Method and device for manufacturing special inorganic thermal insulation felt

A technology of inorganic thermal insulation and thermal insulation felt, which is applied in the direction of processing textile material equipment configuration, spraying/spraying textile material treatment, etc. It can solve the problems of poor uniformity of finished thermal insulation felt, backward production equipment, and difficult performance guarantee, and achieve uniform thickness and surface The effect of smoothness and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

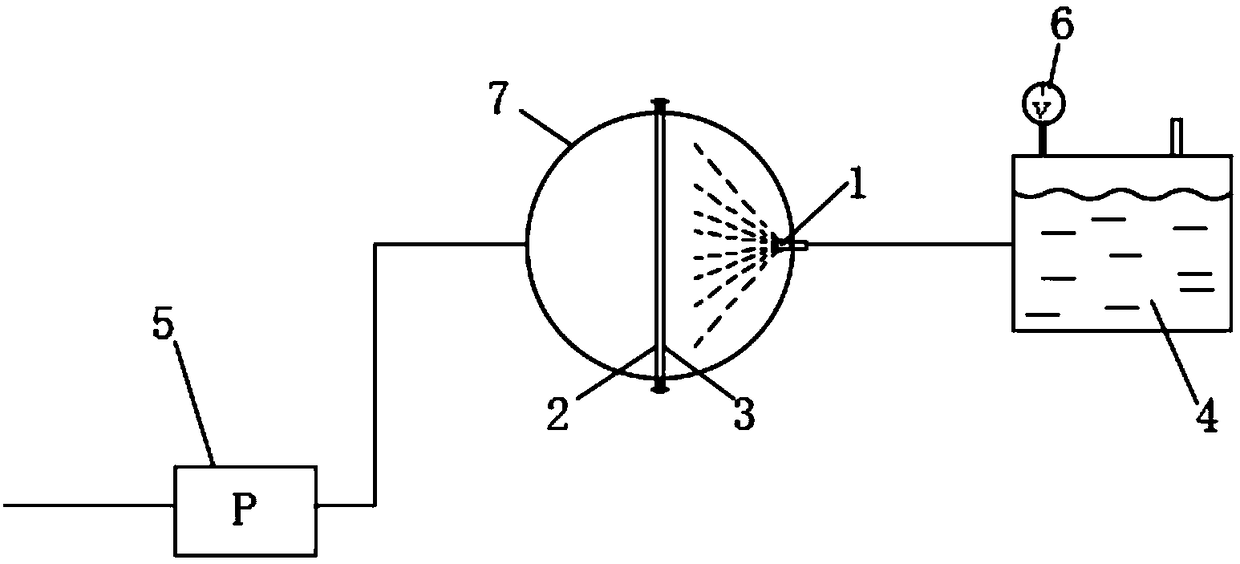

[0022] refer to figure 1 , The device for manufacturing flat-type special inorganic thermal insulation blanket, including nozzle 1, filter screen 2, shell 7, pressure vessel 4 and vacuum device 5. A pressure display device 6 is provided on the pressure vessel 4, and in this embodiment the pressure display device 6 is a pressure sensor for detecting the pressure in the pressure vessel. The shell 7 is spherical and consists of a hemispherical upper shell and a lower shell. A filter screen 2 is interposed between the upper and lower shells. The upper shell communicates with the atmosphere, and the cavity formed by the lower shell and the filter screen 2 passes through the pipeline. It communicates with the vacuum device 5, and the spray head 1 is arranged in the upper casing, and the spray head 1 communicates with the pressure vessel 4 through a pipeline. The casing 7 and the nozzle 1 are fixed. Nozzle 1 can be single or multiple.

[0023] When the above-mentioned device is us...

Embodiment approach 2

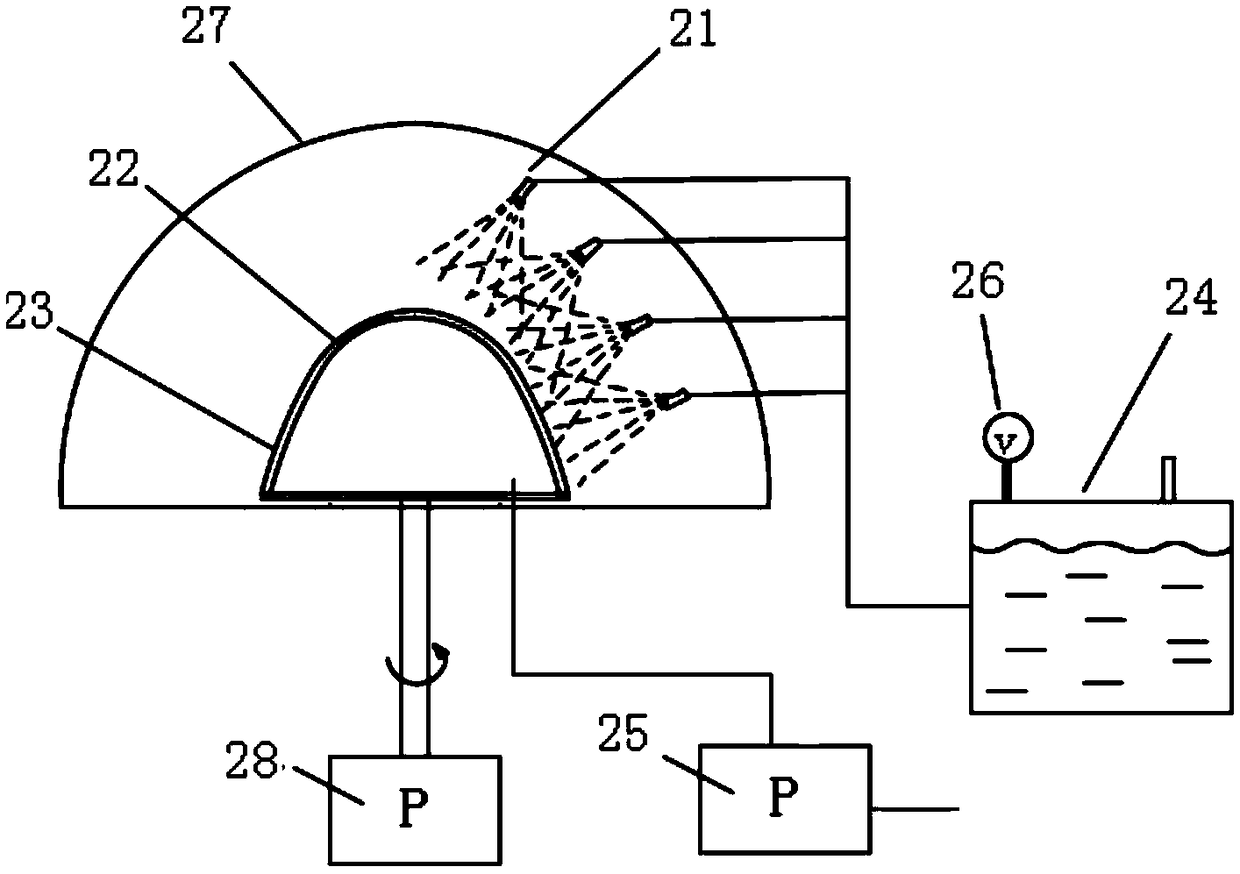

[0027] refer to figure 2 , A device for manufacturing hat-shaped special inorganic thermal insulation felt, including a nozzle 21, a filter screen 22, a housing 27, a pressure vessel 24, a motor 28 and a vacuum device 25. The pressure vessel 24 is provided with a pressure display device 26 for detecting the pressure in the pressure vessel. The filter screen 22 is disposed in the housing 27 , and a distance is provided between the bottom of the filter screen 22 and the housing 27 . The casing 27 communicates with the atmosphere. Filter screen 22 is hat-shaped, is provided with the bottom plate that closes its bottom opening, and base plate is fixedly connected with the output shaft of motor 28, and motor 28 drives filter screen 22 to rotate. The filter screen and the bottom plate form a cavity for vacuum suction, and the cavity communicates with the vacuum suction device 25 through a rotary joint and a pipeline. There are multiple nozzles 21, which are evenly spaced along t...

Embodiment approach 3

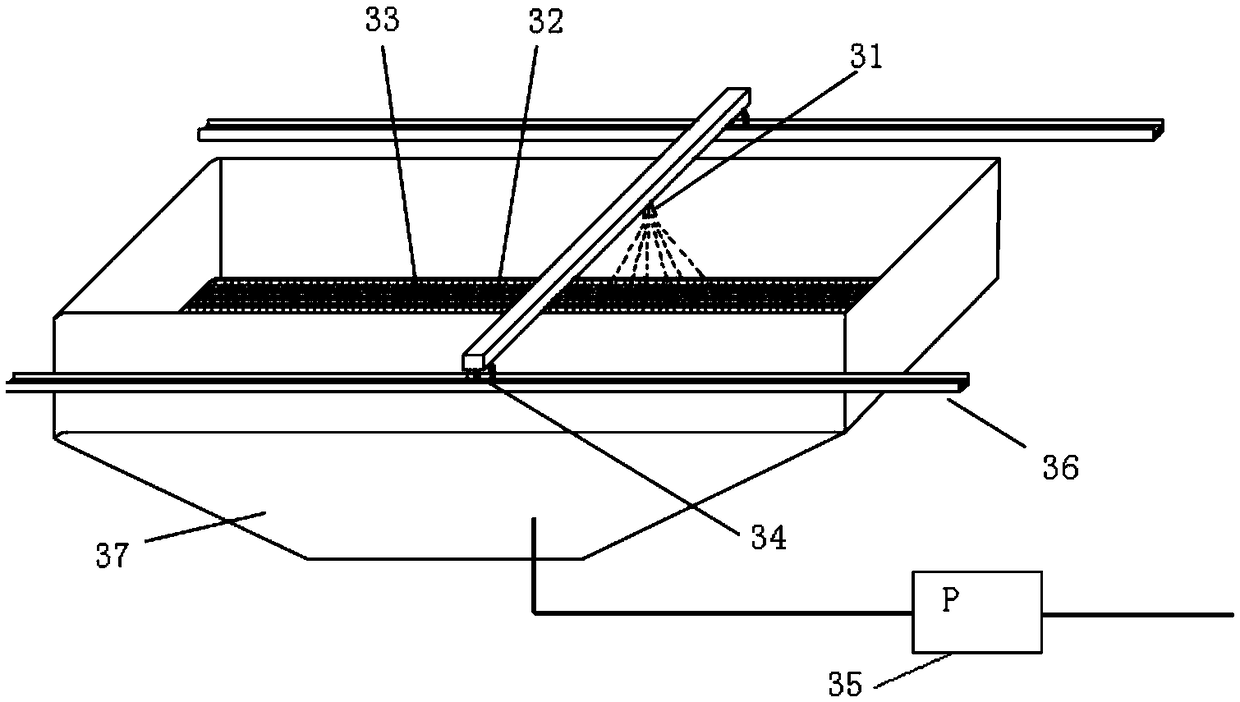

[0031] A device for manufacturing flat-type special inorganic thermal insulation blankets, including a nozzle 31 , a filter screen 32 , a housing 37 , a guide rail 36 , a beam 34 and a vacuum device 35 .

[0032] The housing 37 is in the shape of a cone with an open upper part. The filter screen 32 is arranged on the upper part of the inner cavity of the housing. The filter screen 32 and the lower part of the inner cavity of the housing 37 form a vacuum suction cavity. connected. Both sides of the housing 37 are provided with guide rails 36 , the nozzle 31 is arranged on the beam 34 , the bottom of the beam 34 is provided with a motor and rollers, the motor drives the rollers to rotate, and the rollers drive the beam 34 to move linearly along the guide rail 36 . The spray head 32 communicates with the pressure vessel through a rotary joint and a pipeline. The number of spray nozzles 31 can be single or multiple, specifically selected according to the width of the felt body to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com