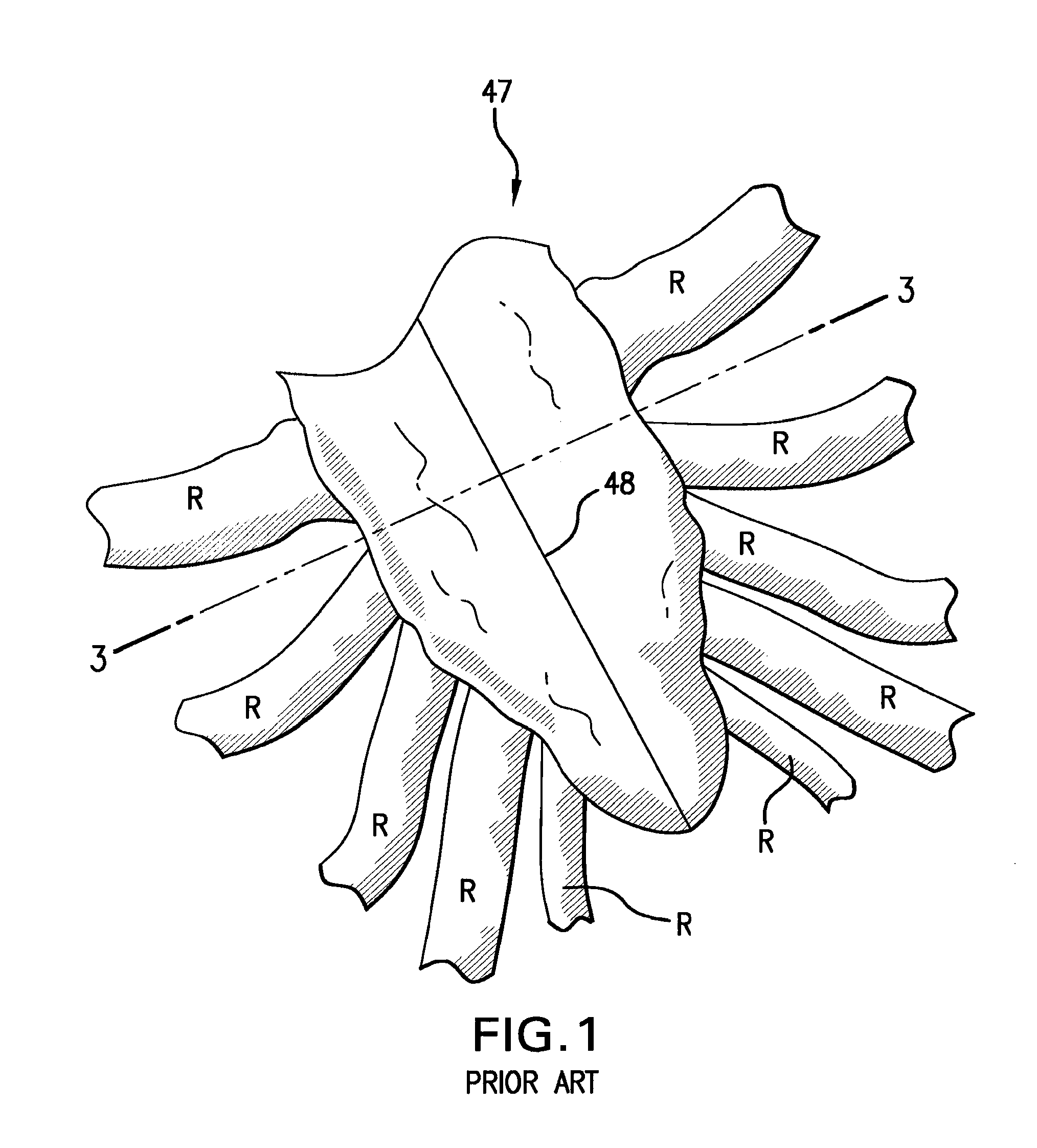

Bioabsorbable band system,a bioabsorbable band, a method for producing a bioabsorbable band, a needle system of a bioabsorbable band and a locking mechanism

ActiveUS20090270923A1Mitigate such drawbackPrecise tensionInternal osteosythesisJoint implantsLocking mechanismOsteotomy

A bioabsorbable band system for securing a bone fracture, or an osteotomy, or a soft tissue on a bone. The bioabsorbable band system includes a needle system and a bioabsorbable band including a bioabsorbable locking member. The bioabsorbable band includes a length having an at least partially oriented structure. The bioabsorbable band further includes a locking mechanism with a locking member. Also a method for producing the bioabsorbable band.

Owner:BIORETEC

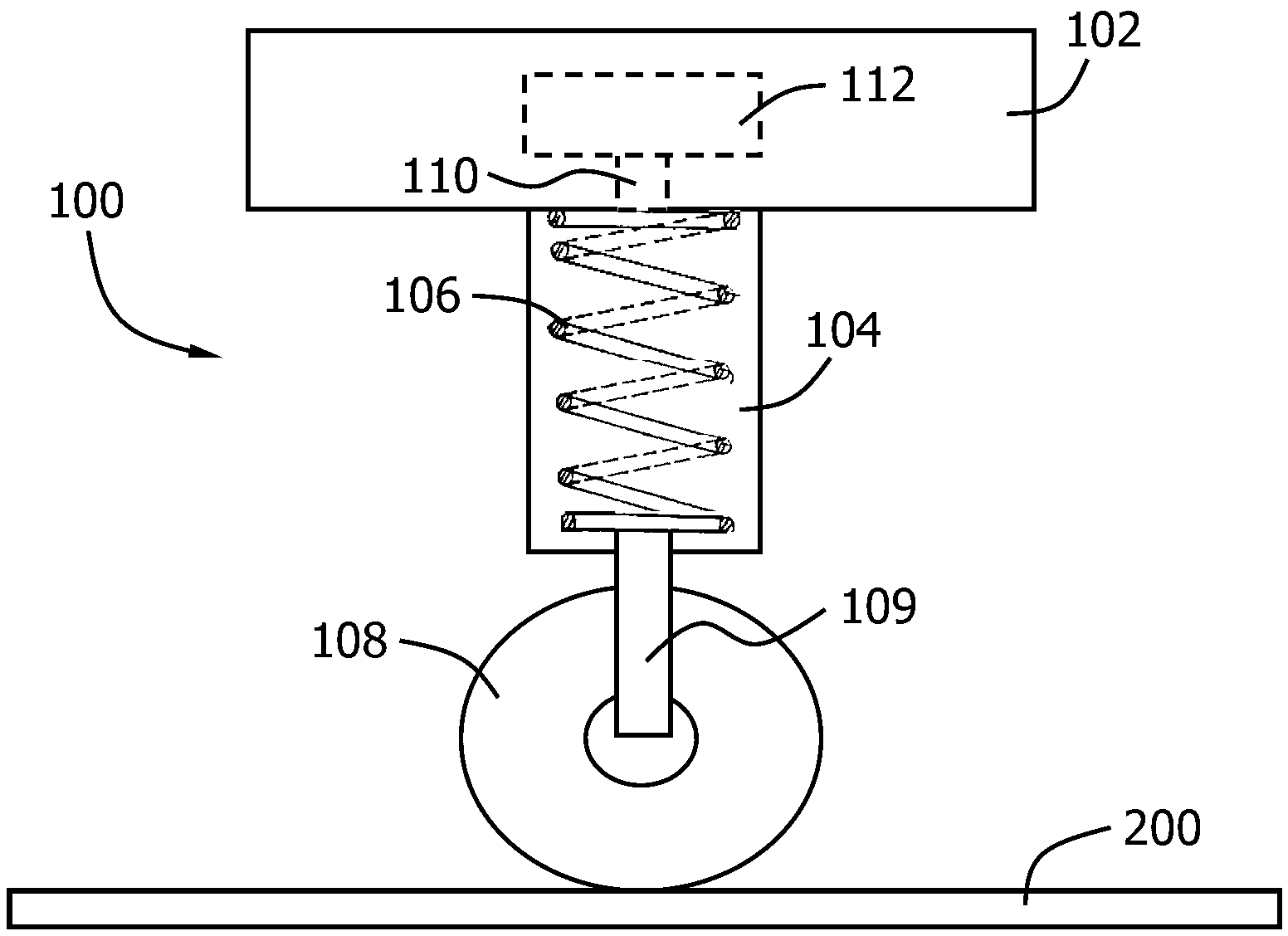

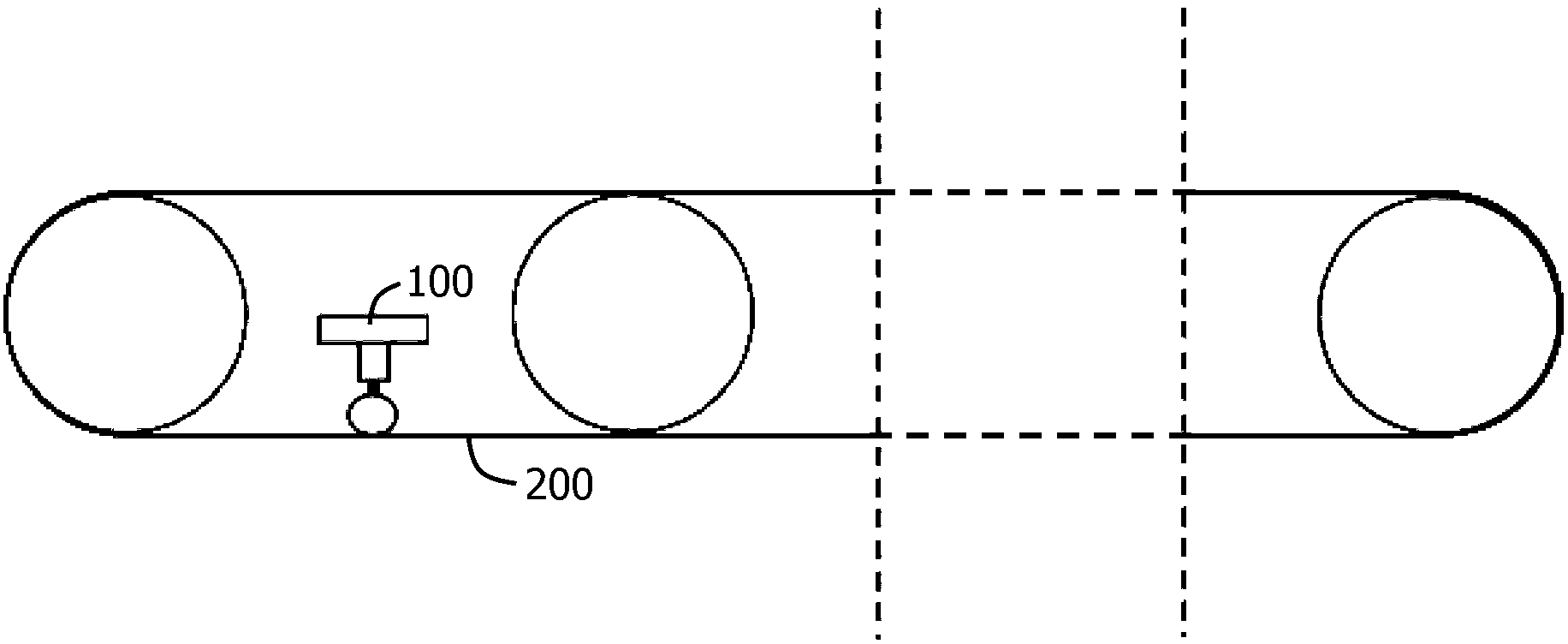

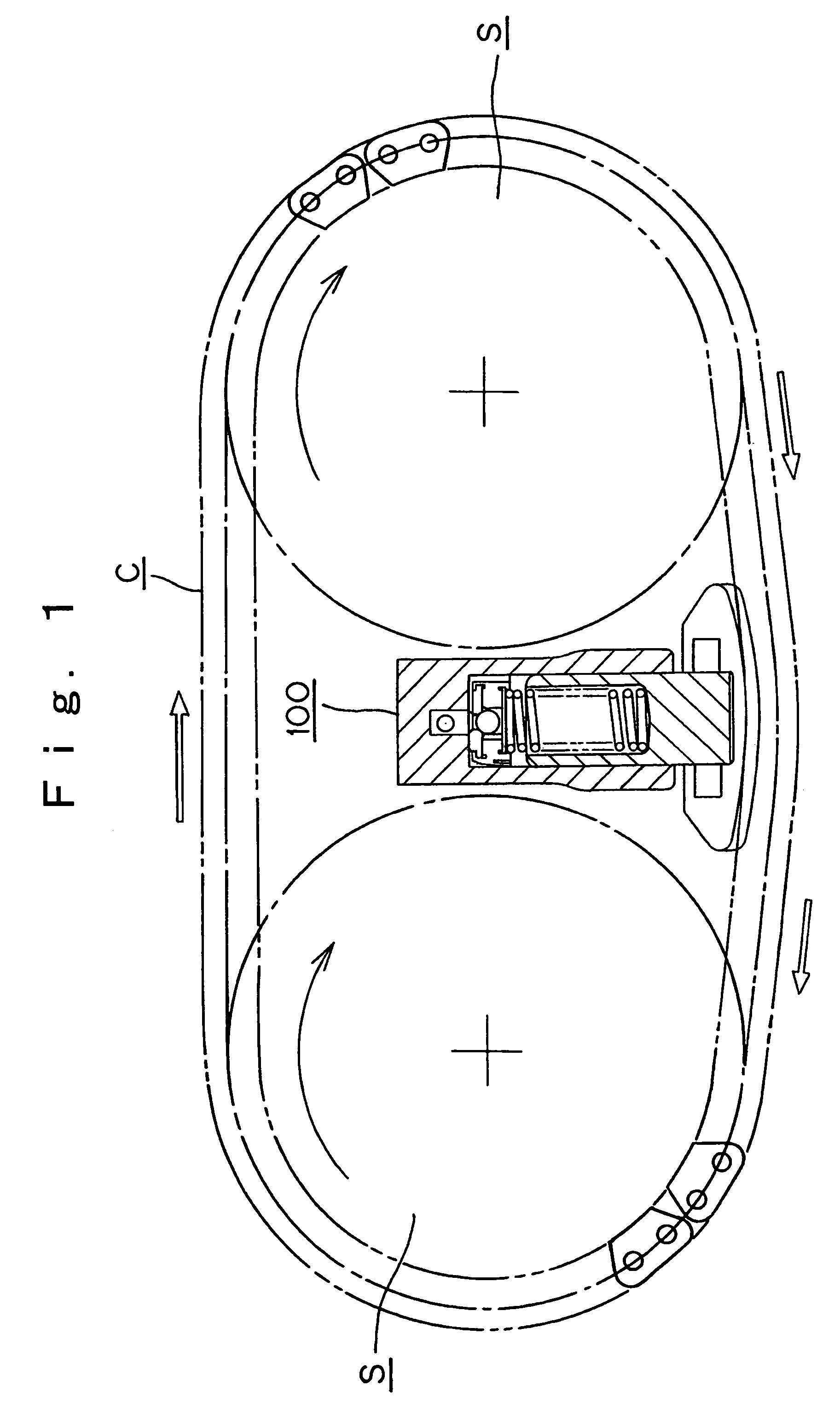

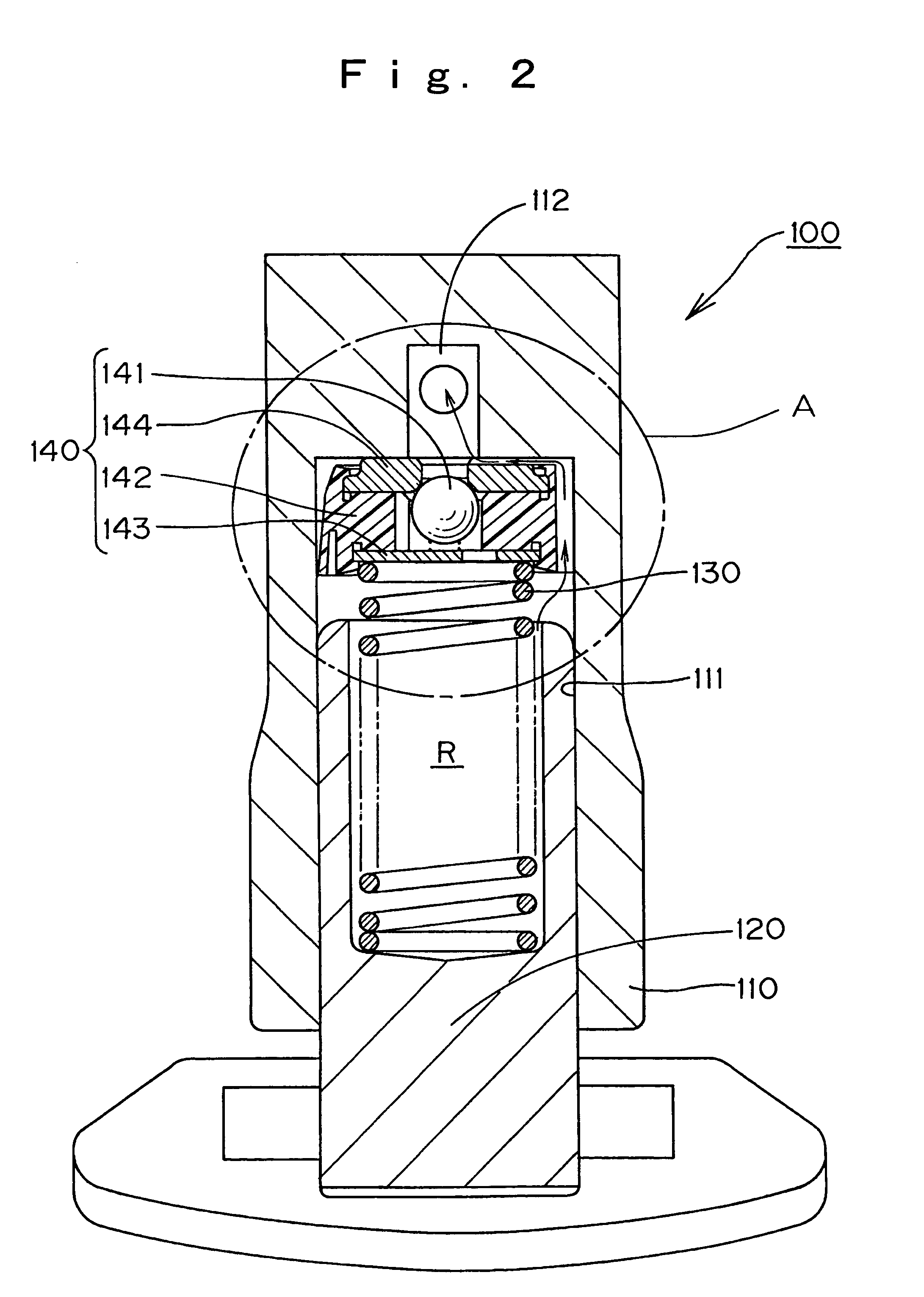

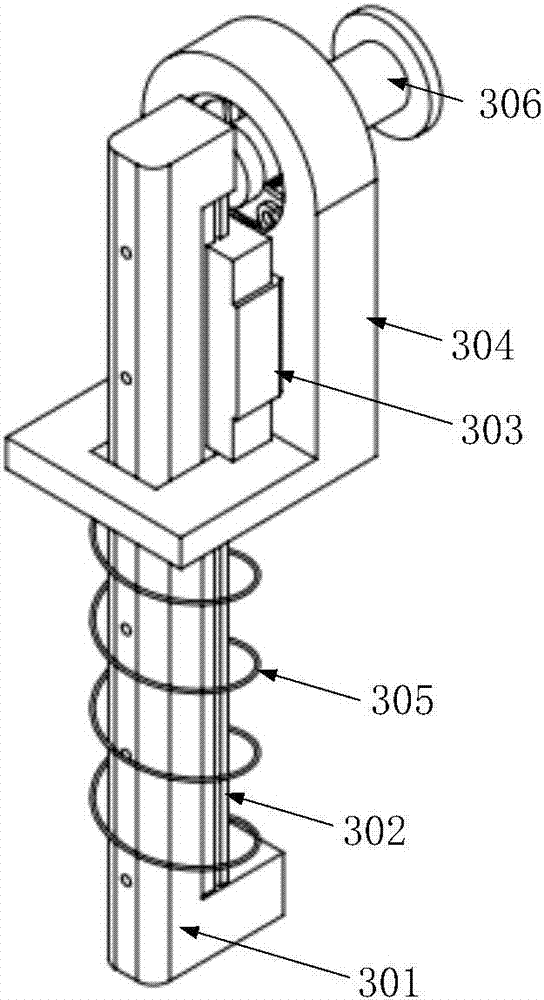

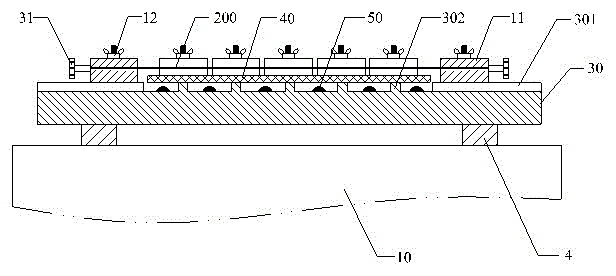

Tensile force detecting device for conveyer belt

The invention discloses a tensile force detecting device for a conveyer belt. The tensile force detecting device comprises a chassis, a pipe, a spring, a pulley, a connecting block and a pressure sensor, wherein the chassis is hollowed and is arranged between the upper side and the lower side of the conveyer belt; the pipe is connected with the chassis, is hollowed and is arranged along a vertical direction; the spring is placed in the pipe; the pulley is arranged at a first end of the spring through a pulley support; a rotating shaft of the pulley is arranged on the pulley support; the pulley is held out against the inner surface of the conveyer belt which moves towards the lower side; the connecting block is arranged at a second end of the spring; the connecting block is placed in the chassis; the pressure sensor is placed in the chassis and is in contact with the connecting block; and the pressure applied by the connecting block to the pressure sensor can be detected by the pressure sensor. According to the tensile force detecting device for the conveyer belt, the real-time tensile force of the conveyer belt is detected through the spring and the pulley; the tensile force is collected from the lower side of the conveyer belt so as to remove the interference caused by the materials borne by the conveyer belt; and the spring ensures that the pulley can be clung to the conveyer belt all the time, so that accurate tensile force can be acquired.

Owner:昆山特力伯传动科技有限公司

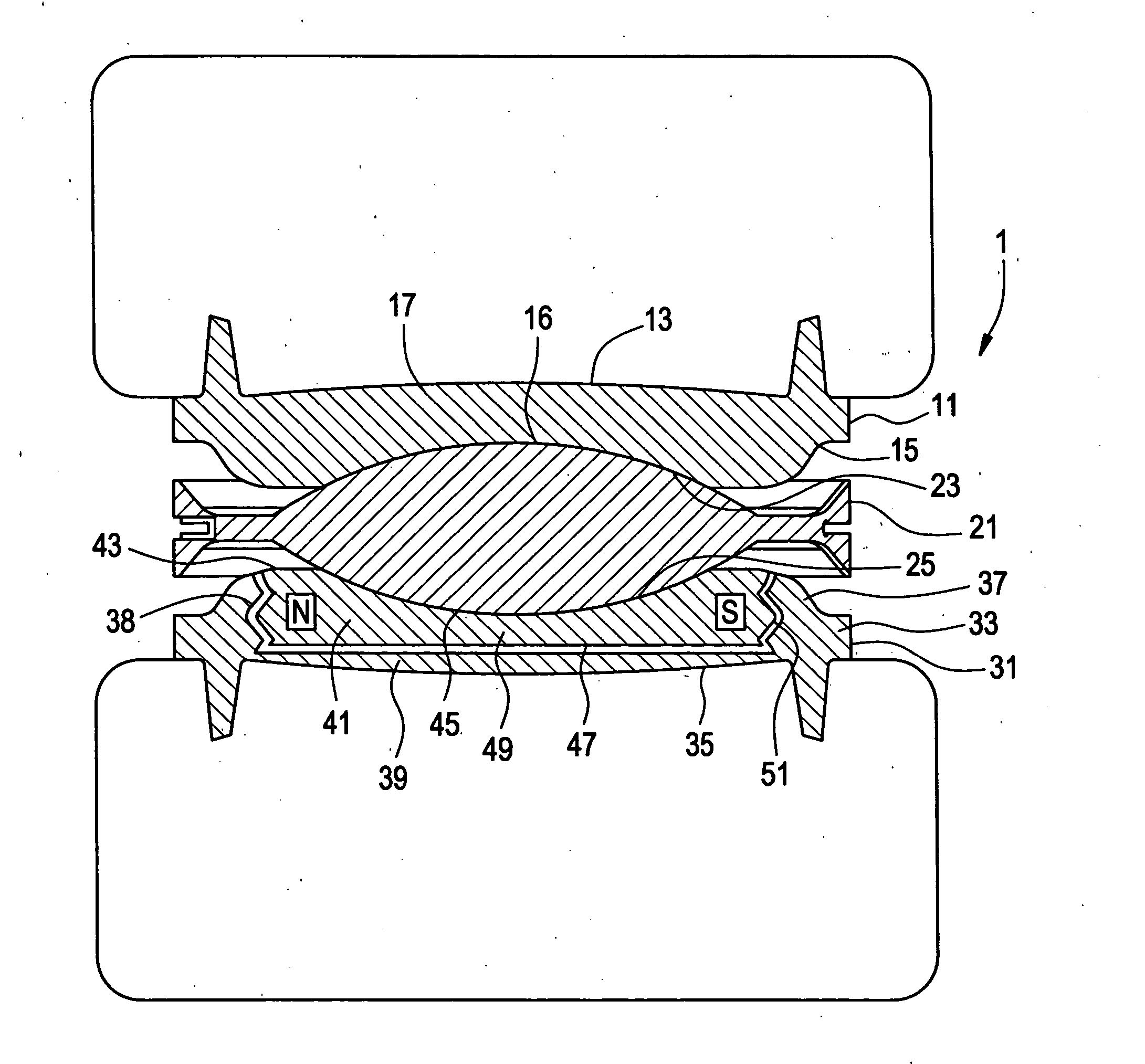

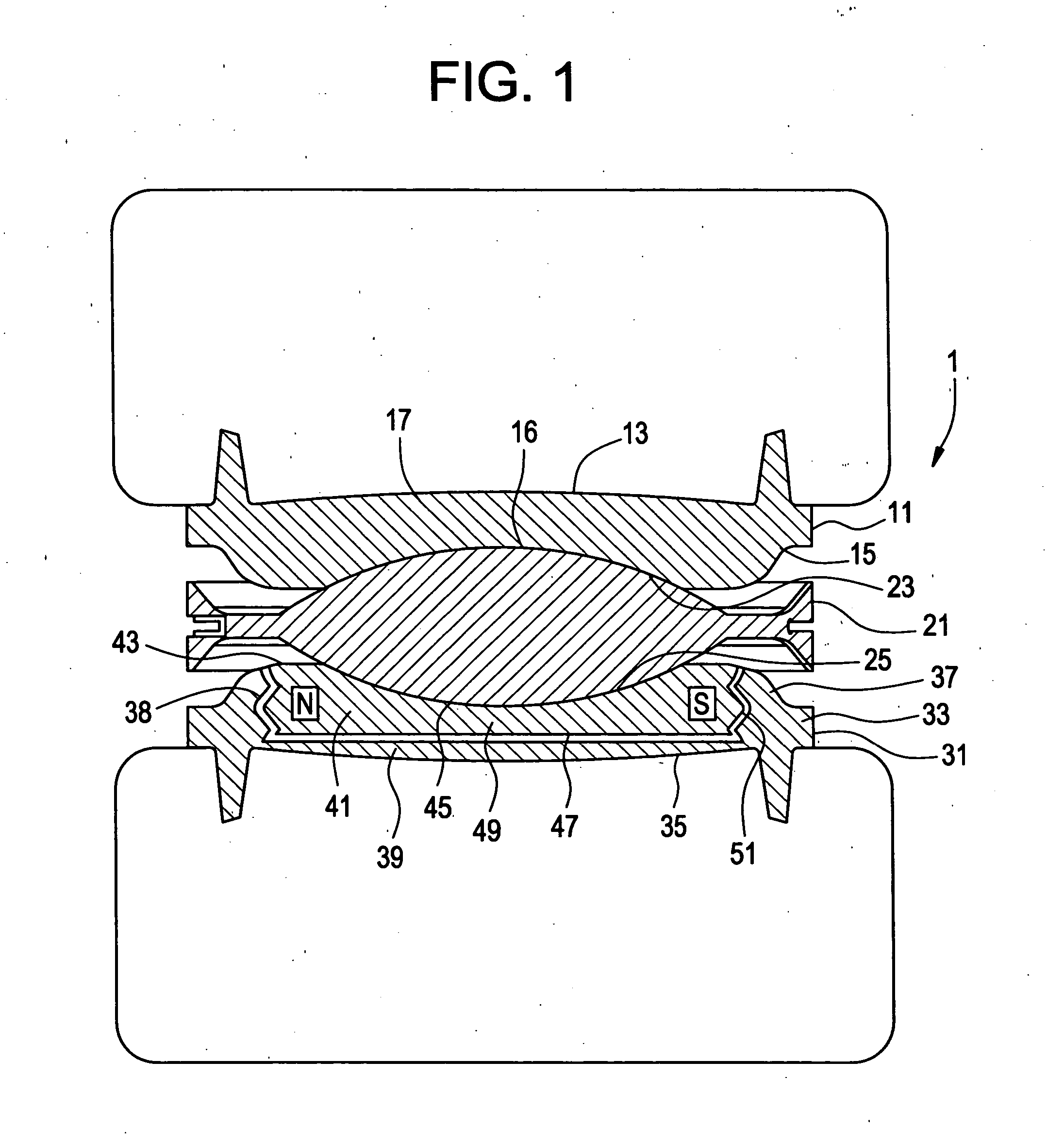

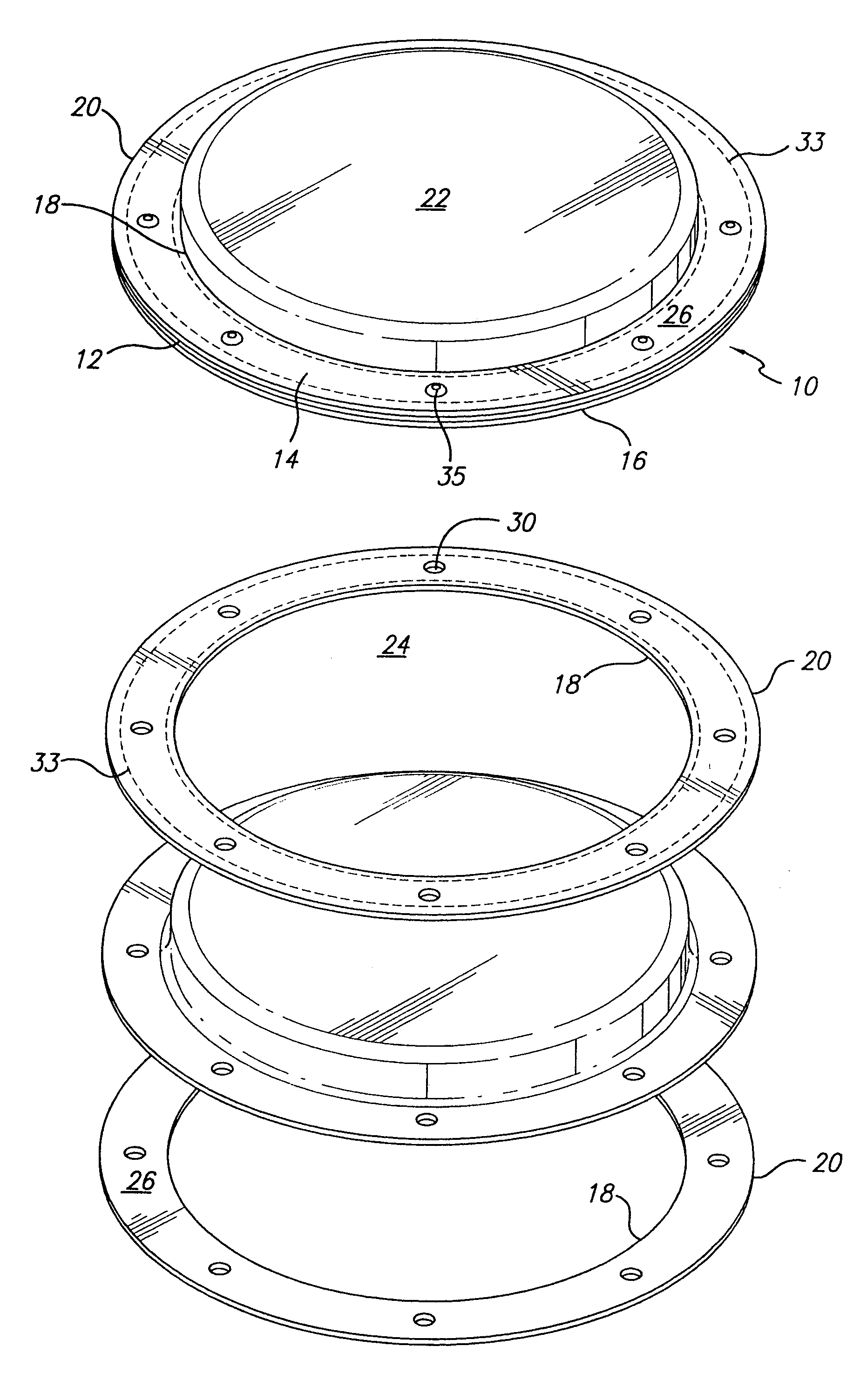

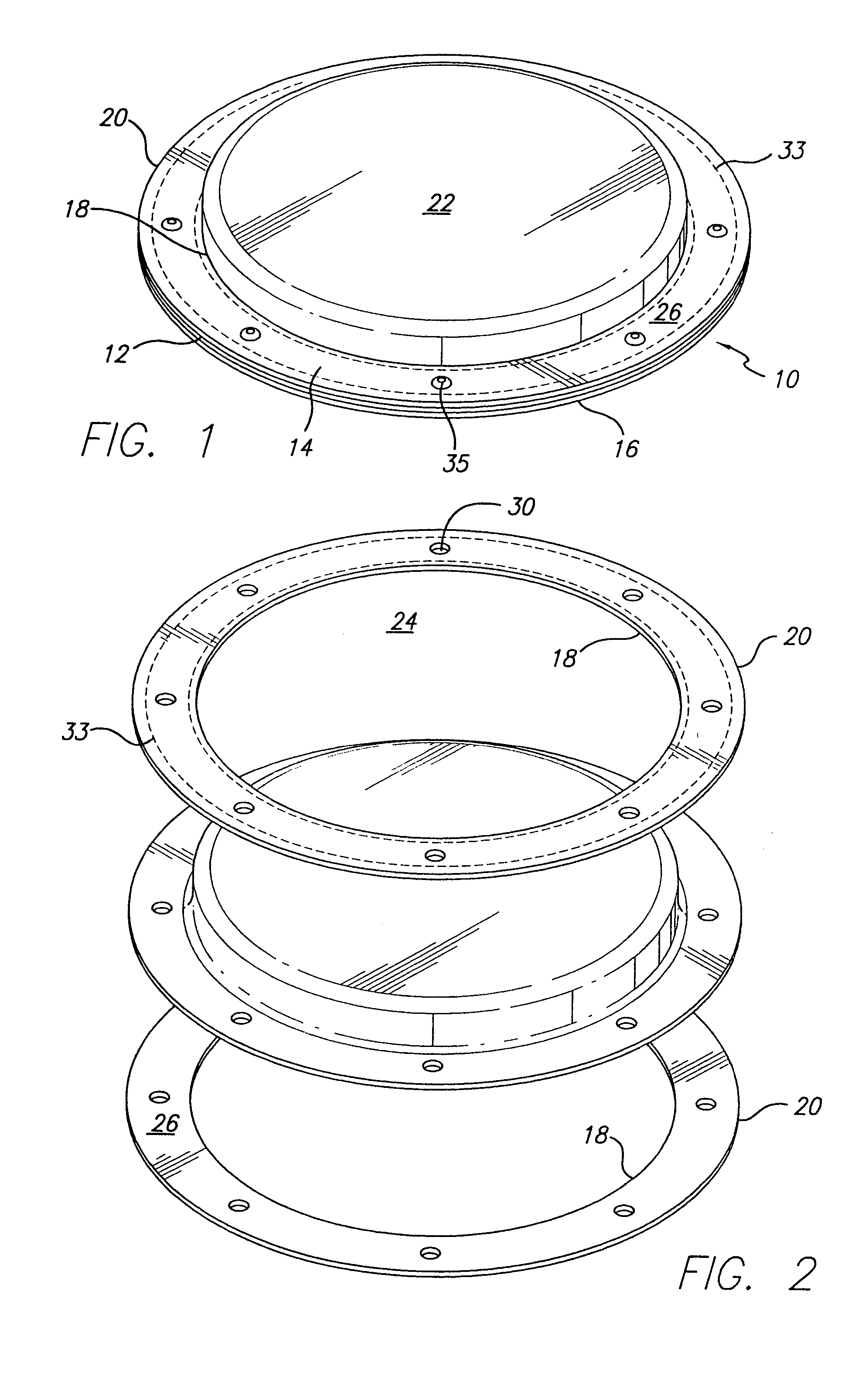

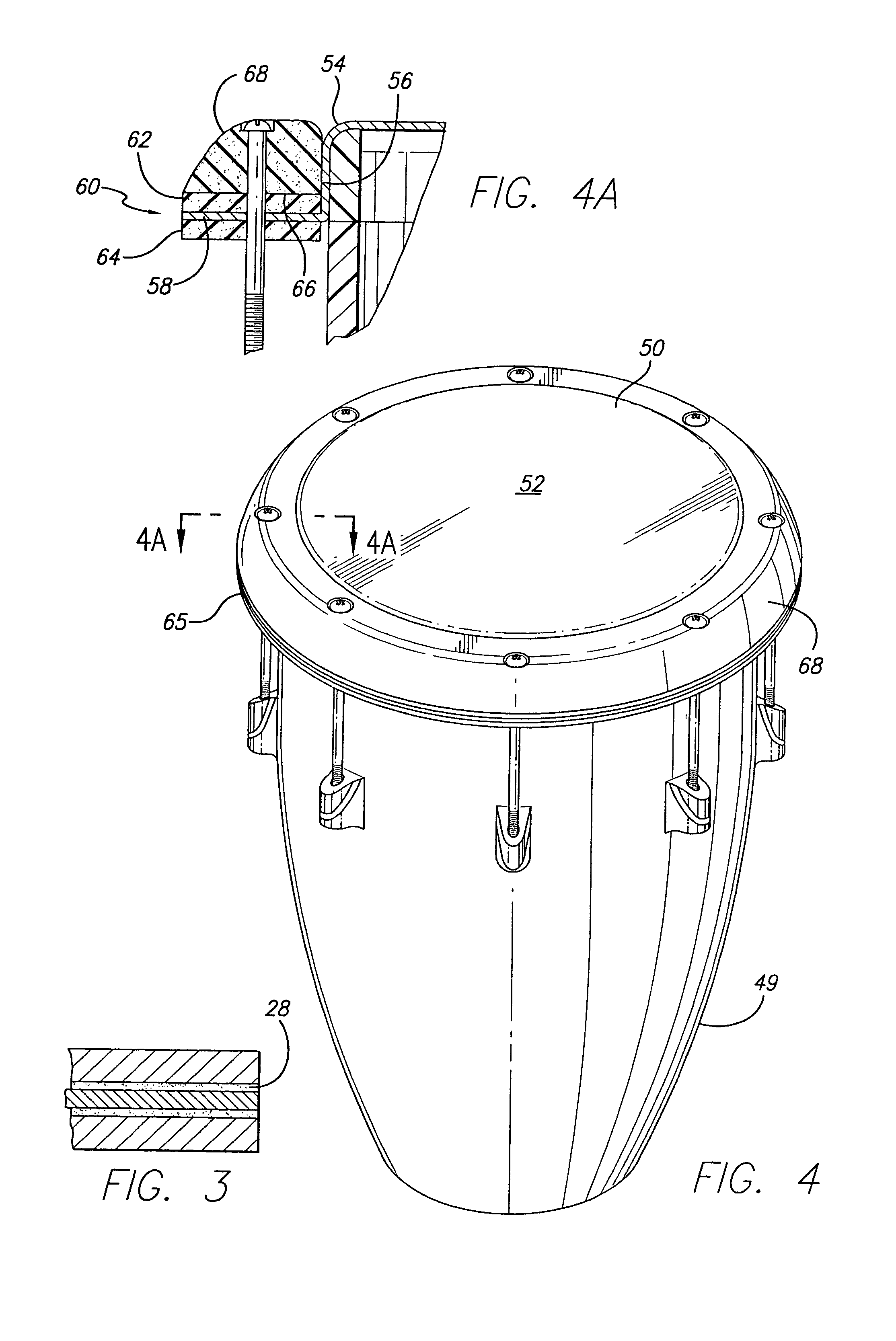

Tunable drumhead

InactiveUS7074994B2Avoid injuryPrecise tensionPercussion musical instrumentsAutomatic musical instrumentsDrumheadMechanical engineering

An improved drumhead comprising a substantially annular hoop having a generally planar upper member spaced apart from a generally planar lower member, a circumferential inner rim and a circumferential outer rim. Also provided is a film material or membrane for constituting a drumming surface, which extends flat across the area defined within the circumferential inner rim and the circumferential outer rim. Integrally formed with the film material or membrane of the drumming surface is an annular shoulder, which extends at its base between the planar upper and lower members in a co-planar orientation with the annular hoop. The drumhead is adaptable for use with a large variety of percussion instruments including toms, snare drums, bass drums, tambourines, congas, bongos and many other types of ethnic and other drums.

Owner:REMO INC

Device for placing a looped belt under tension

A tensioning device has a tension arm mounted on a base. A pulley is mounted on the tension arm for engaging a looped belt. By changing mounting bushings, one can select either a static mode wherein the tension arm is held stationary relative to the base, or a dynamic mode wherein, in response to a changing force applied between the pulley and the belt (due to vibrations or load changes, for example), the tension arm moves relative to the base in such a manner as to maintain the force substantially constant. Several such devices can be employed in a system for controlling the tension of a looped belt, one or more of the devices being in the static mode and one or more being in the dynamic mode. Several such systems can be employed in a complex machine such as a photocopier or medical apparatus for controlling the tension in a number of different belts.

Owner:YORK IND

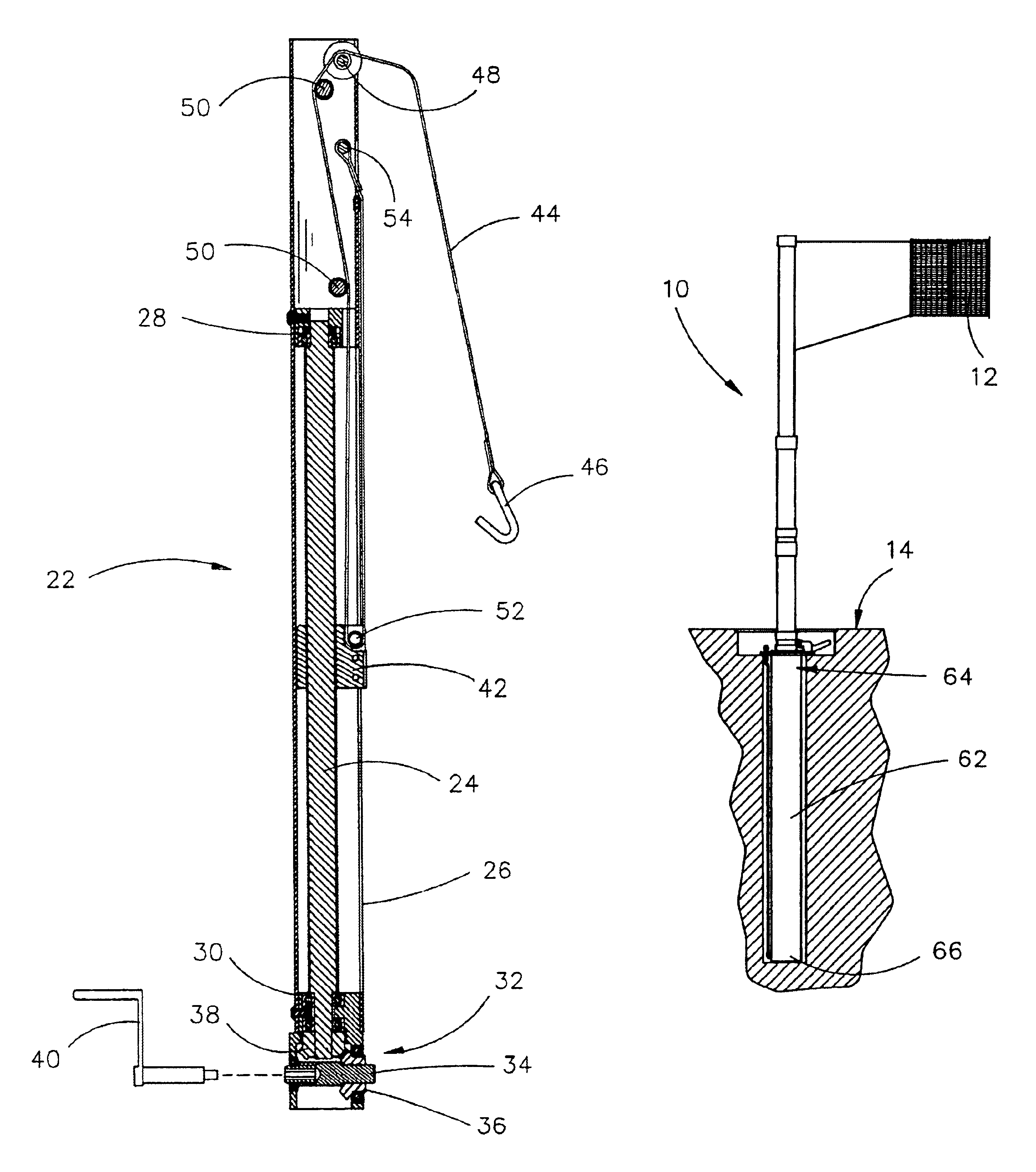

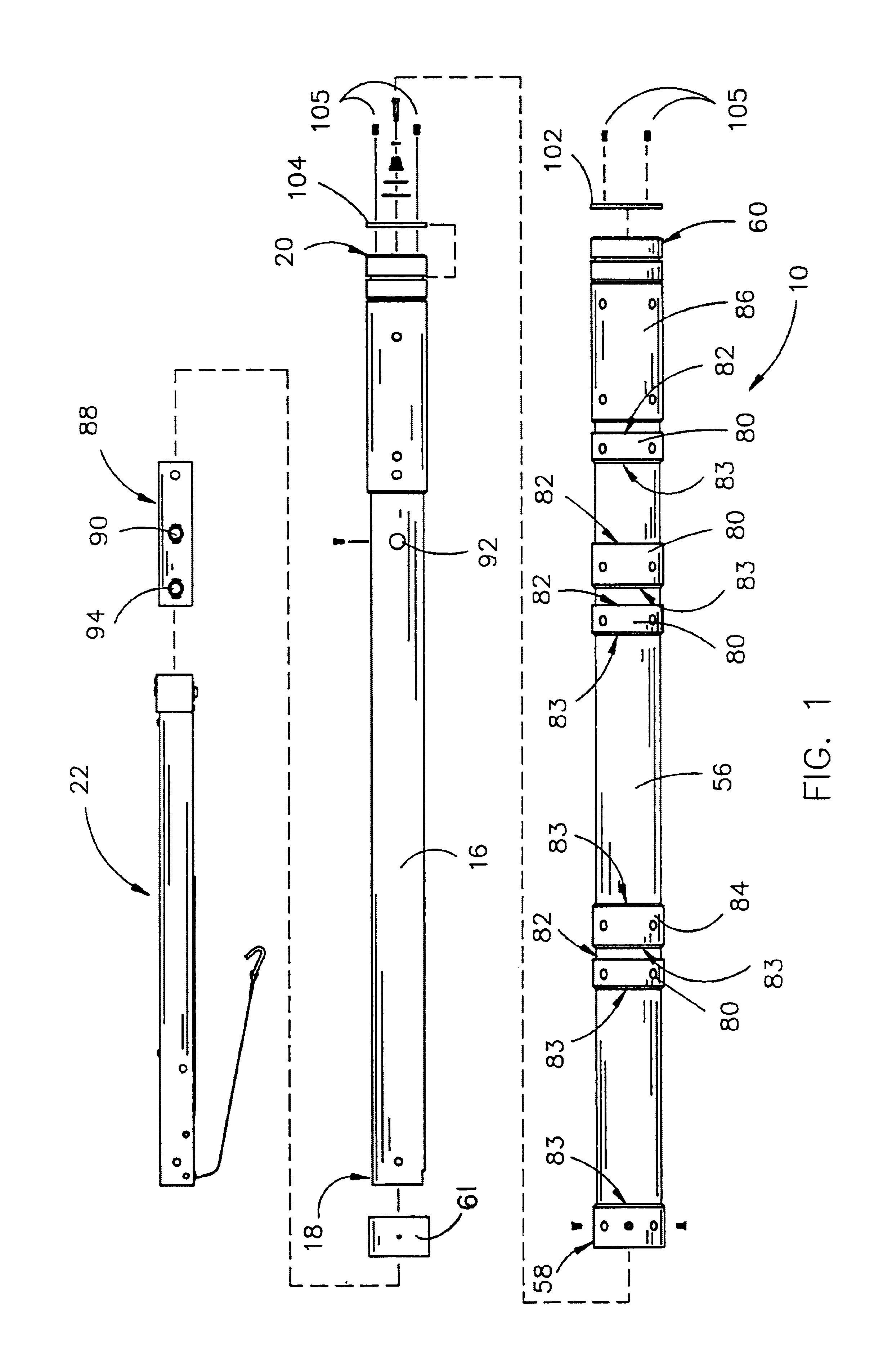

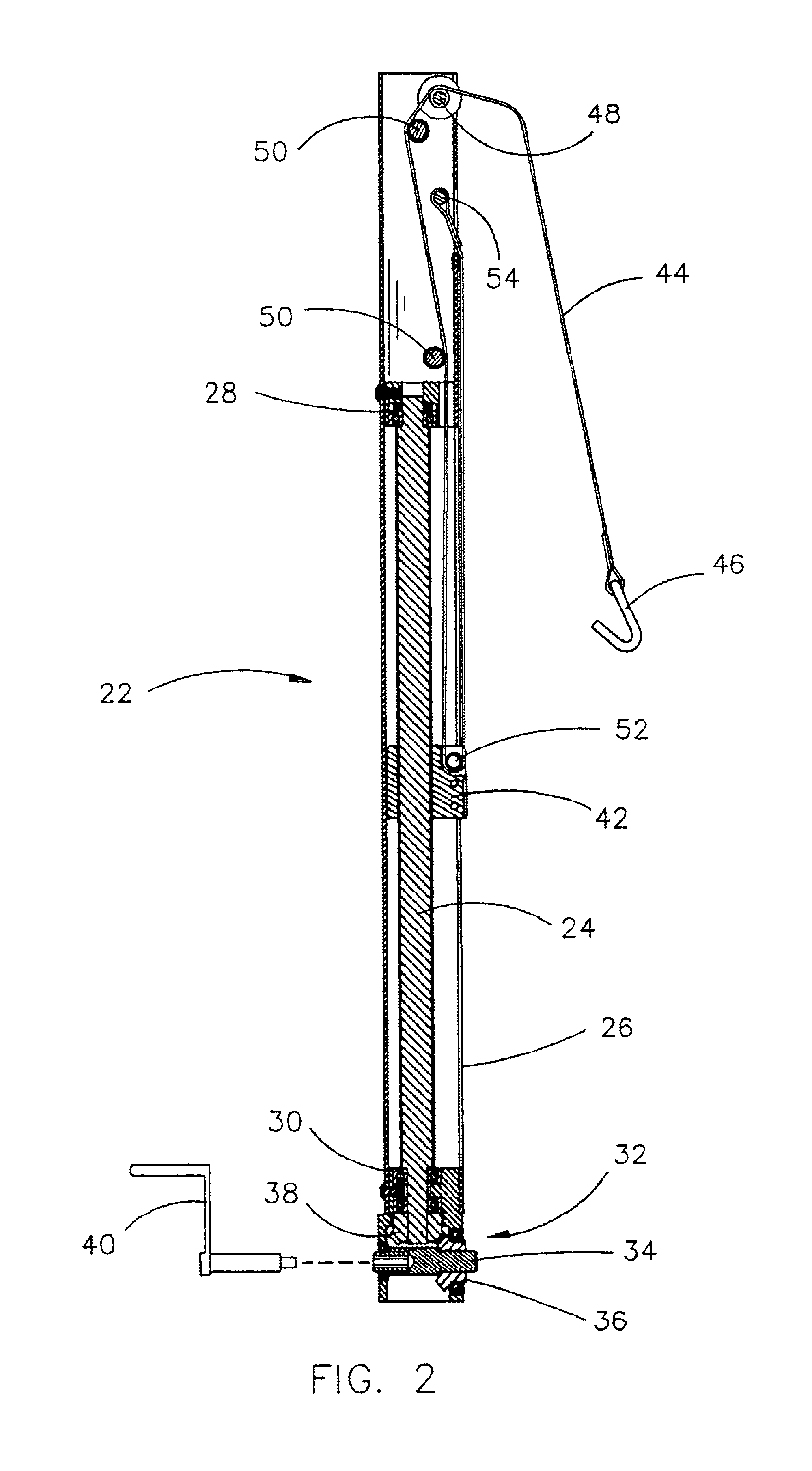

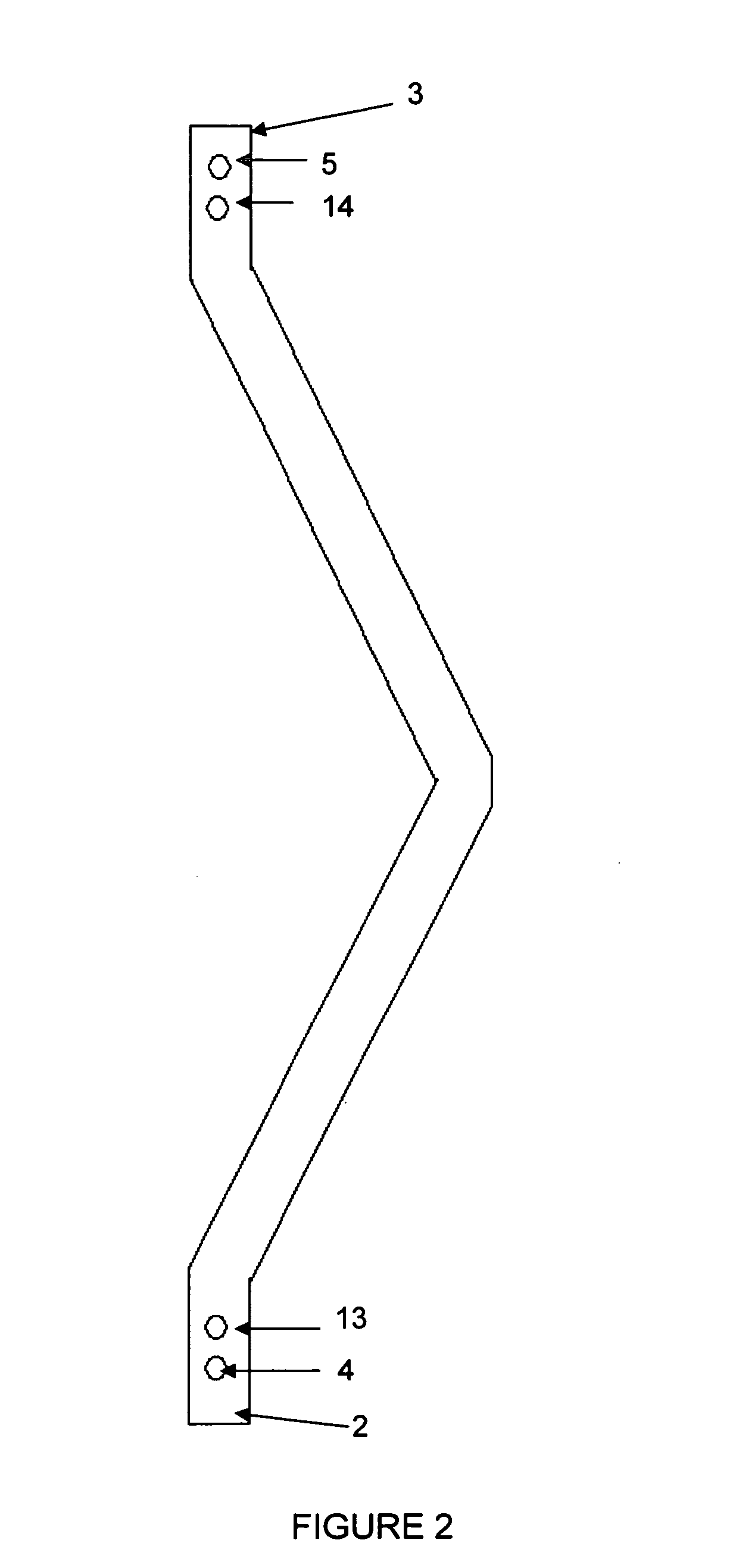

Self-storing standard for a game net

A standard for supporting a game net above a playing surface is provided with an internal net tensioning system which allows the standard to be stored beneath the playing surface. A plurality of pre-set height stops are provided along the length of the standard to allow the net to be set at one of several different heights to accommodate the playing of different games by different playing abilities. Power cylinder mechanics permits the automatic raising and lowering of the standard with respect to the playing surface. A quick attachment system is provided for quickly and easily engaging and disengaging the net from the standard.

Owner:WEWEL JOSEPH S +2

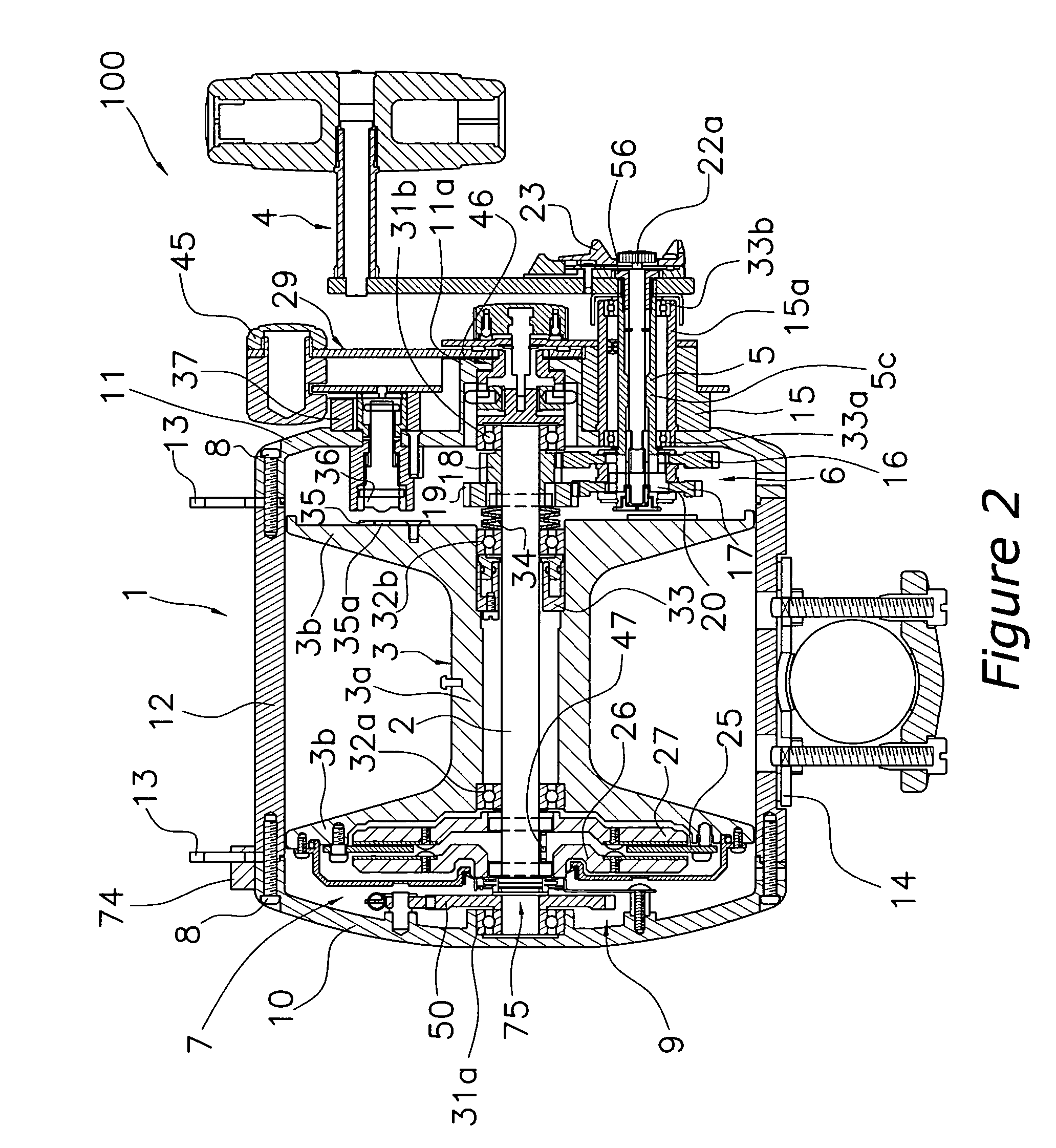

Hydraulic tensioner

A check valve unit in a hydraulic tensioner comprises a check ball which controls the flow of the oil to and from a high pressure oil chamber formed by a plunger and the plunger-receiving hole of the tensioner housing, a ball guide in which the check ball moves, a retainer which seals the check ball in the ball guide, and a ball seat which blocks reverse flow of oil by seating the check ball. Grooves, which ventilate air from the high pressure oil chamber to an oil supply passage, are formed on an outer circumferential surface of the ball guide and a bottom surface of the ball seat.

Owner:TSUBAKIMOTO CHAIN CO

Spare brake beam having replaceable brake heads

ActiveUS20060219502A1Quick installationAvoid disassemblyRail brake actuationAutomotive engineeringHead parts

Owner:STUCKI DE MEXICO S DE R L DE C V

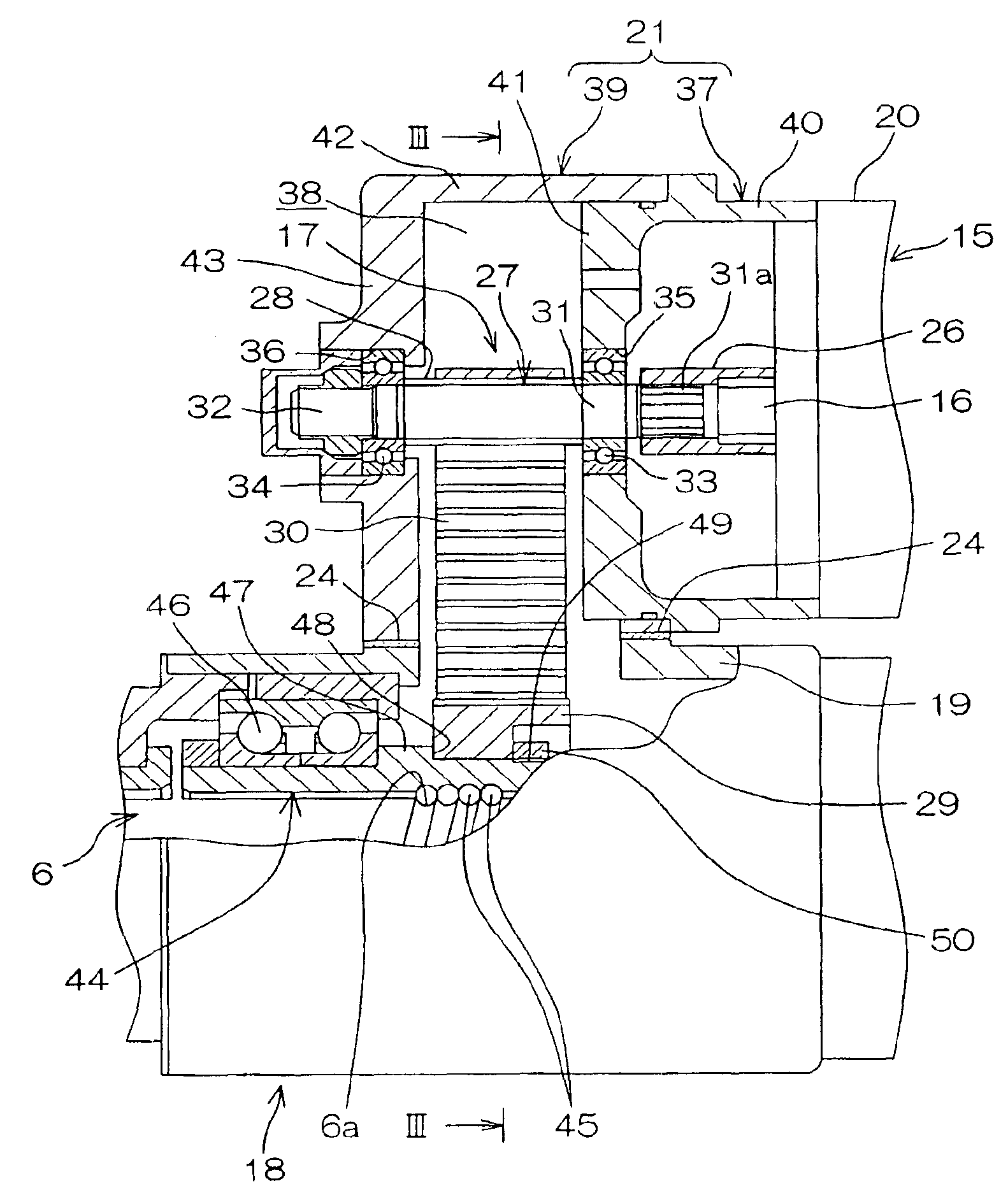

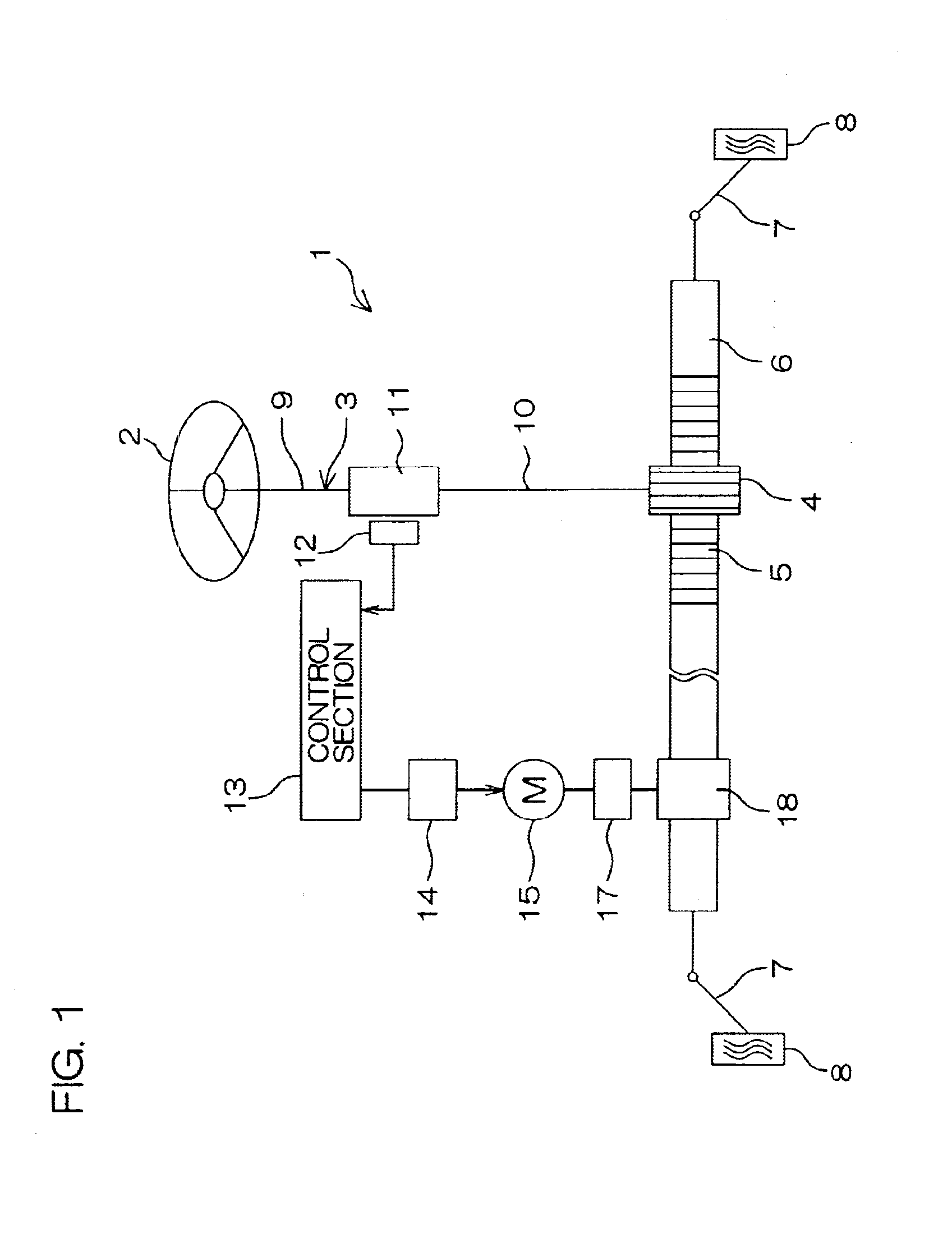

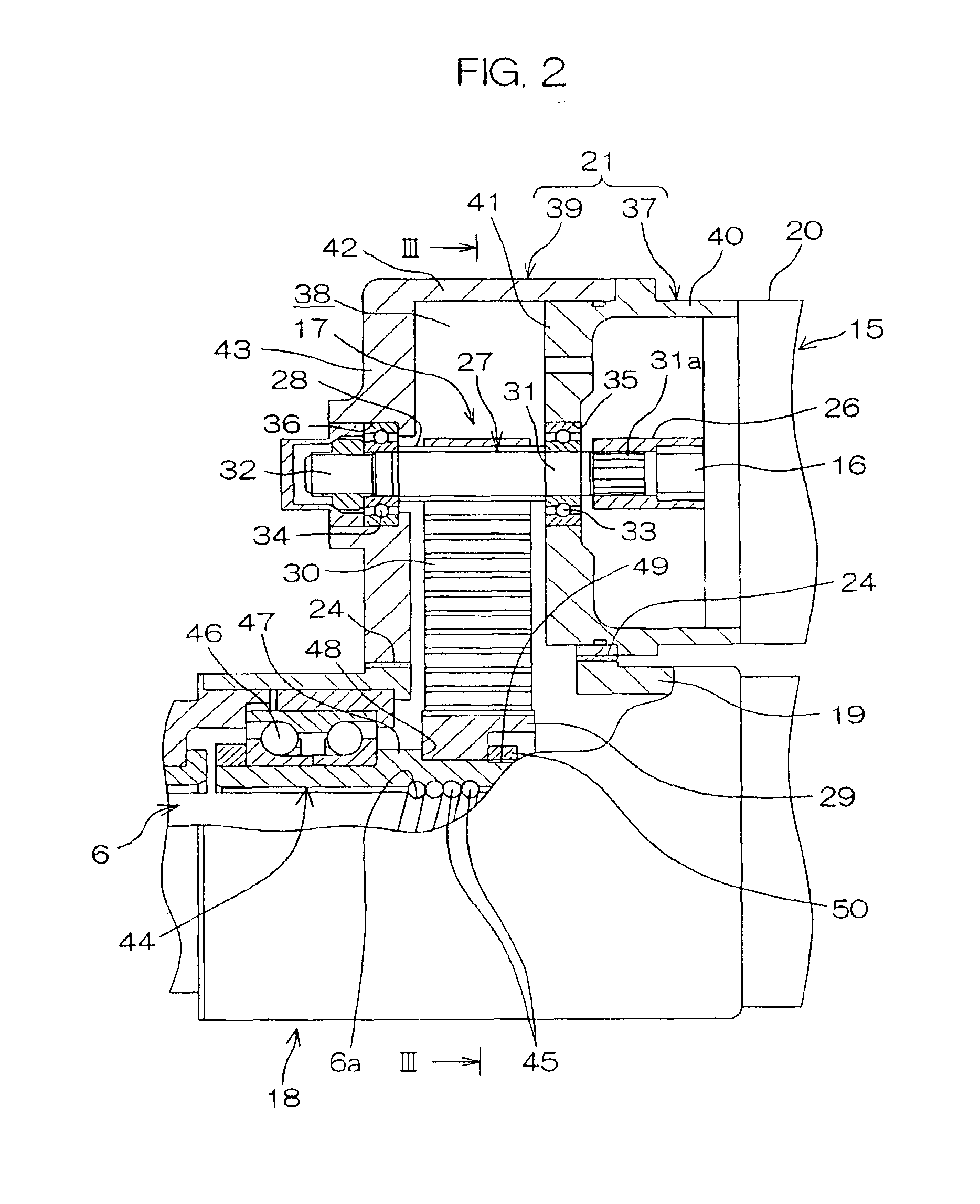

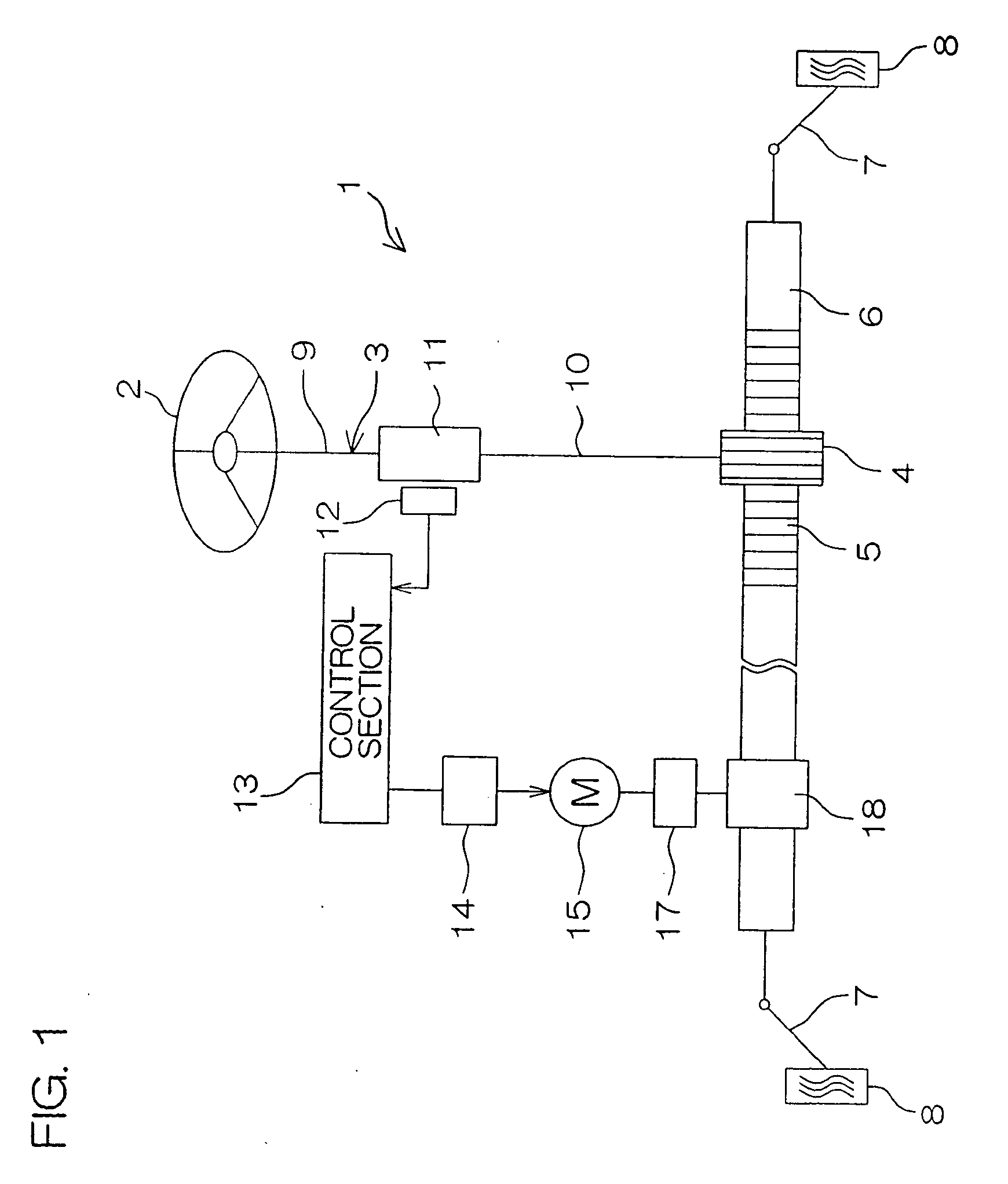

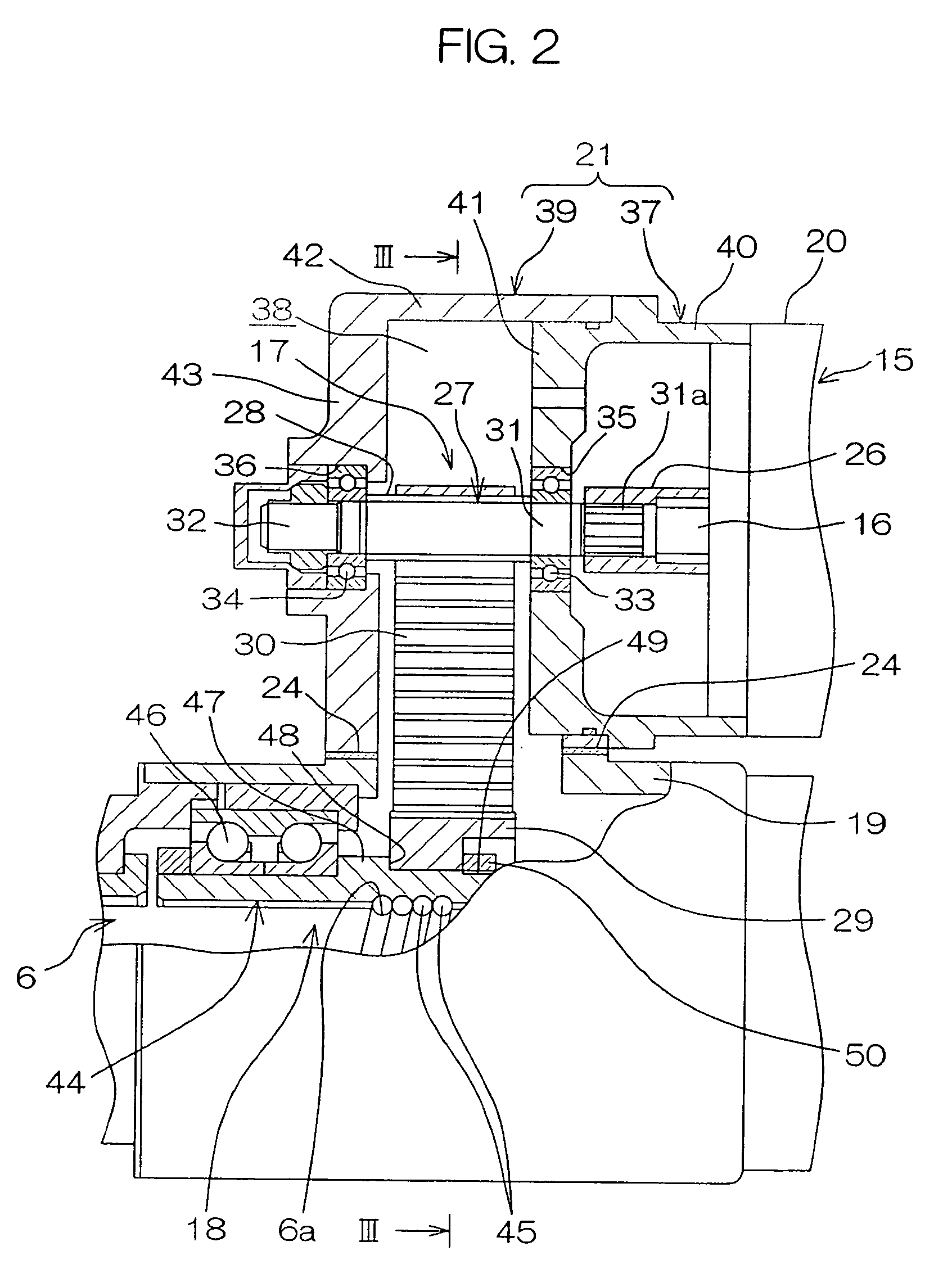

Electric power steering apparatus

InactiveUS20050189162A1Reduce vibrationReduce noiseGearingElectrical steeringElectric power steeringEngineering

An electric power steering apparatus comprises a speed reducing mechanism for decelerating the rotation of a rotatable shaft in an electric motor and a converting mechanism for converting the output rotation of the speed reducing mechanism into the axial movement of a steering shaft extending toward the right and left sides of a vehicle. The speed reducing mechanism comprises an input pulley driven by the electric motor, an output pulley arranged with the steering shaft enclosed thereby, a belt for connecting the input pulley and the output pulley to each other, and means for adjusting the tension of the belt.

Owner:JTEKT CORP +1

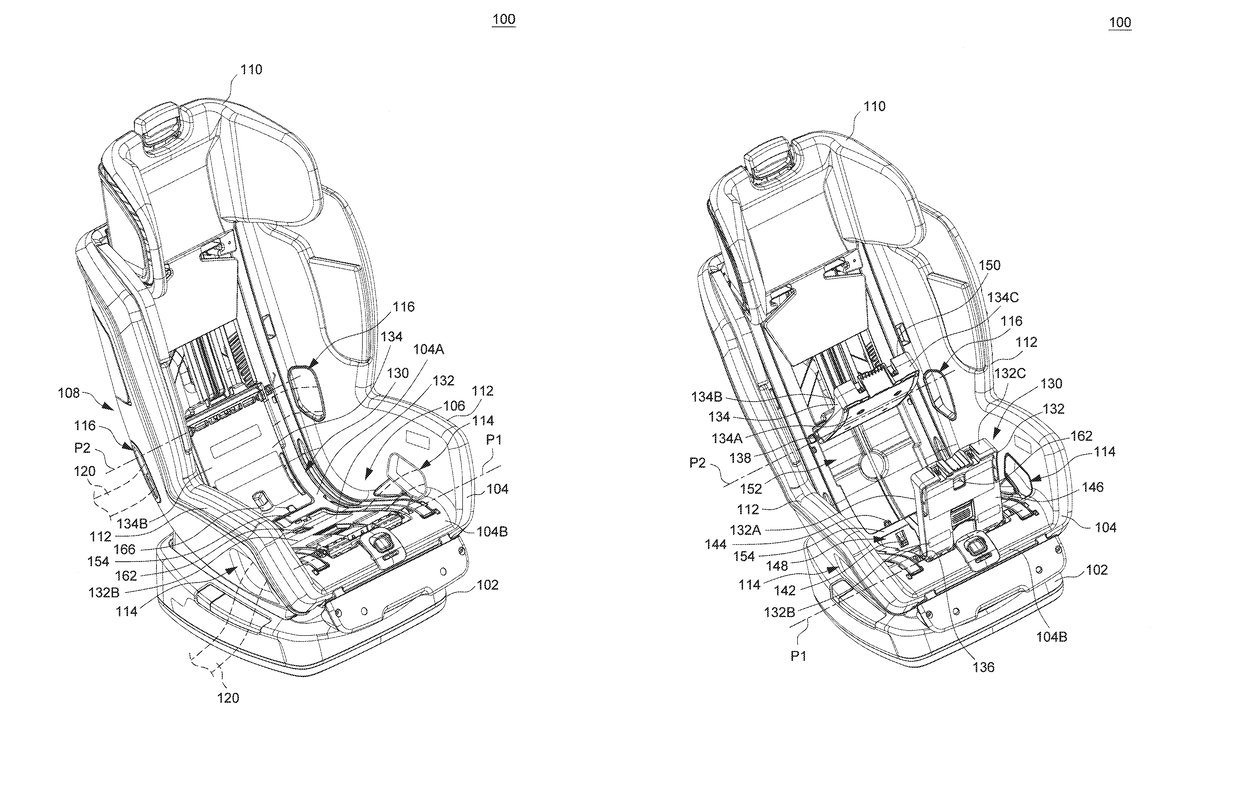

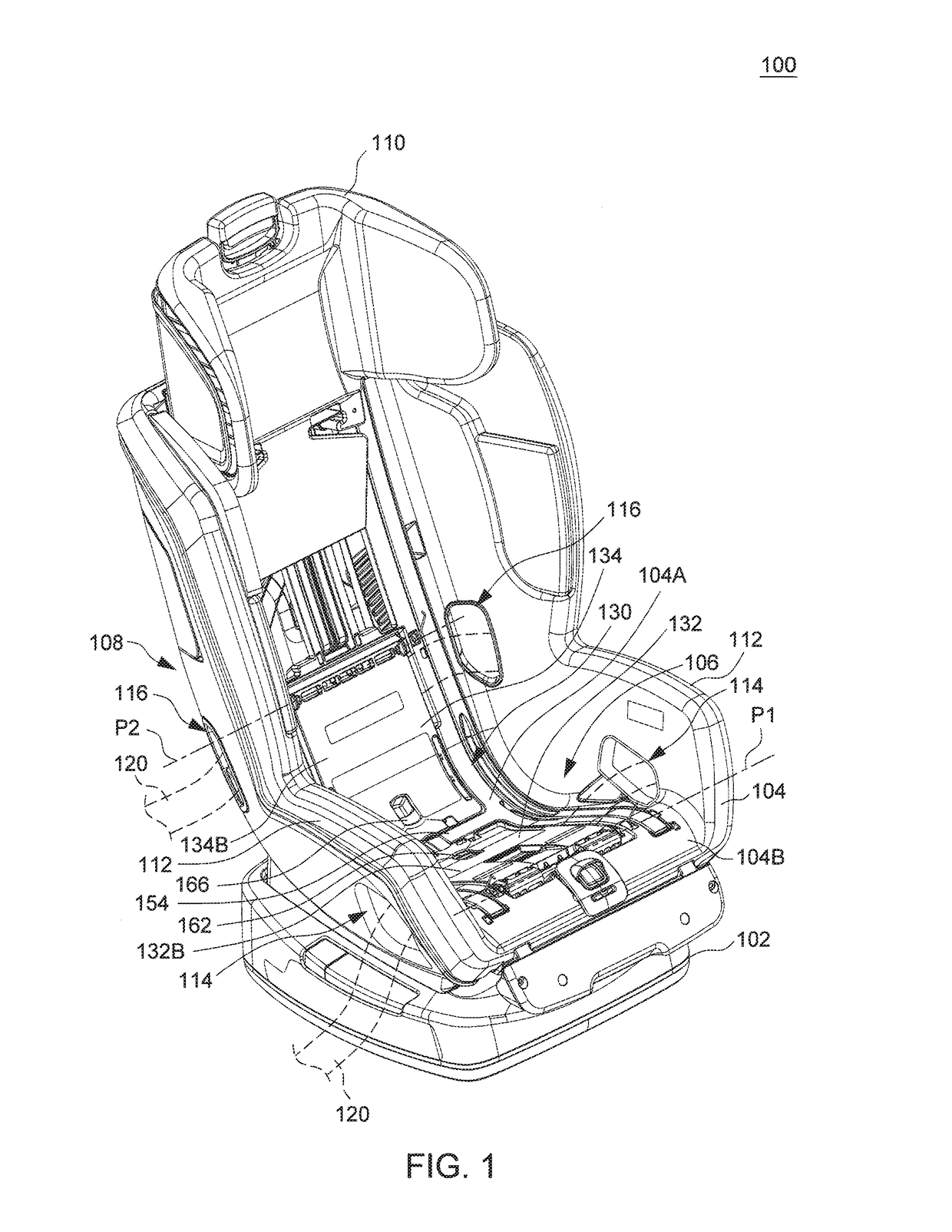

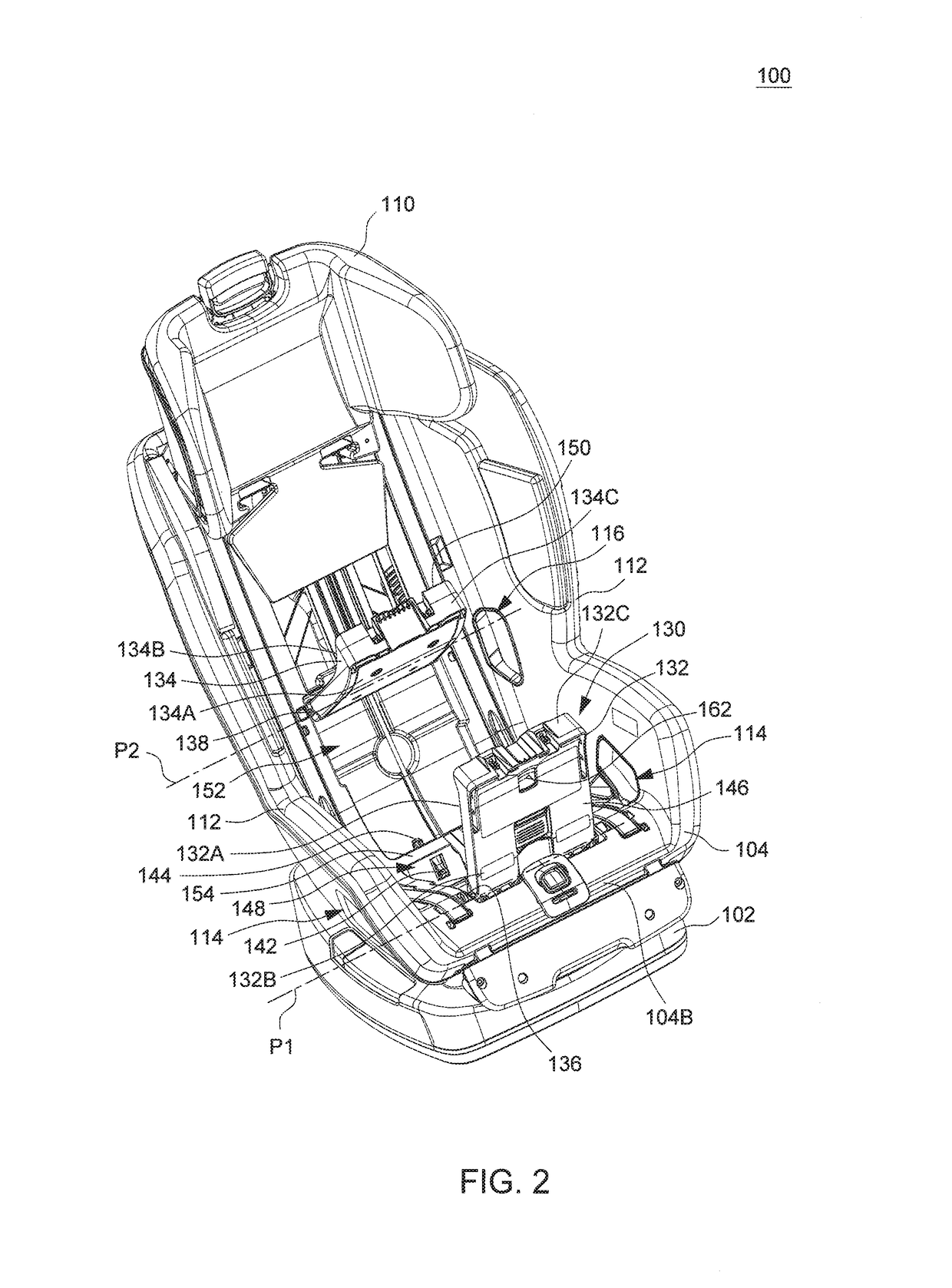

Child safety seat

ActiveUS9937823B2Easy to operateFacilitates installation and removalKids chairsChild seatsEngineeringMechanical engineering

A child safety seat includes a seat shell, and a first and a second belt restraining member respectively connected with the seat shell. The seat shell has a shell surface, and a first and a second opening for selective passage of an anchoring belt to attach the child safety seat on a vehicle seat in two different configurations, which include a rearward and a forward facing configuration. The first belt restraining member is independently operable to press against an anchoring belt passing through the first opening, and the second belt restraining member is independently operable to press against an anchoring belt passing through the second opening.

Owner:WONDERLAND SWITZERLAND AG

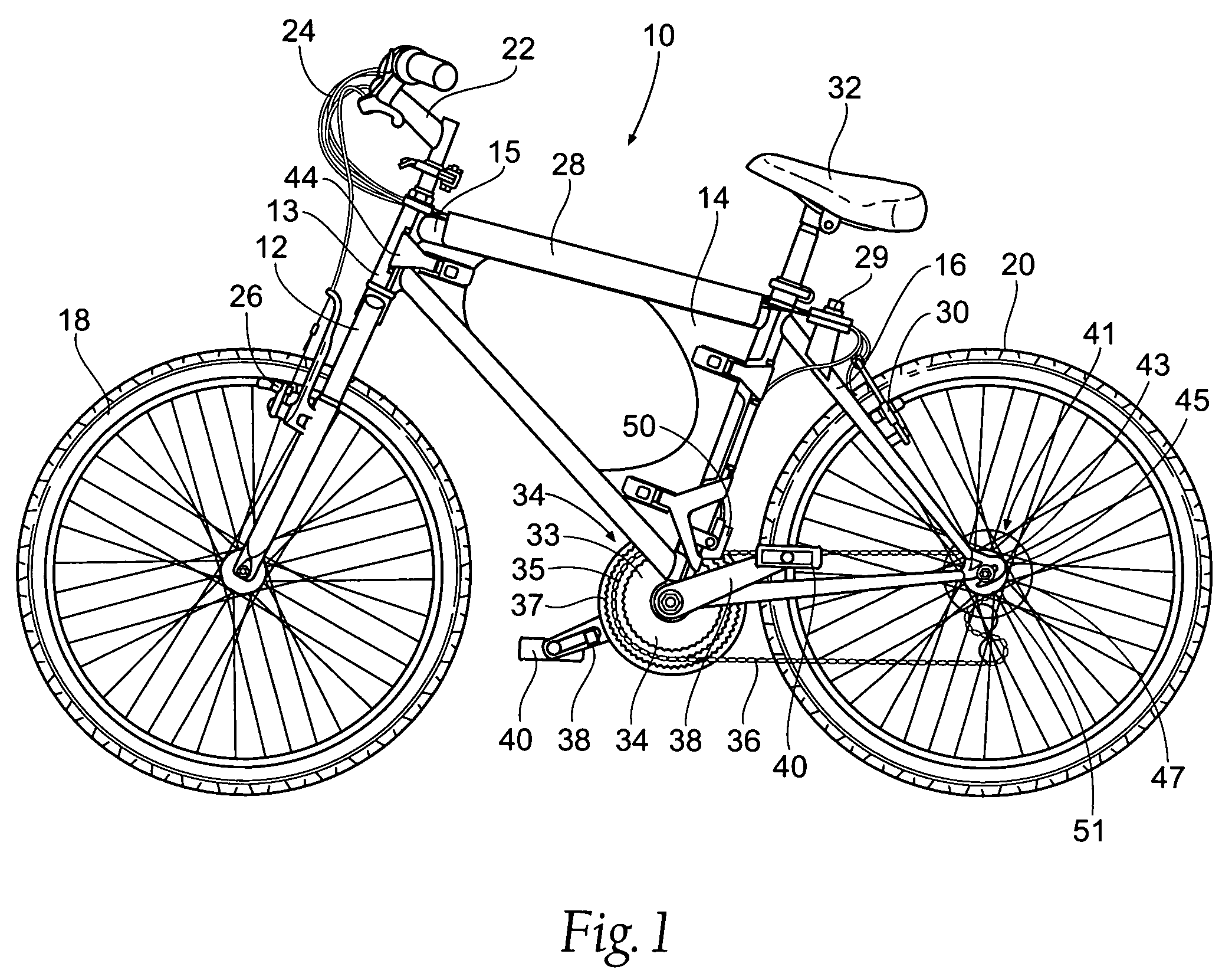

Split bottom bracket

InactiveUS7762571B2Improve versatilityCompromising strengthPassenger cyclesWheel based transmissionVehicle frameEngineering

A bottom bracket assembly for use on a bicycle, the assembly provided as a split bracket assembly with an upper portion formed integrally with the bicycle frame and a lower portion detachably connectable to the upper portion, the lower portion completely removable from the upper portion. The bottom bracket assembly provided to capture a crank shaft therein with associated bearings to facilitate the rotation of the crank shaft assembly.

Owner:CANNONDALE BICYCLE CORPORATION

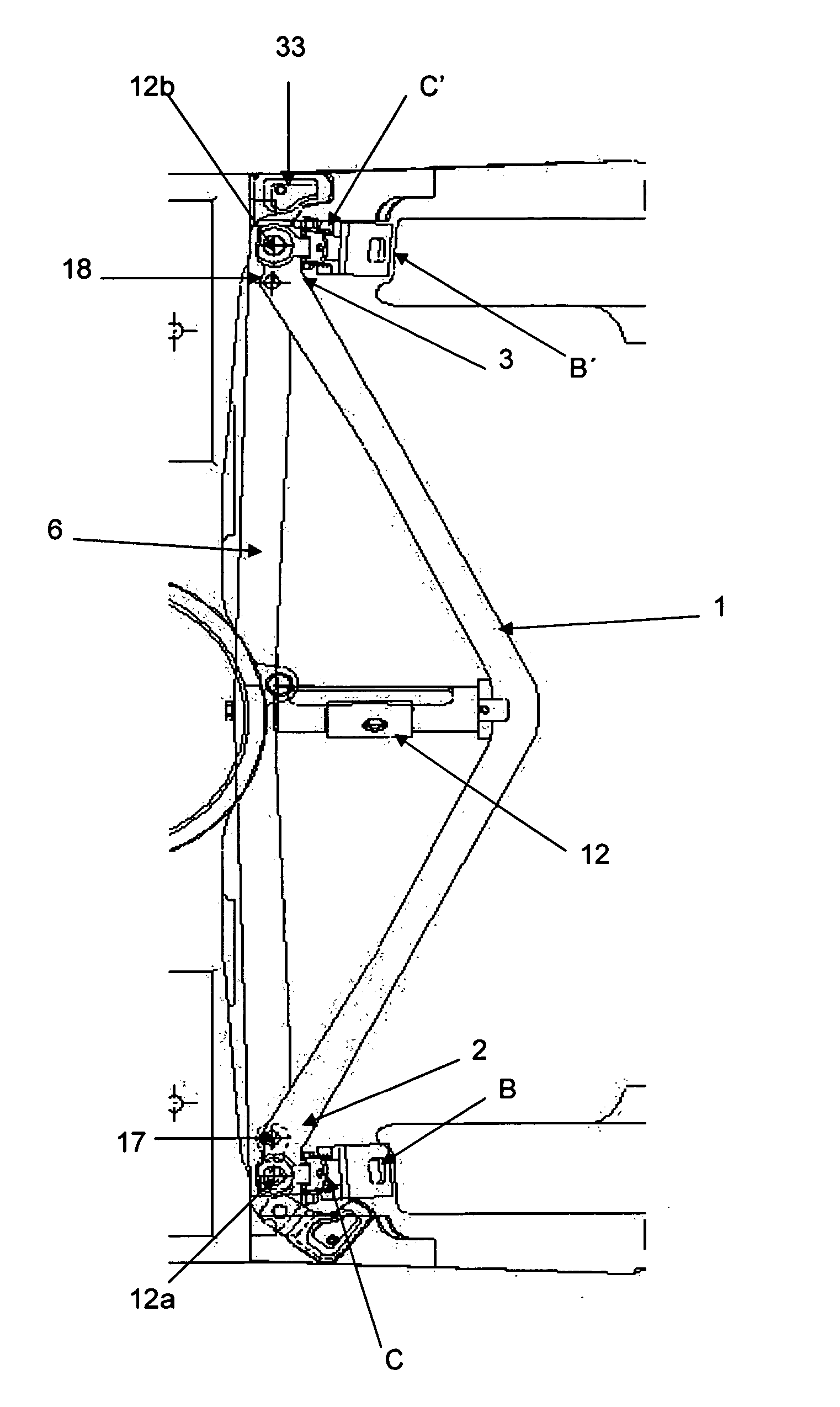

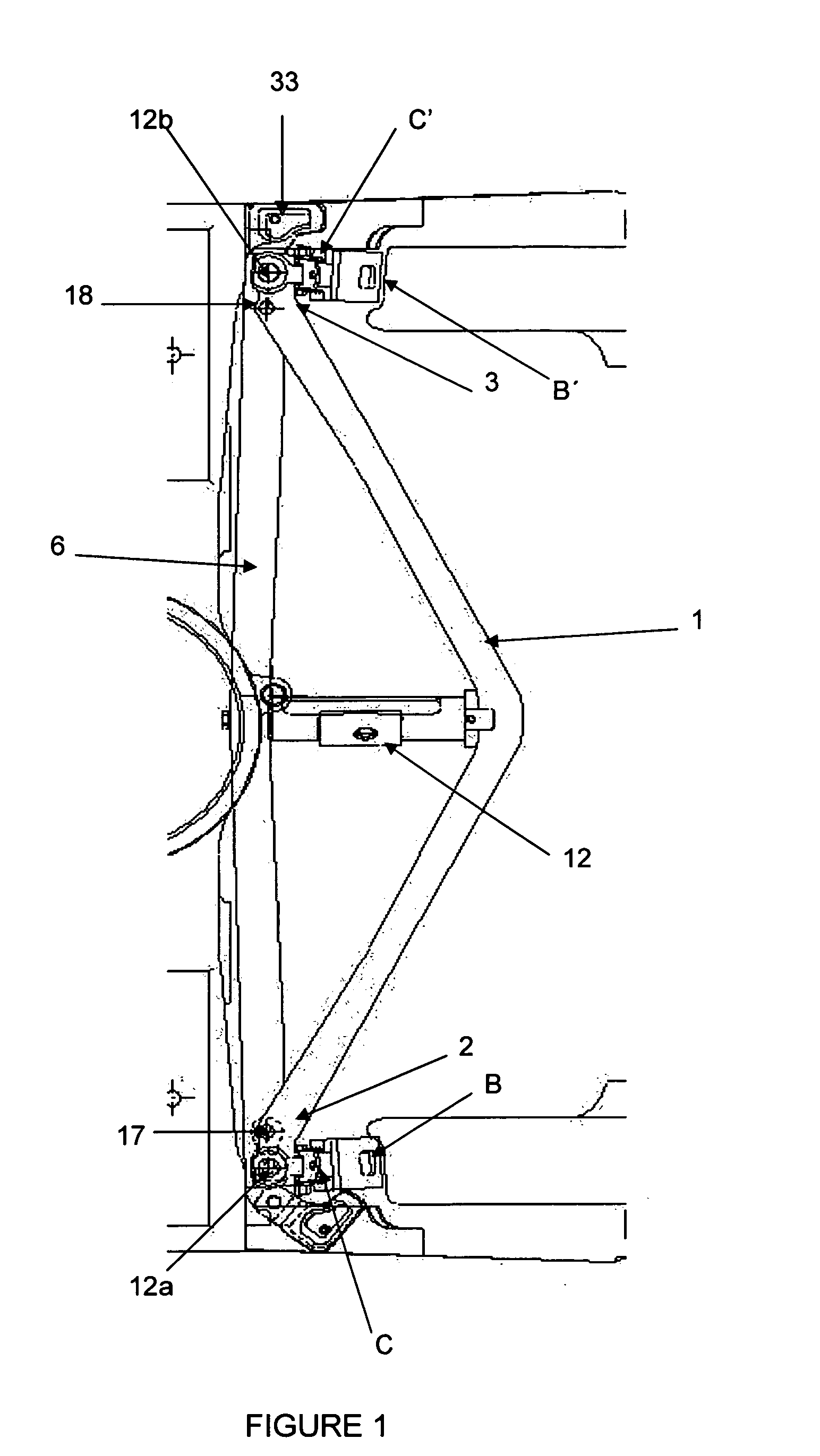

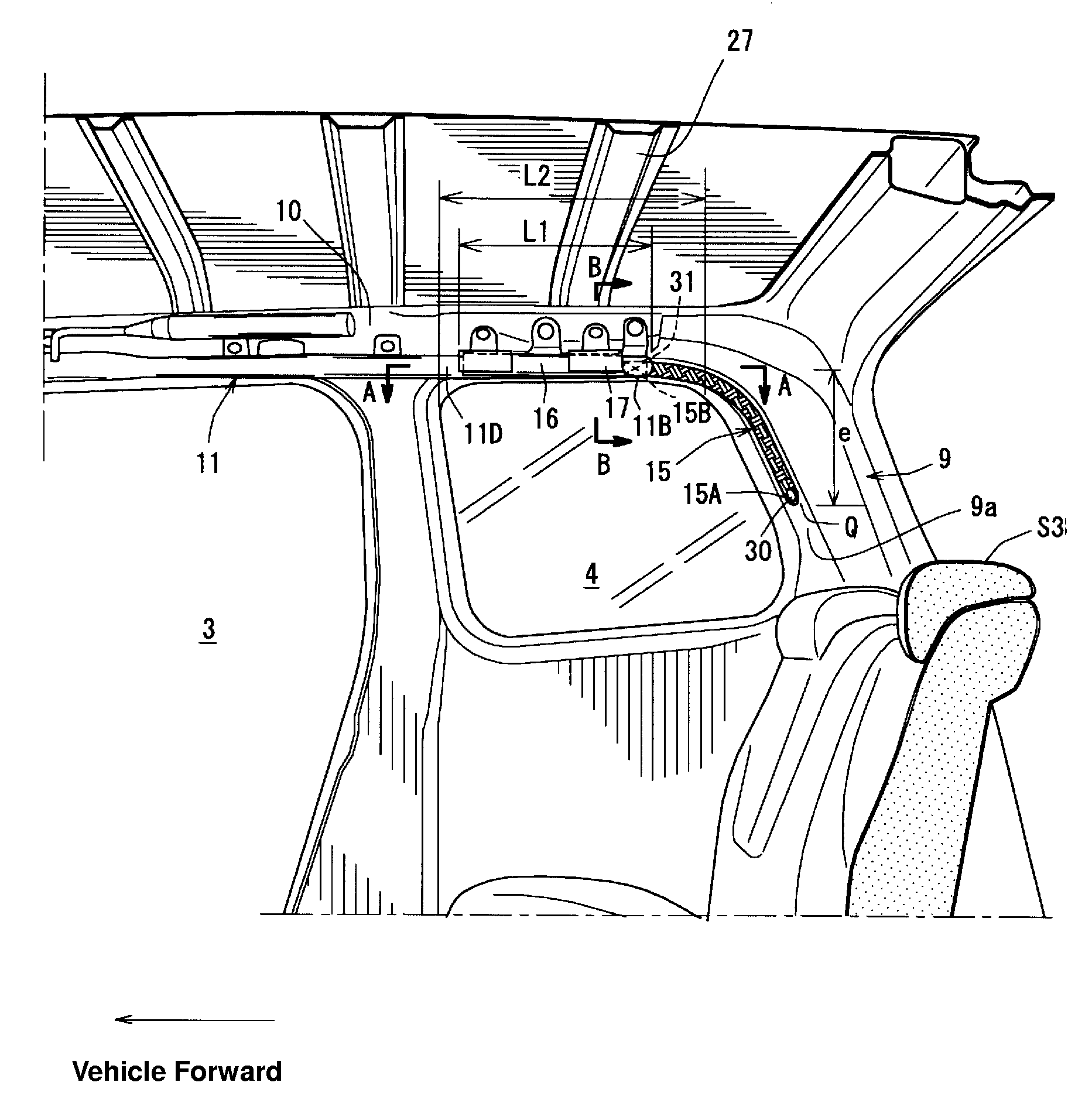

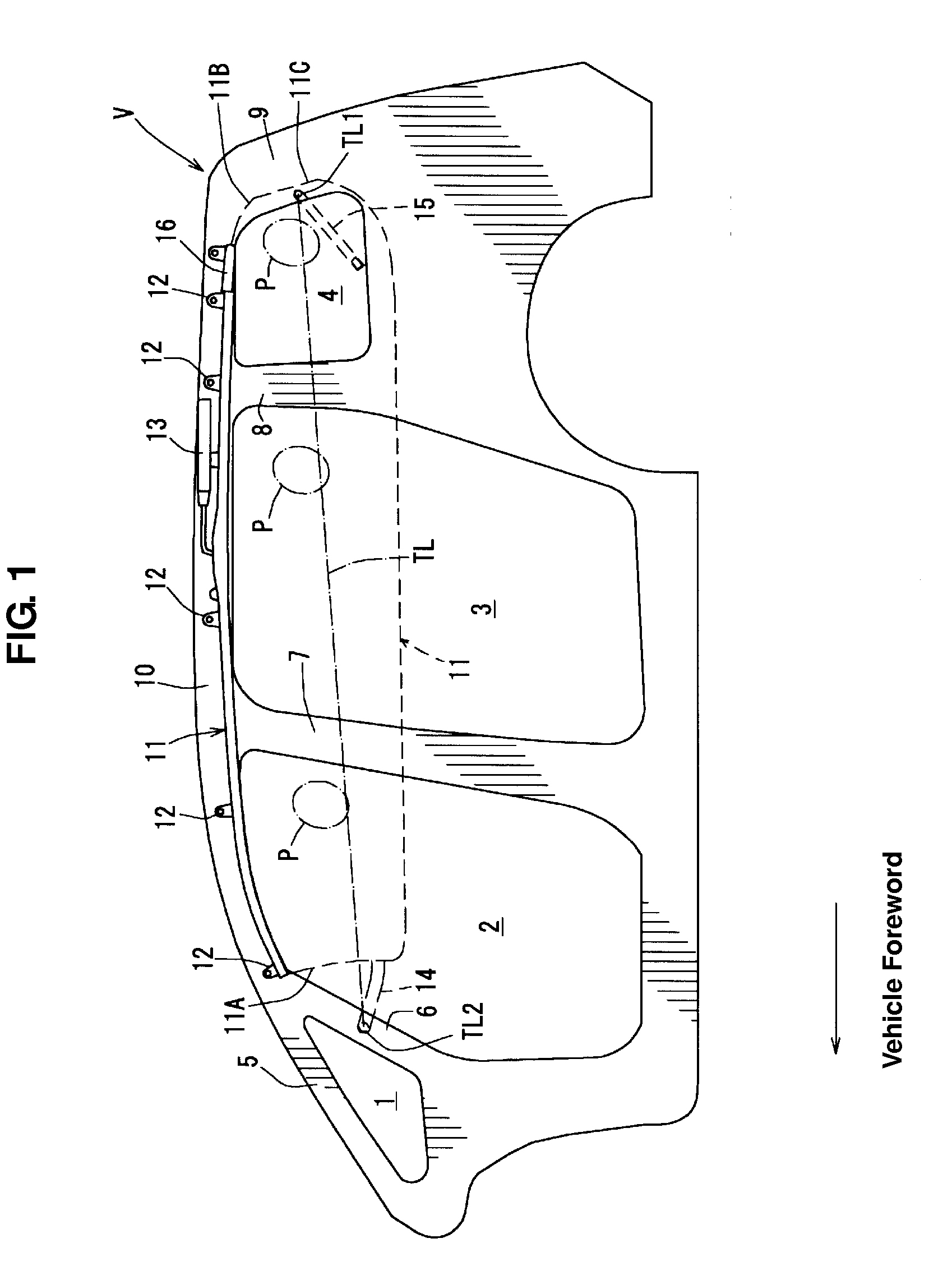

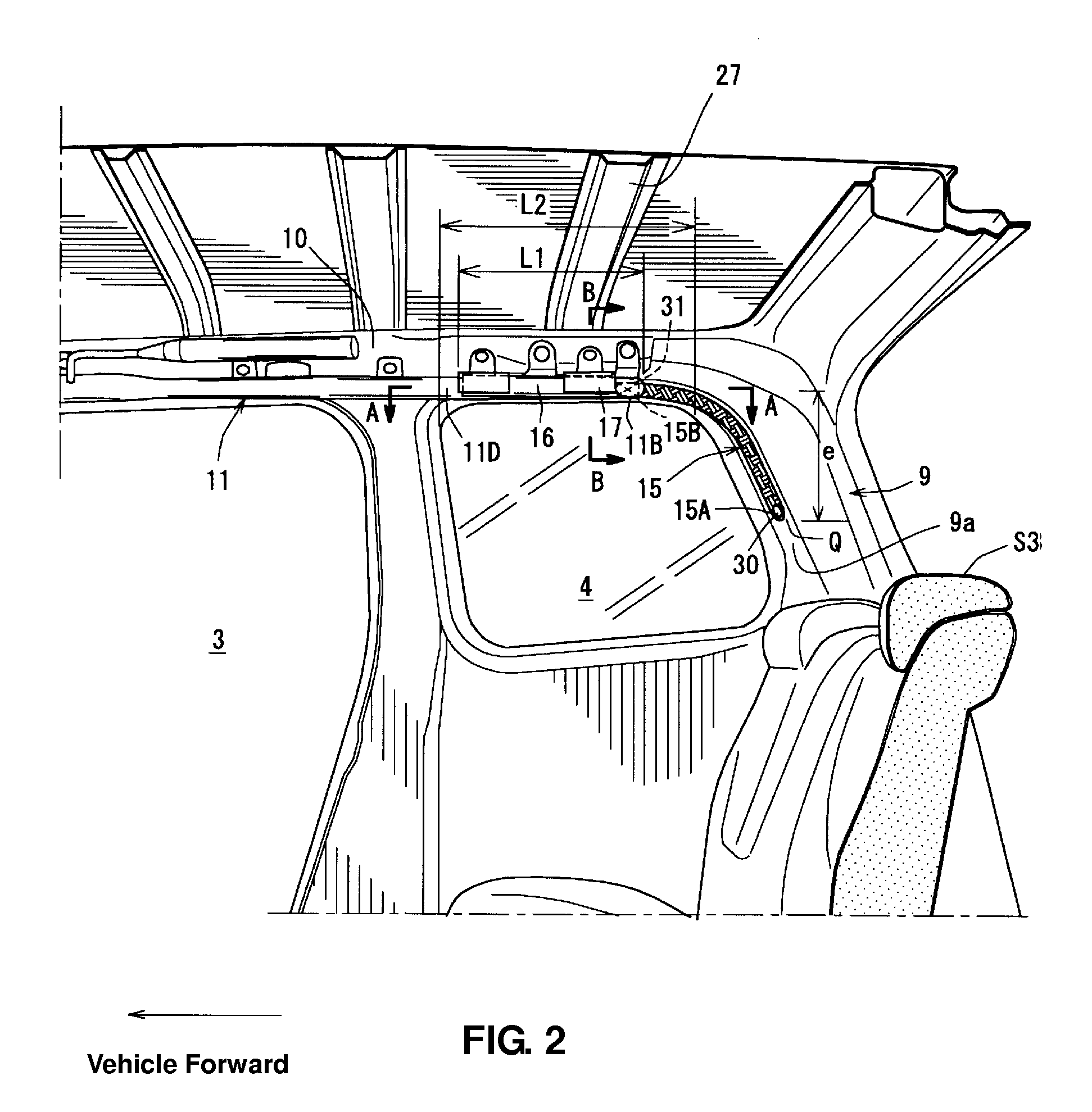

Interior structure of vehicle equipped with curtain airbag

InactiveUS20100032928A1Precise tensionPedestrian/occupant safety arrangementVehicle safety beltsTension linesAirbag

Owner:MAZDA MOTOR

Welding wire spool and drive cartridge

InactiveUS20060157461A1Changed out quickly and easilyFast and efficientElectrode supporting devicesEngineeringHousing design

A modular welding wire cartridge for use in a welding system. The welding wire cartridge is designed to be detachably connected to the welding wire feed system of the welding system. The welding wire cartridge includes a drive housing designed to be detachably connectable to the welding wire feed system, a wire contact arrangement designed to controllably feed welding wire through the welding wire cartridge, and a spool of welding wire.

Owner:LINCOLN GLOBAL INC

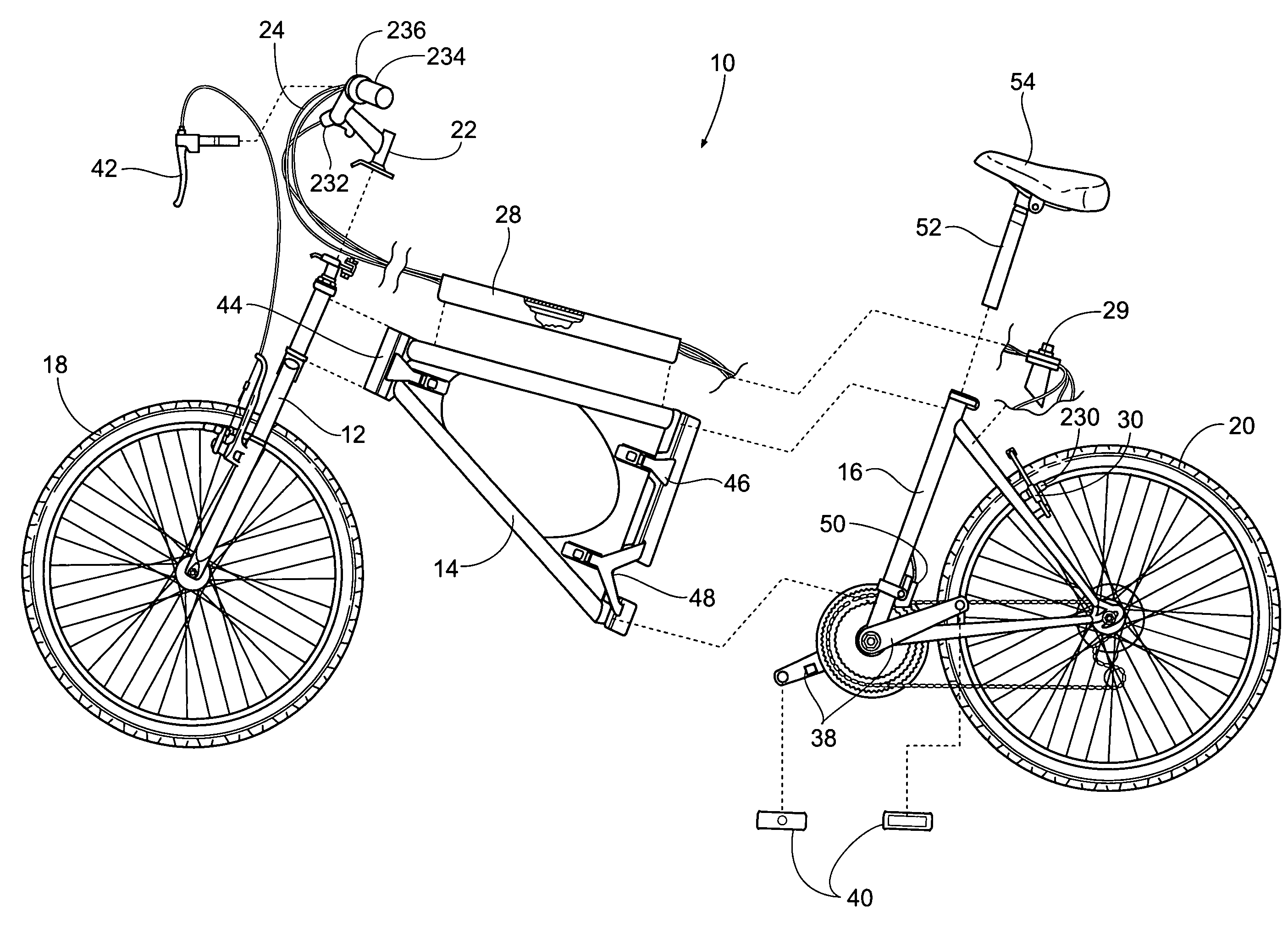

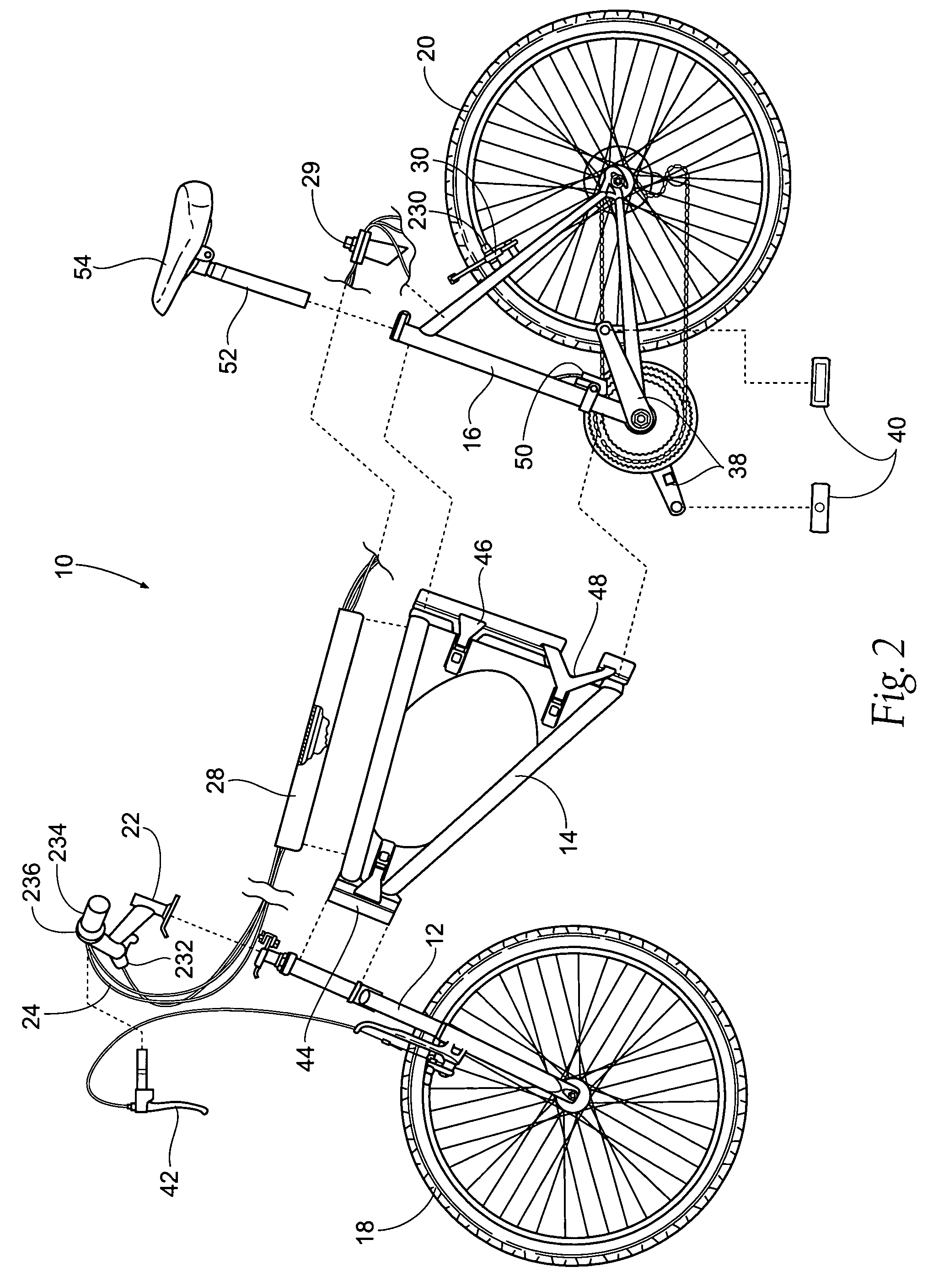

Sectional bicycle

InactiveUS7578515B2Easy to disassembleEasy to reassemblePassenger cyclesWheel based transmissionEngineeringMechanical engineering

A modular bicycle comprising a first section having a front frame section and a first tire, a second section being couplable to the first section and comprising a central frame, and a third section being couplable to the second section and the first section, with the third section comprising a rear frame section, a second tire, and a handle bar. The bicycle also comprises pedals that are removably securable to the crank arms of the bicycle.The pedals comprise a foot rest, a base section secured to the foot rest, and a locking member pivotally connected to the base section. The locking member is insertable into a through bore located on the crank arm and is pivotally rotatable towards the crank arm, thereby securing the pedal to the crank arm.

Owner:APPLEMAN HARRY

Automatic plate-feeding device of printer

ActiveCN102180000ASimple structureReduce manufacturing costPrinting press partsCamMechanical engineering

The invention discloses an automatic plate-feeding device of a printer. The device comprises a plate cylinder, a central shaft, a bearing plate, a plate supporting roller, a plate tail clamp bar and a plate head clamp bar, wherein cam shafts are arranged on the plate tail clamp bar and the plate head clamp bar respectively; a pressing plate is arranged opposite to the plate tail clamp bar and theplate head clamp bar; the device also comprises a plate tail tensioning device and a pneumatic control device; the pneumatic control device comprises a rotary pneumatic device and a telescopic pneumatic device; a plate tail tensioning pushing swing rod and a plate tail tensioning transmission swing rod are sleeved on a plate tail tensioning swing rod shaft; a transmission tooth is arranged on a driving swing rod; the transmission tooth on the driving swing rod is in engaged transmission with a plate tail tensioning swing rod driving shaft; a rotary cylinder is arranged outside the bearing plate; a rotary cylinder driving swing rod is in engaged transmission with a transmission gear of a telescopic cylinder; the telescopic cylinder is fixed outside the bearing plate; and transmission grooves are formed at end parts of a gear shaft respectively. The automatic plate-feeding device of the printer has the advantages of simple structure, accurate tensity of a printing plate, simple transmission process, high working efficiency, low manufacturing cost and application to printing houses of all scales.

Owner:河北万杰机械科技股份有限公司

Bioabsorbable band system

InactiveUS7648504B2Precise tensionLocking is particularly safeSuture equipmentsInternal osteosythesisEngineeringOsteotomy

Owner:BIORETEC

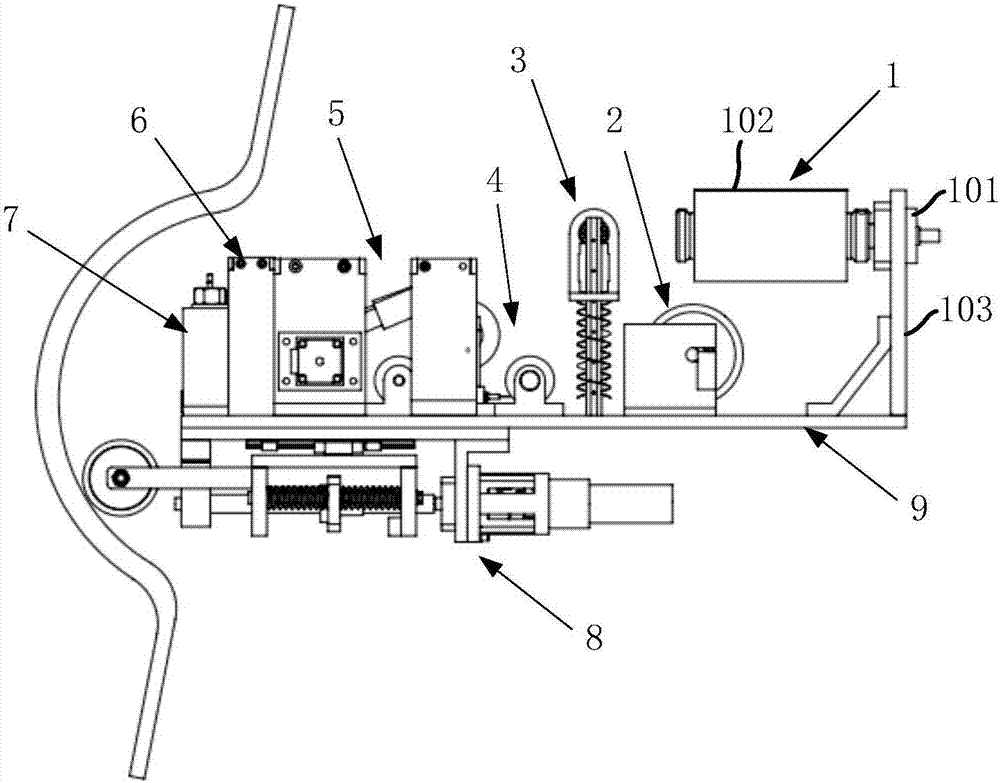

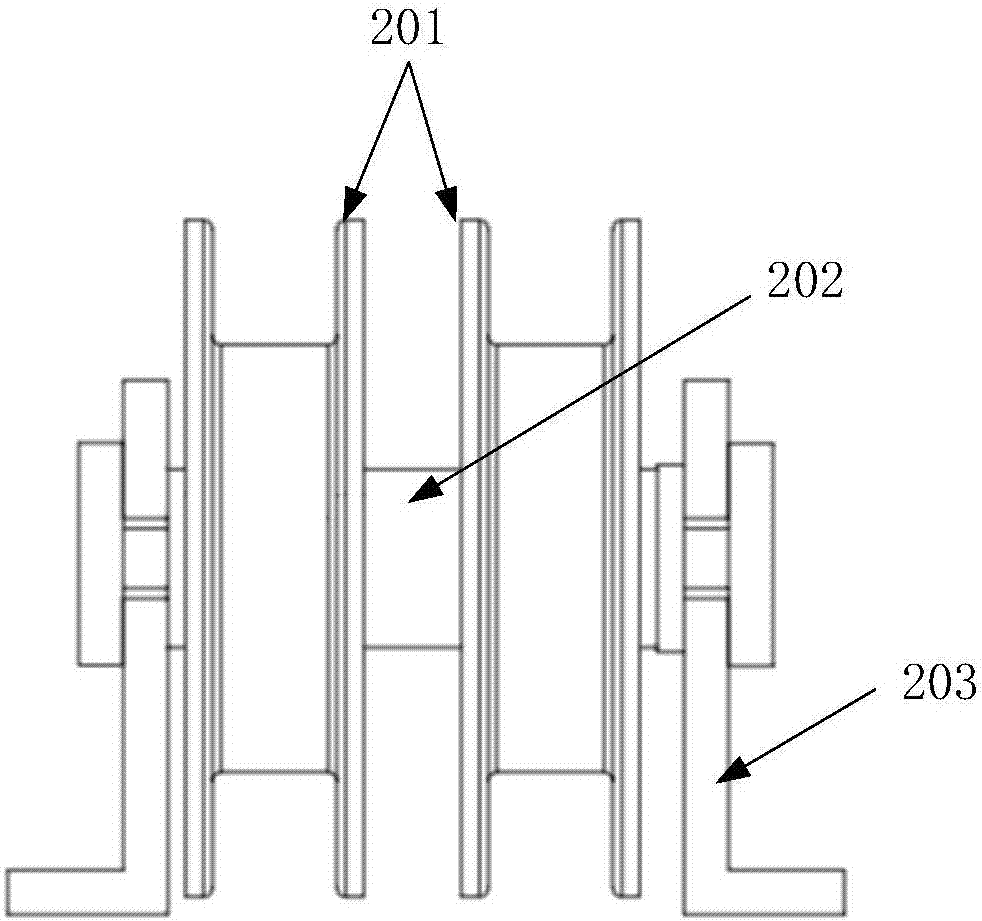

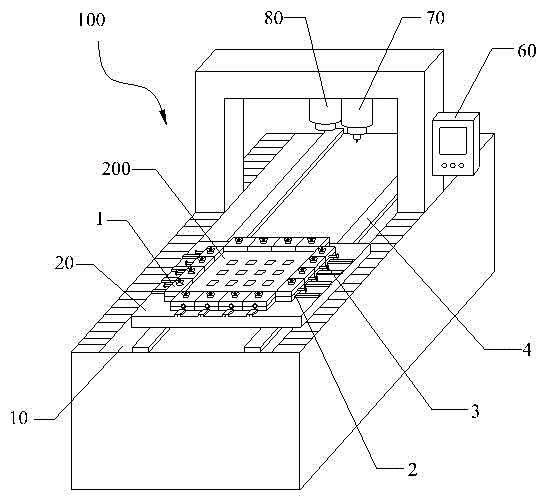

Carbon fiber integrated laying device

The invention discloses a carbon fiber integrated laying device. The device comprises a material supply unwinding mechanism, a guide mechanism, a tension adjusting mechanism, a tension measuring mechanism, a re-feeding mechanism, a clamping mechanism, a shear mechanism and a compaction mechanism located below the bottom plate, wherein the material supply unwinding mechanism, the guide mechanism, the tension adjusting mechanism, the tension measuring mechanism, the re-feeding mechanism, the clamping mechanism and the shear mechanism are located above the bottom plate. Fibers on the material supply unwinding mechanism pass through the re-feeding mechanism, the clamping mechanism and the shear mechanism and then are compacted and cured on the surface of a mold through the compaction mechanism, in the above transmission process, guidance through the guide mechanism is achieved, the fiber bundle tension is adjusted passively through the tension adjusting mechanism, and the fiber bundle tension is measured through the tension measuring mechanism. Through elastic force effect of a spring, the distance between a compaction roller of the compaction mechanism and the surface of the mold can be passively adjusted, and therefore the device can meet the mold laying requirements of different curve faces and control requirements of a monofilament bundle.

Owner:BEIHANG UNIV

Electric power steering apparatus

InactiveUS20050192143A1Reduce vibrationReduce noiseGearingGearing controlElectric power steeringPulley

An electric power steering apparatus comprises a speed reducing mechanism for decelerating the rotation of a rotatable shaft in an electric motor and a converting mechanism for converting the output rotation of the speed reducing mechanism into the axial movement of a steering shaft extending toward the right and left sides of a vehicle. The speed reducing mechanism comprises an input pulley driven by the electric motor, an output pulley arranged with the steering shaft enclosed thereby, a belt for connecting the input pulley and the output pulley to each other, and means for adjusting the tension of the belt.

Owner:THE GATES CORP +1

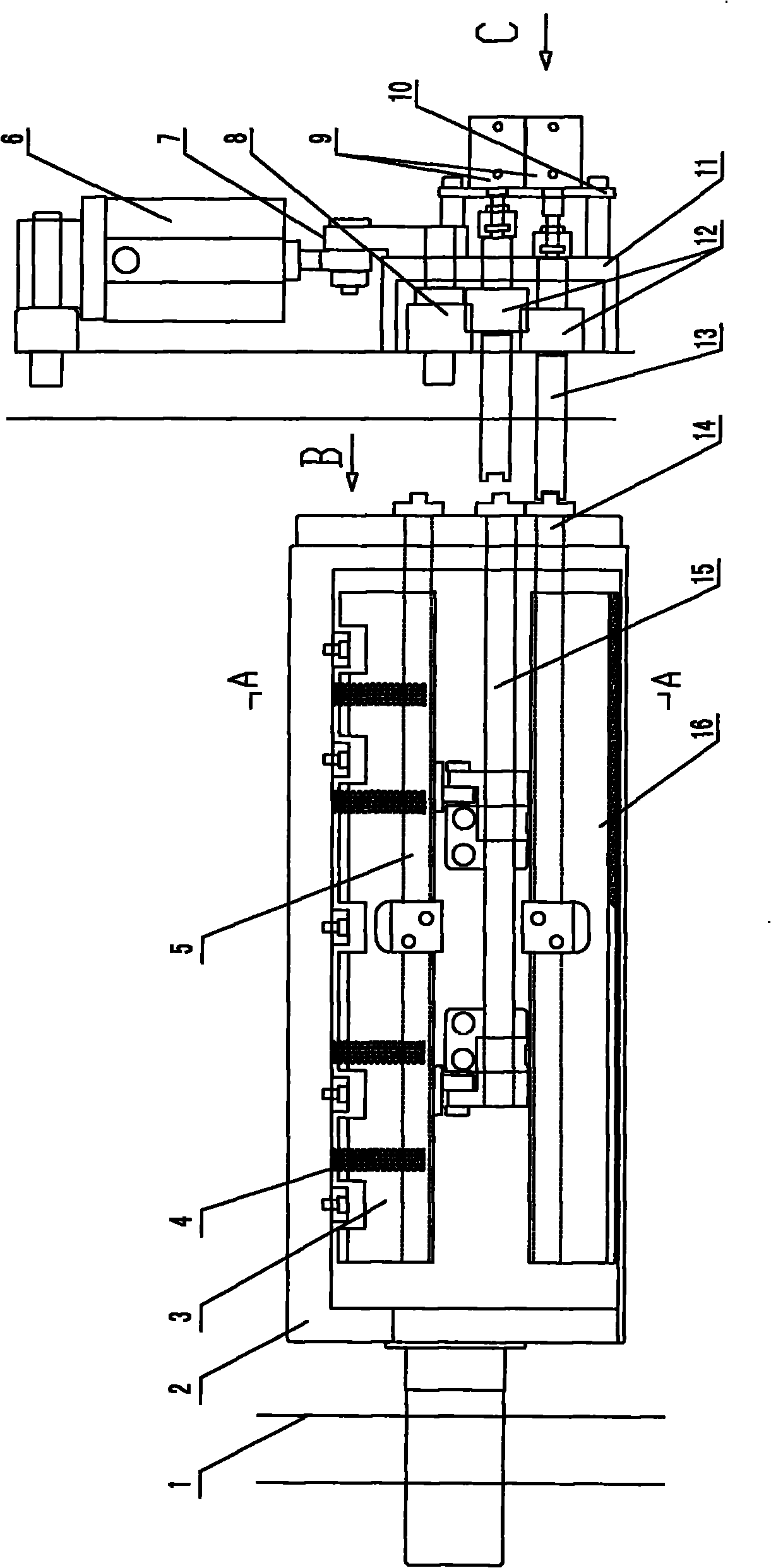

Metal mask plate tensioning machine

InactiveCN103143868AReduce tensionEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLight-emitting diode

The invention relates to a metal mask plate tensioning machine, which comprises a tensioning device, wherein the tensioning device comprises a clamping mechanism used for clamping a metal mask plate, a horizontal adjustment mechanism and a tension adjustment mechanism; the clamping mechanism comprises a plurality of independent clamping sheets suitable for clamping the four edges of the metal mask plate; the horizontal adjustment mechanism is connected with the clamping mechanism and used for roughly adjusting the horizontal tension force of the metal mask plate; and the tension adjustment mechanism is arranged on the clamping mechanism and used for finely adjusting the horizontal tension force of the metal mask plate. According to the metal mask plate tensioning device, the metal mask plate can be accurately fixed and tensioned before being welded to a plate frame and cannot be deformed, so that the welding efficiency of the metal mask plate is effectively improved and the welding precision of the metal mask plate is improved, thereby improving the production quality of OLEDs (organic light emitting diodes).

Owner:南京澄超光电科技有限公司

Fabricating apparatus and method for secondary battery

ActiveUS20160036086A1Exact tensionMaintain tensionAssembling battery machinesFinal product manufactureElectrical batteryEngineering

Provided is a fabricating apparatus for a secondary battery, the fabricating apparatus including: a base material supplier configured to supply a base material; a winder configured to wind the base material through a mandrel; and a controller configured to control a base material supply amount of the base material supplier and a mandrel rotation amount of the winder, wherein the controller is further configured to store a profile of the base material supply amount with respect to the mandrel rotation amount, and to synchronously control the base material supply amount and the mandrel rotation amount based on the profile.

Owner:SAMSUNG SDI CO LTD

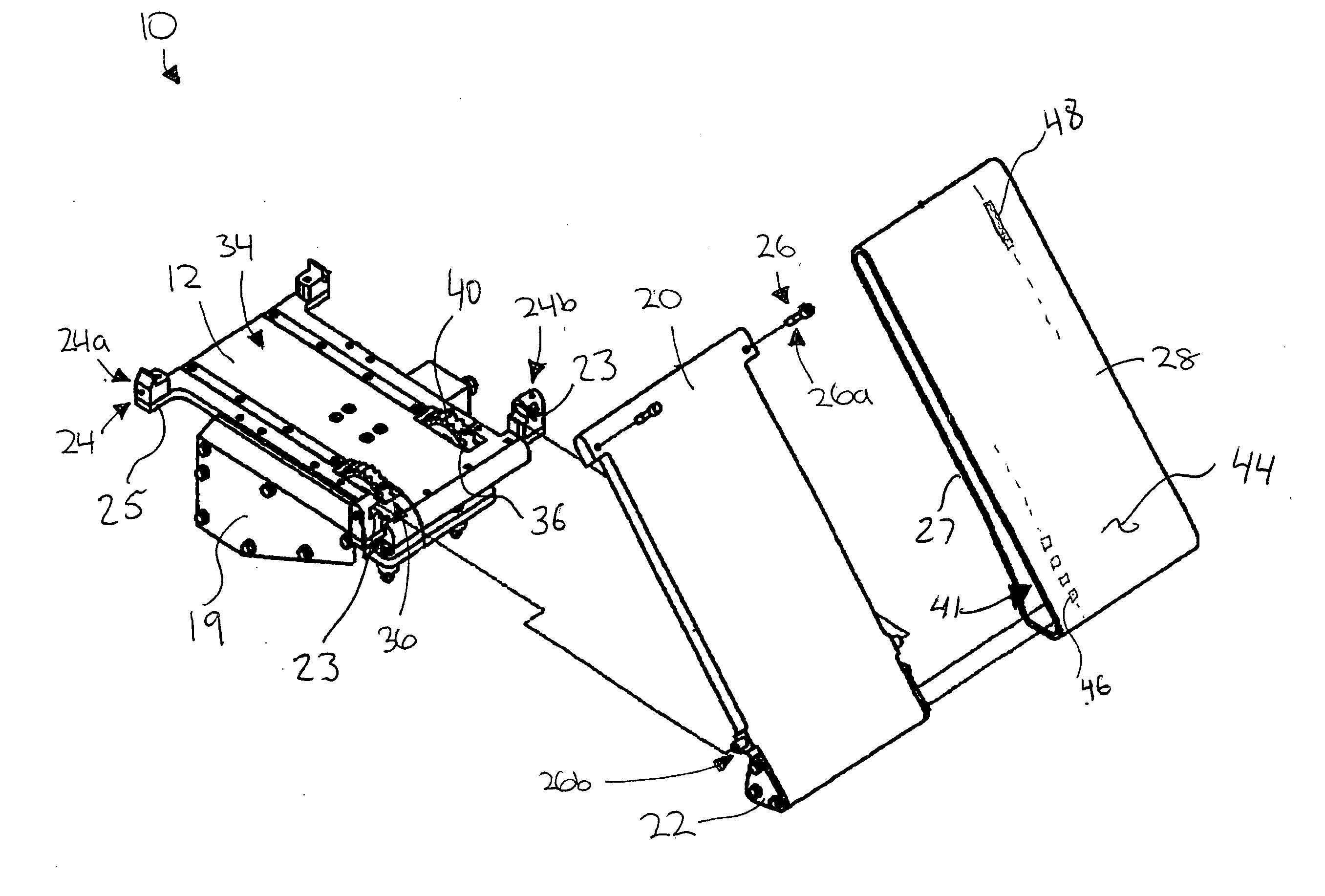

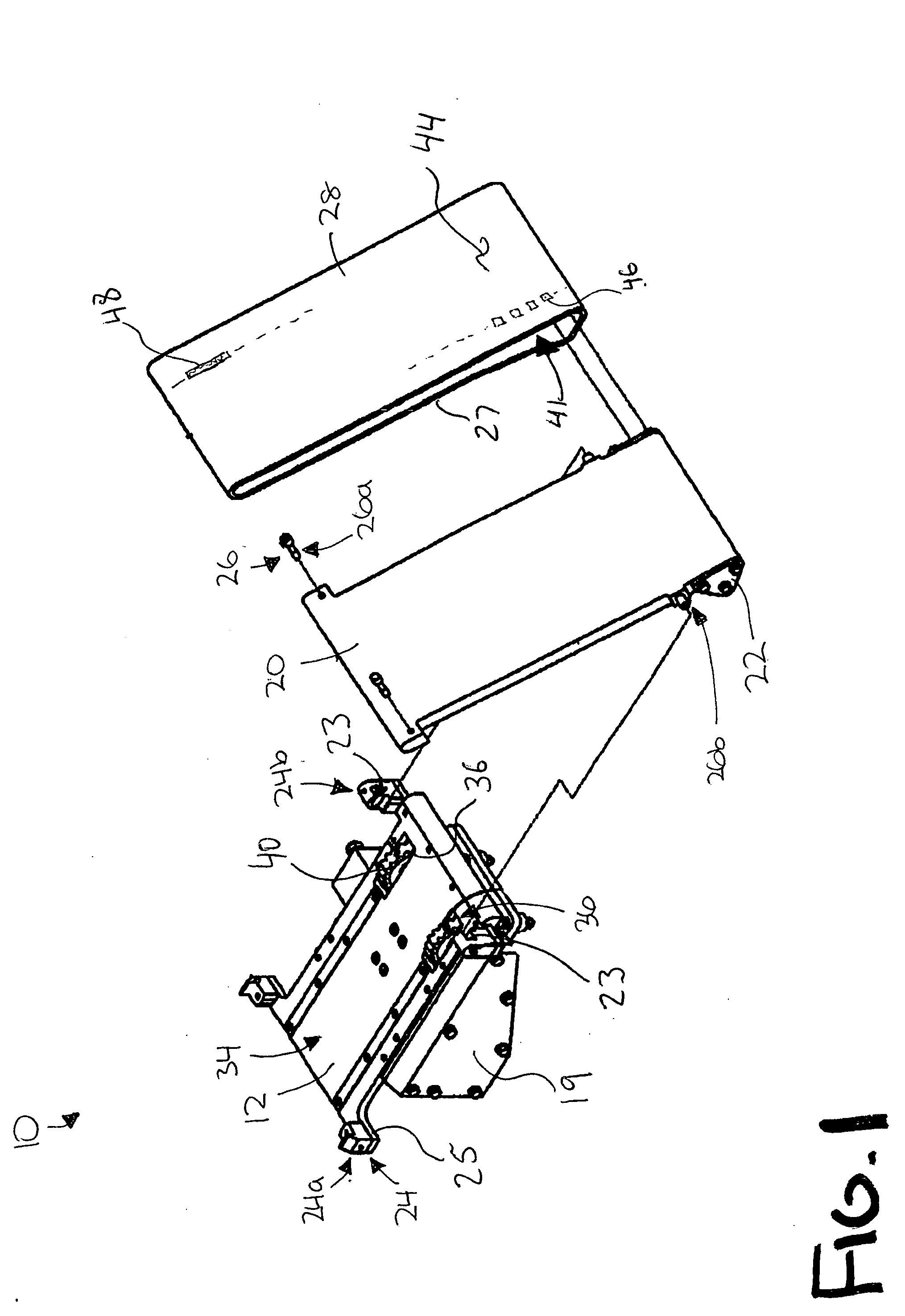

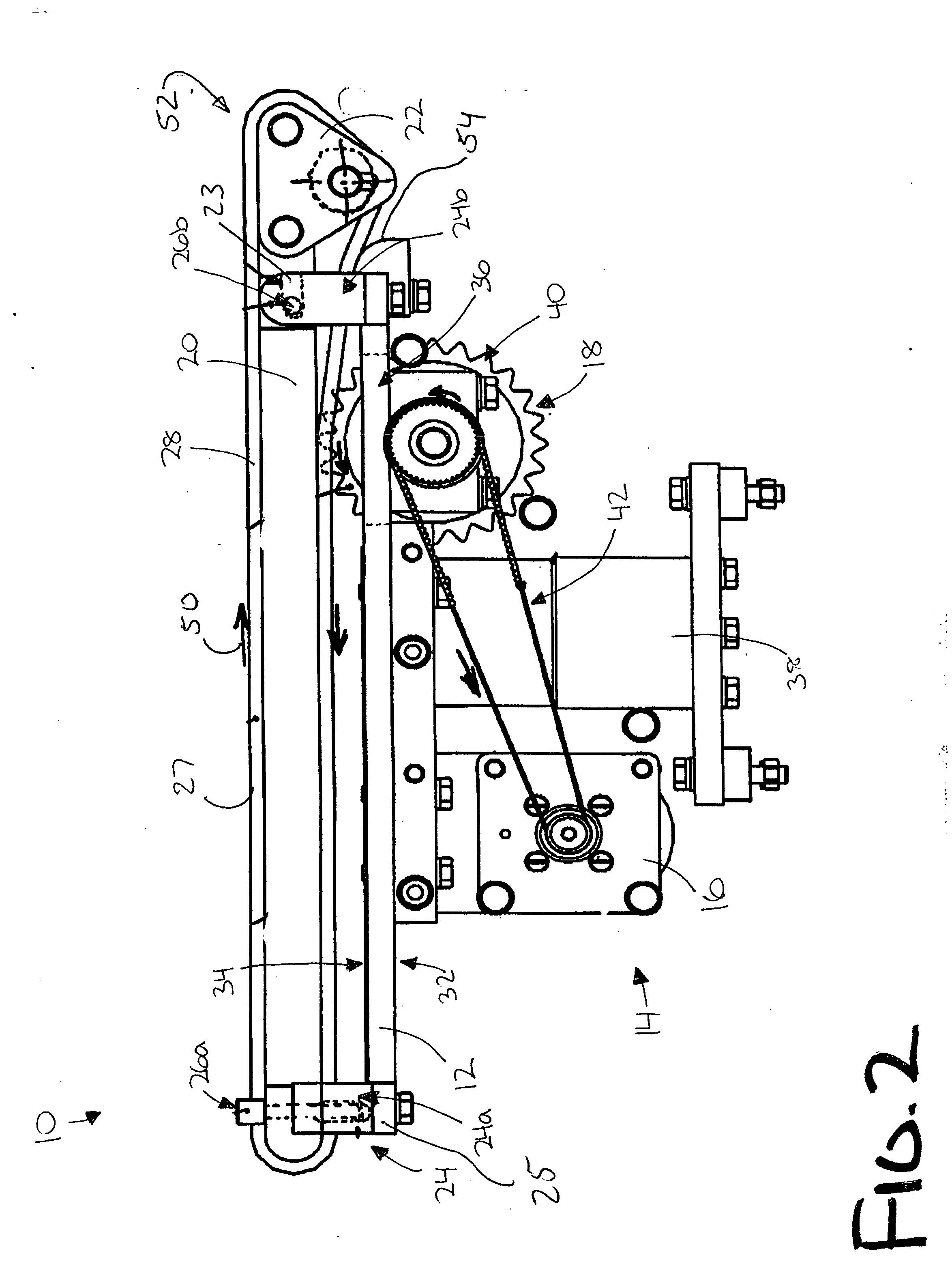

Belt conveyor with external drive

InactiveUS20060252591A1Easy to disassembleMinimal obstructionConveyorsGearingEngineeringDelivery system

A belt conveyor system (10) having a continuous, looping carrier belt (28) entrained around a belt plate (20) which is supported by a frame (12). The belt plate (20) is secured to the frame (12) by securement pins (26a) and pivot pins (26b). The carrier belt (28) is driven externally rather than internally and is tensioned with minimal obstruction to removing the belt (28), which thereby facilitates disassembly of the system (10), particularly frequent removal, cleaning, and replacement of the belt (28) as may be necessary or desirable in, for example, the food processing industry. More specifically, the drive mechanism (14) is located substantially completely outside of and adjacent to the internal area (41) defined by the looping belt (28), and the tensioning mechanism (22) is low profile presenting minimal to no obstruction when removing the belt (28) from the belt plate (20).

Owner:JOHNSON FOOD EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com