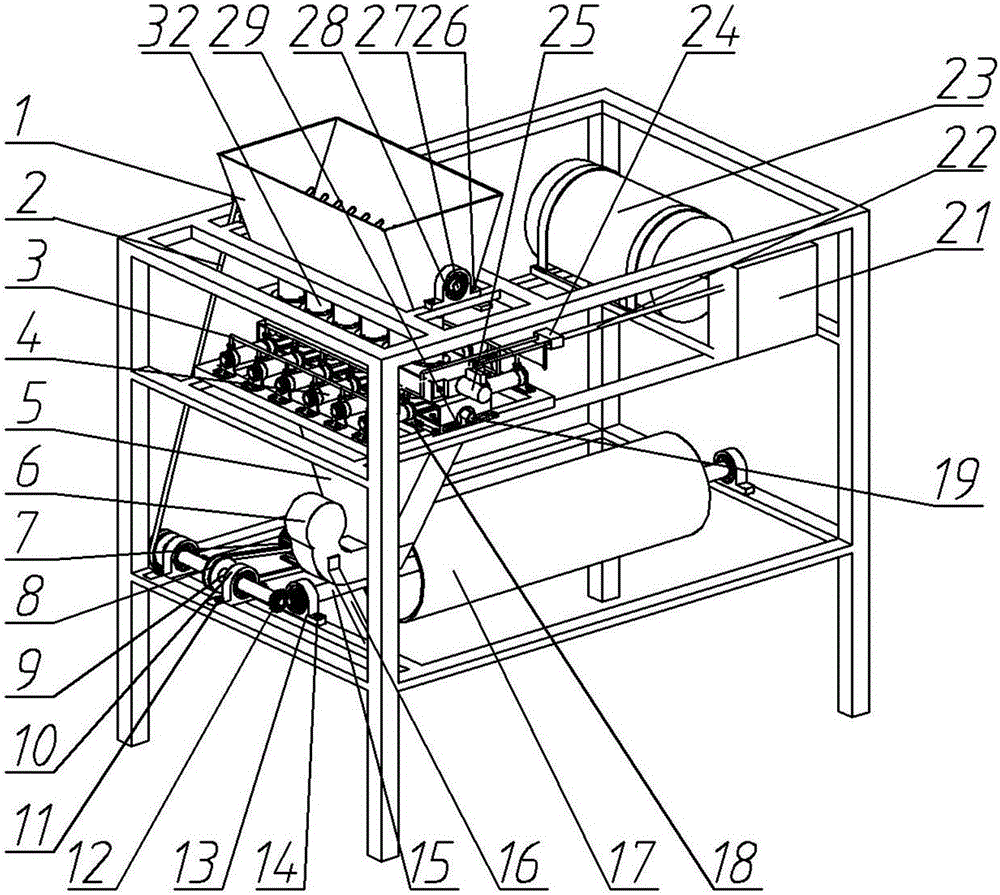

Walnut shell smashing device with automatic conveying and positioning functions and method for applying walnut shell smashing device

A shell breaking device and automatic conveying technology, which is applied to conveyor objects, transportation and packaging, shelling, etc., can solve the problem of inefficient control of walnut feeding and shell breaking process, deep processing, inconvenience in eating, and poor adaptability of walnuts. and other problems, to achieve the effect of reducing labor costs, flexible and adjustable speed, and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

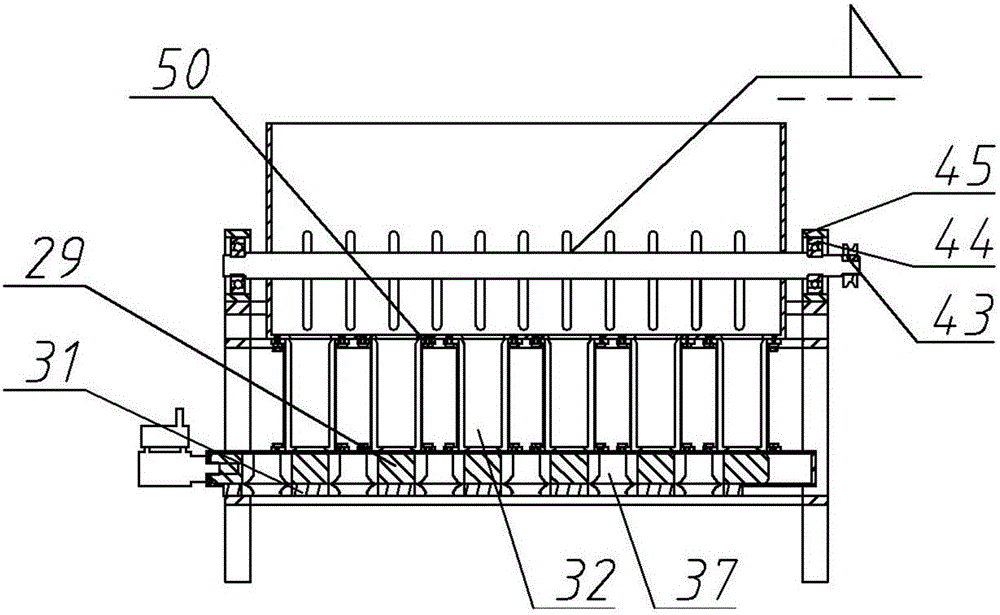

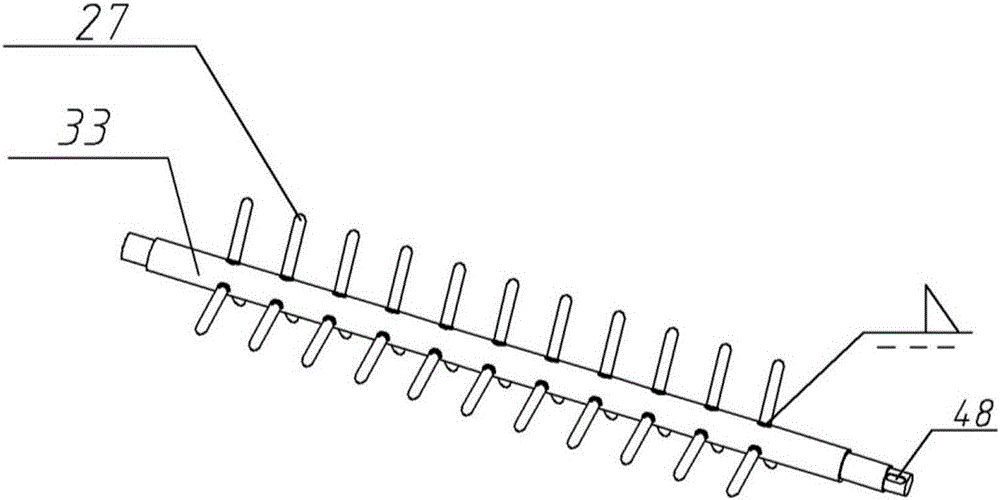

[0166] The difference between this embodiment and embodiment 1 is:

[0167] A baffle plate with holes is set below the walnut shelling mold, such as Figure 16 As shown, in the initial position, the through holes 13 of the baffle are interlaced with the positions of the walnut positioning holes, so as to stop the walnut from falling. Plate reversing cylinder 19 is provided with perforated baffle plate reversing cylinder gas injection hole 62 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com