Tensioning device for MPCVD

A tensioning device and tensioning technology, applied in gaseous chemical plating, crystal growth, coating and other directions, can solve the problem of inability to measure and adjust the tensioning force of connecting rods in MPCVD equipment in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

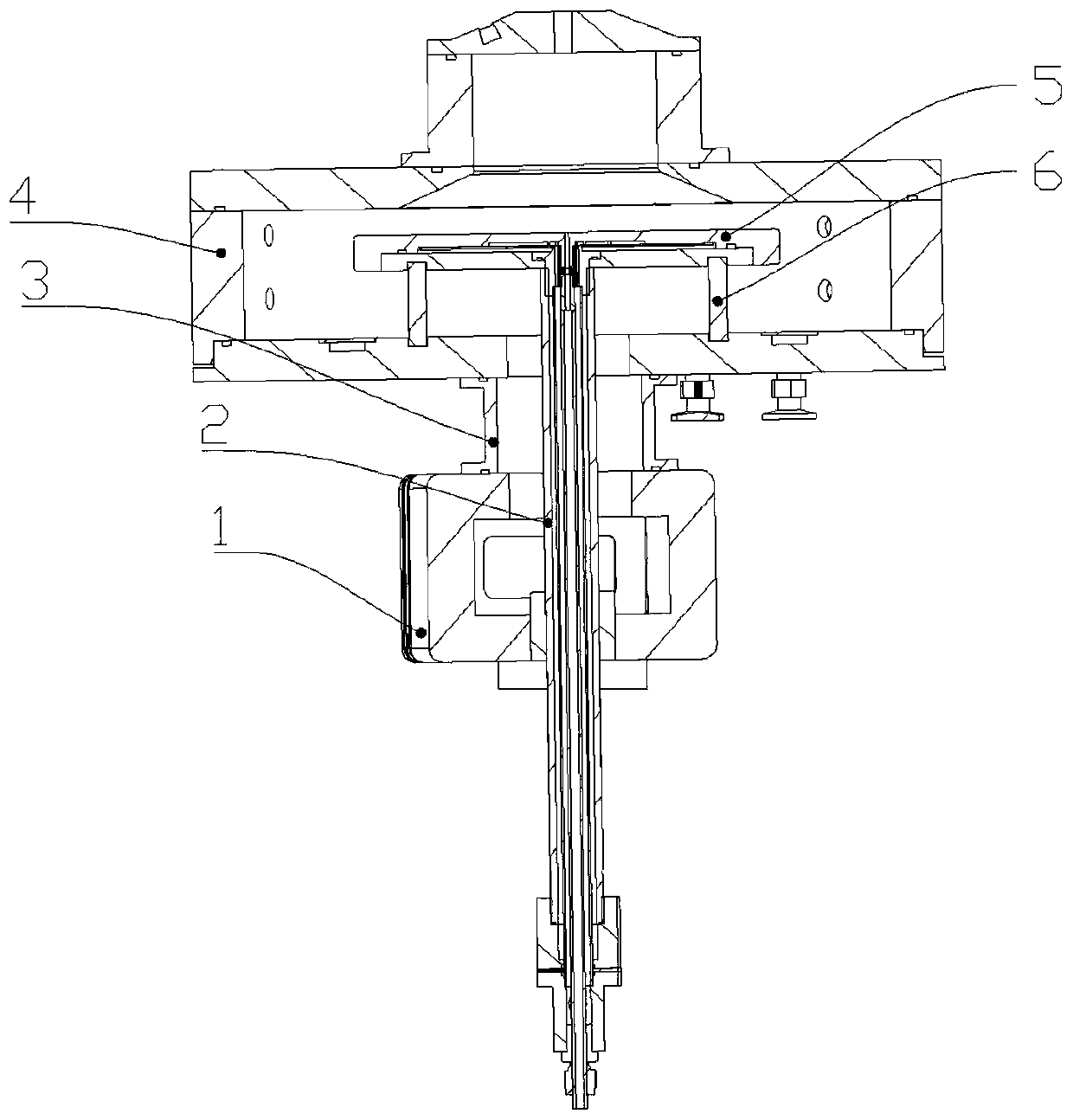

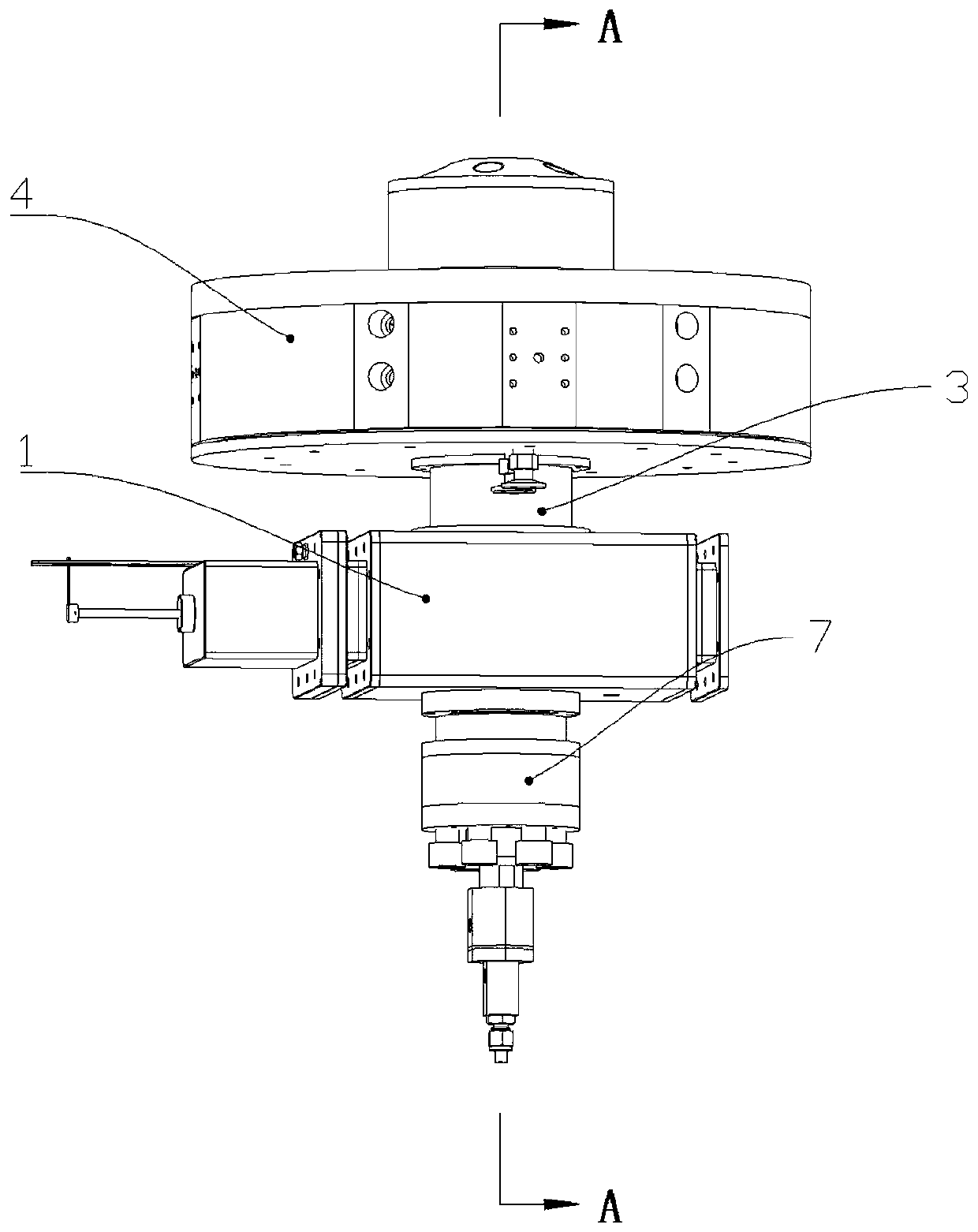

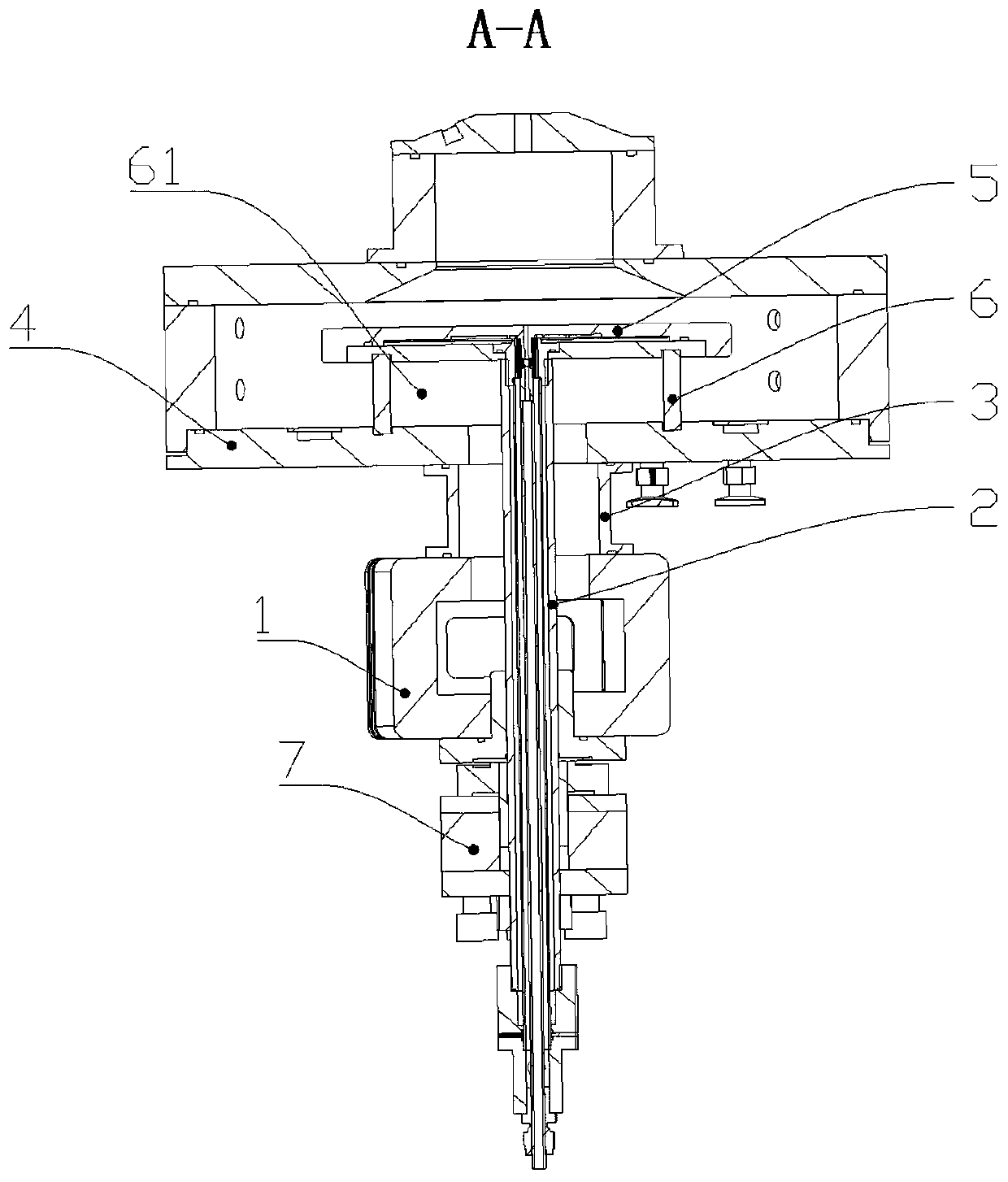

[0039] Such as Figure 2-6 As shown, a tensioning device for MPCVD includes a reaction cavity 4 and a waveguide cavity 1, the reaction cavity 4 and the waveguide cavity 1 are passed through by the same connecting rod 2, and the connecting rod 2 is also installed with a waveguide The tensioning device 7 below the cavity 1, the tensioning device 7 includes a tensioning assembly installed on the connecting rod 2, a plurality of pretensioning chambers 731 are opened in the tensioning assembly, each pretensioning chamber 731 is equipped with a The elastic element 77 in the vertical direction, the bottom surface of the tensioning assembly is equipped with a tray 72, and a plurality of pretensioning parts 71 corresponding to the elastic element 77 are installed on the tray 72, and the connecting rod 2 is also installed with the bottom surface of the tray 72. A tension member 78 is provided, and a load cell 75 is installed on the top surface of the tension assembly, and the load cell ...

Embodiment 2

[0044] Such as Figure 4-7 As shown, on the basis of Embodiment 1, this embodiment provides a more specific preferred structure of the tensioning device. That is, the tension assembly includes a tension disc 73 and a cover plate 74 , the cover plate 74 is installed on the top surface of the tension disc 73 , the tension disc 73 is installed on the top surface of the pallet 72 , and the elastic element 77 is in contact with the bottom surface of the cover plate 74 .

[0045] Preferably, the tray 72 is provided with a preloading hole 721 corresponding to the preloading chamber 731 one by one, the preloading member 71 is installed in the preloading hole 721 through threads, and an adjustment block 79 is also installed in the preloading chamber 731, and the elastic element 77 is installed on the adjustment block 79, and the pretensioner 71 is in contact with the adjustment block 79.

[0046] Preferably, the number of pretension chambers 731 is six, and the six pretension chambers...

Embodiment 3

[0051] Such as Figure 4-12 As shown, on the basis of Embodiment 1, this embodiment provides a more specific preferred structure of the tensioning device. That is, the connecting rod 2 is also equipped with a closing cover 76 positioned at the top surface of the load cell 75. The closing cover 76 extends into the reaction chamber 4. The closing cover 76 includes a closing plate 761 and a closing column 762 formed integrally with each other. The closing plate 761 is installed on the bottom surface of the waveguide cavity 1 , and the closing column 762 extends into the waveguide cavity 1 . The closing column 762 will have an interference fit with the waveguide cavity 1, the closing plate 761 can increase the contact area with the waveguide cavity 1, and the closing cover 76 can better seal the connection rod 2 and the waveguide cavity 1 .

[0052] The remaining parts are the same as those in Embodiment 1, so they will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com