Collision resistant quad-rotor spherical unmanned aerial vehicle system

A drone and quadrotor technology, applied in the field of drones, can solve the problems that drones cannot enter the scene, are vulnerable to impact, crashes, etc., to reduce the possibility of damage and fall, improve collision resistance, reduce Effects of impact or disturbance of flight attitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

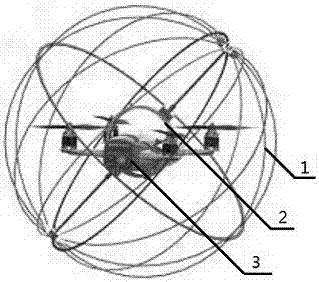

[0056] A collision-resistant quadrotor spherical UAV system, such as Figure 10 As shown, it includes the flight platform 001 for performing flight missions, the mission payload 002 mounted on the flight platform 001 for detection, and the ground equipment for remote control, telemetry, and data transmission of the flight platform 001 or mission payload 002.

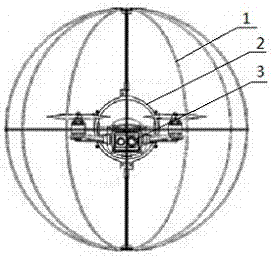

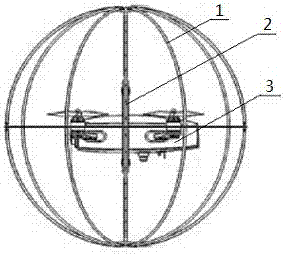

[0057] Such as Figure 1-Figure 5 As shown, the flight platform 001 includes a spherical frame mechanism 1, an aircraft body 3 completely located inside the spherical frame mechanism 1, and a support mechanism 2 that connects the spherical frame mechanism 1 and the aircraft body 3 as a whole.

[0058] The spherical frame mechanism 1 is in the structure of a globe latitude and longitude frame as a whole. The support mechanism 2 includes an annular connector located at the center of the spherical frame mechanism 1 and two support tubes 204 respectively arranged along the rotation axis of the globe. The center of gravity ...

Embodiment 2

[0063] This embodiment further optimizes the structure of the flying platform 001 on the basis of Embodiment 1, as Figure 1-Figure 4 As shown, the flight platform 001 is mainly composed of a spherical frame mechanism 1, an aircraft body 3 and a support mechanism 2 that connects the spherical frame mechanism 1 and the aircraft body. The spherical frame mechanism 1 and the support mechanism 2 together form a spherical protective structure that protects the aircraft body 3, improves the collision resistance of the entire flight platform 001, and effectively protects the aircraft body 3 from flying safely in complex environments. The task load 002 is integrated on the aircraft body 3 for easy disassembly and maintenance.

[0064] In this embodiment, the specific structures of the spherical frame mechanism 1 and the support mechanism 2 will be explained emphatically, and the principle of the spherical protection mechanism making the aircraft body 3 resistant to collisions will be ...

Embodiment 3

[0083] In this embodiment, on the basis of Embodiment 2, the material of the spherical frame mechanism 1 is further optimized. Such as Figure 5 As shown, the latitude annular frame 101 is a complete annular carbon fiber sheet; the longitude annular frame 102 is composed of four fan ring carbon fiber sheets; the longitude tube 103 is a glass fiber stringer; the bearing housing 104, The bearings 105 are all lightweight plastics; the end faces of the bearing seat 104 are respectively fixed with the glass fiber stringers passing through the annular carbon fiber sheet, and the fan ring carbon fiber sheet with one end fixed on the annular carbon fiber sheet. Each additional annular latitude ring is composed of four fan ring carbon fiber sheets spliced together, or each additional annular latitude ring adopts a head-to-tail ring fiberglass stringer, or the additional annular latitude ring part adopts four fan ring carbon fiber It is composed of sheet splicing and partly adopts en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com