Pressure-stabilized simulated grouting test device and application method thereof

A technique of grouting test and grouting, which is applied in the field of grouting in geotechnical engineering, can solve the problems of repeated simulation of various working conditions and difficult control of grouting pressure, and achieve easy quantification of test results, grouting pressure and grouting pressure. Slurry volume can be controlled to achieve the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

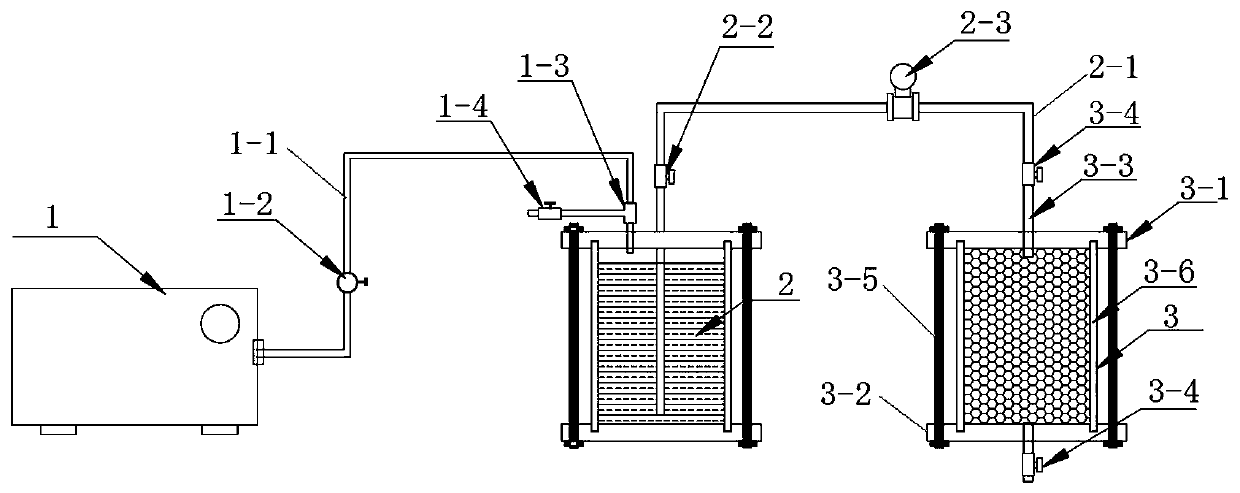

[0044] Embodiment 1, a kind of steady pressure simulated grouting test device, such as figure 1 and figure 2 As shown, the grout storage tank 2 is included, and the grout storage tank 2 is connected to the air compressor 1 through the first conduit 1-1, and the first conduit 1-1 is provided with a pressure regulating valve 1-2 ,, By adjusting the pressure regulating valve 1-2, the supply pressure value of the air compressor 1 to the grouting tank 2 can be adjusted. The slurry storage and injection tank 2 is connected to the sample mold through the second conduit 2-1, and the slurry in the slurry storage and injection tank 2 can be transported to the sample mold through the second conduit 2-1. By adjusting the pressure regulating valve 1- 2. The slurry under different pressure values can be injected into the sample mold. The second conduit 2-1 is provided with a slurry outlet valve 2-2, and the opening and closing of the slurry outlet valve 2-2 controls the process of grou...

Embodiment 2

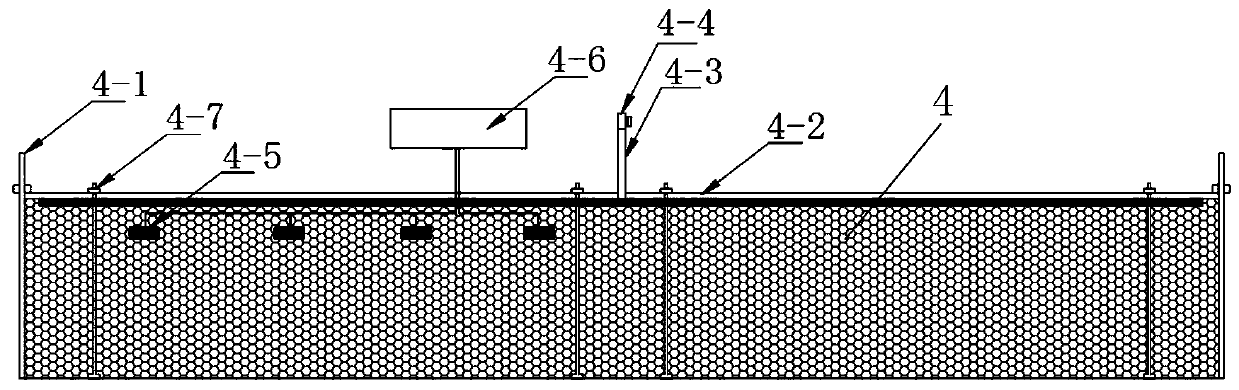

[0052] Embodiment 2, a kind of stable pressure simulated grouting test device, such as figure 2 As shown, the visualized slurry diffusion radius and real-time medium pressure detection sample mold 4 includes a metal cylinder 4-1 and a PMMA plate 4-2 sealed on the top of the metal cylinder 4-1, and the PMMA plate 4-2 passes through the second The screw assembly 4-7 is reinforced and connected to the top of the metal cylinder 4-1, the PMMA plate 4-2 is provided with a central hole, and a second inlet that is detachably connected to the second conduit 2-1 is inserted in the central hole. Serous duct 4-3. During the experiment, the visualization of the grouting radius of the structural layer can be realized through the PMMA plate 4-2, which is conducive to the quantification of data.

[0053] Further, a pressure sensor 4-5 is arranged inside the metal cylinder 4-1, and a signal collector 4-6 connected with the pressure sensor 4-5 is arranged outside the metal cylinder 4-1. The ...

Embodiment 3

[0055] Embodiment 3, a pressure-stabilizing simulated grouting test device, the first grout inlet valve 3-4 is set on the first grout inlet conduit 3-3, and the second grout inlet valve 3-3 is arranged on the second grout inlet conduit 4-3. The slurry inlet valve 4-4. The setting of the first slurry inlet valve 3-4 and the second slurry inlet valve 4-4 can further ensure the stability of the pressure control during the experiment.

[0056] Other structures of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com