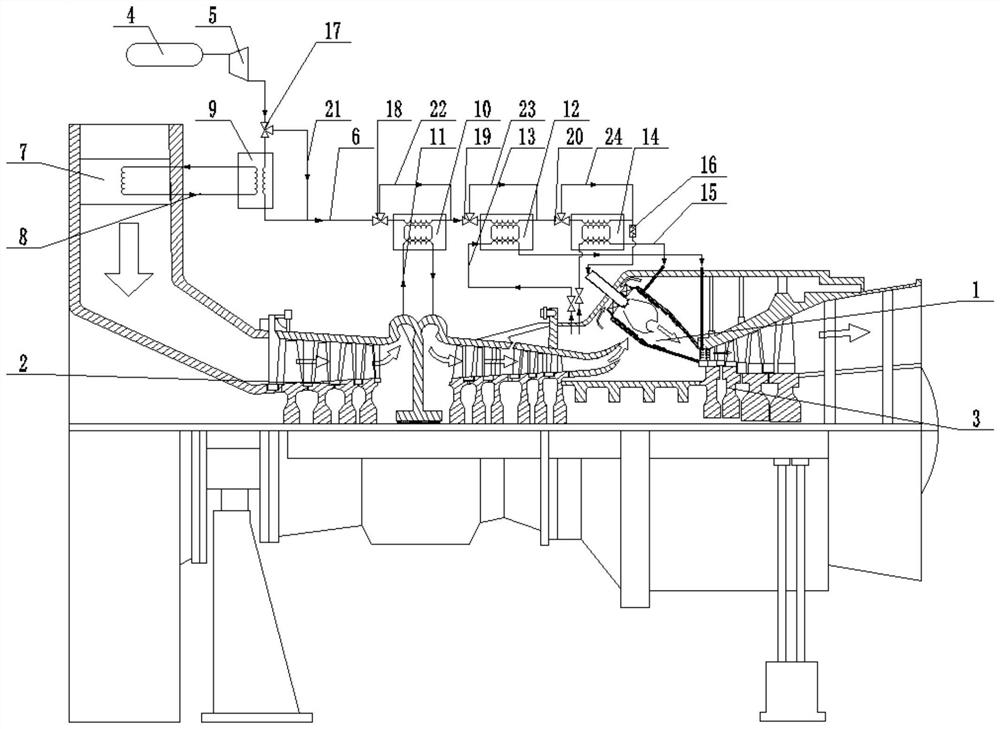

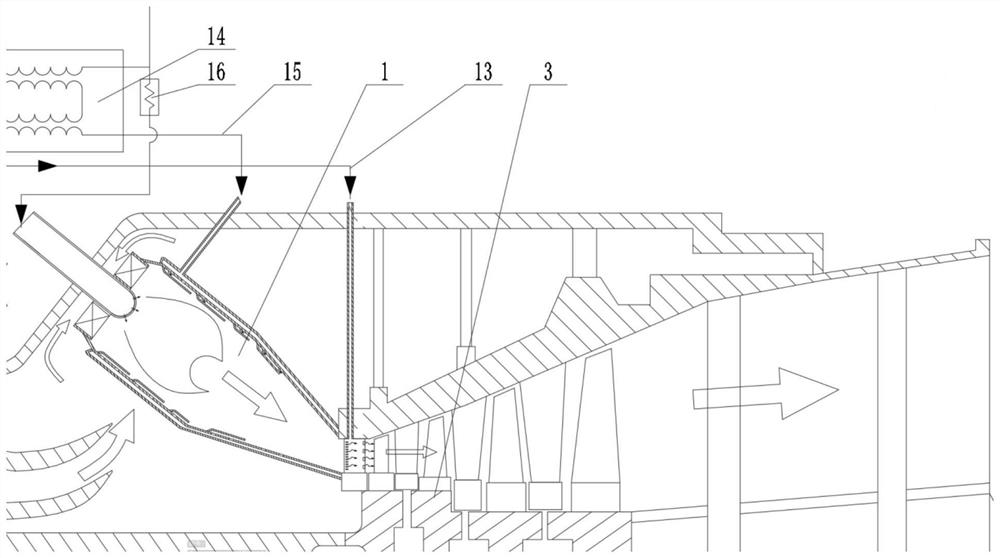

Efficiency improving system of hydrogen fuel gas turbine and control method

A gas turbine and hoisting system technology, which is applied to gas turbine devices, turbine/propulsion fuel delivery systems, and fuel control of turbine/propulsion devices, etc., can solve problems such as the reduction of gas turbine efficiency, and achieve improved combustion efficiency, overall efficiency, and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

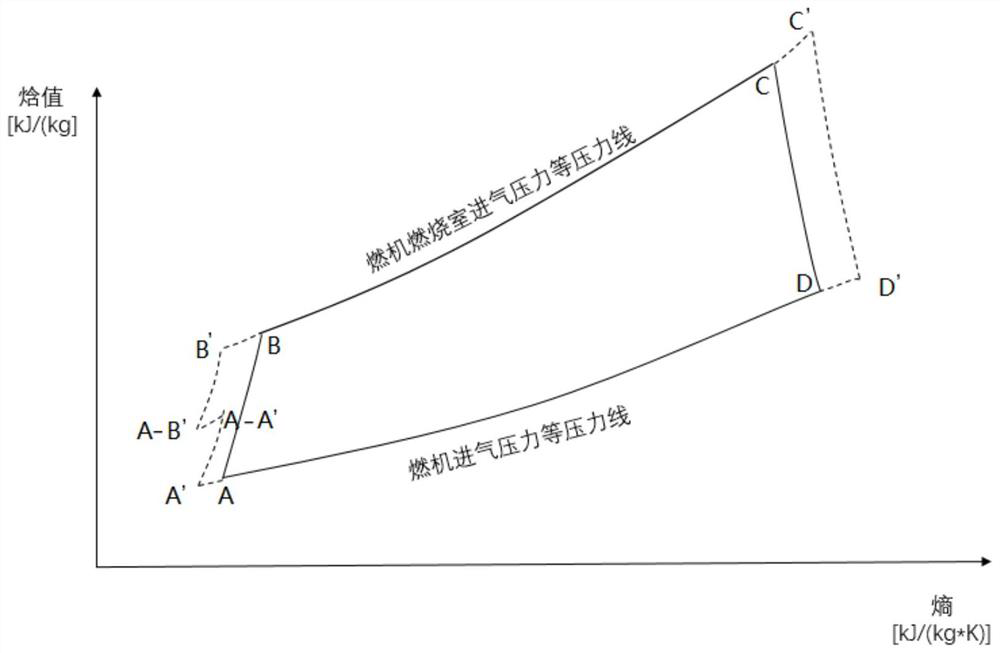

[0105] Such as Figure 4 As shown, this embodiment provides a control method, which is applied to the efficiency improvement system of the hydrogen-fueled gas turbine in the first embodiment above, taking the hydrogen fuel supply part as the above-mentioned cryogenic liquid hydrogen supply part as an example, the specific steps are as follows:

[0106] Step S1: start the gas turbine 1; the start of the gas turbine 1 includes the following steps:

[0107] Step S101: cranking;

[0108] Step S102: start the motor;

[0109] Step S103: purging the gas turbine 1;

[0110] Step S104: the electric heater is turned on;

[0111] Step S105: gas turbine 1 is ignited;

[0112] Step S106: the speed of the gas turbine is 1 liter;

[0113] Step S107: gas turbine 1 is under load;

[0114] Step S2: The gas turbine 1 reaches the first working state; at this time, the intake heat exchange part of the compressor, the interstage heat exchange part of the compressor, the turbine cooling air he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com