Automatic plate-feeding device of printer

A technology of a printing press and a pneumatic device, which is applied in the field of automatic plate loading devices of printing presses, can solve the problems of complex structure, high production cost, and reduce the accuracy of tensioning degree, and achieves simple transmission process, low production cost, and high tensioning degree. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

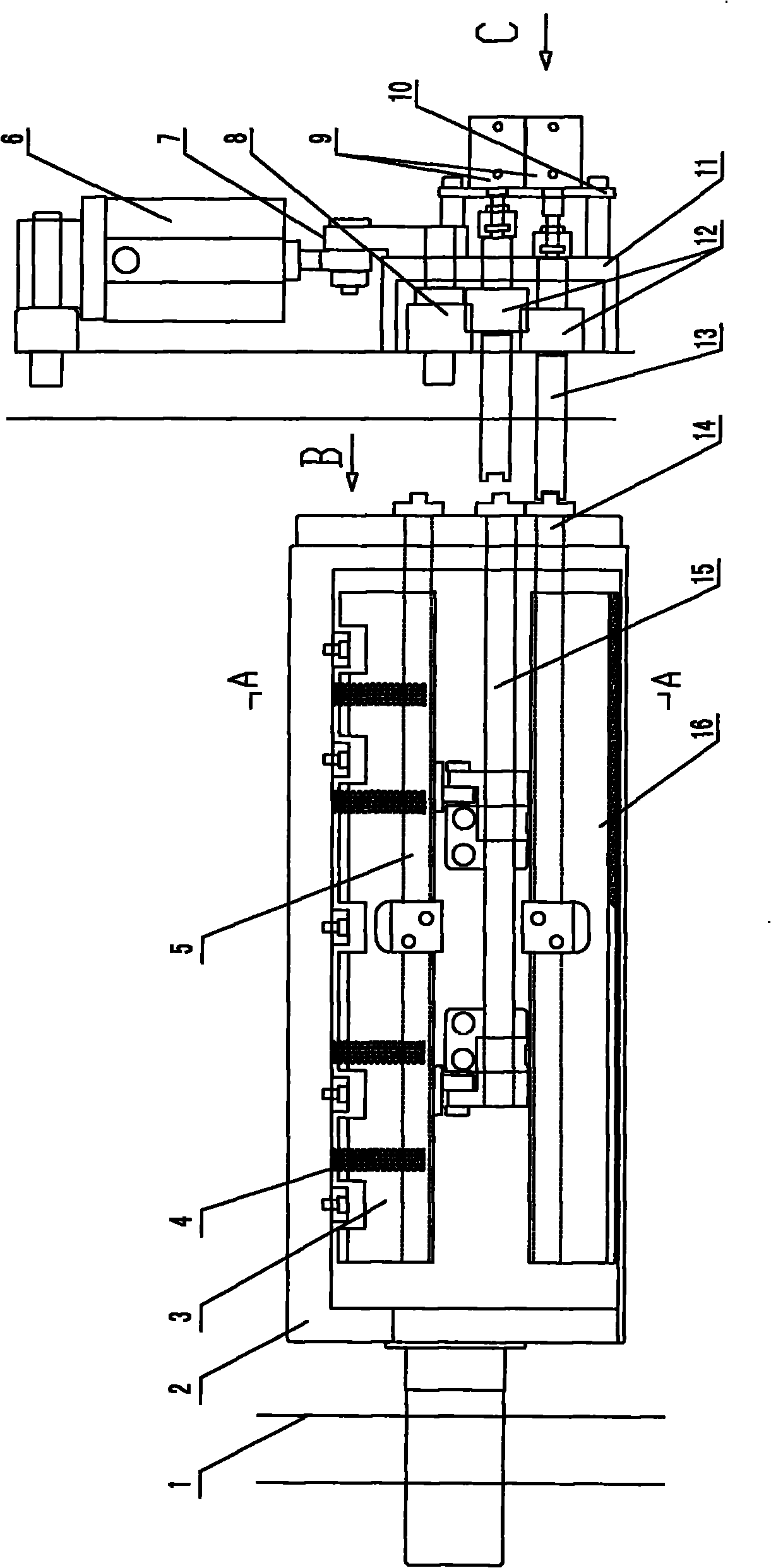

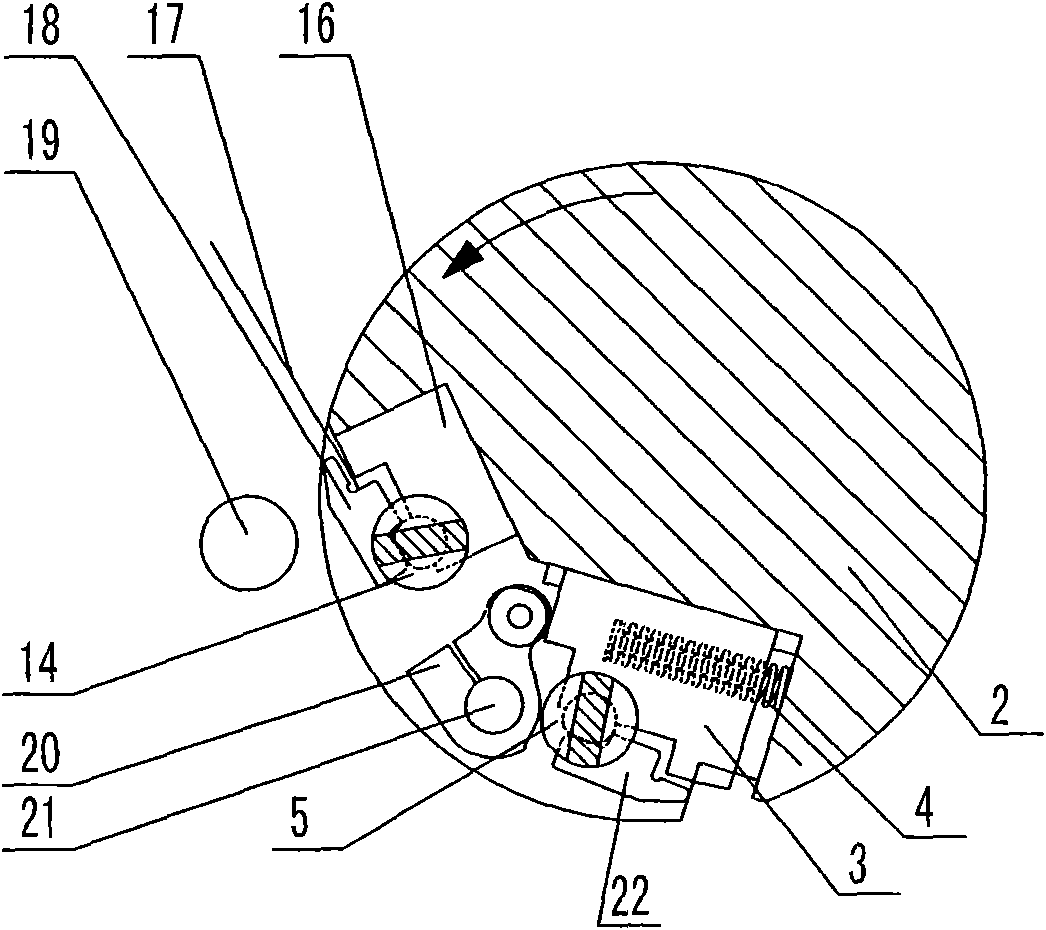

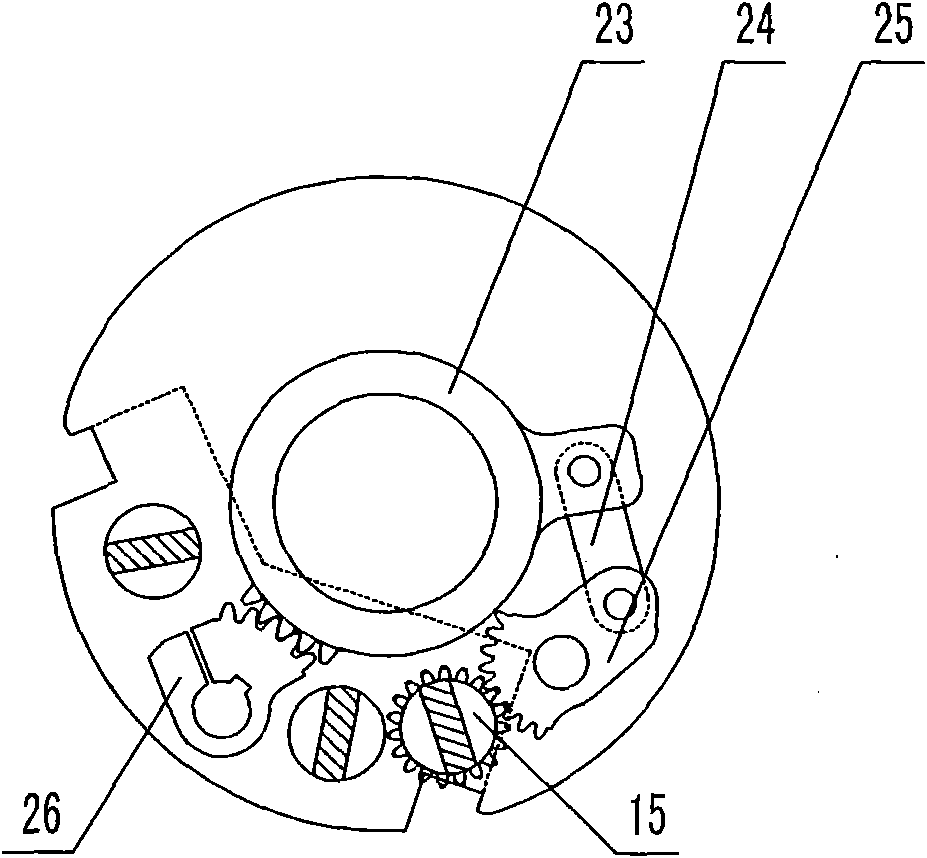

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] See attached Figure 1-4 , what is disclosed in this embodiment is a plate loading device that utilizes the propulsion and contraction of the cylinder to clamp and loosen the printing plate.

[0019] The automatic plate loading device of this printing press includes a plate cylinder 2, a central axis of the plate cylinder 2, and a support plate 1 arranged at both ends of the plate cylinder 2 for supporting the plate cylinder 2, and one side of the plate cylinder 2 The support plate 1 is also provided with a supporting plate roller 19, and the groove on the plate roller 2 is fixedly connected with the plate tail plate clamp 3 and the plate head plate clamp 16, and the plate tail plate clamp 3 and the plate head plate clamp 16 are both Camshafts are provided, that is, the camshaft 5 for the tail clamp and the camshaft 14 for the front clamp. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com