Patents

Literature

102results about How to "Timely measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

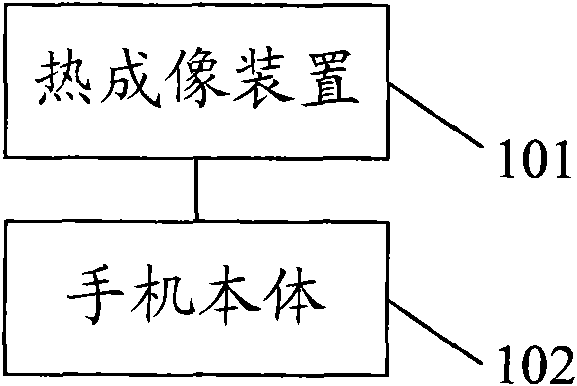

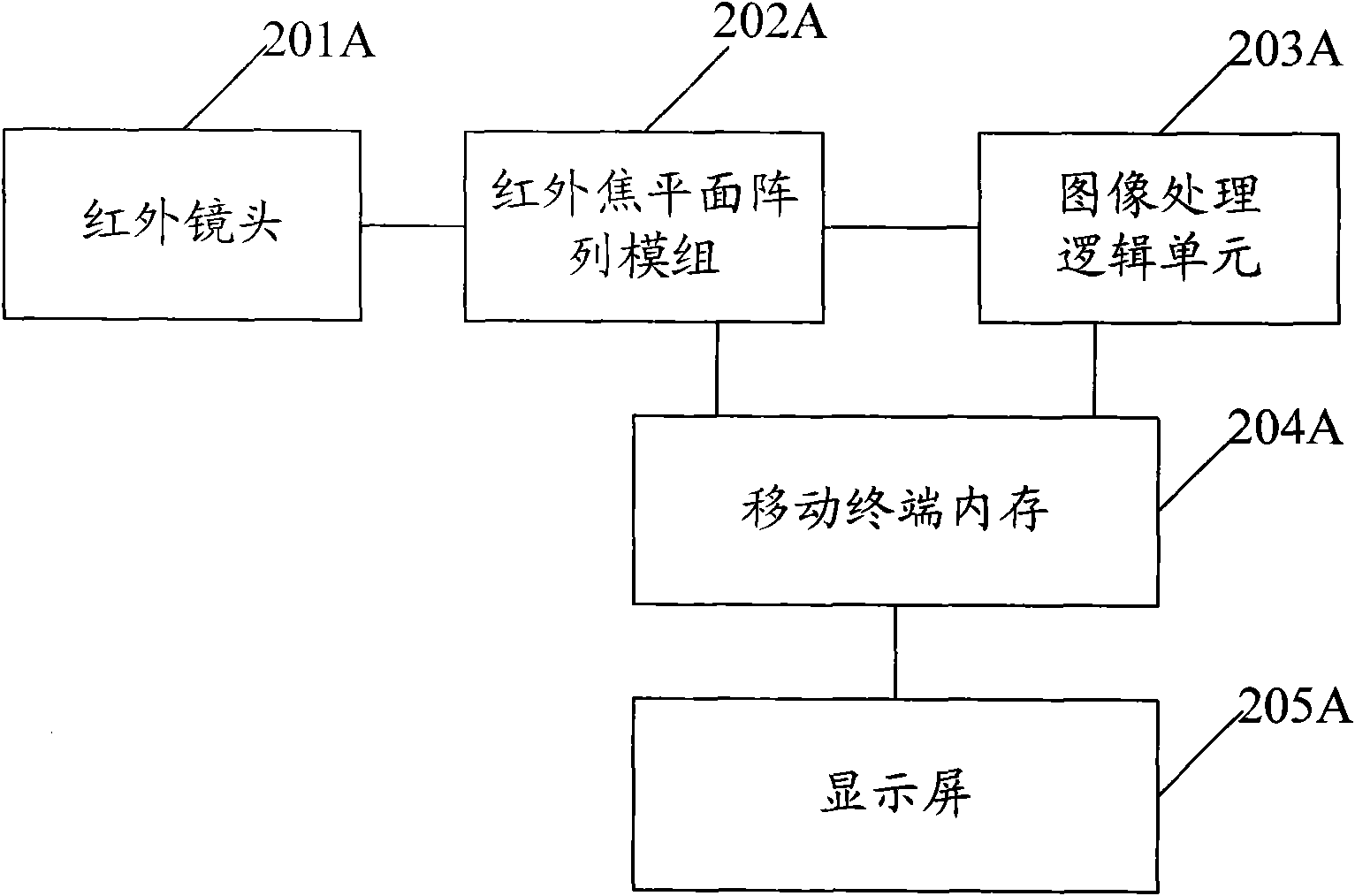

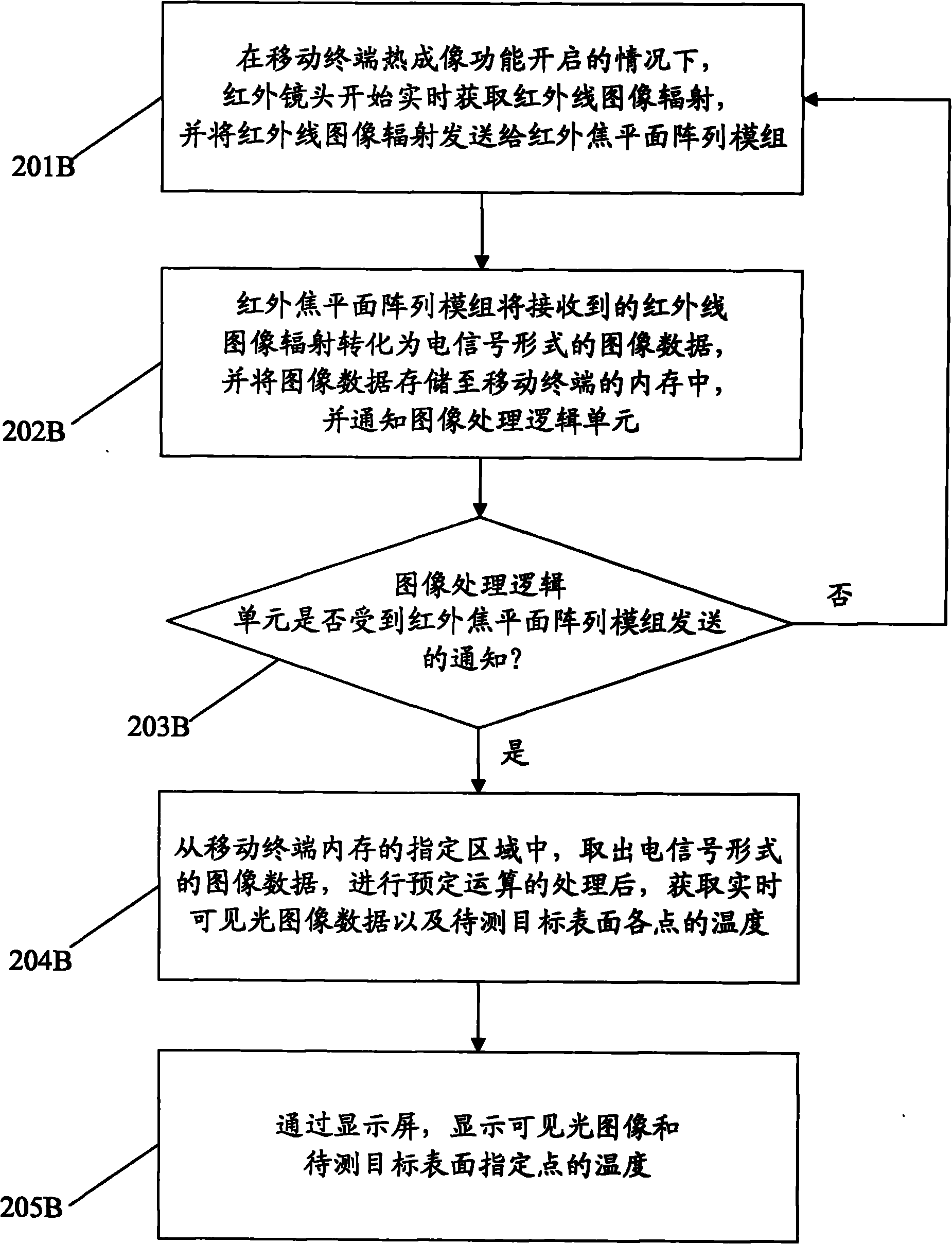

Mobile terminal and method for detecting temperatures by using same

InactiveCN102045423ATimely measurementAccurate measurementPyrometry using electric radation detectorsTelephone set constructionsComputer terminalComputer science

The invention discloses a mobile terminal and a method for detecting temperatures by using the same. The mobile terminal comprises a temperature detector, wherein the temperature detector comprises an infrared lens, a data processing module and a display module; the infrared lens is used for acquiring real-time infrared image radiation emitted from the surface of an object to be detected; the data processing module is used for converting the acquired real-time infrared image radiation into real-time visible light image data and temperatures of designated points on the surface of the object to be detected; and the display module is used for displaying the acquired real-time visible light image data and the temperatures of the designated points on the surface of the object to be detected. According to the invention, the advantages of the mobile terminal and the infrared temperature detection are given full play, so that the temperature can be measured comprehensively and accurately in time.

Owner:YINGHUADA (SHANGHAI) ELECTRONIC CO LTD

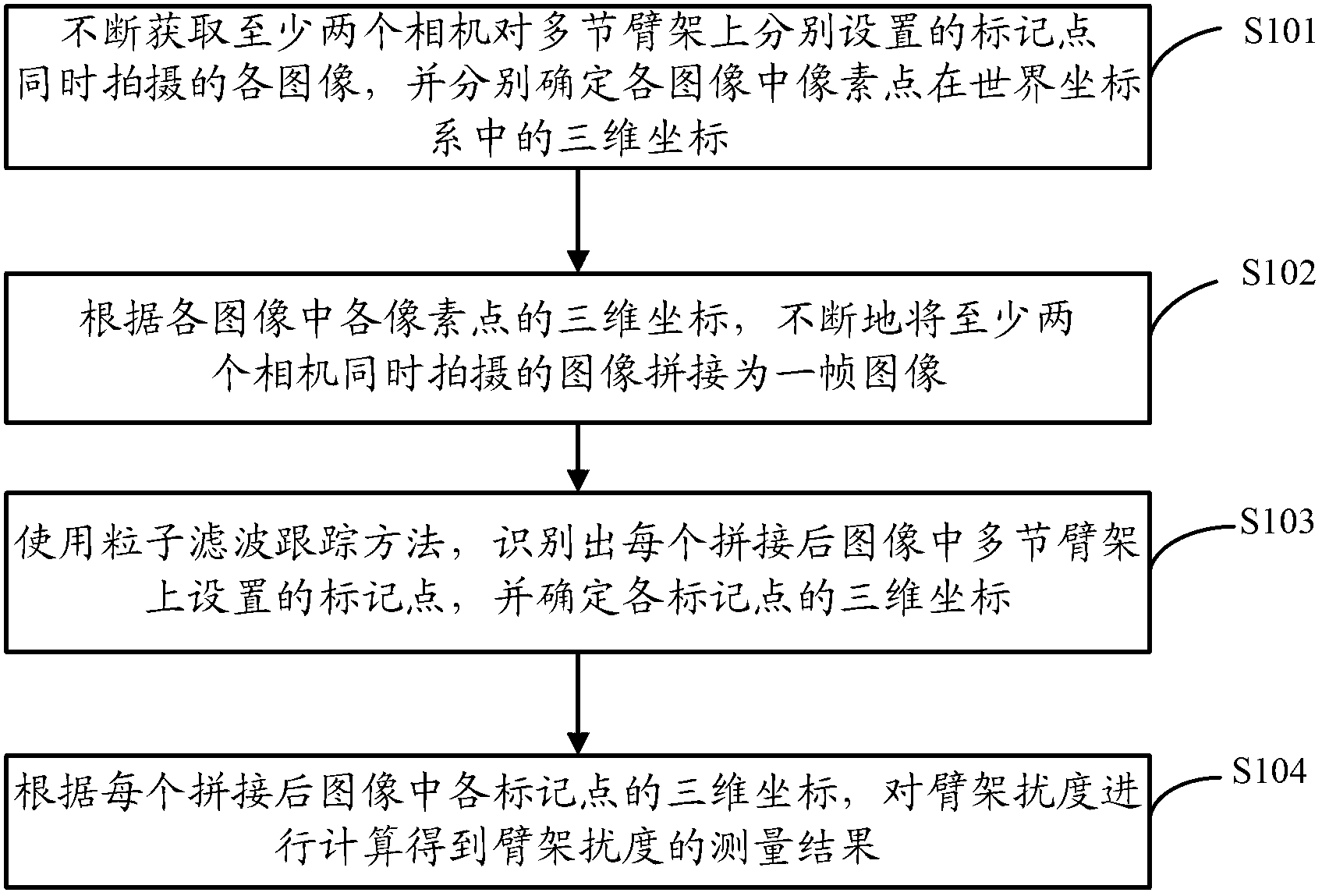

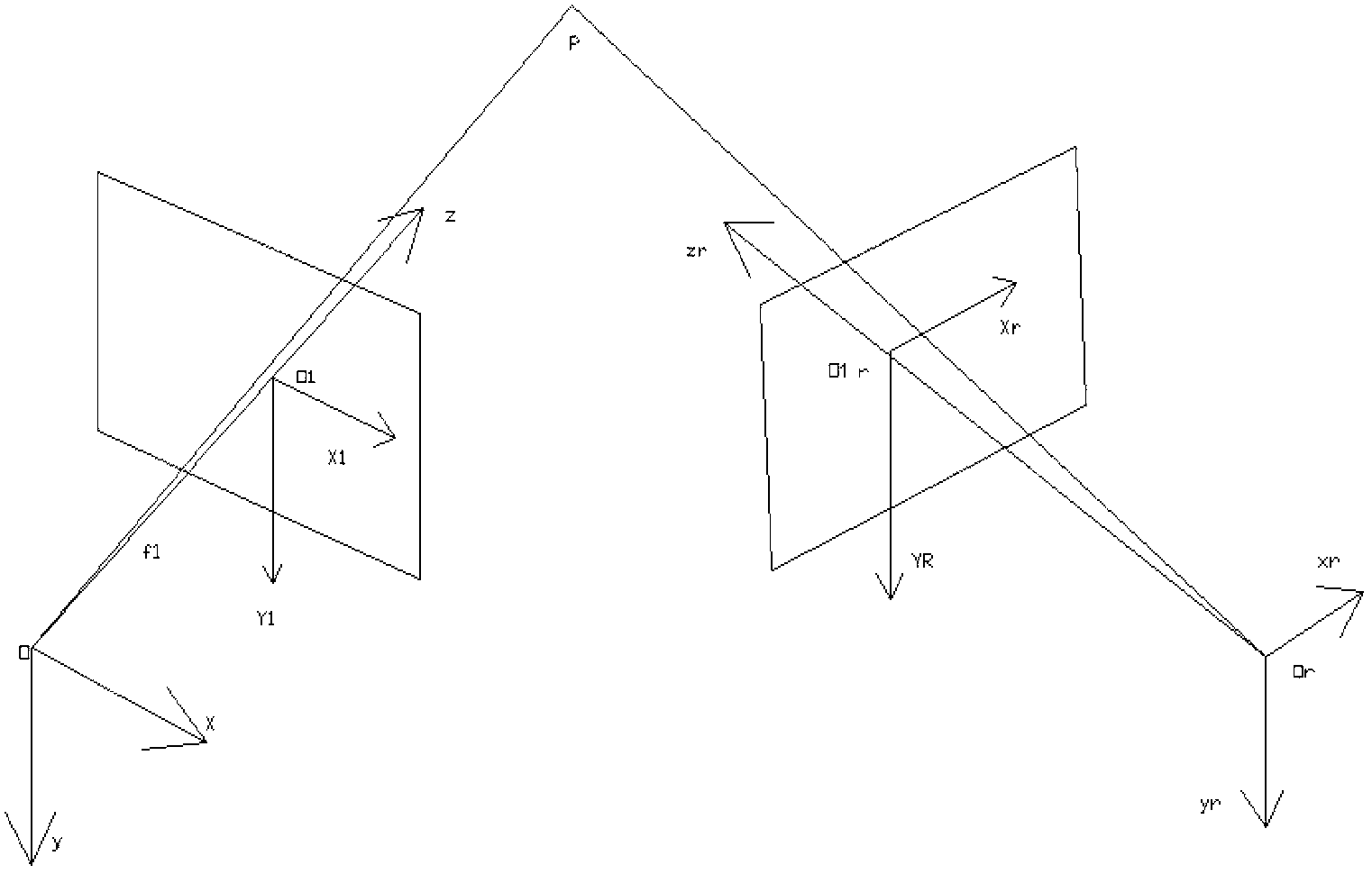

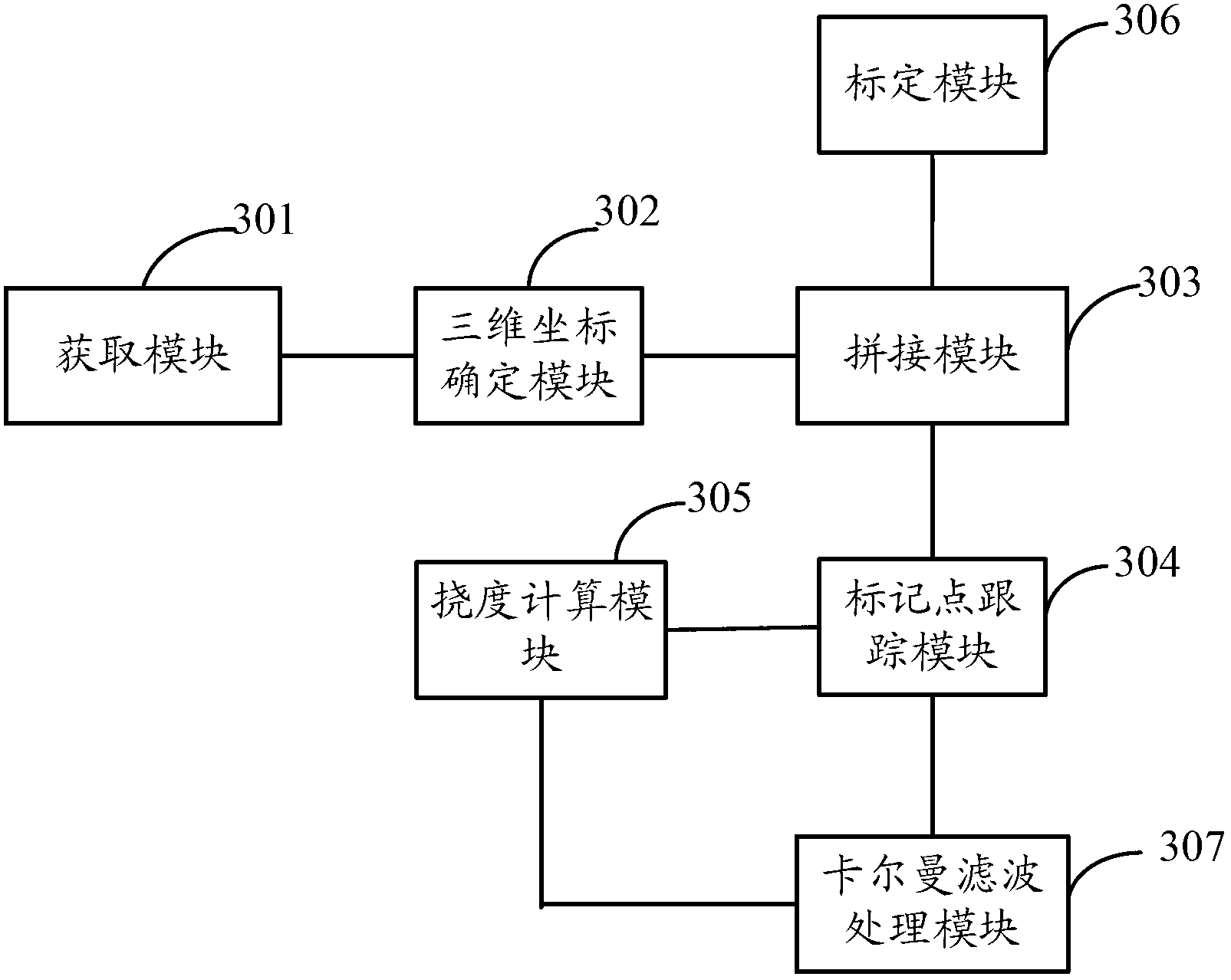

Method, device and system for measuring deflection of arm support

ActiveCN102798350AEasy to measureHigh measurement accuracyUsing optical meansAccuracy and precisionNon contact measurement

The invention discloses a method, device and system for measuring the deflection of an arm support. The method comprises the following steps of: continuously acquiring images, which are simultaneously photographed by at least two cameras, of mark points which are respectively arranged on the multi-section arm support, and respectively determining three-dimensional coordinates of pixel points of the images in a world coordinate system; continuously splicing the images which are simultaneously photographed by at least two cameras into frame images according to the three-dimensional coordinates of the pixel points of the images; identifying the mark points arranged on the multi-section arm support from the spliced images by using a particle filtering and tracking method, and determining three-dimensional coordinates of the mark points; and calculating the deflection of the arm support according to the three-dimensional coordinates of the mark points in the spliced images, thereby obtaining a measurement result on the deflection of the arm support. According to the method, the device and the system, a manner of non-contact measurement is utilized, so that the measurement manner is simple and convenient, the measurement accuracy of is higher, the real-time performance is good, and the deflection of the arm support can be measured promptly and quickly.

Owner:ZOOMLION HEAVY IND CO LTD

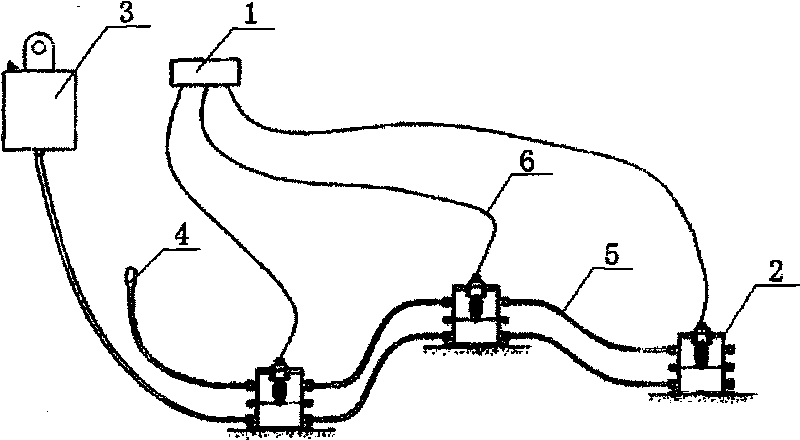

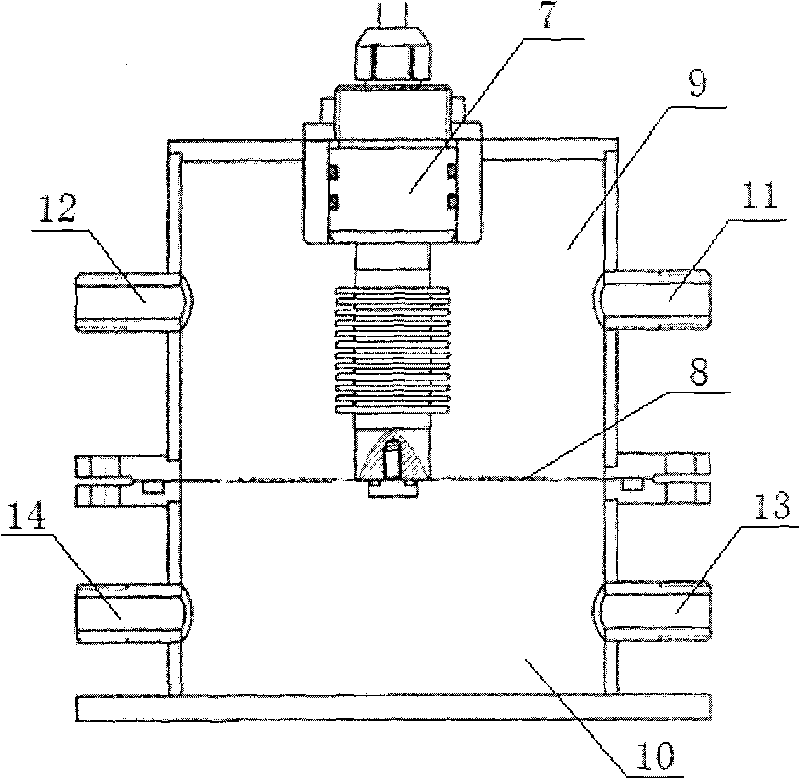

Static level monitoring system

InactiveCN101718544ATimely measurementLarge measuring rangeHydrostatic levellingMonitoring systemData acquisition

The invention provides a static level monitoring system, comprising a data acquisition system, a reference water tank, a static level gauge and a communicating pipe; at least one static level gauge is respectively connected with the reference water tank through the communicating pipe; and the data acquisition system is connected with the signal end of the static level gauge. The invention has the following advantages: the sedimentation or flotation of structures such as foundation fill is measured in time; the measuring range is large, the sensitivity is high, and the measuring efficiency is high; and the system is applied to round-the-clock remote monitoring and automatic data acquisition.

Owner:NANJING GEOT CIVIL ENG INSTR

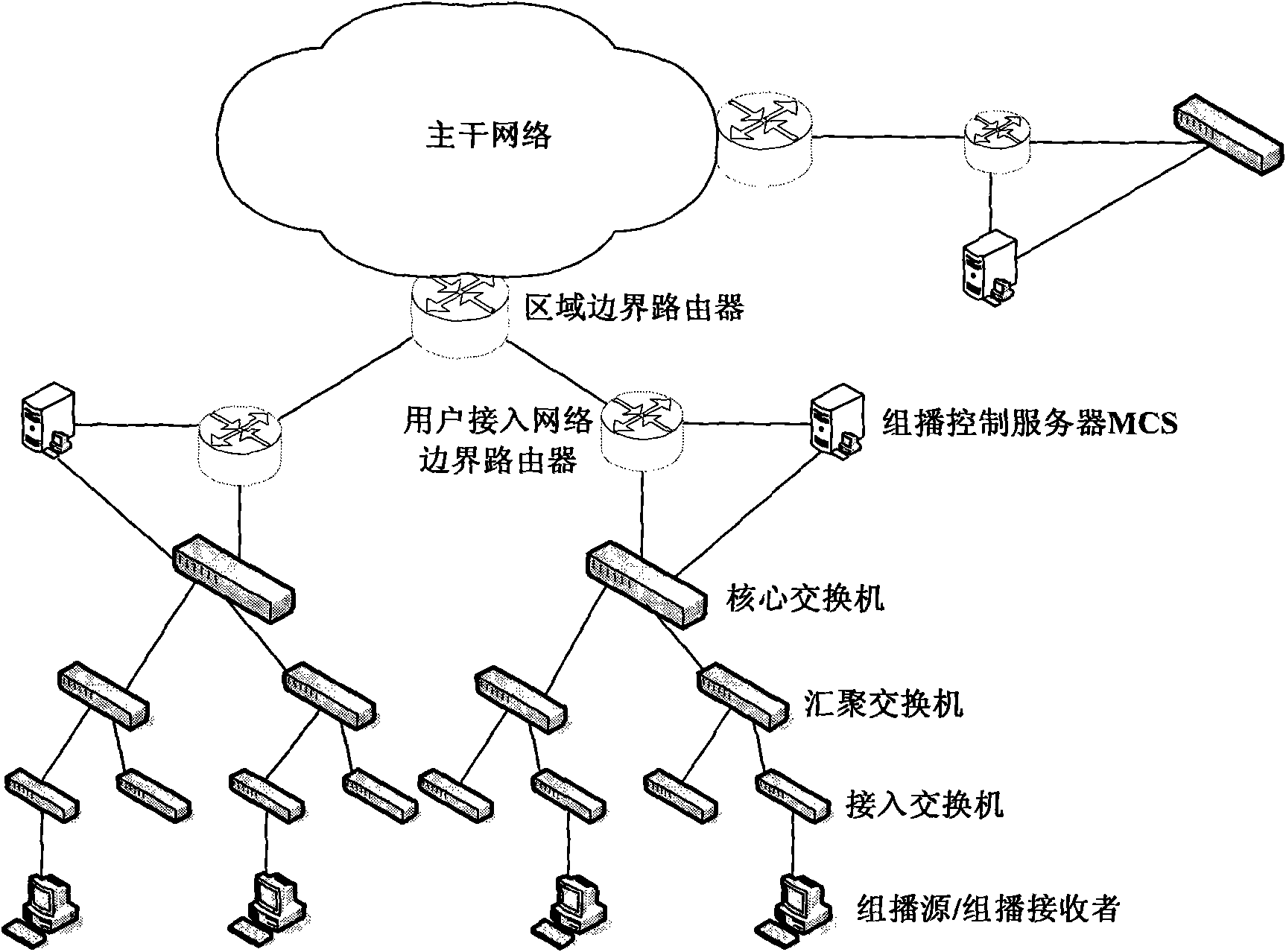

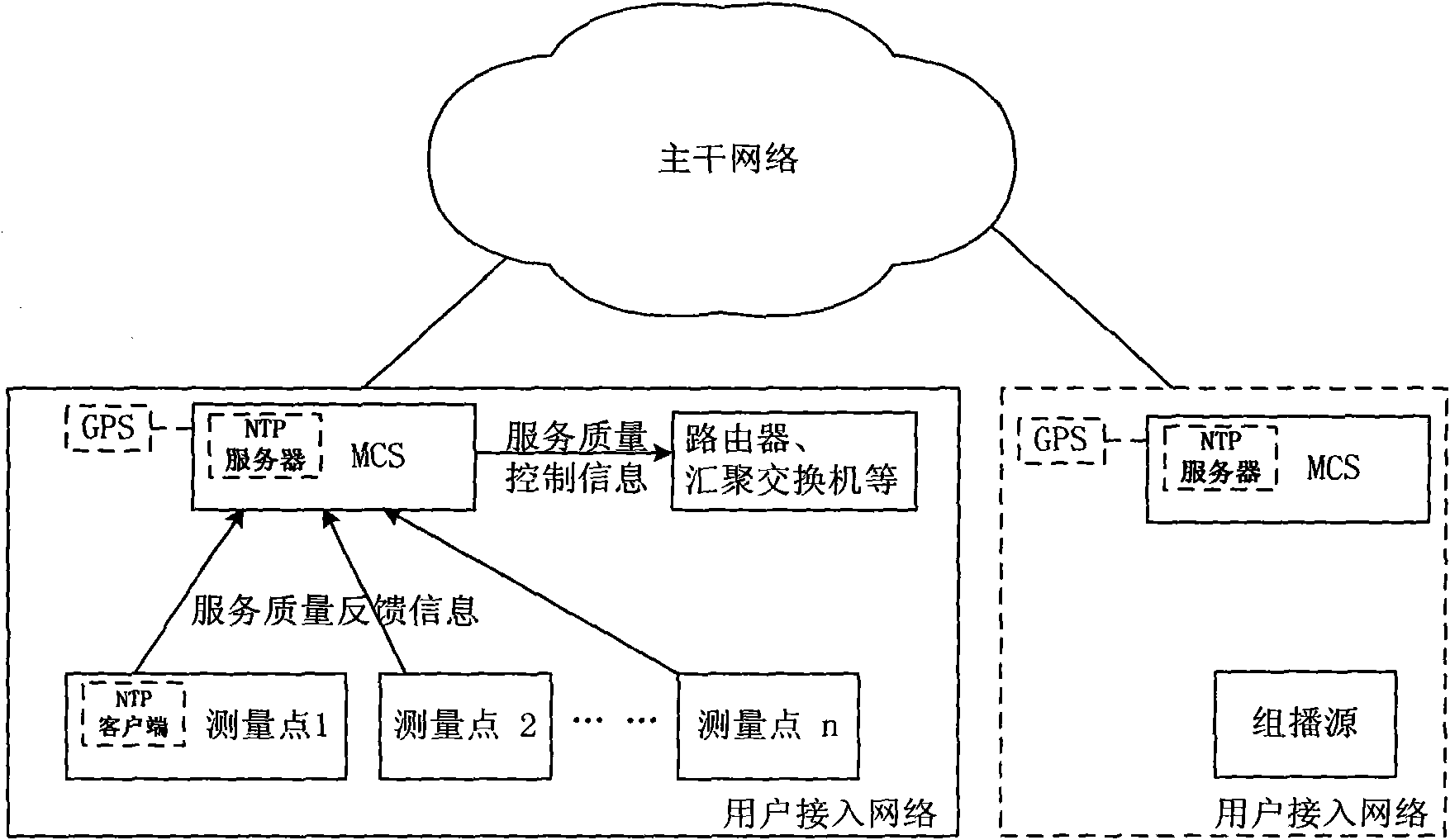

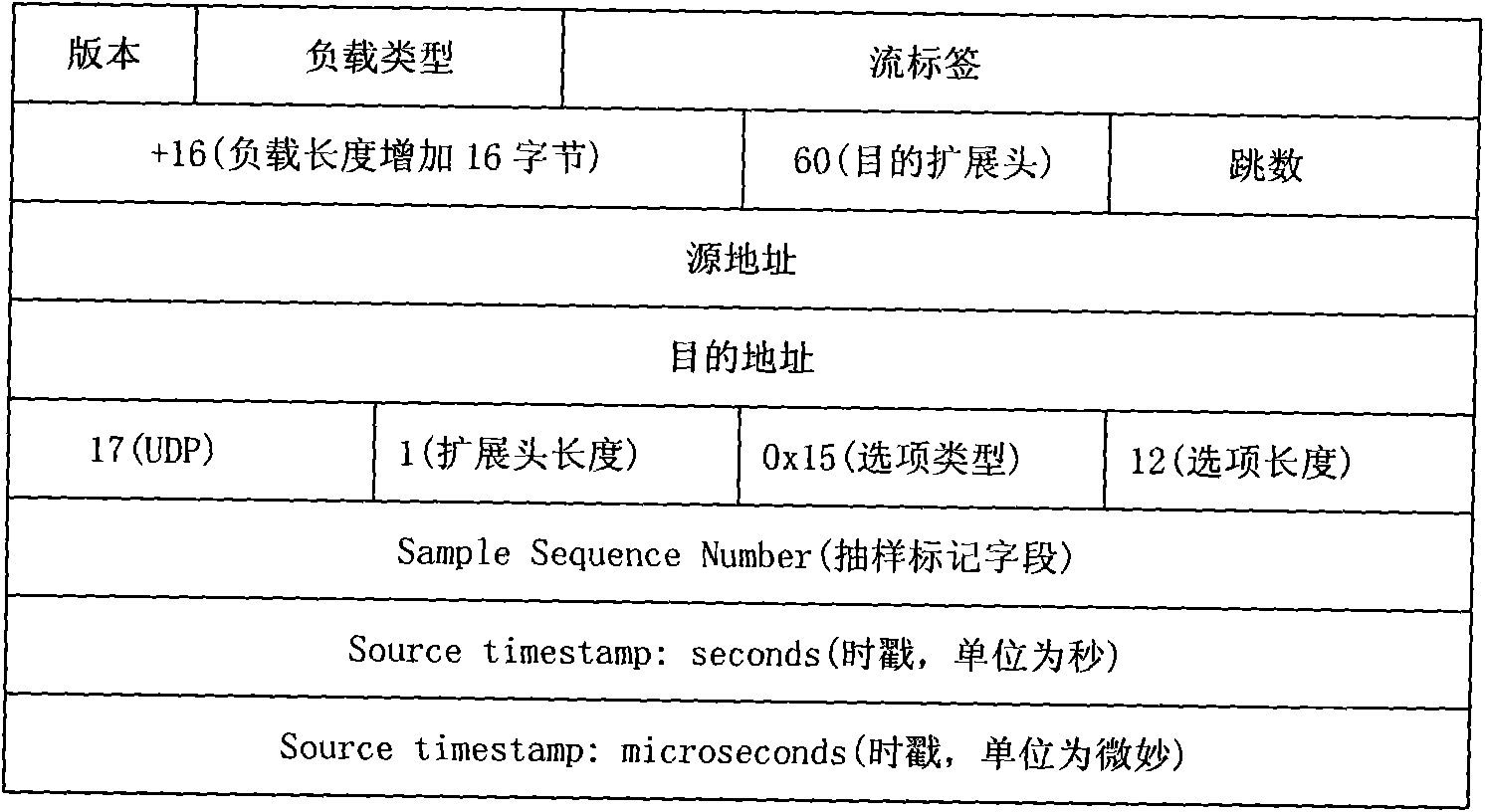

Method for measuring multimedia multicast service quality based on client

InactiveCN101674204ATimely measurementImprove friendlinessData switching networksActive measurementIPv6

The invention discloses a method for measuring the multimedia multicast service quality based on a client under a large-scale IPv6 network environment. The method provides a whole set of schemes to solve the multimedia multicast service quality measurement, comprising the time synchronization of a closed system, the message sampling and time stamp adding of a multicast source end system, the selection of a dynamic measurement point, the measurement of multicast service quality parameters of a single measurement point, and the assessment and control of a multicast control server to the access network multimedia multicast service quality. The method not only can overcome the invasion and non-reliability of active measurement as well as the locality of passive measurement, but also can timelyand truly measure the multimedia multicast service quality, and has the advantages of convenient deployment, good expansibility and the like.

Owner:SOUTHEAST UNIV

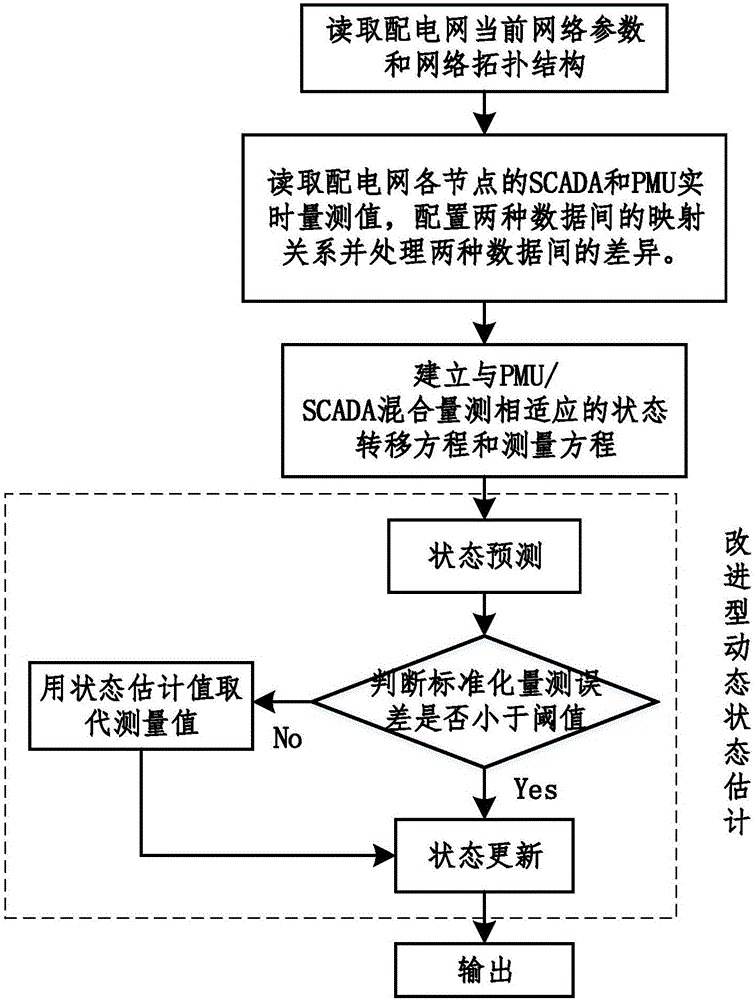

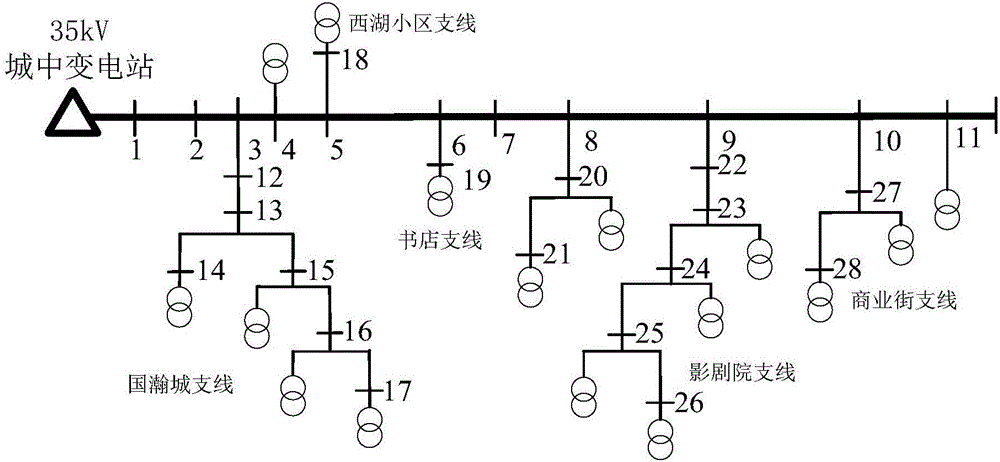

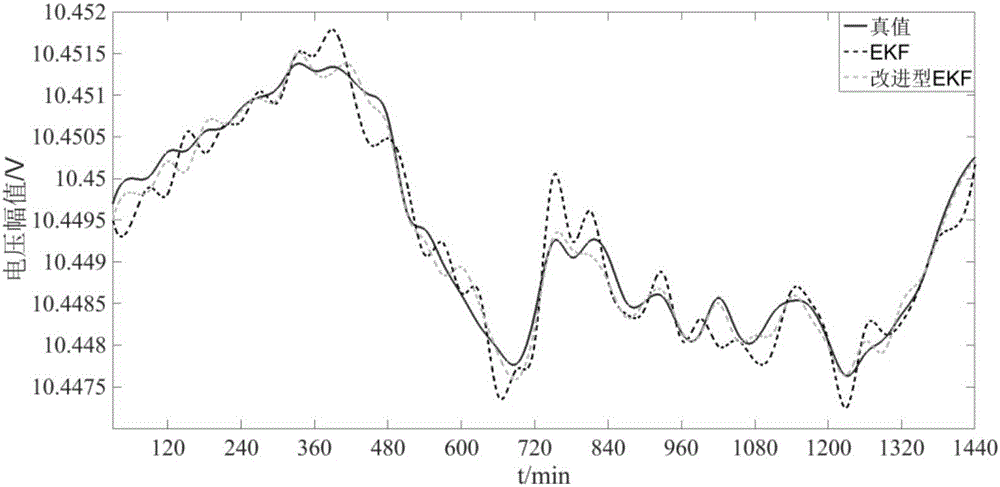

Hybrid measurement based power distribution network dynamic state estimation method

The invention discloses a hybrid measurement based power distribution network dynamic state estimation method, which comprises the steps of reading current network parameters and a network topology structure of a power distribution network, and forming a node admittance matrix and a branch-node association matrix; reading SCADA data and PMU data of each node of the power distribution network, configuring a mapping relation between the two kinds of data, and processing differences between the two kinds of data; building a state transition equation and a measurement equation which are adapt to PMU / SCADA hybrid measurement; adding a fault-tolerant mechanism to a traditional extended Kalman filter method, and performing state estimation on the power distribution network by adopting the improved extended Kalman filter method. Dynamic state estimation is applied to hybrid measurement, and the accuracy of state estimation is improved. Meanwhile, an adaptive data detection mechanism is introduced, and the accuracy of dynamic state estimation is improved.

Owner:HUNAN UNIV

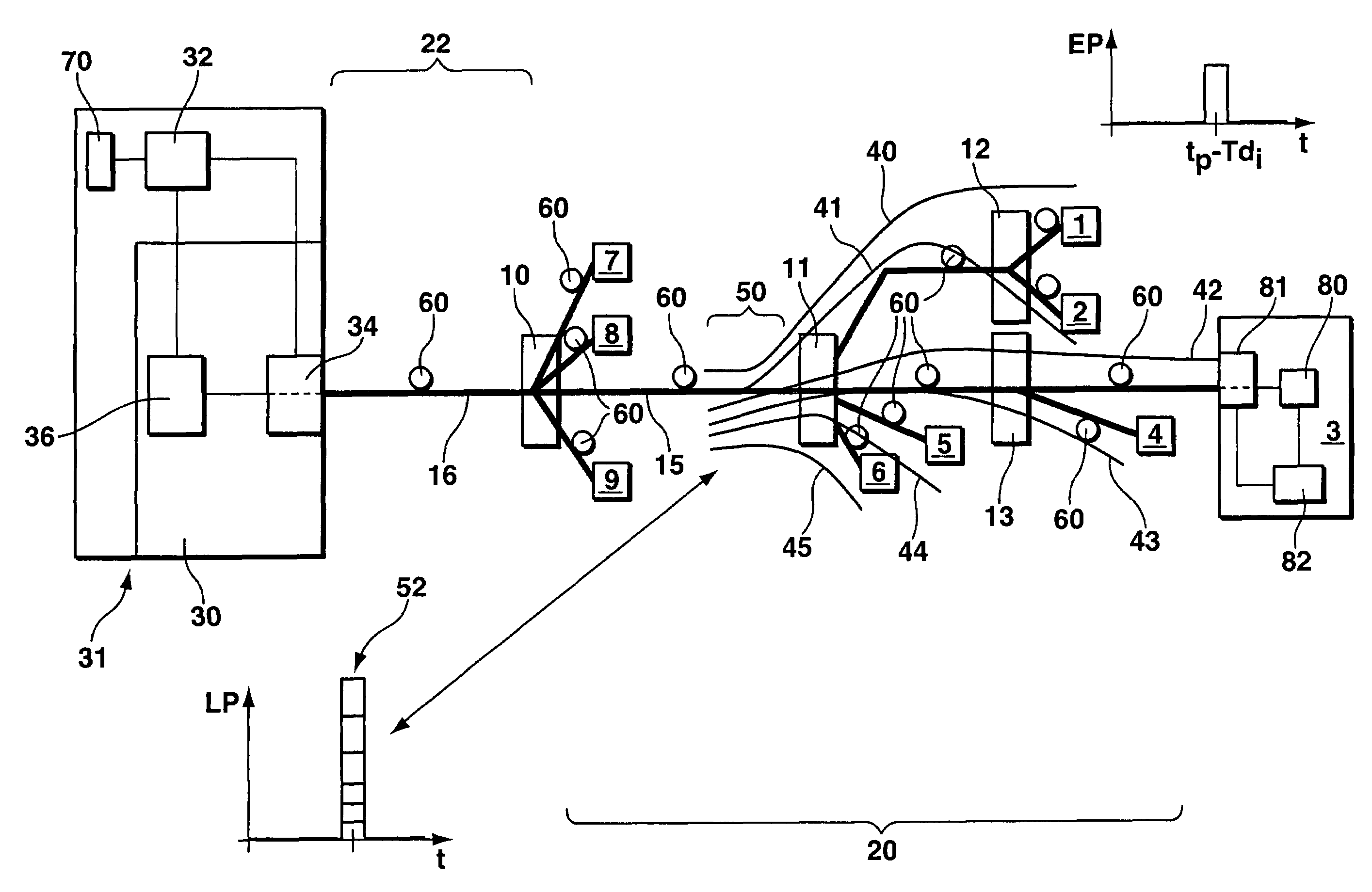

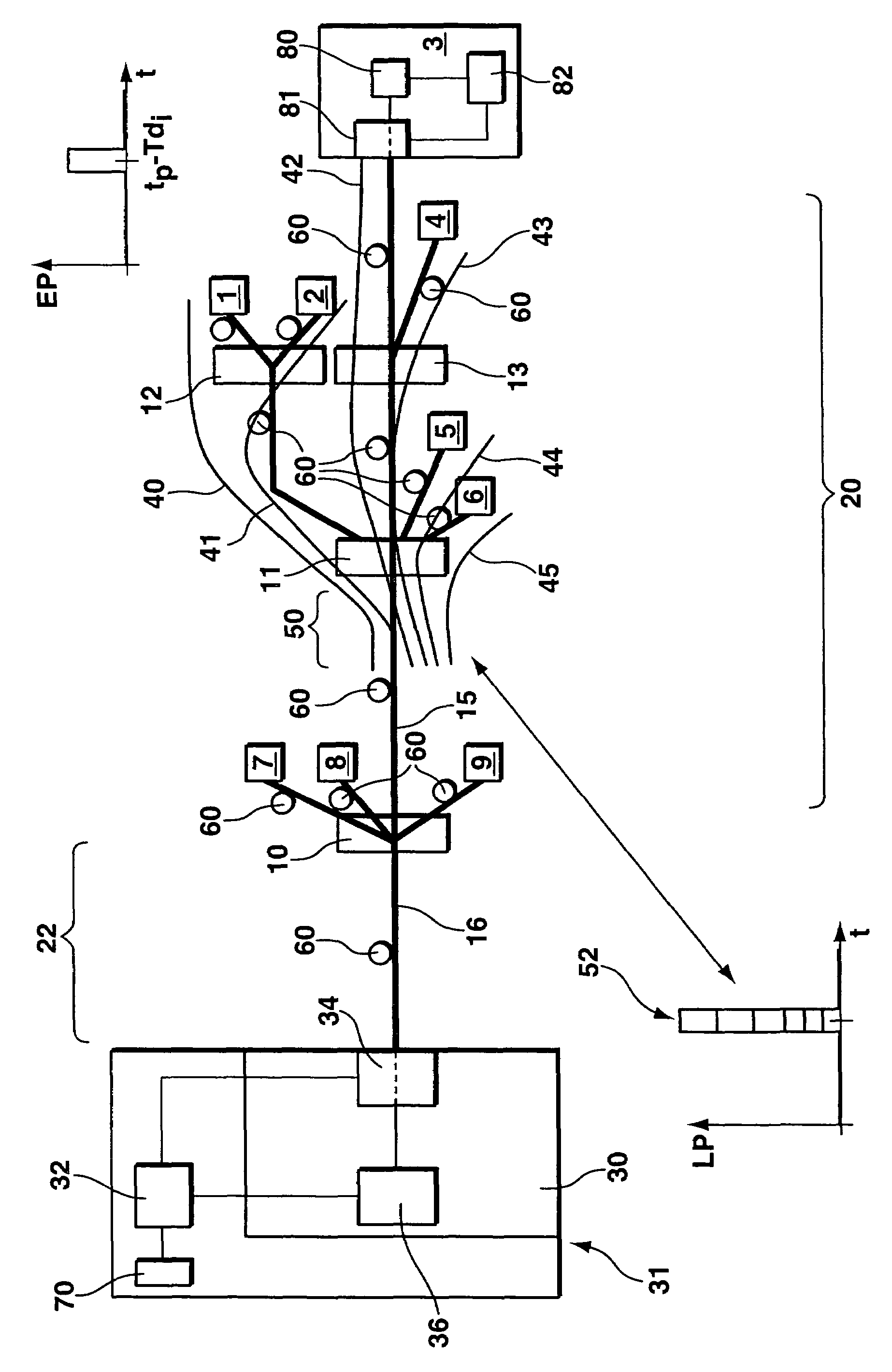

Passive optical network monitoring method and passive optical network

InactiveUS7620319B2Avoid the needTimely measurementTransmission monitoringOptical multiplexTime domainTransceiver

This invention relates to a method for monitoring at least one section (50) of an optical fiber link (15,16), preferably a distribution section behind a passive distribution node (10-13), of a passive Optical Network, and a passive Optical Network being designed to perform the steps of the method. The method is comprising the steps of:—sending a first optical monitoring signal (40) through said section at a first signal sending time by sending means (81,34) of a first transceiver device (30,1-9) of the passive Optical Network,—sending at least a second optical monitoring signal (41-45) through said section at a second signal sending time by sending means (81,34) of a second transceiver device (30,1-9) of the passive Optical Network, wherein the sending times of said optical monitoring signals (40-45), preferably Optical Time Domain Reflectometry Signals, are coordinated in such a way that the optical monitoring signals (40-45) are superimposed while travelling through said section, building a measuring signal (52), and—detecting and analysing characteristics of at least parts of said measuring signal (52) preferably by at least one of the optical monitoring signal sending transceiver devices (1-9).

Owner:RPX CORP

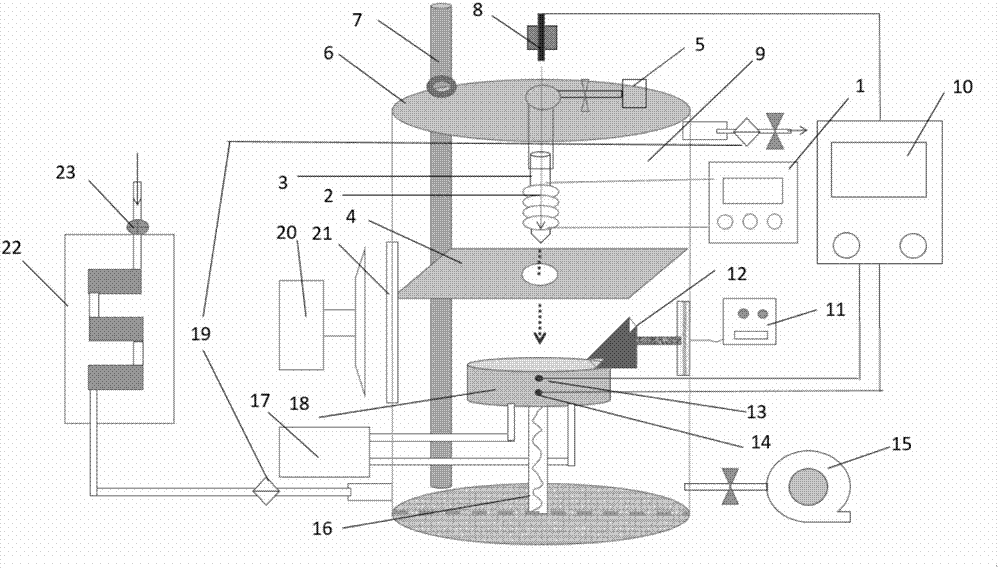

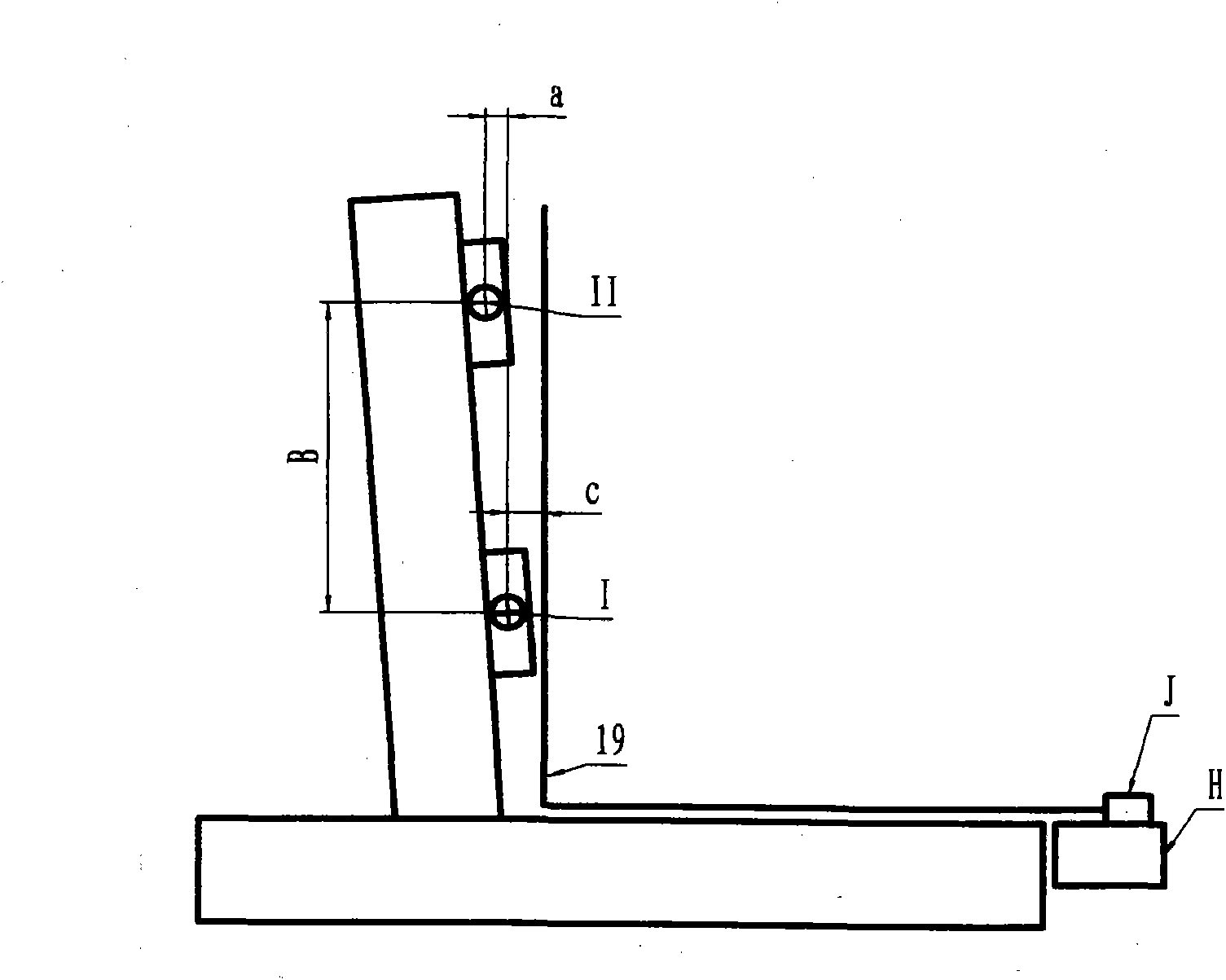

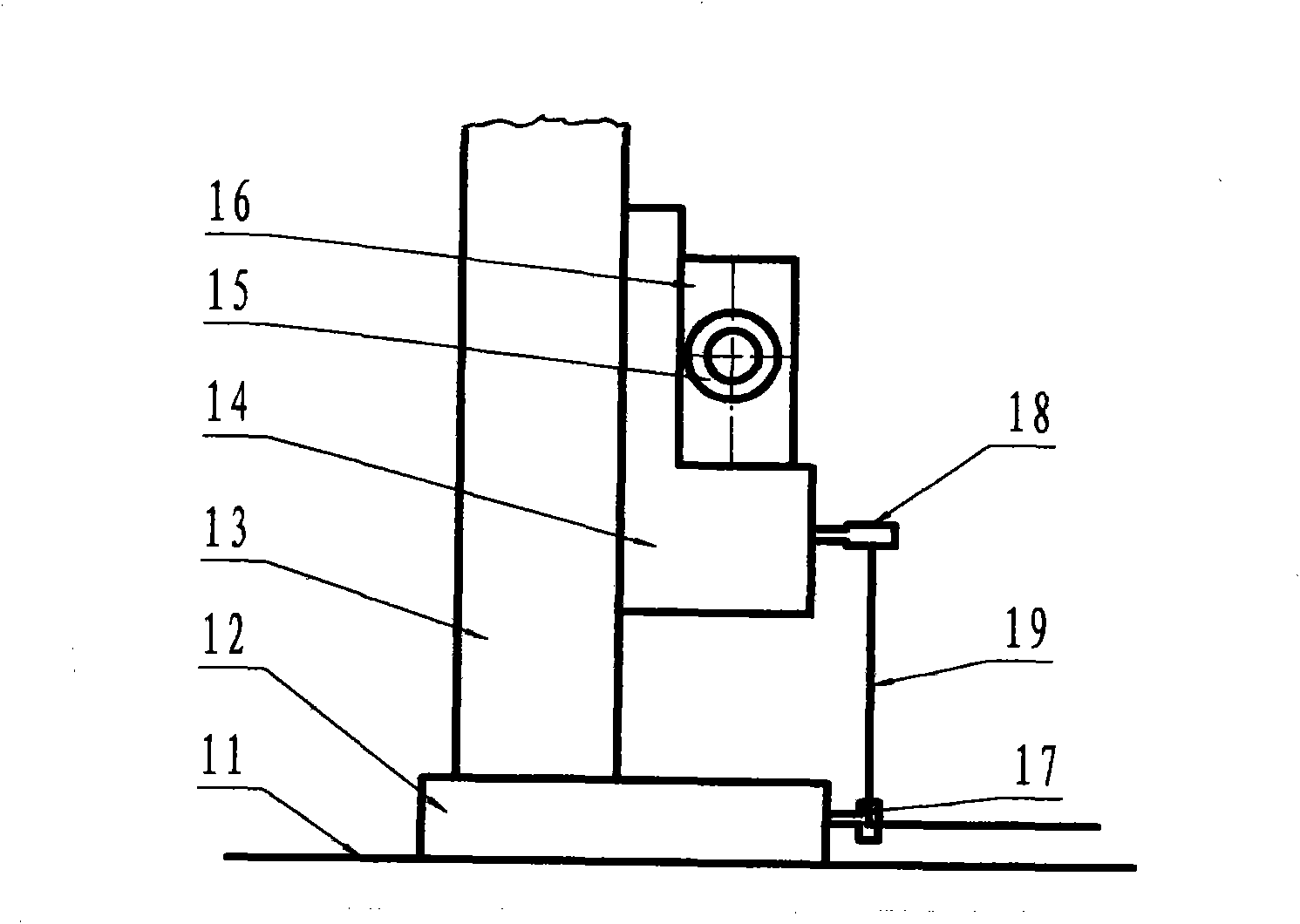

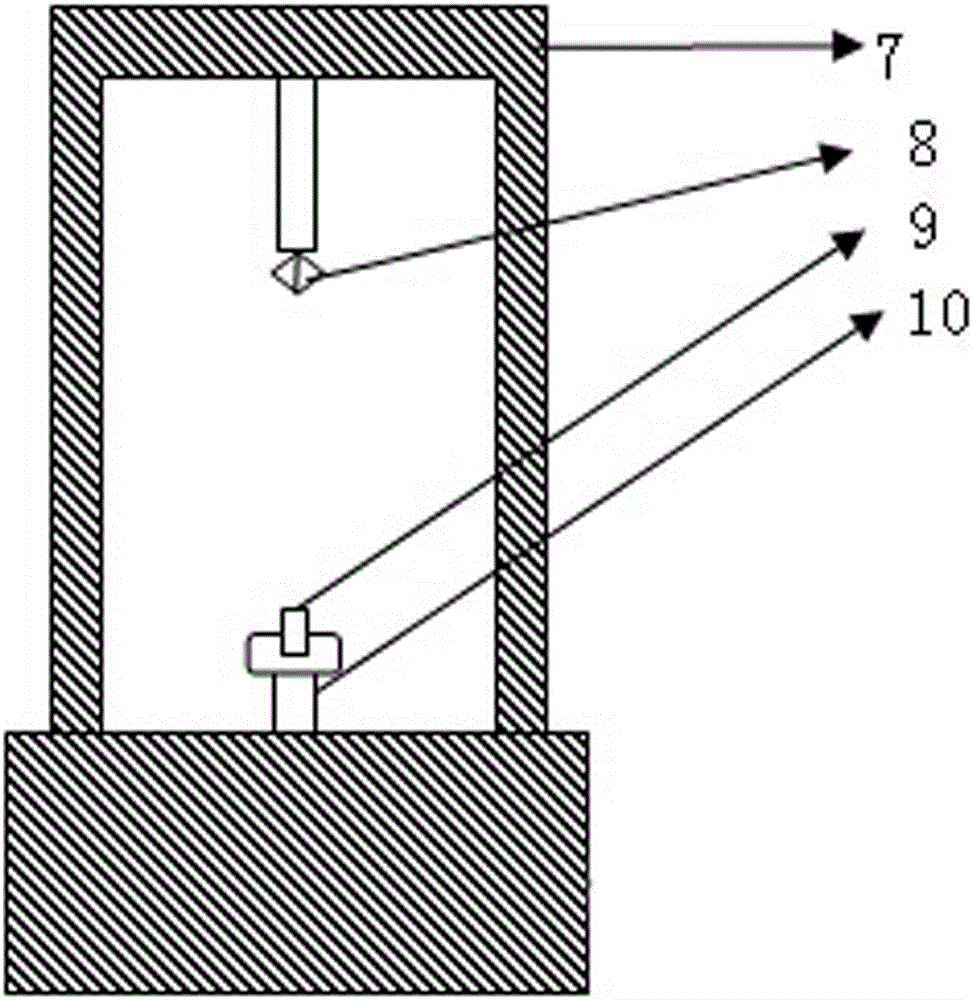

Method for testing rapid solidification behavior and solidification heat flow of metal material

InactiveCN106872512AEasy to operateEasy to useMaterial heat developmentData acquisitionDeoxygenation

The invention discloses a method for testing the rapid solidification behavior and the solidification heat flow of a metal material. A vacuum pump and a deep deoxygenation device are used for regulating and controlling protective atmosphere, an induction coil is used for heating and melting a metal material sample, inert protective gas is introduced into a quartz glass tube through a pulse air pressure controller, a metal molten drop is injected to the upper surface of a water cooling copper mould, the change pattern of a metal molten drop solidification process is captured through a high-speed pick-up device on site in real time, meanwhile, a temperature data acquisition device is synchronously started, the temperatures of two thermocouples embedded in the upper vertical position and the lower vertical position of the center of the cooling copper mould are collected and stored, the work of the high-speed pick-up device and the temperature acquisition device can be stopped after the metal molten drop is completely solidified, and then, the analysis and conversion calculation of collected information can be carried out so as to obtain an image which reflects the solidification behavior of the metal material and the change rule of the heat flow in a solidification process. The method has the advantages of convenience and simpleness in operation, good stability, low test cost, high detection efficiency, visual and intuitive result, high accuracy, wide applicable range and the like.

Owner:CENT SOUTH UNIV

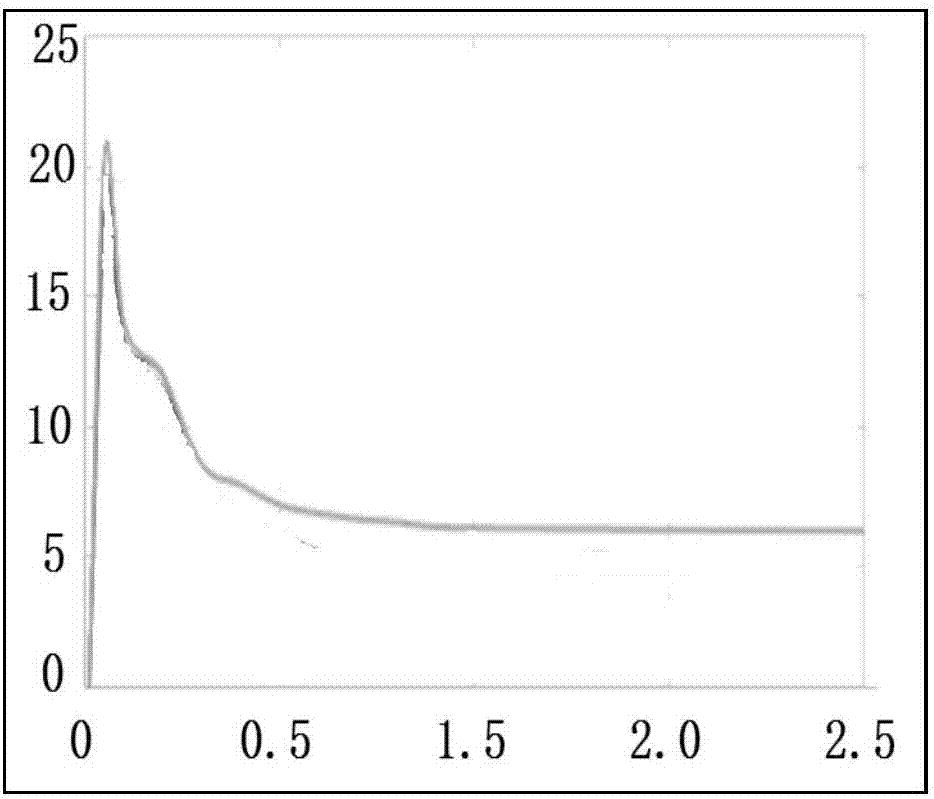

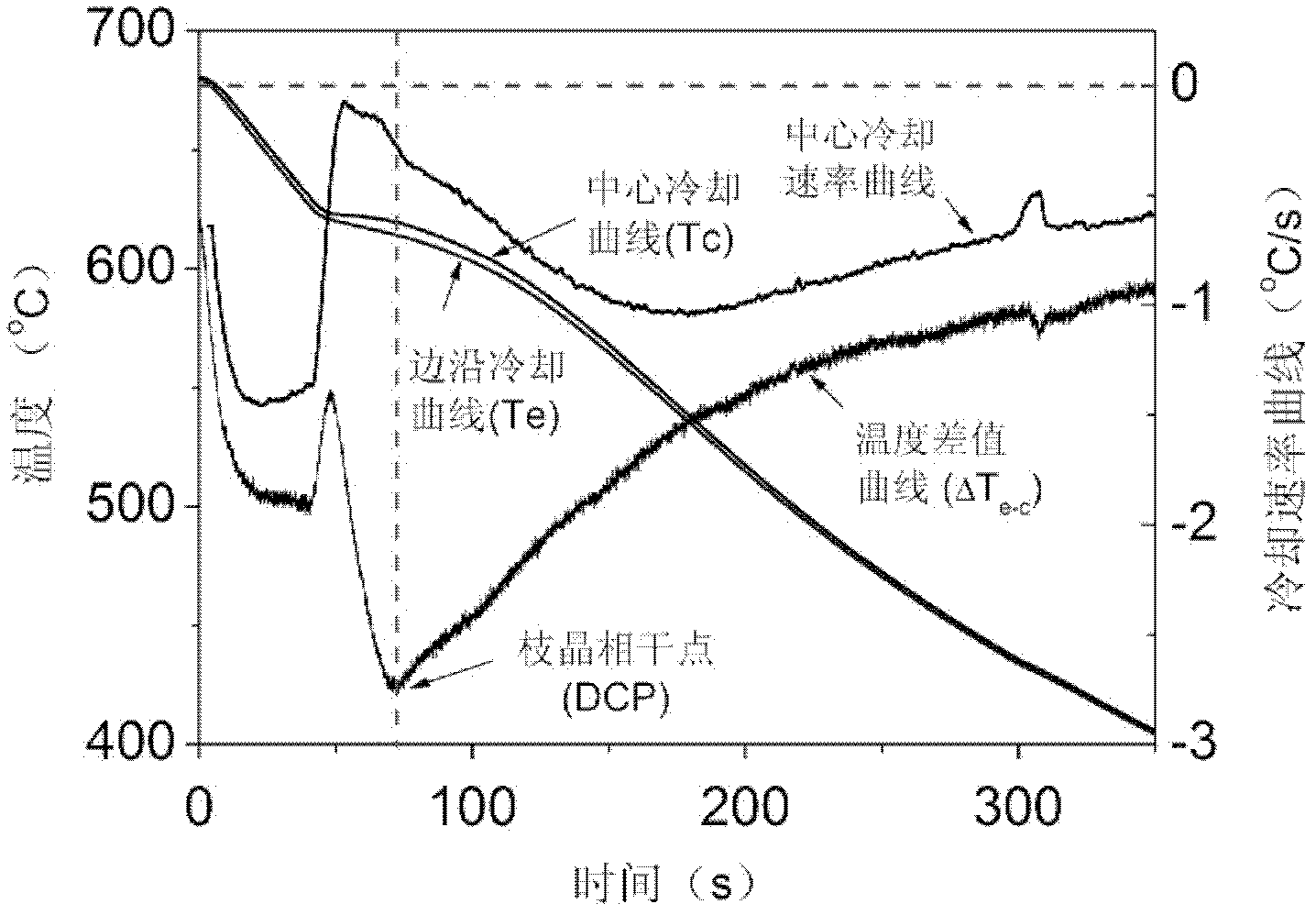

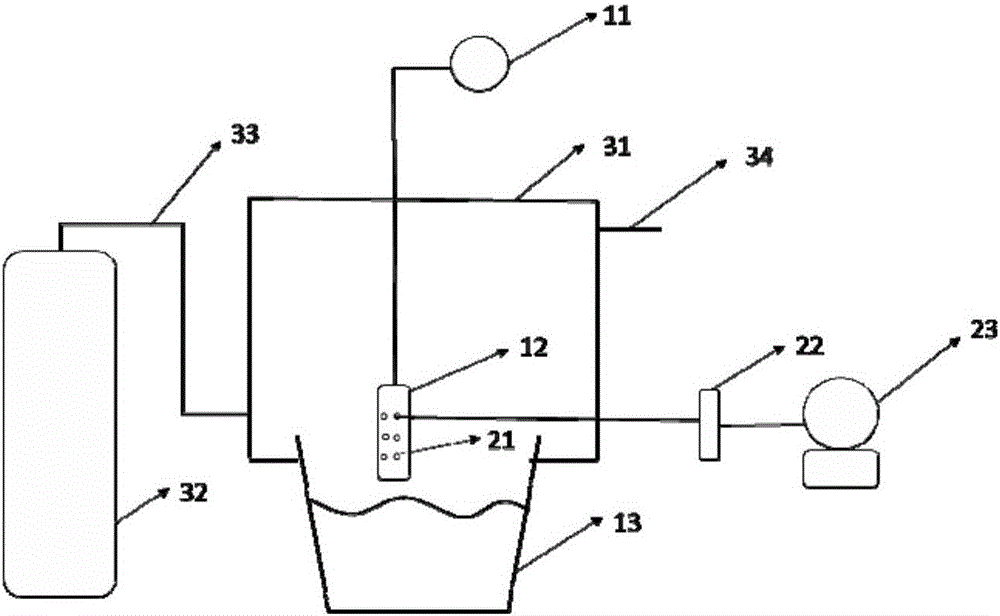

Thermal analysis and detection method and device for solidification grain size of magnesium alloy melt

ActiveCN102998324ALow costMetamorphic effect in timeParticle size analysisMaterial thermal analysisSolid phasesAlloy element

The invention provides a thermal analysis and detection method and device for solidification grain size of a magnesium alloy melt and belongs to the fields of magnesium alloy melt treatment and casting solidification. The thermal analysis and detection method provided by the invention comprises that certain amounts of magnesium and magnesium alloy melt are poured into a sampling cup to be cooled, two thermocouples are adopted for respectively determining temperatures at the center and the edge of the melt in a solidification process in a magnesium alloy melt cooling process, a temperature acquisition device is used for acquiring temperature data, a computer program is used for recording variation of the temperatures at the center and the edge of the melt in the solidification process along with time, then dendritic crystal coherence point solid phase fractional number is determined by virtue of a thermal analysis and detection method, and the dendritic crystal coherence point solid phase fractional number is compared with a standard value to judge a refining or roughening effect on the grain size of a magnesium alloy by modification, grain refining or alloying element addition. According to the thermal analysis and detection method and device provided by the invention, recalescence is not required in a thermal analysis cooling curve of the solidification process, the thermal analysis and detection method and device provided by the invention are especially applicable to the magnesium alloy with lower solidification latent heat release, a modification effect can be represented within a wider solidification speed range, and solidification grain size can be predicted.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

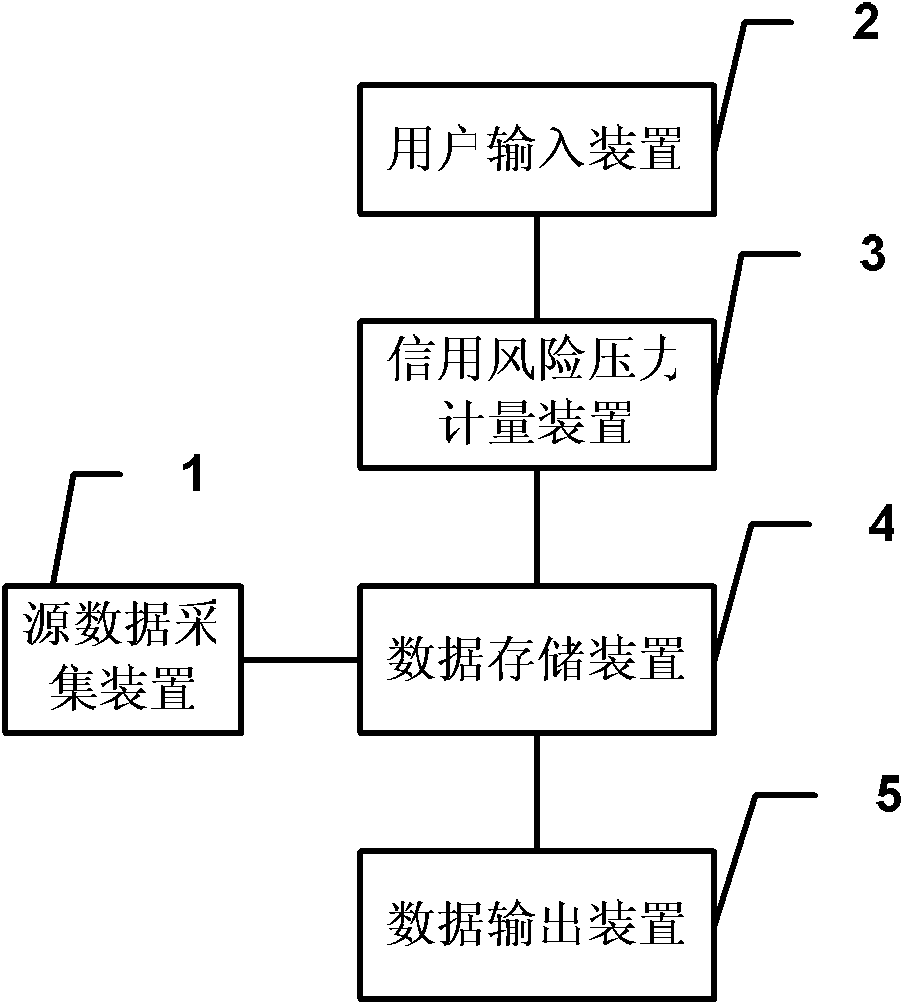

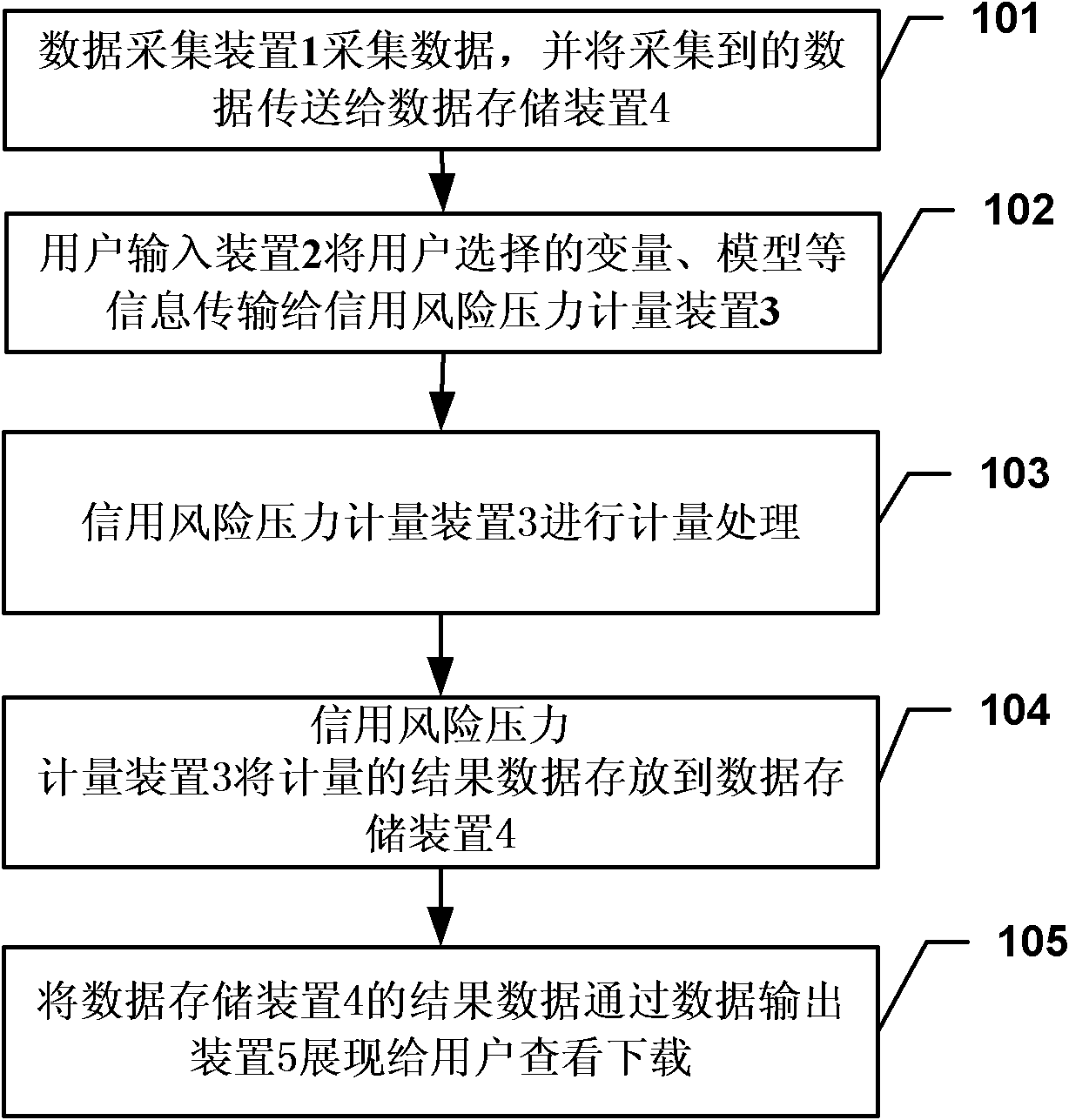

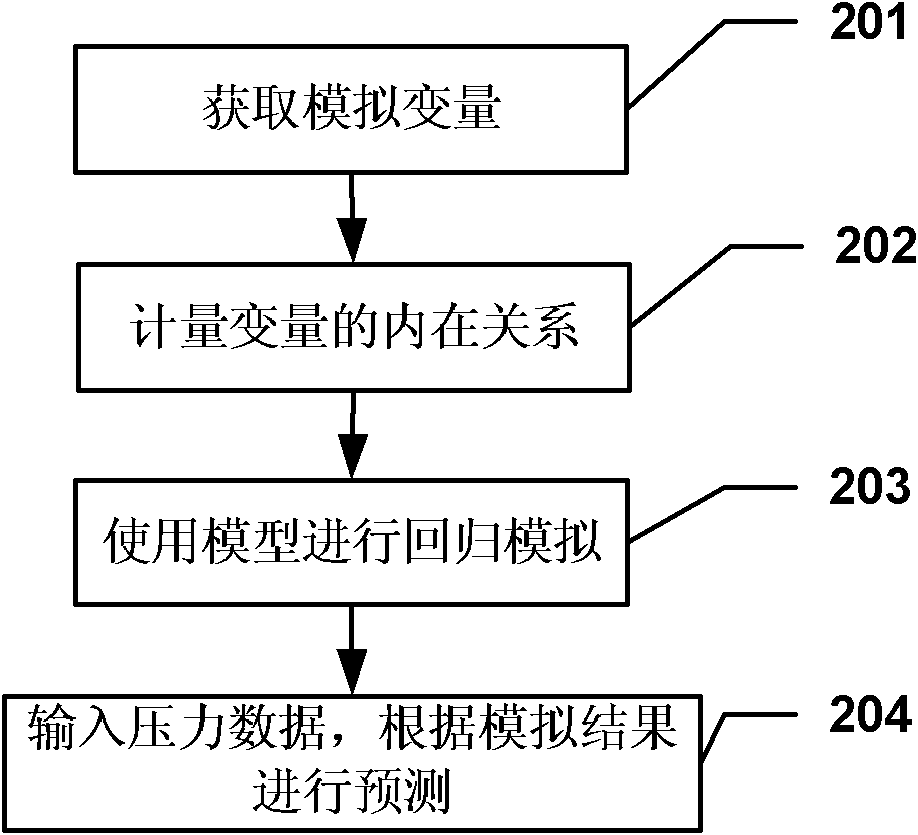

System and method for estimating credit risks

The invention discloses a system and a method for estimating credit risks in extreme cases. The system comprises a source data acquisition device, a user input device, a credit risk pressure measurement device, a data storage device and a data output device, wherein the source data acquisition device is connected with the data storage device; the user input device, the credit risk pressure measurement device, the data storage device and the data output device are connected sequentially; and the credit risk pressure measurement device reads source data collected by the source data acquisition device from the data storage device, and conducts simulation and prediction processing on the source data and user input information input by the user input device so as to realize the estimation of the credit risks in the extreme cases. The system and the method overcome the problem that objective, accurate and efficient estimation cannot be realized since the quantification and the estimation of the credit risks in the extreme cases of a bank are mainly dependent on the experience of personnel, and greatly improve the accuracy and safety of the data.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

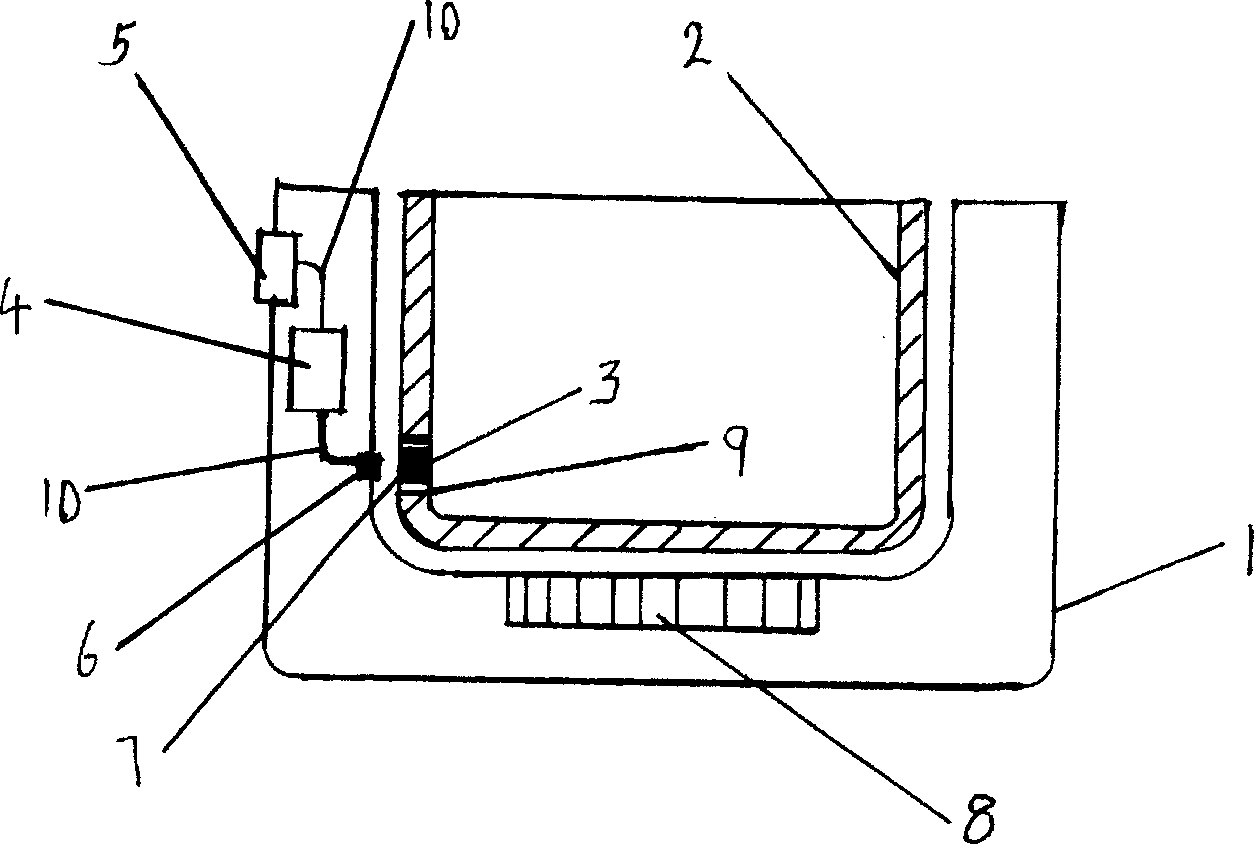

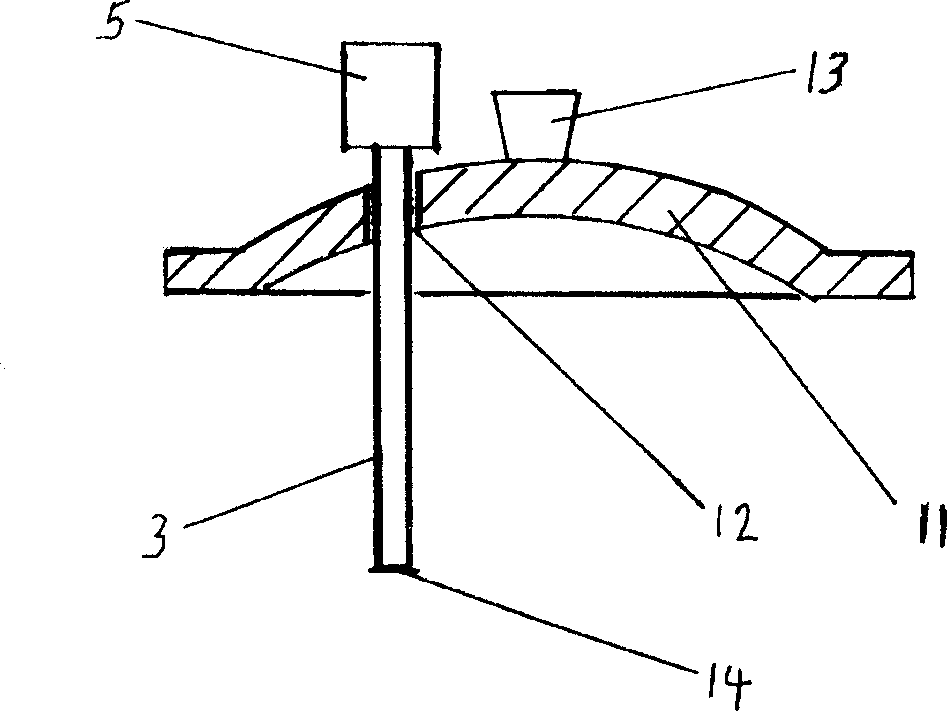

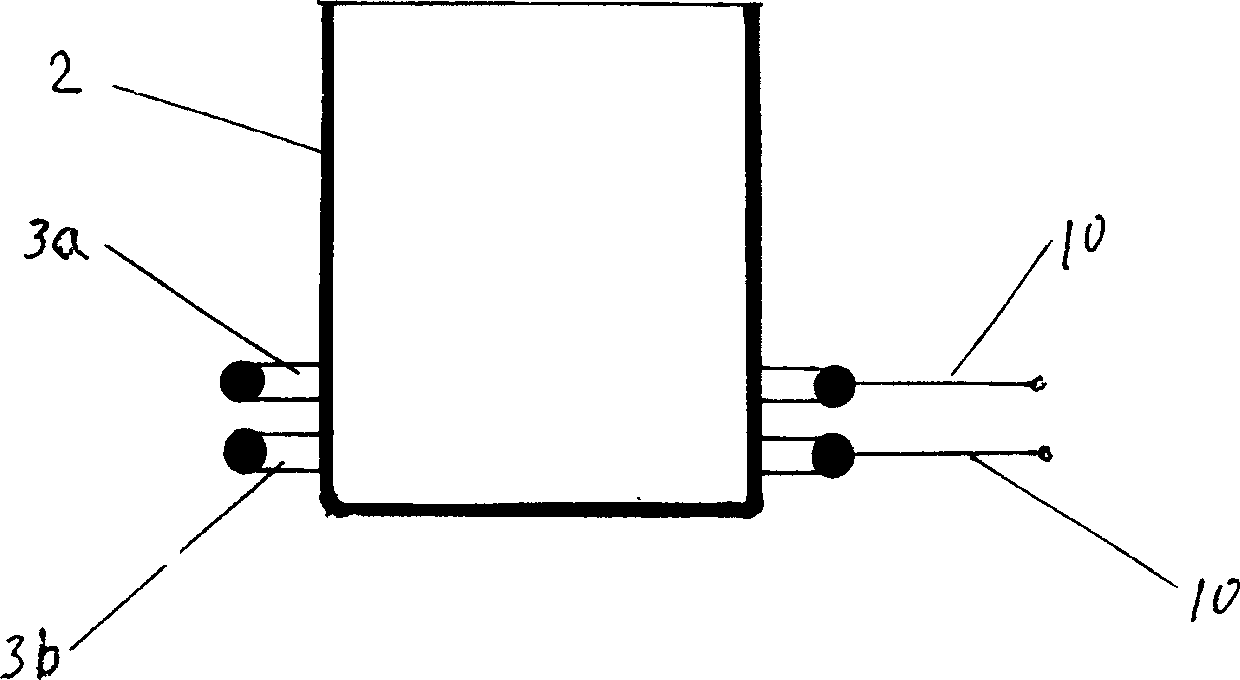

Electric cooker with electronic salinity measuring and displaying device

InactiveCN1895139AEasy to measureTimely measurementMaterial analysis by electric/magnetic meansCooking vesselsElectricityDisplay device

An electric cooker with electronic salinity measuring and displaying unit is composed of a main body, a cover, an internal cooking container in said main body, and an electronic salinity measuring and displaying unit with a salinity sensor which is arranged on main body, or internal cooking container, or cover and electrically connected with electronic salinity measuring and displaying unit in the manner of contact connector, plug-socket connector, or wireless or wire connection.

Owner:王晓东

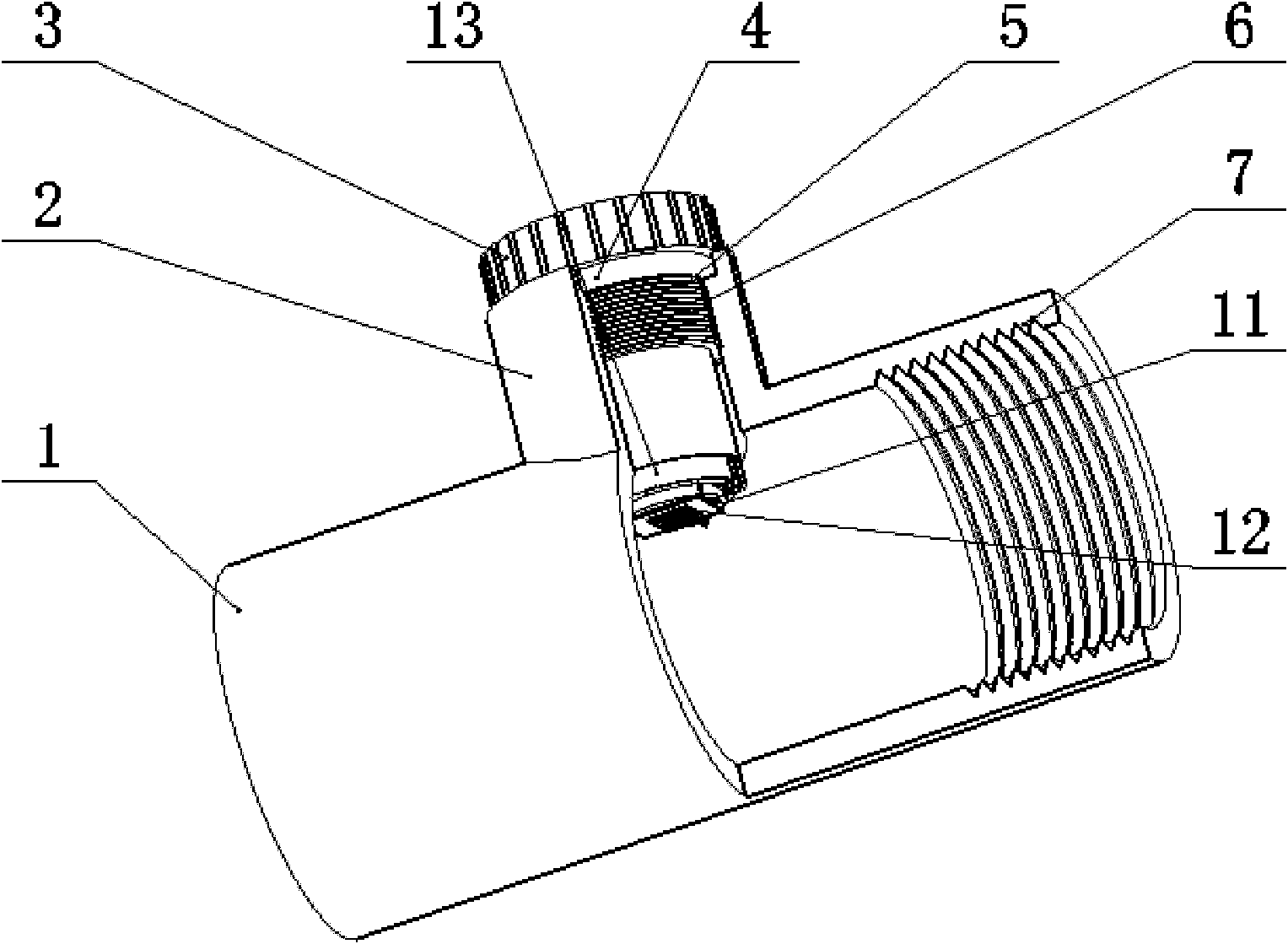

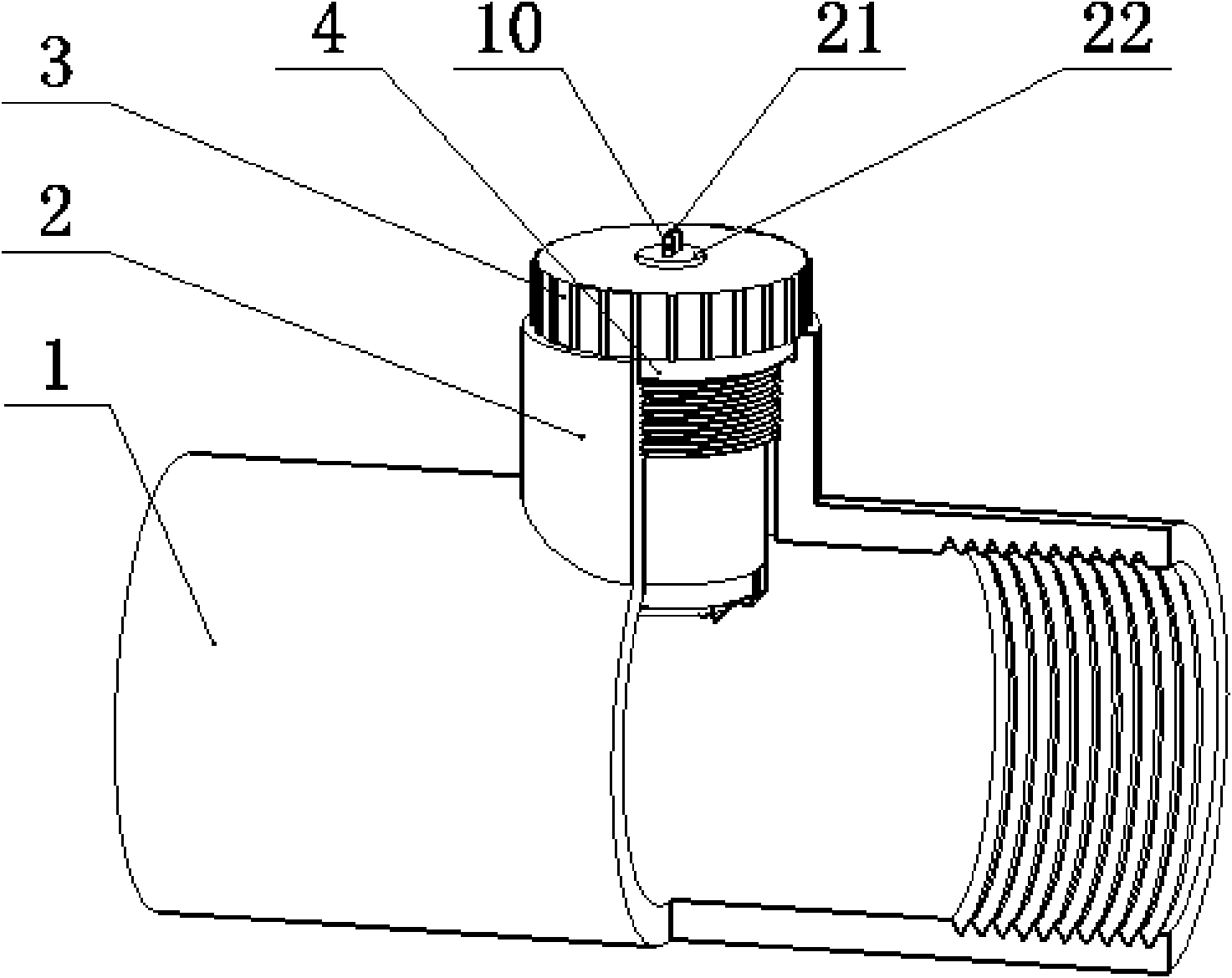

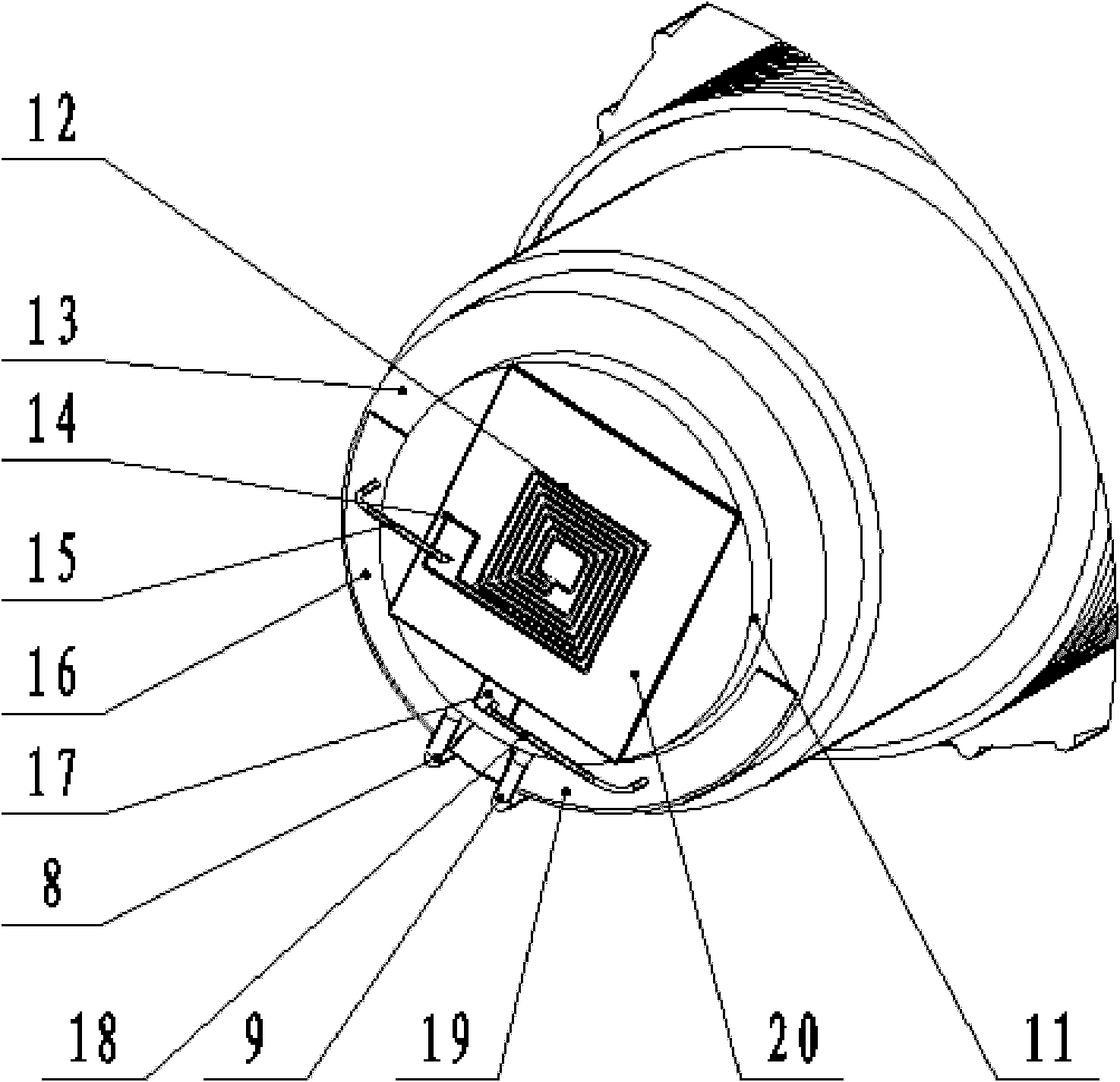

Micro-inductance sensor used for detecting metal fragments in oil liquid

InactiveCN102147230ARealize online detectionRealize Array MeasurementUsing electrical meansMaterial magnetic variablesMicro coilFerromagnetism

The invention discloses a micro-inductance sensor used for detecting metal fragments in oil liquid, which belongs to the application field of sensors. The micro-inductance sensor comprises a tee pipe joint, a piston, a micro-coil, a PCB (printed circuit board), a welding lead, a bonding lead and an insulating layer. The micro-inductance sensor has the characteristics that: (1) the online detection of the metal fragments in the oil liquid can be realized; (2) the metal fragments with small size can be measured by the micro-coil, such as the diameter of 20-120mum, forecast is given off in the early stage of wear failure of equipment so as to take maintenance and repair measures; (3) the ferromagnetism or non-ferromagnetism of the metal fragments can be judged, and more diagnostic messages can be provided for judging whether the wear part is a bearing or a gear; and (4) the array measurement of the oil liquid can be realized, and the amount of oil sample measurement is increased.

Owner:BEIJING UNIV OF TECH

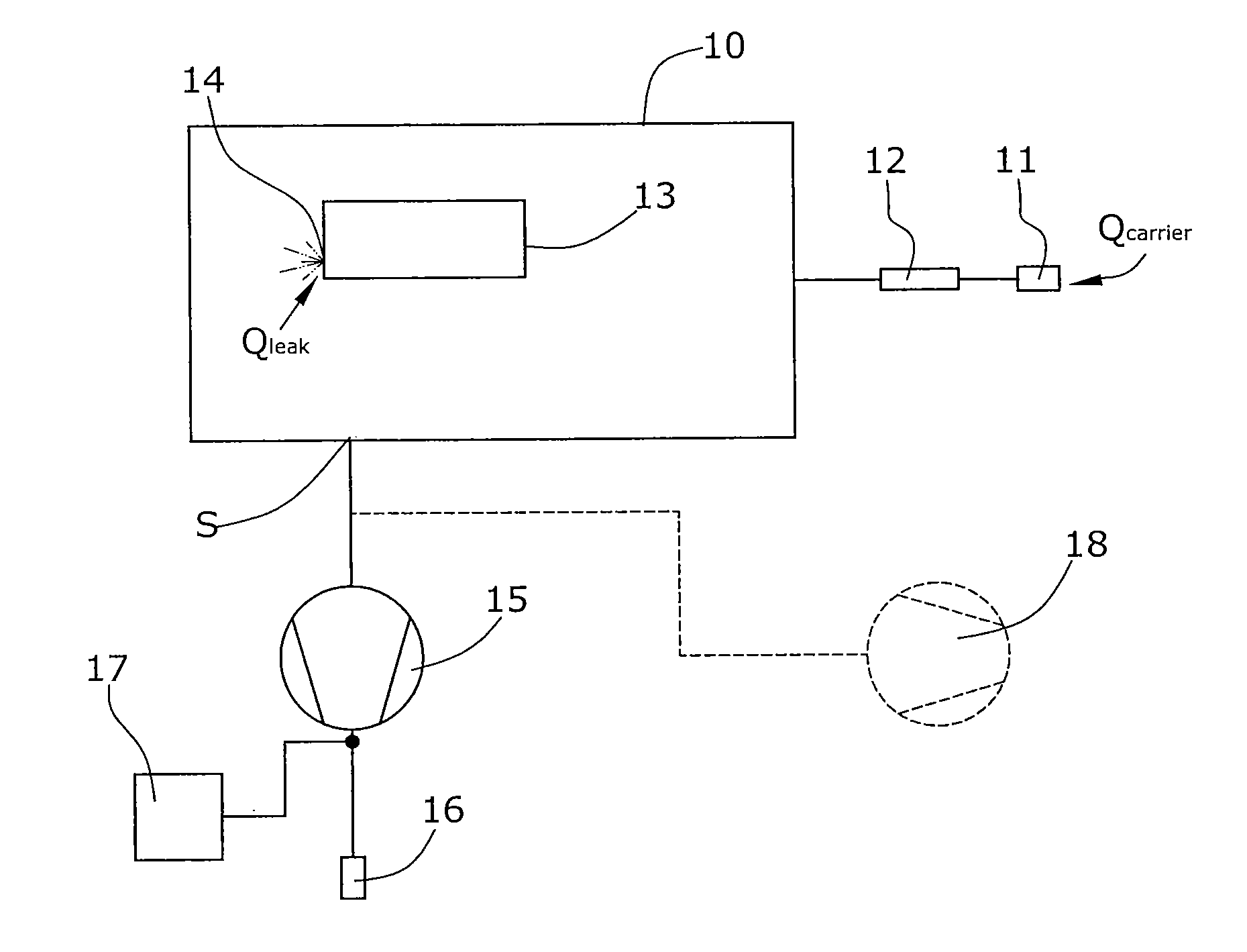

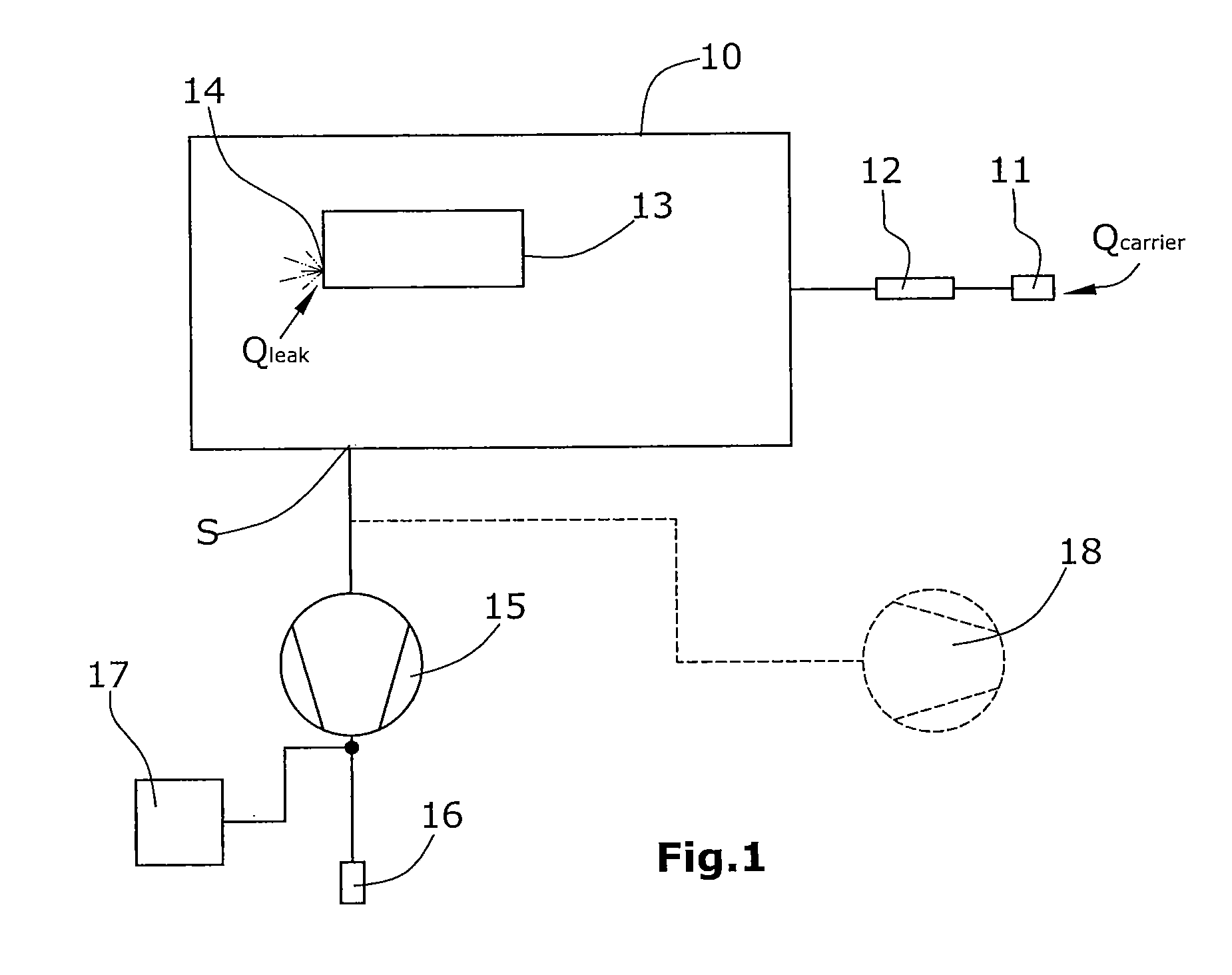

Method and device for tightness testing

ActiveUS20100313634A1Increase partial pressureFast system reaction timeDetection of fluid at leakage pointProduct gasEngineering

A test subject, which is filled with test gas, is placed in a testing chamber, which can be evacuated. A carrier gas is conducted into the testing chamber, so that a gas mixture made of carrier gas and test gas forms therein. The gas mixture is suctioned out of the testing chamber by a compressor pump. A testing gas sensor is connected to the outlet of the compressor pump. The test gas is contained in the compressed gas mixture at a partial pressure which is increased by the compression ratio. In this manner, the sensitivity of the test gas recognition is increased and / or the time constant of the measurement is shortened.

Owner:INFICON GMBH

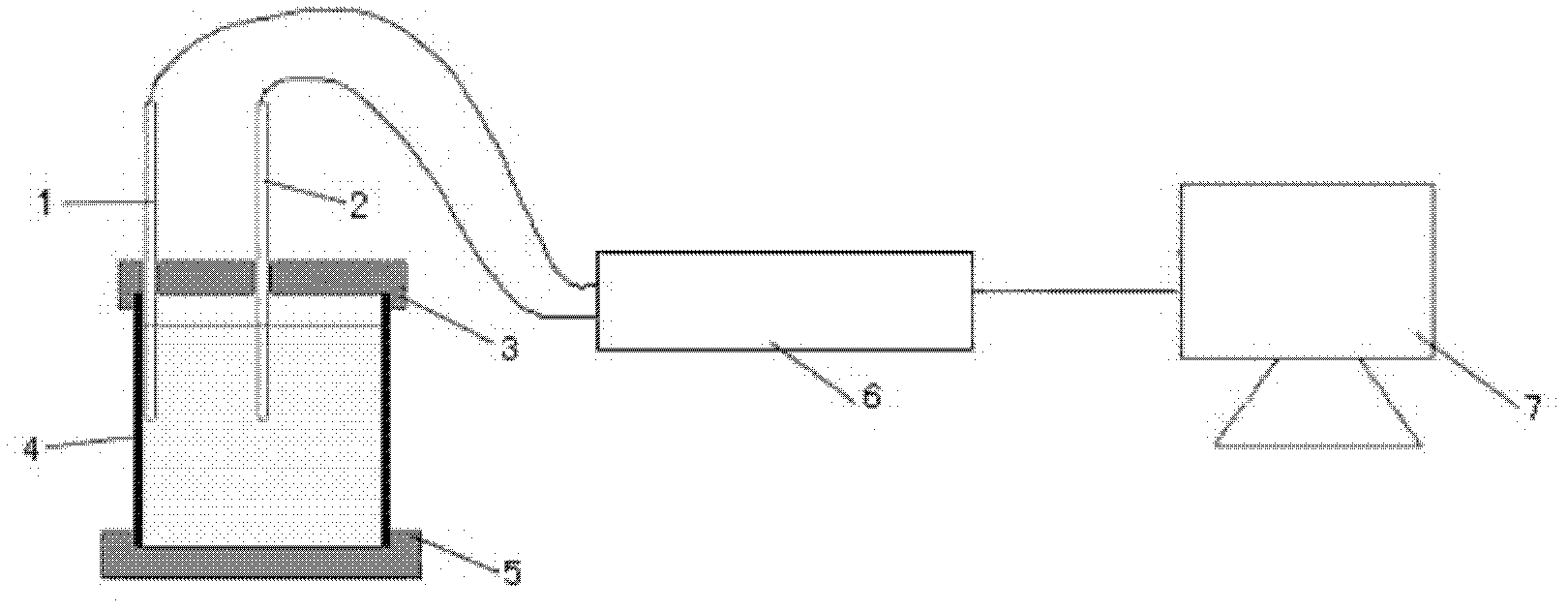

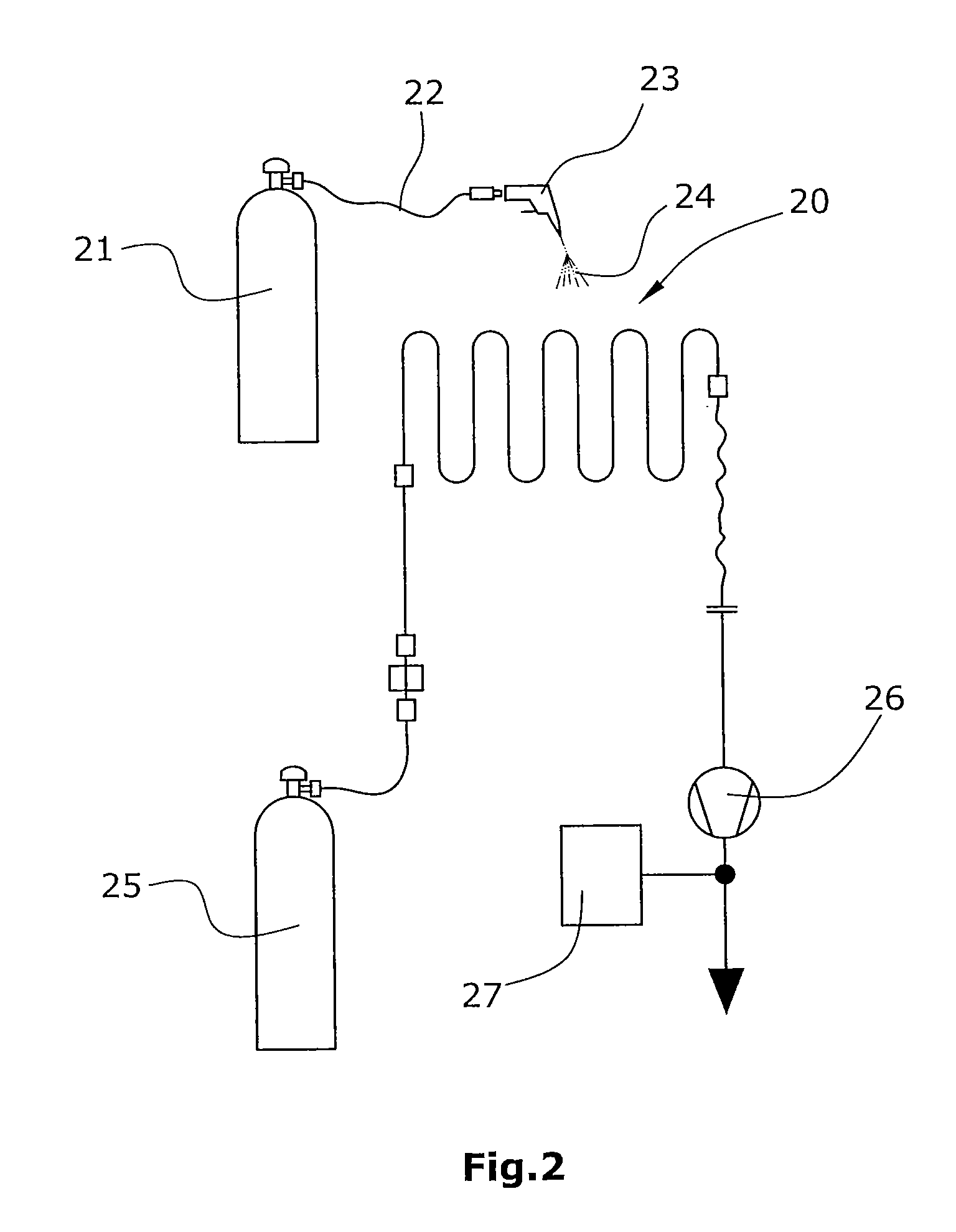

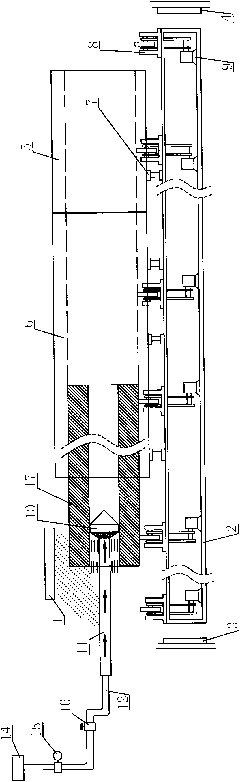

Rapid immersion type metal solidification heat transfer test device and application and application method thereof

InactiveCN106645278ASimple methodSimple test equipmentMaterial heat developmentDirect testGas cylinder

The invention discloses a rapid immersion type metal solidification heat transfer test device and an application method of the device. The test device comprises a mechanical system, a data acquisition system and an atmosphere control system; the mechanical system comprises an induction furnace heated electrically, and an immersion type copper mould controlled by a motor; the data acquisition system comprises a thermocouple located in the copper mould and an external data acquisition card and computer; the atmosphere control system comprises a protective gas hood for accommodating the induction furnace and the copper mould, gas inlet and outlet pipes and a gas cylinder; the mechanical system and key parts of the data acquisition system are both arranged in an atmosphere protection room of the atmosphere control system. The test equipment disclosed by the invention is simple and easy in method, high in accuracy and wide in application range and can be used for carrying out heat transfer testing during a metal rapid solidification process in a laboratory scale, thereby replacing direct testing in industrial production, not affecting the normal production, and further being small in consumption and low in test cost.

Owner:CENT SOUTH UNIV

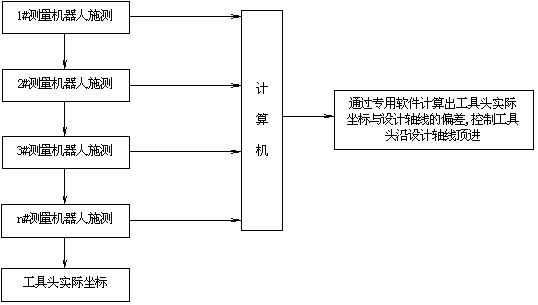

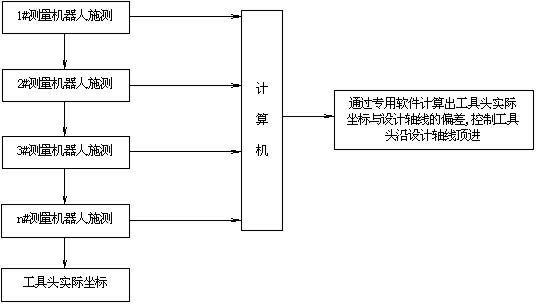

Pipe jacking project automatic measurement system and method thereof

InactiveCN102564389AHigh precisionEliminate or reduce error factorsAngle measurementOptical rangefindersData terminalShielded cable

The invention relates to a pipe jacking project automatic measurement system and a method thereof. The pipe jacking project automatic measurement system comprises auxiliary observation stations established at the turning positions in the pipe jacking construction. Each auxiliary observation station consists of an automatic leveled base and a measurement robot total station. A data terminal of each measurement robot total station is connected with a data port of a computer by a shielded cable. Measurement data is processed by the computer. Each total station is sequentially controlled by the computer to orderly carry out transfer measurement. According to the invention, measurement robots are adopted to be connected with the programmed computer and the computer commands each measurement robot to carry out automatic tracking measurement according to a program. The system and the method thereof can be used for conveniently and timely measuring actual coordinate values of a tool head in various curve pipe jacking projects.

Owner:SHANGHAI FOUND ENG GRP

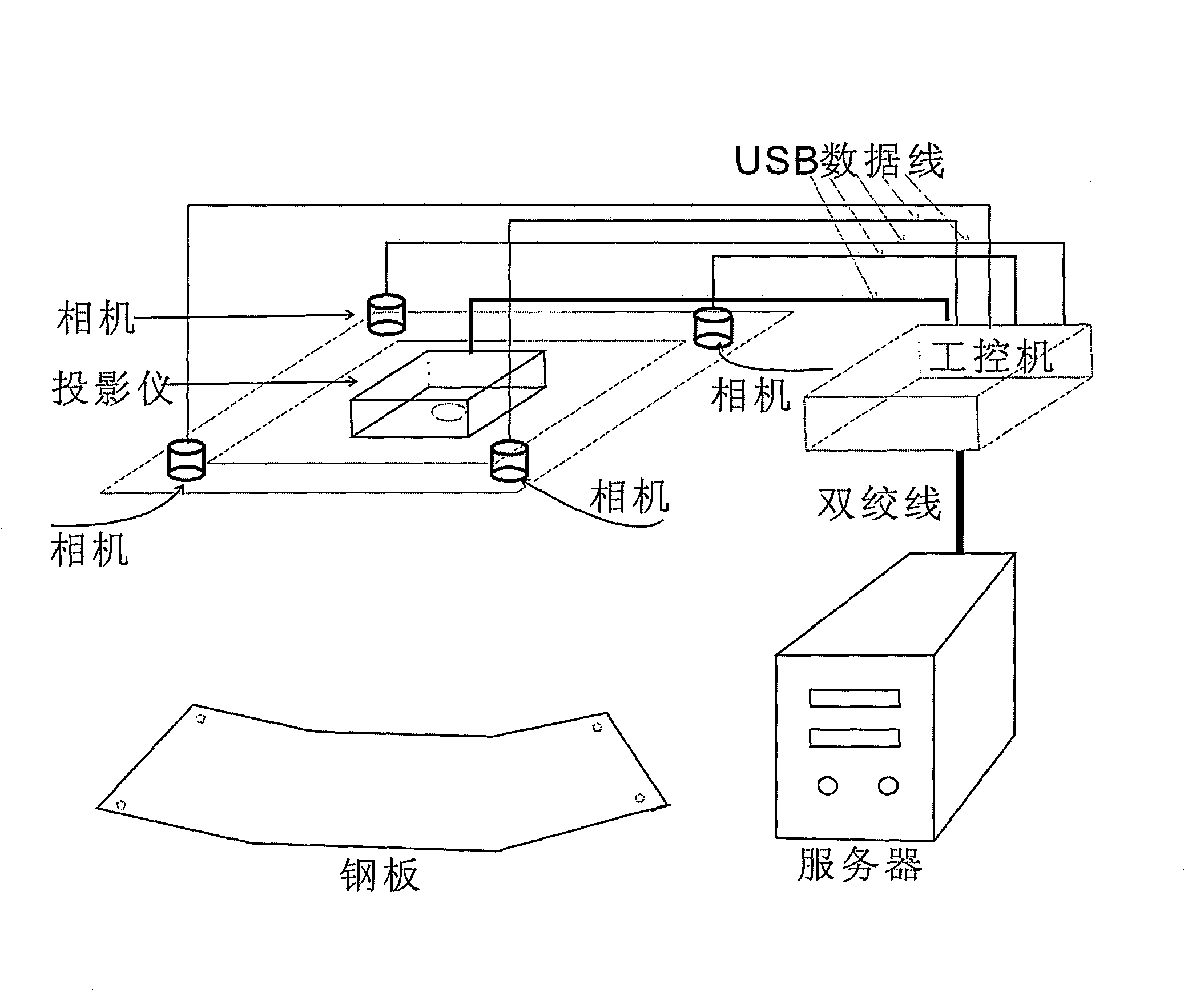

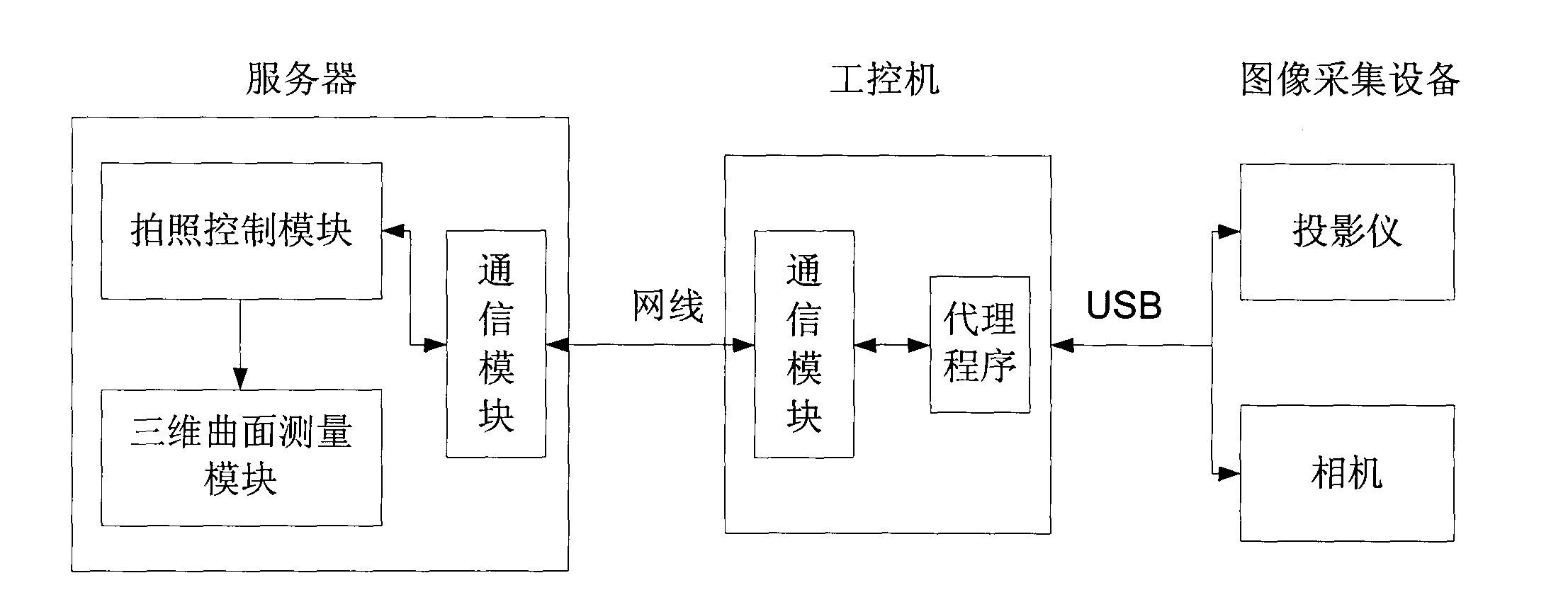

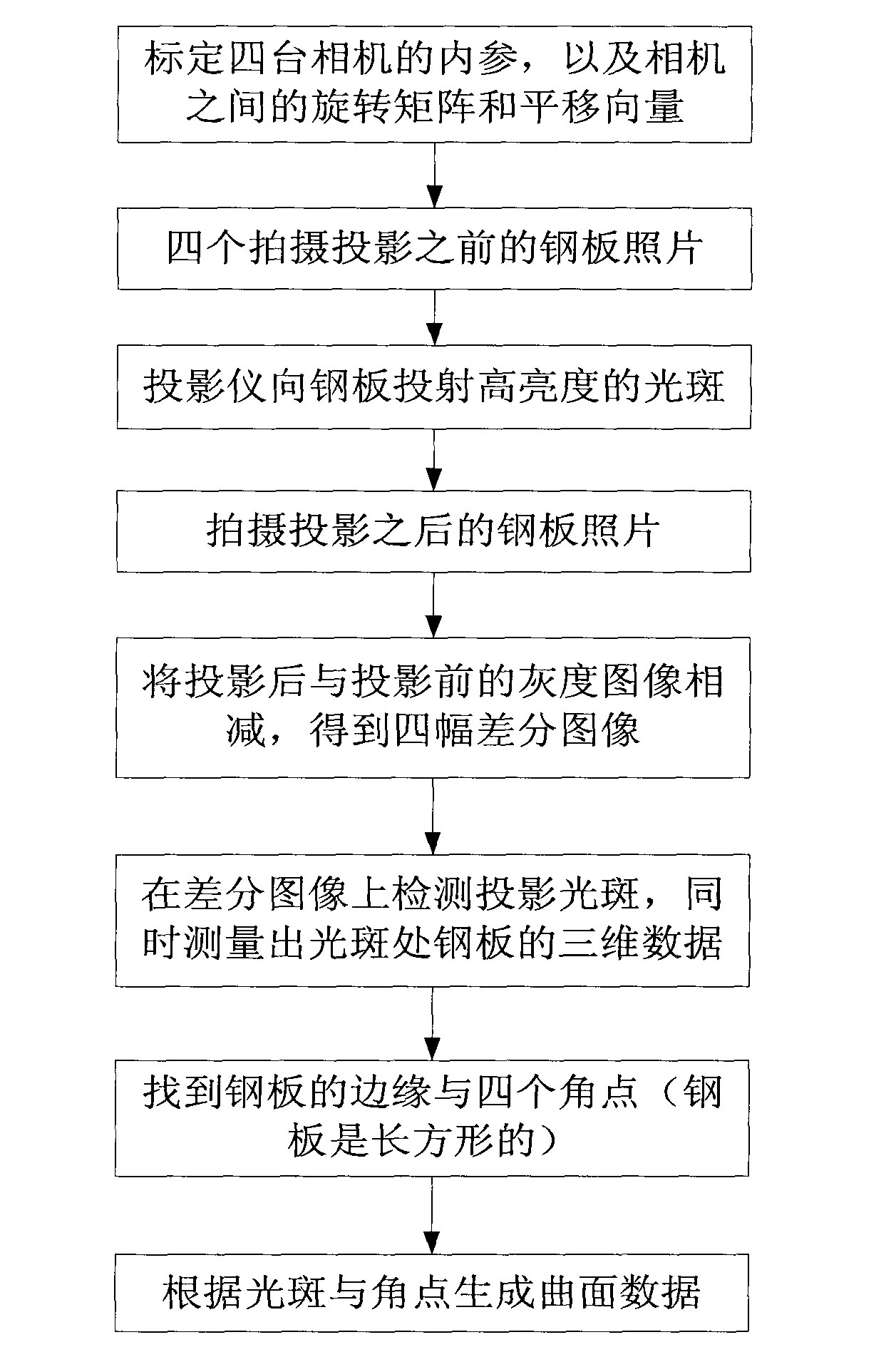

Ship steel plate dynamic three-dimension measurement method based on multi-camera vision

InactiveCN102679937ATimely measurementEasy to measureMeasurement devicesMulti cameraDimension measurement

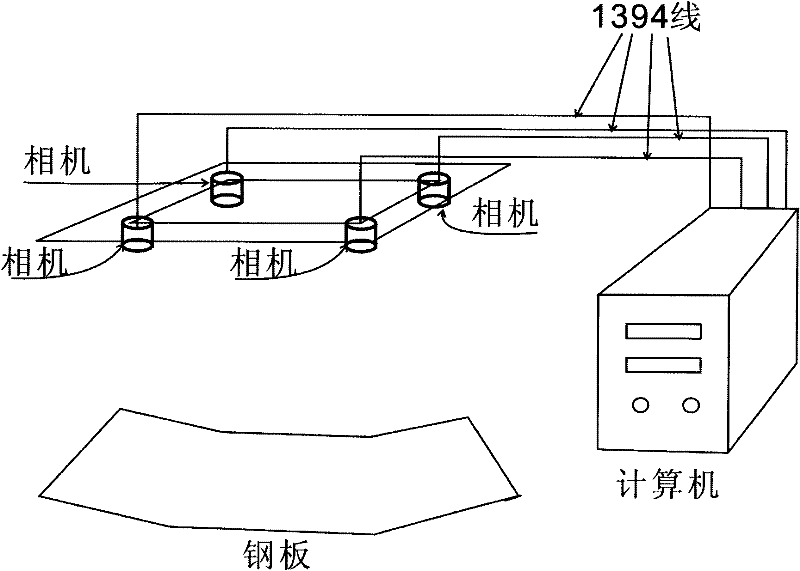

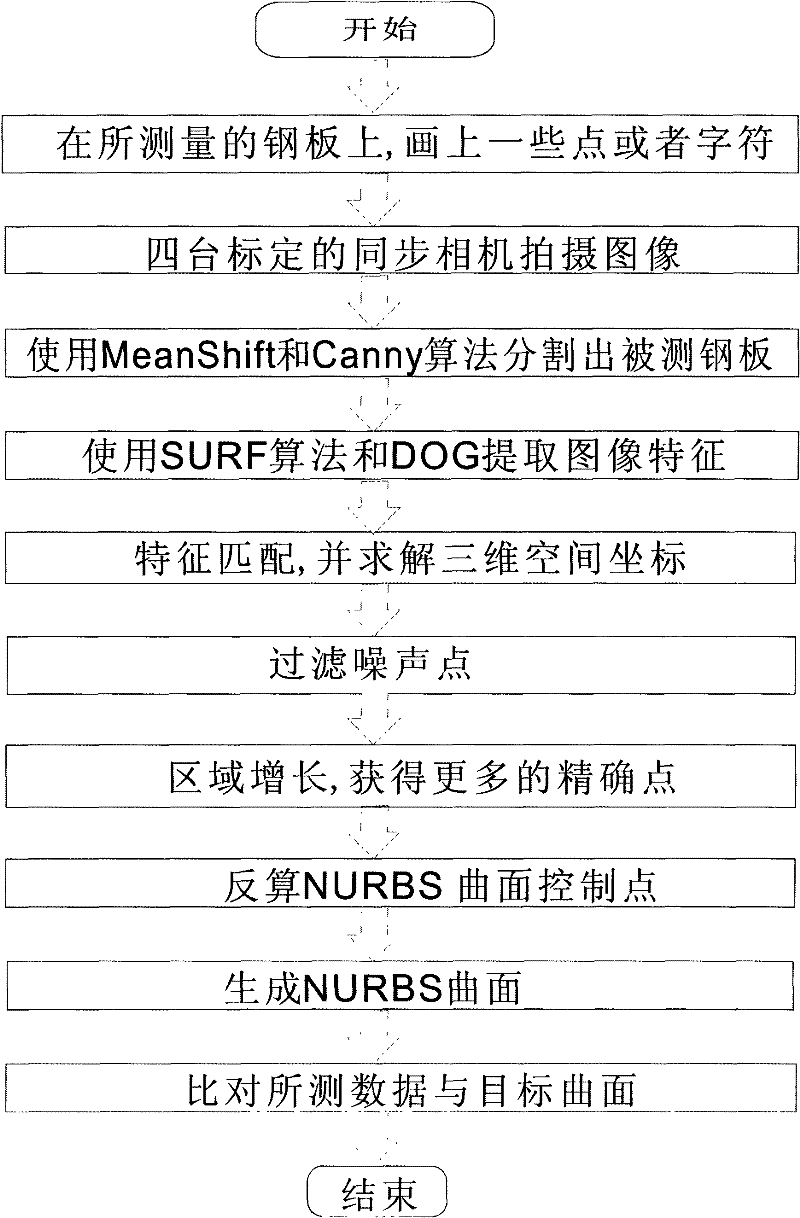

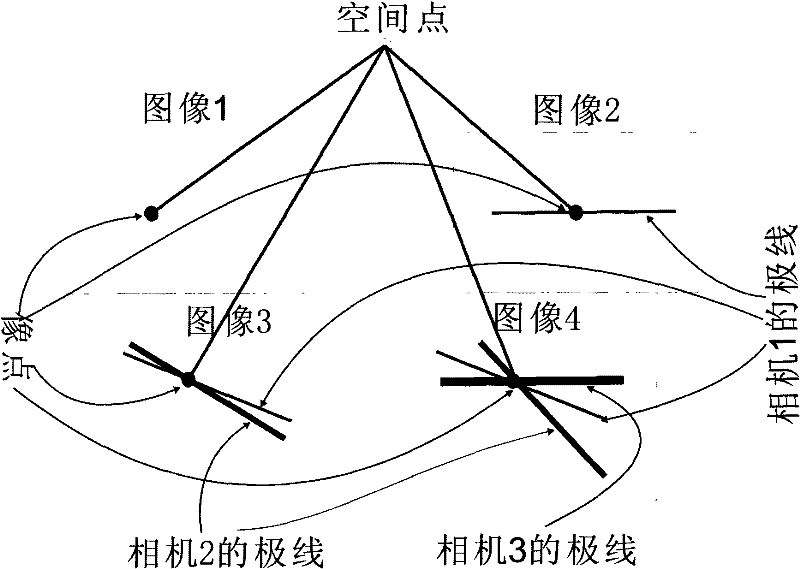

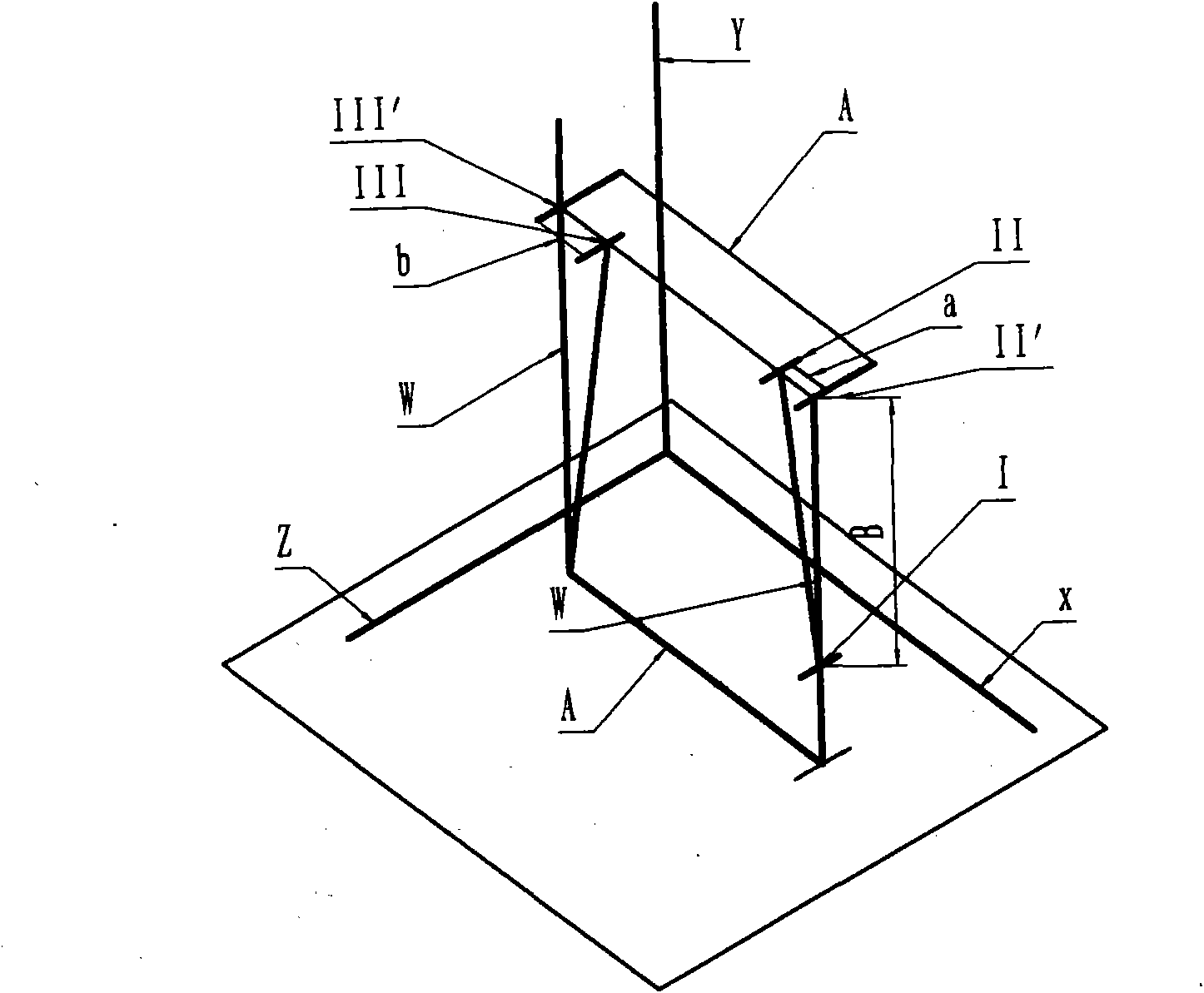

The invention relates to a technique for measuring ship steel plate bending deformation in the ship manufacture process, in particular to a ship steel plate dynamic three-dimension measurement method based on multi-camera vision. The method is that four synchronous high-resolution industrial cameras with resolution ratio above 1440*1080 and frame rate as 10fps are fixed on a measuring frame of a ship steel plate bending automated control system, images shot by the four industrial cameras are transmitted to a high-performance computer capable of performing storing and analyzing through a 1394 line and a 1394 card, and ship steel plate dynamic three-dimension measured data analysis including steps of dynamic three-dimension measurement and algorithm is conducted. By aid of the ship steel plate dynamic three-dimension measurement method, the steel plate surface is not contacted, and dynamic three dimensions of a ship steel plate can be measured automatically, timely, conveniently and accurately.

Owner:ZHENJIANG YIHAI SOFTWARE

Method for detecting and compensating floor-type boring and milling machine space position by using double-frequency laser measurement system

InactiveCN101890659AHigh precisionImprove stabilityUsing optical meansOther manufacturing equipments/toolsLaser interferenceEngineering

The invention discloses a method for detecting and compensating a floor-type boring and milling machine space position by using a two-frequency laser measurement system, and belongs to the field of numerical control machines. In the method, a fixed datum plane is established on a tip of a horizontal lathe guide rail of the numerical control floor-type boring and milling machine, a laser generator of a double-frequency laser interference measurement system which is provided with a computer is fixed on the datum plane, a laser beam emitted by the laser generator is controlled to be higher than the plane of the lathe guide rail, a lower sliding seat of the lathe is provided with a vertical conversion lens, the laser beam emitted by a double-frequency laser generator is conversed by the conversion lens into a vertically upward laser beam, and an interference target lens is arranged on a ram seat of the lathe; and the position of the central point of a boring bar is taken as the first positioning point when an upright column of the lathe and the ram seat are at certain positions, the points of new positions of the upright column of the lathe and the ram seat after movement are taken as second and third positioning points, the laser beam emitted by the double-frequency laser generator is utilized to measure an error due to lathe precision and foundation variation, and the error is compensated by a numerical control system of the lathe, so that the machining precision of the numerical control floor-type boring and milling machine is improved.

Owner:SHENJI GRP KUNMING MACHINE TOOL

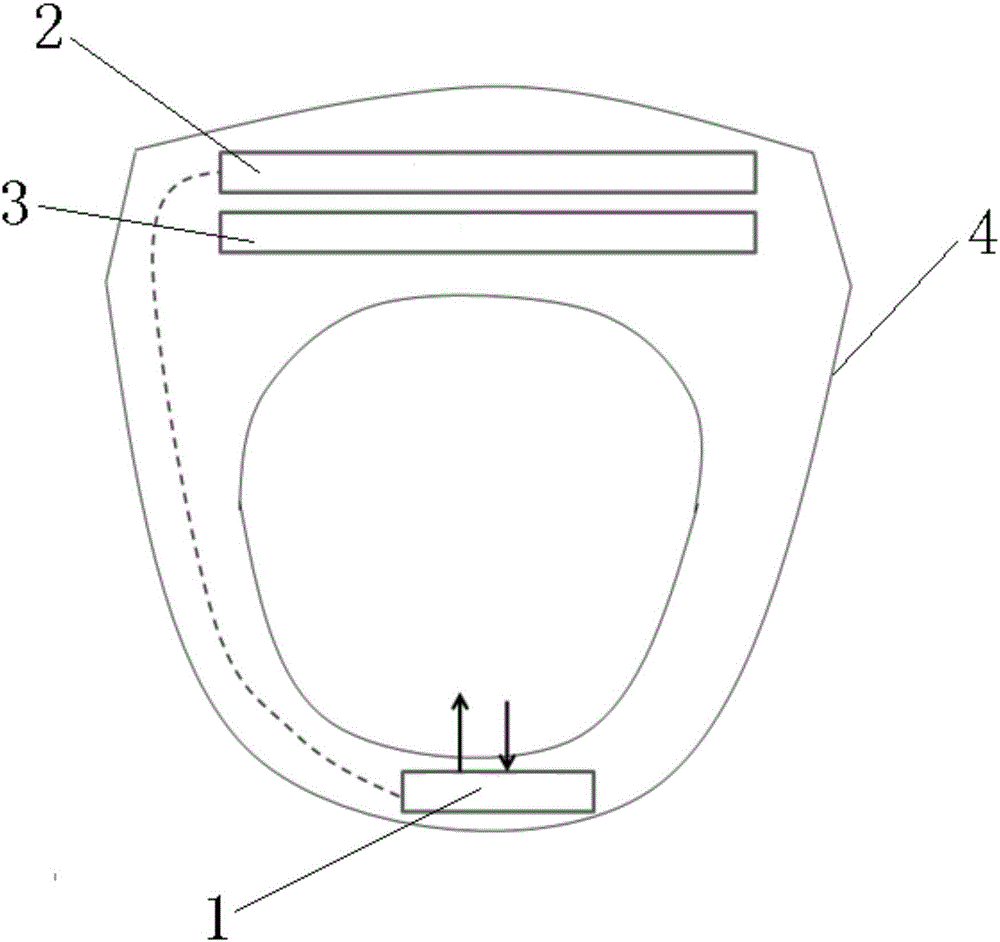

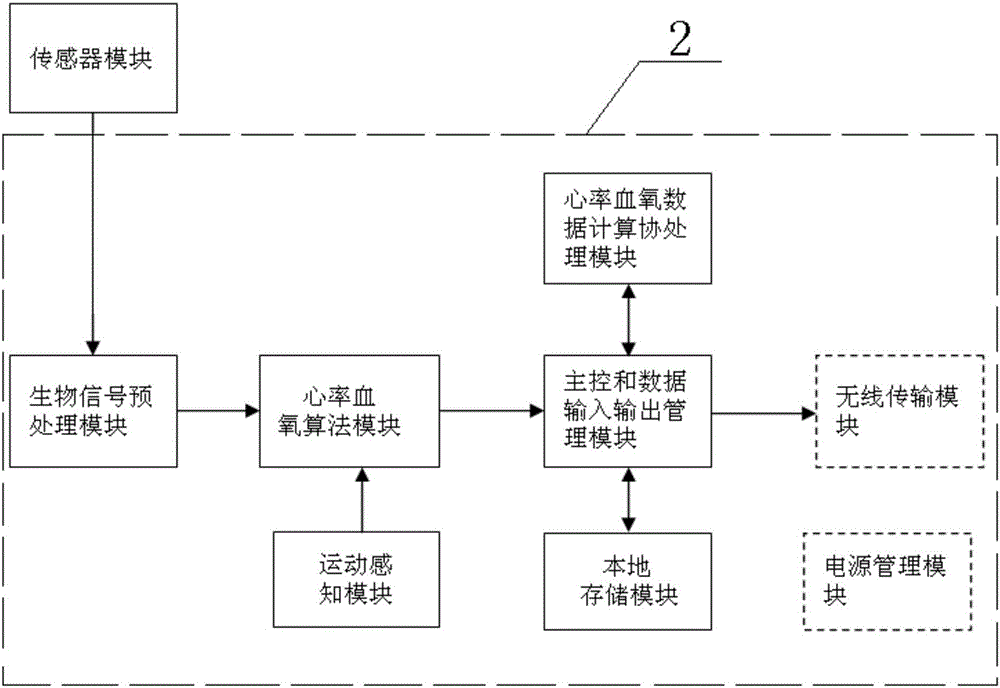

Portable blood oxygen measuring system

InactiveCN106236105AGuaranteed timelinessGuaranteed accuracySensorsMeasuring/recording heart/pulse rateElectricityPulse rate

The invention discloses a portable blood oxygen measuring system. The portable blood oxygen measuring system is characterized by comprising a sensor module for detecting signals from the surface skin of a human body and a master control module electrically connected with the sensor module and used for processing the measurement signals of the sensor module to obtain physiological information of a detector, wherein a battery is connected to the master control module, the sensor module, the master control module and the battery are integrally arranged on a housing worn on the finger or wrist. The portable blood oxygen measuring system makes activities of a wearer not limited at the finger or wrist of the human body without accessories for heart rate and blood oxygen saturation degree measurement, the wearer can perform daily continuous monitoring in a static or dynamic state, and the portable blood oxygen measuring system is more convenient to use and can provide continuous and reliable data recording and analysis results for a user or a medical worker and provide an effective basis for follow-up diagnosis and give treatment.

Owner:CHENGDU ICARETECH

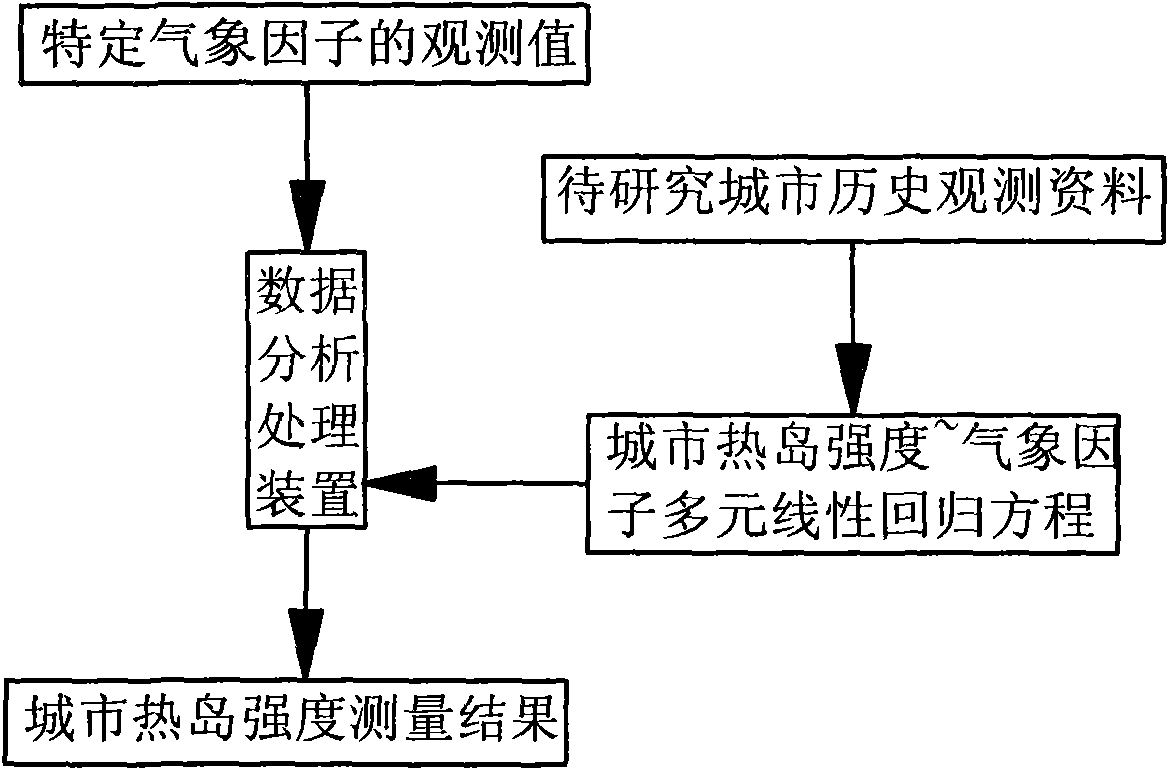

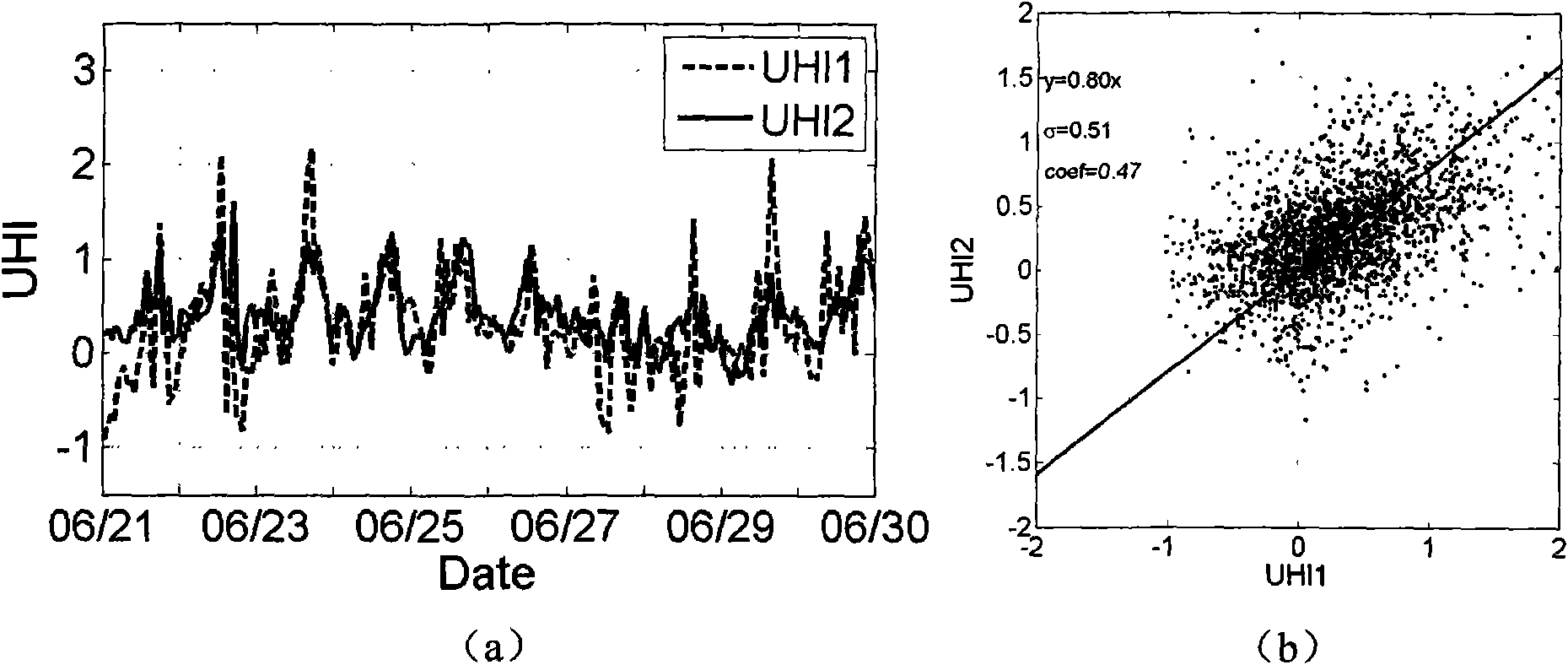

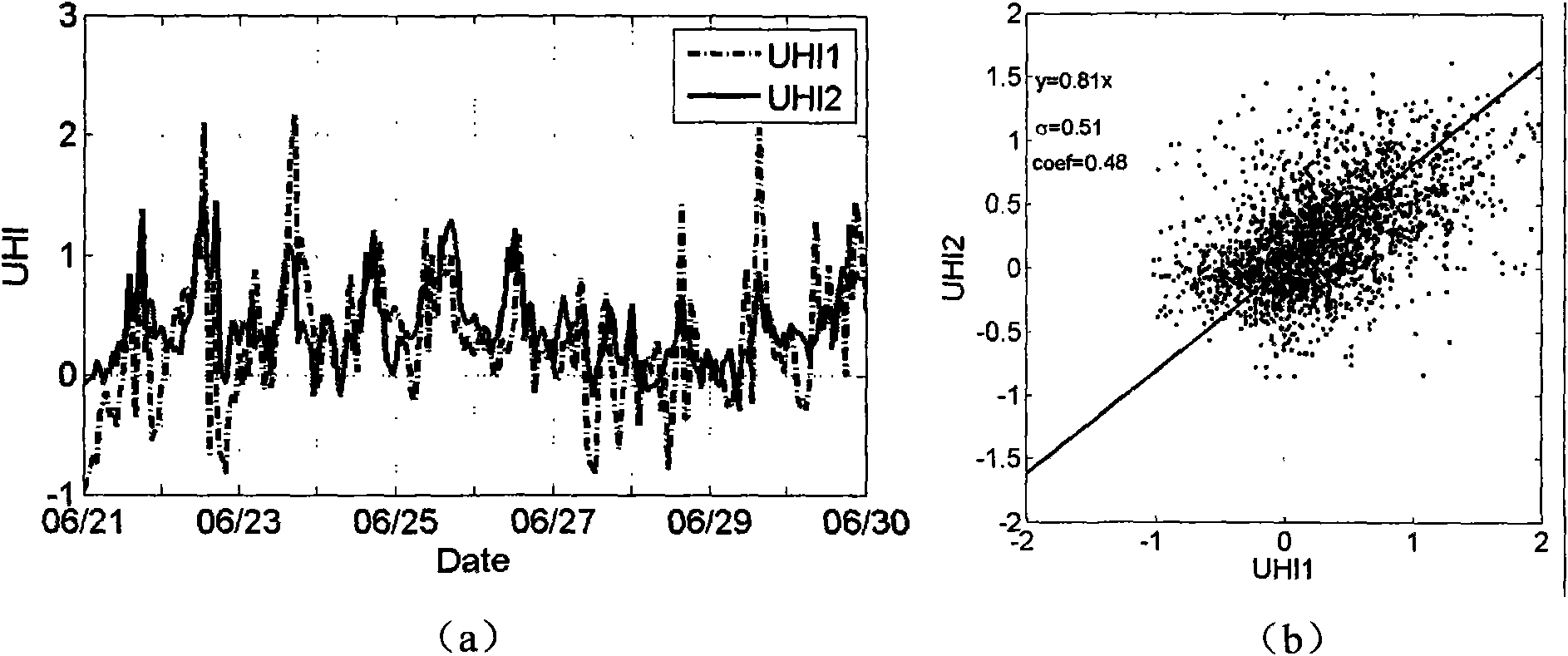

Measuring method and measuring apparatus for urban heat island strength

InactiveCN101587195AEasy to measureAccurate measurementClimate change adaptationInstrumentsWeather factorMeasurement device

The invention relates to a measuring method and a measuring apparatus for the urban heat island strength, which considers the influence of at least three weather factors such as horizontal total wind speed, wind direction and air temperature to the measuring result of the urban heat island strength, applies the historical observation data of the city to be researched for establishing a data analysis process apparatus, and observes the observed result of the specific weather factors such as horizontal total wind speed, wind direction and air temperature of the city to be researched so as to correctly measure the urban heat island strength and provide a certain technology support for the weather study and atmosphere science.

Owner:NANJING UNIV +1

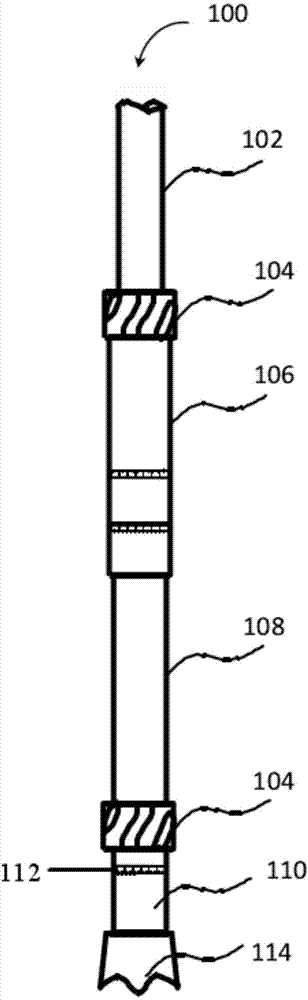

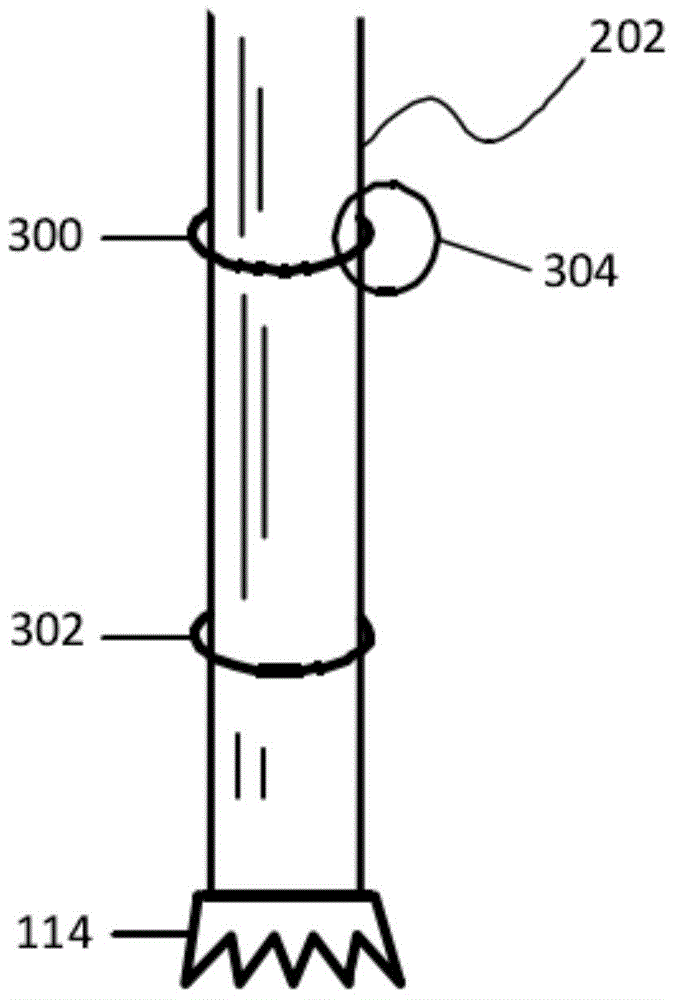

Device of measuring formation resistivity of drill

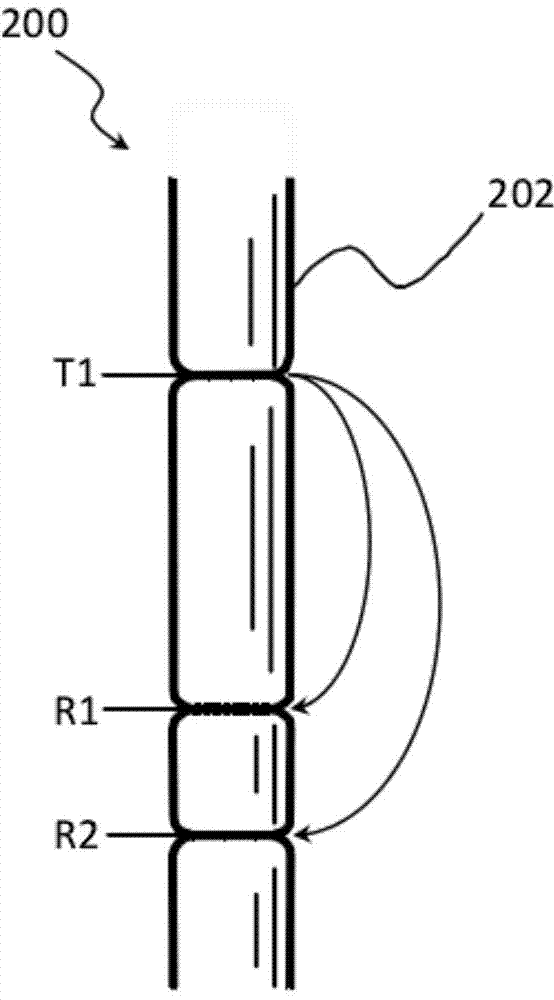

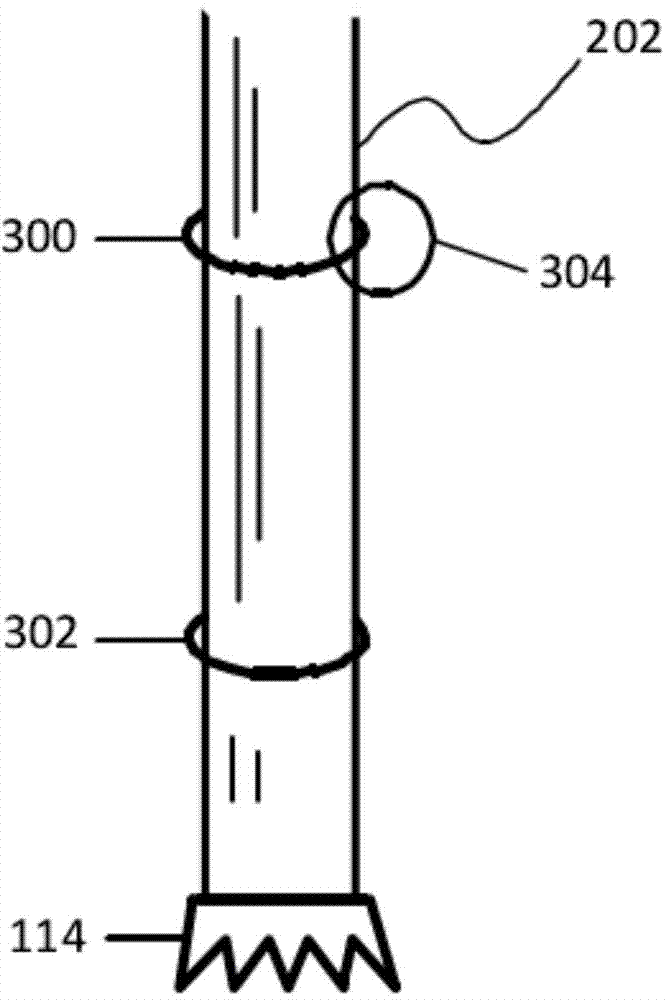

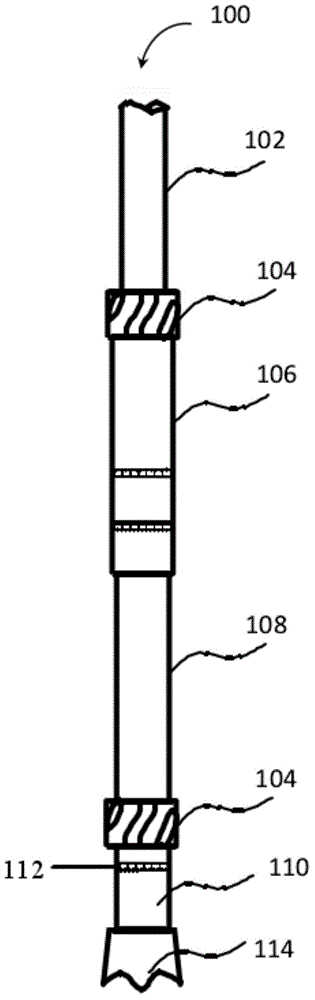

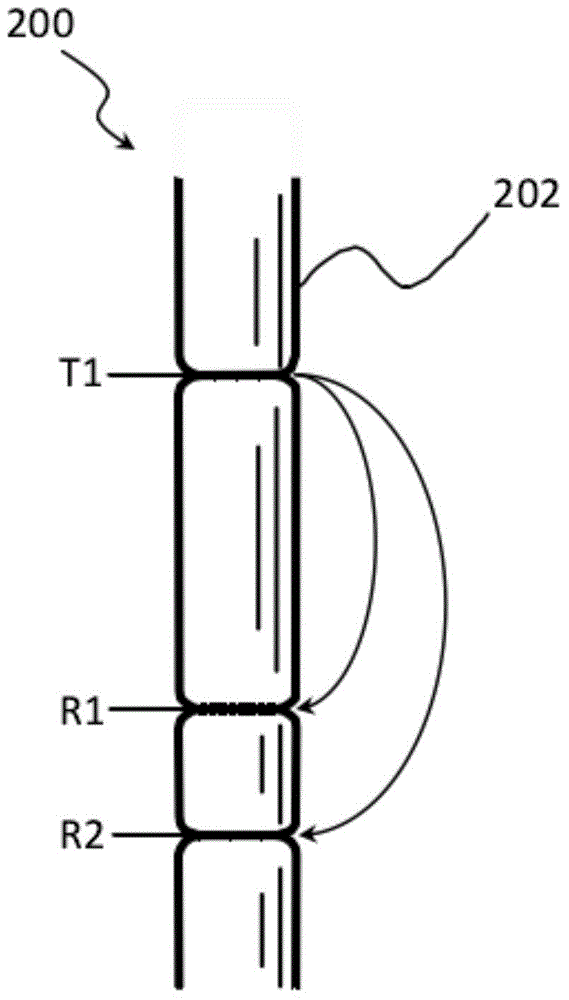

ActiveCN103590823ATimely measurementSolve the problem of measurement lag caused by distanceElectric/magnetic detection for well-loggingBorehole/well accessoriesPhase differenceEngineering

The invention discloses a device of measuring formation resistivity of a drill. The device comprises a tool housing; an emitter disposed on the tool housing and used for generating electric signals and converting the electric signals into electromagnetic signals to be emitted to a formation; a receiver arranged on the tool housing, positioned at an axial place of the emitter and used for measuring amplitude and phase of the electromagnetic signals from the emitter; and an emission signal coupler coupled to the emitter and used for coupling part of electric signals of an antenna of the emitter and measuring amplitude and phase of the coupled electric signals. An amplitude and phase difference between the electromagnetic signals received by the receiver and the electric signals coupled by the emission signal coupler is utilized to calculate resistivity. The device of the invention helps to solve problems of measurement lag caused by a distance between a drill and a conventional propagation logging tool. The device is improved to be more practical.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for measuring formation resistivity at drill place

ActiveCN103603657ATimely measurementSolving Measurement Lag ProblemsElectric/magnetic detection for well-loggingBorehole/well accessoriesUltrasound attenuationPhase difference

The invention discloses a method for measuring formation resistivity at a drill place. The method comprises that a tool housing is placed into a borehole; a transmitter transmits an electromagnetic signal to the stratum; a transmission signal coupler is utilized to measure the amplitude and the phase of an electrical signal generated on antenna of the transmitter; a receiver is utilized to measure the amplitude and the phase of the electromagnetic signal from the transmitter; according to the amplitude and the phase of the electrical signal measured by the transmission signal coupler and the amplitude and the phase of the electromagnetic signal measured by the receiver, the amplitude attenuation and the phase difference are calculated; and according to the amplitude attenuation and the phase difference, the formation resistivity at the drill place is calculated. The method solves a problem of a conventional transmission resistivity logging tool of measurement lag due to the difference between a measuring point position and the drill, and improves the practicability of the equipment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

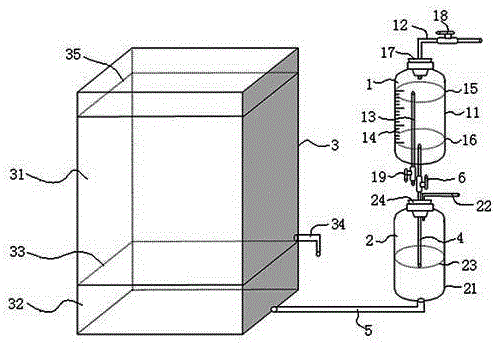

Simple type underground water constant compensation lysimeter

ActiveCN106324224AGuaranteed supplyLow costLevel controlEarth material testingWater storageEngineering

The invention discloses a simple type underground water constant compensation lysimeter, comprising a water supply metering device, a water level regulation and control device and a lysimeter testing tank, wherein the water supply metering device is connected with the water level regulation and control device through a guide pipe; the water level regulation and control device is connected with a water inlet of the lysimeter testing tank through a communicating pipe; the water supply metering device comprises a Marriotte bottle with scale marks, a water supply pipe and an overflow pipe; the upper end port of the overflow pipe is flushed with the highest scale of the scale marks of the Marriotte bottle; the upper end port of the guide pipe is flushed with the undermost scale of the scale marks of the Marriotte bottle; the water level regulation and control device comprises a water control bottle and an aeration pipe which communicates the water control bottle with the outside; a pressure regulation water line is arranged on the water control bottle; the lower end port of the guide pipe is flushed with the pressure regulation water line; and the upper part of the lysimeter testing tank is backfill, the lower part of the lysimeter testing tank is a water storage layer, and the junction of the backfill and the water storage layer is a constant water line. The simple type underground water constant compensation lysimeter can realize regulation and control of constant water level and metering of water supply and drainage, and has the advantages of stable regulation and control of water level, timely water compensation and high metering accuracy.

Owner:GANSU DESERT CONTROL RES INST

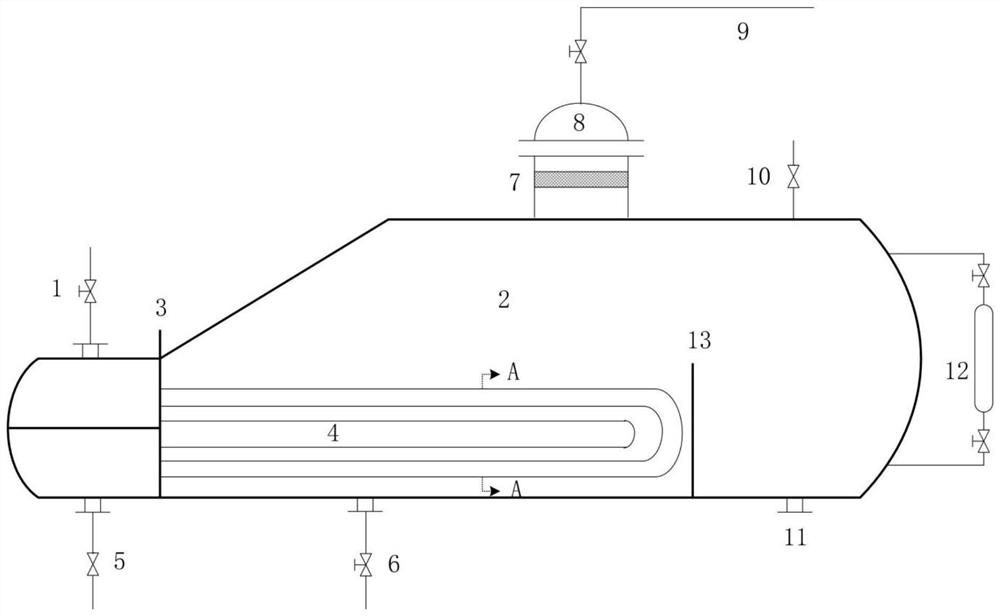

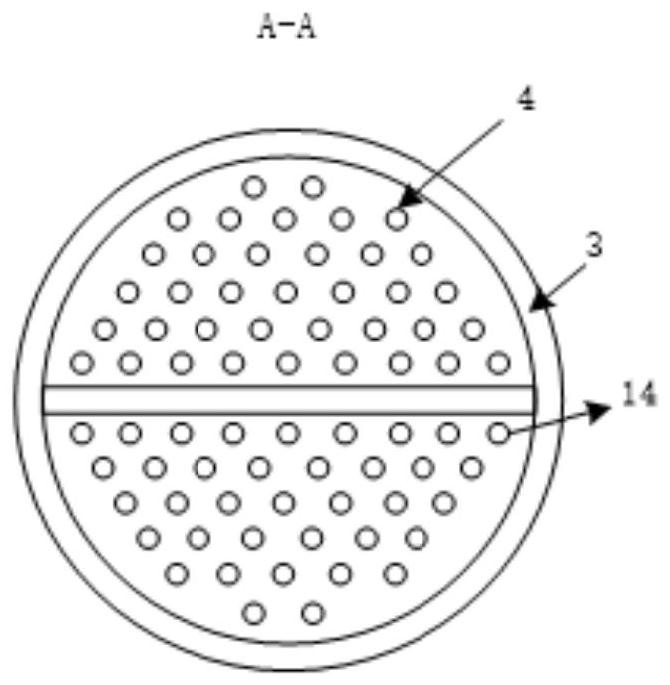

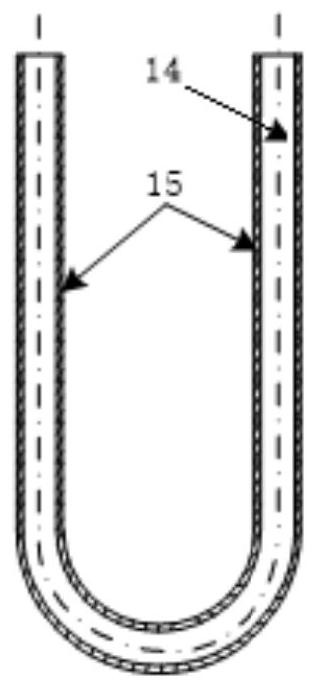

Urea catalytic hydrolysis reactor for flue gas denitrification and method

PendingCN113750948AEasy to disassemble and installShorten the hydrolysis reaction timeChemical/physical/physico-chemical stationary reactorsAmmonia preparation/separationProcess engineeringCatalytic hydrolysis

The invention relates to a thermal power plant flue gas denitration technology, in particular to a urea catalytic hydrolysis reactor for flue gas denitration and a method. The system comprises a kettle body and a coil pipe cluster fixedly arranged in the kettle body through a plug; a urea solution inlet is formed in the bottom of the kettle body, and an ammonia outlet is formed in the top of the kettle body; a saturated steam inlet and a drain outlet are respectively formed in the outer side of the plug; the coil pipe cluster comprises a plurality of coil pipes inserted into the kettle body; the end part of the coil pipe is fixed with the inner side of the plug, the outer surface of the coil pipe is coated with a catalyst coating, the inlet end of the coil pipe is communicated with the saturated steam inlet, the outlet end of the coil pipe is communicated with the drain outlet, and the coil pipe is a U-shaped pipe made of a 316L stainless steel material; a partition plate is arranged on the bottom surface in the kettle body; the coil pipe cluster is arranged at one side of the partition plate, and the bottom surface of the kettle body on the other side is provided with a drain outlet. The reactor has the advantages of economy, feasibility, simple structure, convenience in catalyst supplement and long service life.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

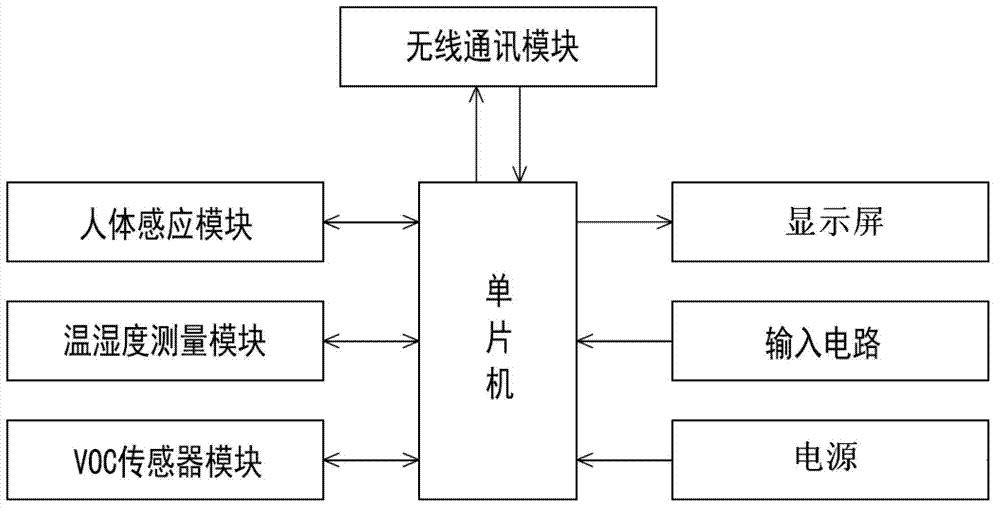

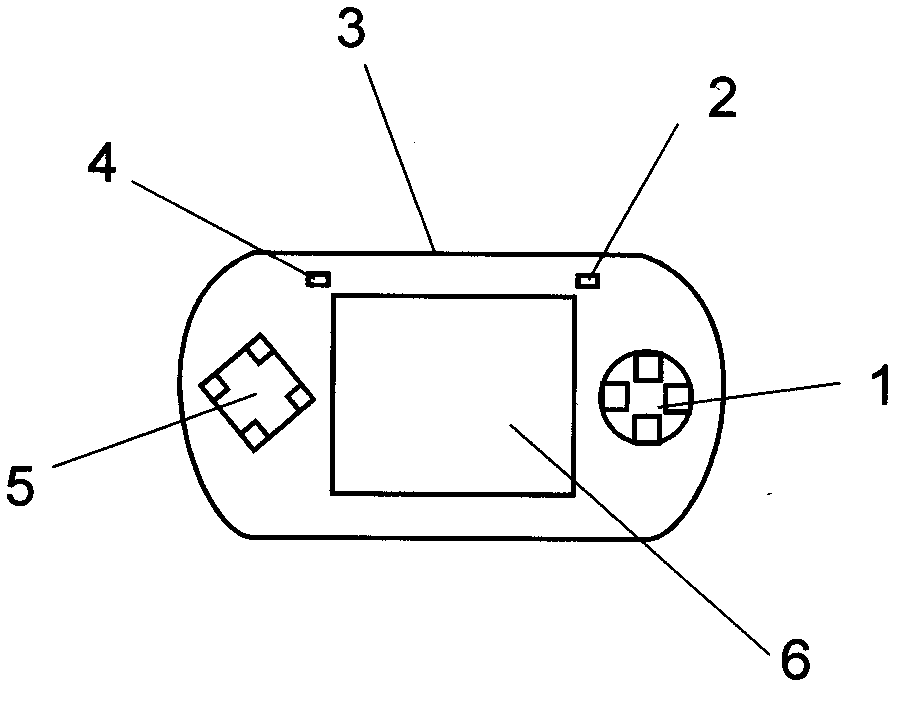

Multifunctional mobile wireless remote transmission controller

ActiveCN103399509ATimely measurementFlexible useProgramme controlEnergy efficient ICTMicrocontrollerEngineering

The invention relates to a multifunctional mobile wireless remote transmission controller, comprising a portable controller shell, wherein a singlechip is arranged in the controller shell, the singlechip is respectively connected with a human body induction module, a temperature and humidity measurement module, a VOC (volatile organic compounds) sensor module, a wireless communication module, a display screen, an input circuit and a power supply, and the wireless communication module is connected with an upper computer in a wireless manner. The multifunctional mobile wireless remote transmission controller has the beneficial effects that the concentration, temperature and humidity of VOC can be accurately and timely measured and uploaded; the controller can be started in time under human body induction; a lithium battery is adopted to supply power, the controller can be flexibly moved and used, and measuring points can be set optionally; the components are suitable for long-term sleep, and can be started intermittently or started under human body induction, the power consumption is low, the radiation is low, and the energy saving effect is remarkable.

Owner:CHINA RAILWAY CONSTR GROUP

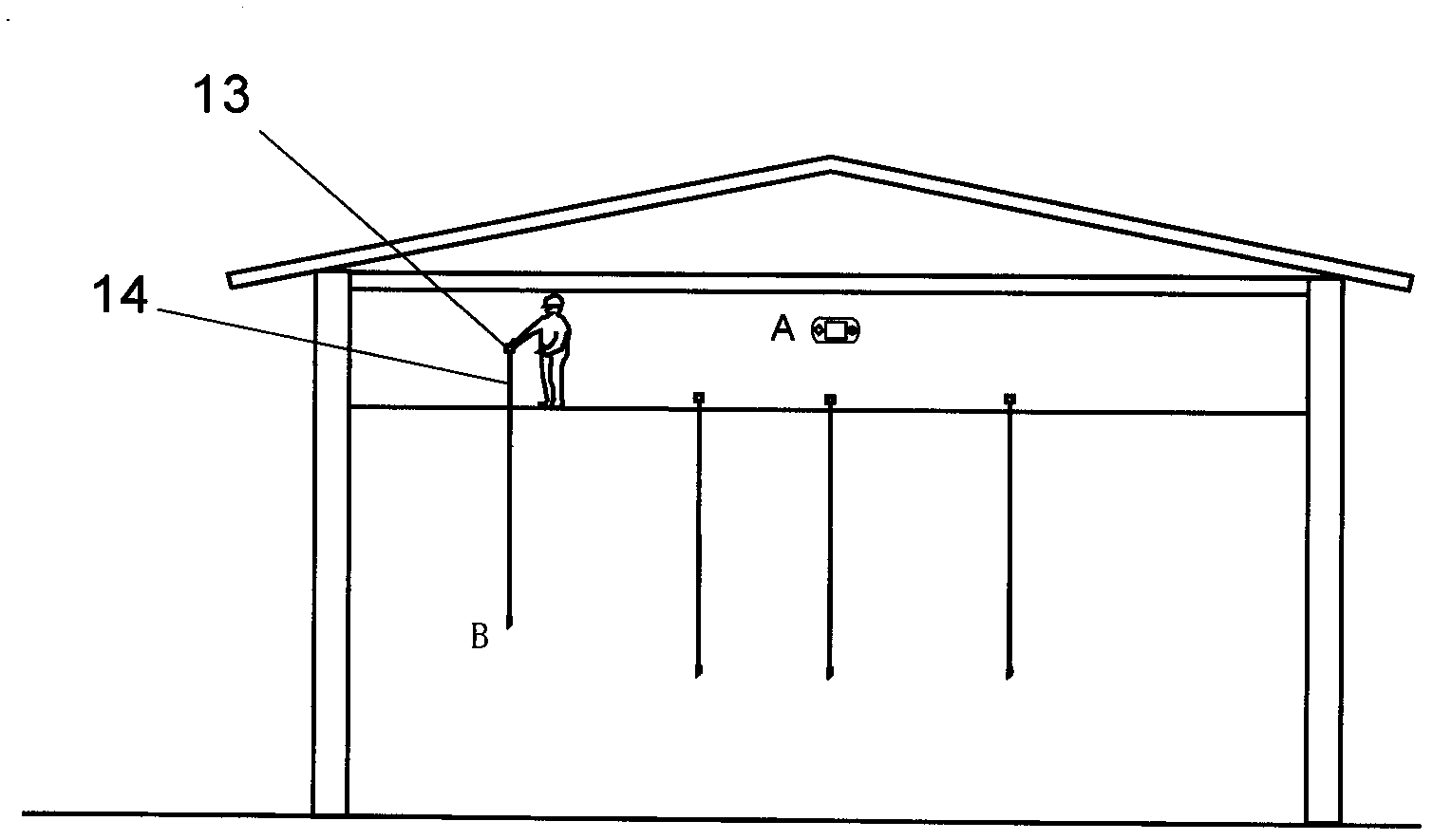

Portable grain status detector

InactiveCN102426036ATimely measurementInvestigating moving fluids/granular solidsThermometer applicationsLiquid-crystal displayReturn function

The invention discloses a portable grain status detector. The portable grain status detector consists of a hand-held liquid crystal display and a wireless detection rod, and is characterized in that: the hand-held liquid crystal display consists of a sensing receiver battery and a shell; a function key area, a selection key area, a switch key and a return function key are arranged on the outer front surface of the hand-held liquid crystal display; the wireless detection rod mainly comprises an emitter, a storage battery, a sensor, a micro camera, a data wire and a sensing probe; the temperatures and the moisture of grains are sensed to the sensor through the sensing probe, the sensor is used for transmitting the temperatures and the moisture to the emitter through the data wire, and the emitter is used for emitting the temperatures and the moisture to the hand-held liquid crystal display; and a high-transmission prism is arranged on the micro camera, and the shading values of light rays can be adjusted according to the environment, so that the optimal display effect is achieved. The detector replaces the conventional equipment and method for detecting grain statuses such as the temperatures, the moisture and the like, the grain status in a grain bin can be measured in time, and the effects of quickness and convenience are achieved.

Owner:ANHUI JIESHOUSHI YUNLONG FOOD MACHINE ENG

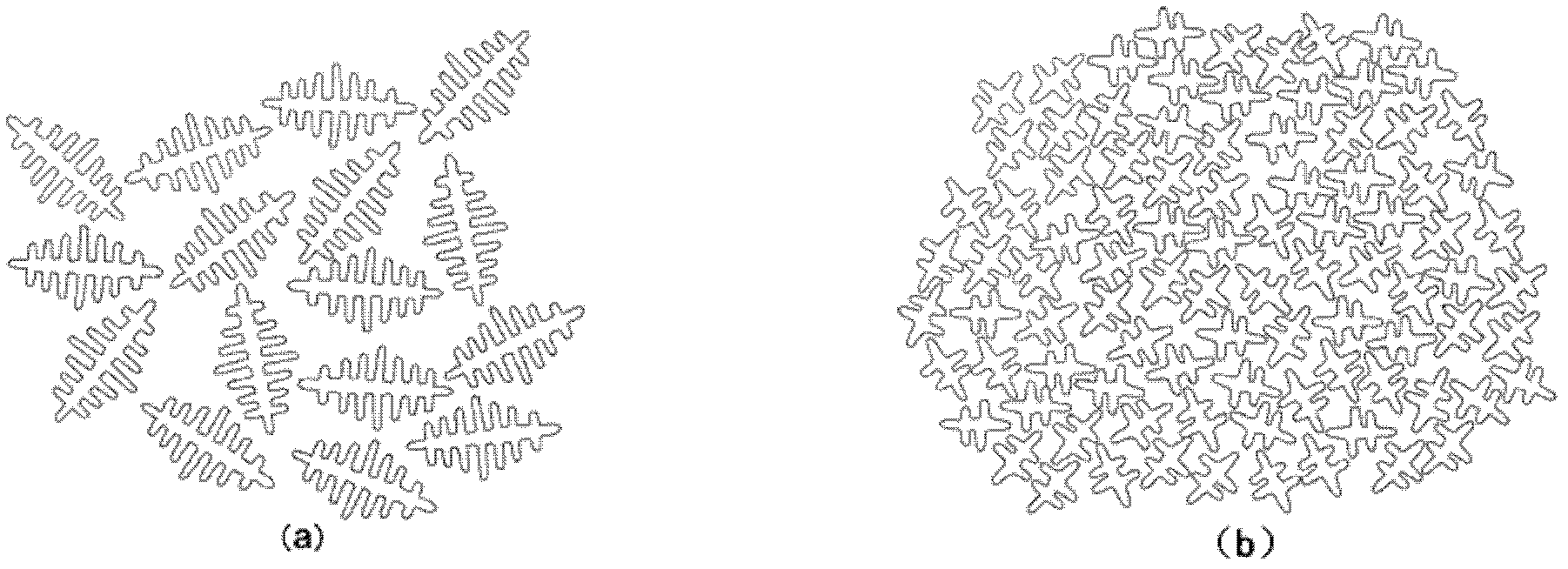

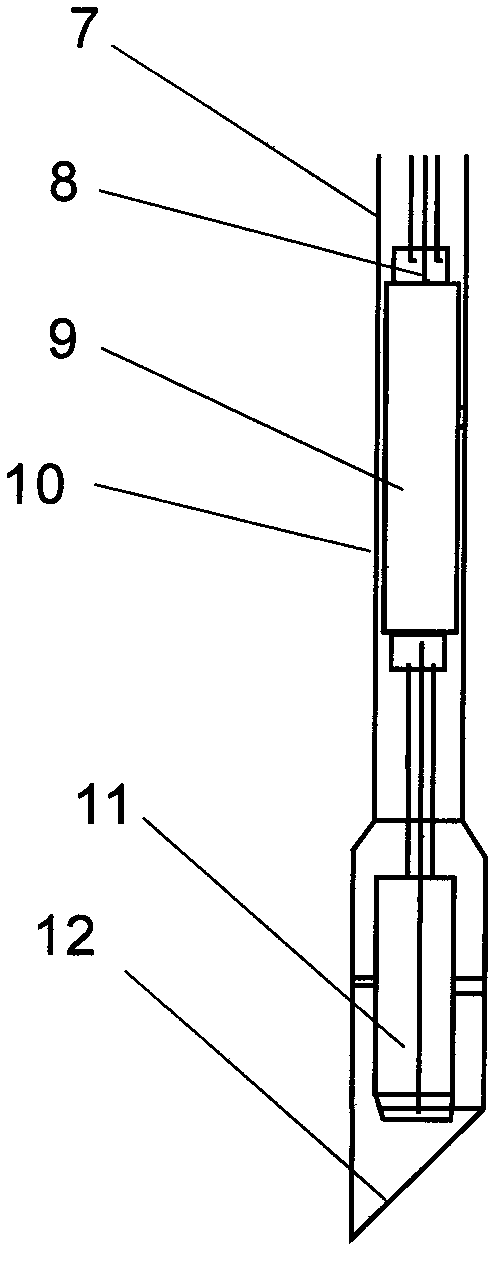

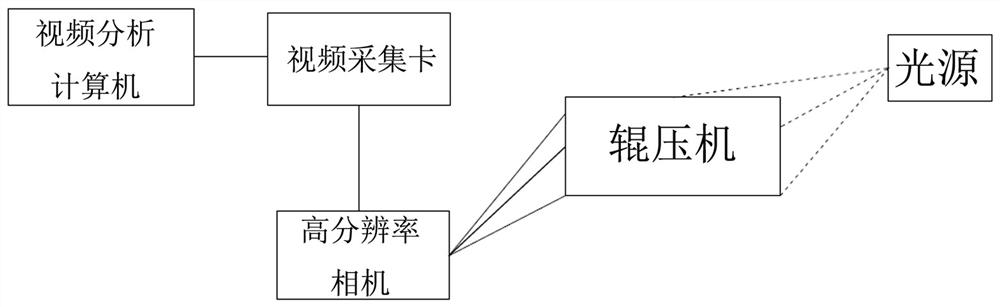

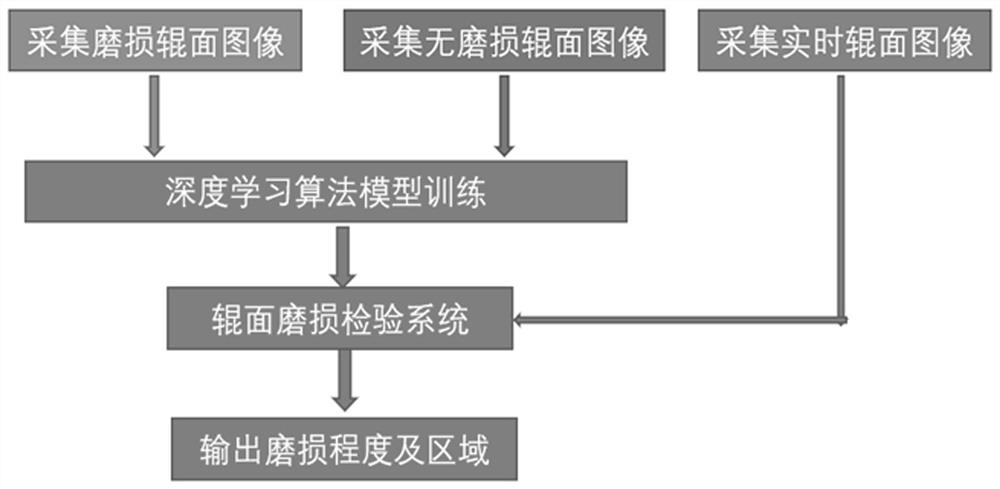

Roller press roller surface abrasion detection method and device based on machine vision

PendingCN112485257ATimely outputGuarantee grinding productionImage enhancementImage analysisEngineeringData input

The invention discloses a roller press roller surface abrasion detection method and device based on machine vision. The roller press roller surface abrasion detection method and device are used for detecting the roller press roller surface abrasion situation on line. According to the detection method and device, the high-resolution camera is used for collecting roller surface image data, and the roller surface image data is transmitted into the analysis computer through the video collection card. Machine vision analysis software based on a deep learning algorithm is installed in the analysis computer, model training is carried out through previously collected roller surface image data of the abraded roller press and the unabraded roller press, and an analysis model is continuously optimized. After roller surface data collected on site is input into the model, roller surface abrasion area and abrasion condition data are output through multiple times of iterative processing. The problemthat roller surface abrasion measurement of the roller press is not found in time is solved, roller surface images are collected and analyzed in time by applying a deep learning algorithm and fusing amachine vision technology, and the method has positive significance in daily production, operation and maintenance of the roller press.

Owner:中材邦业(杭州)智能技术有限公司

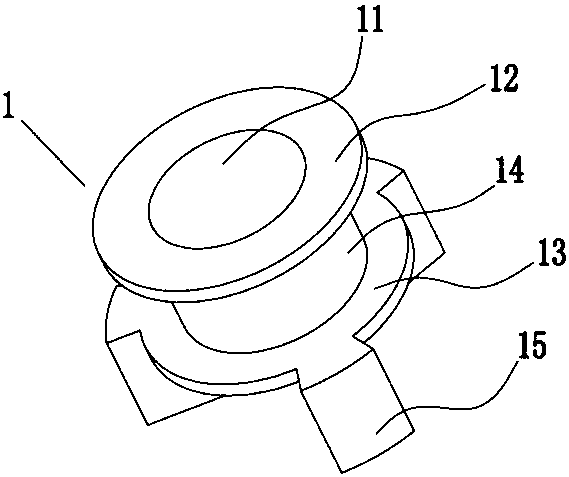

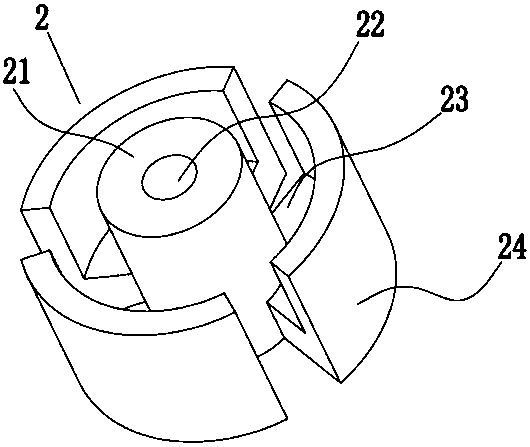

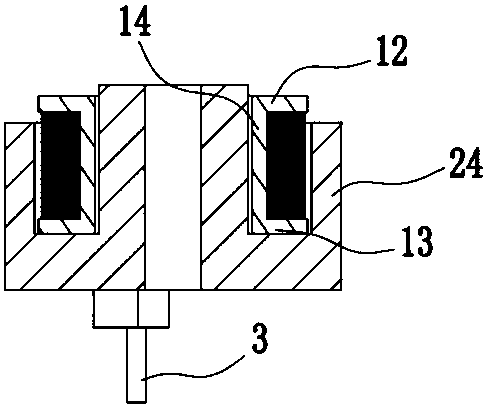

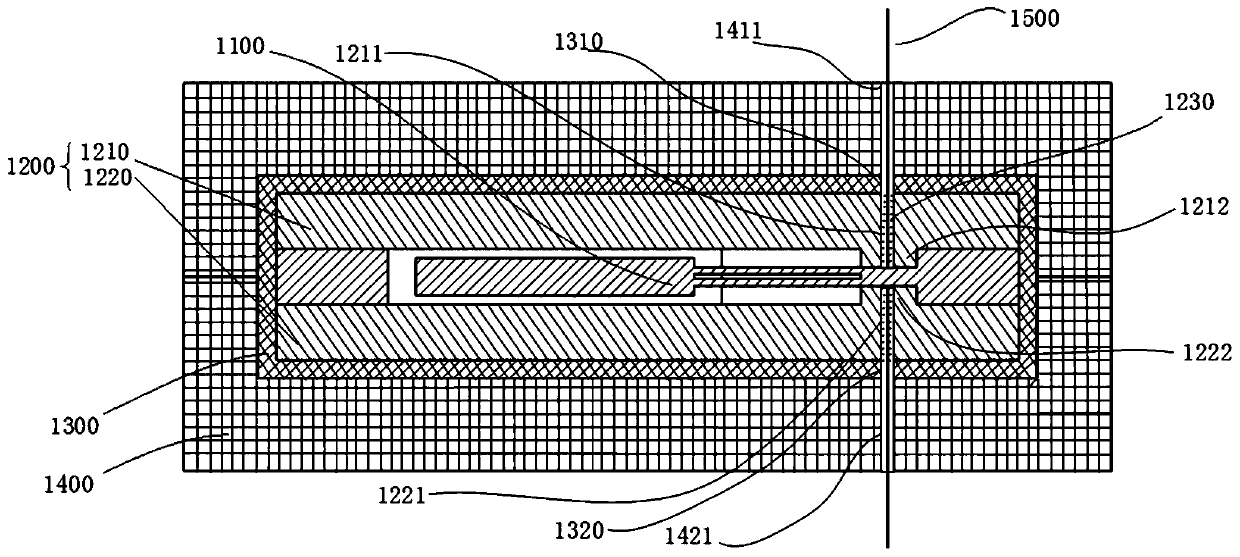

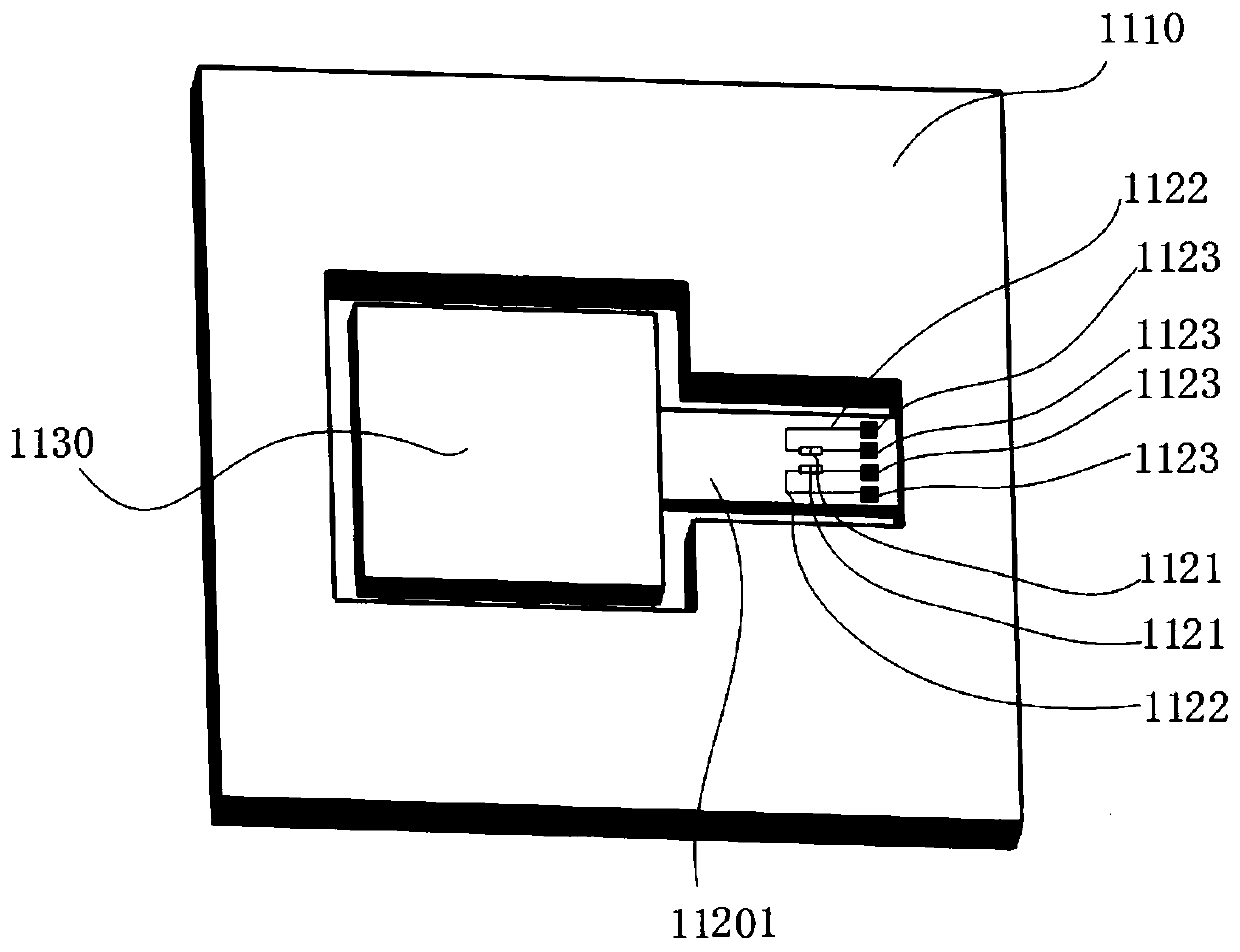

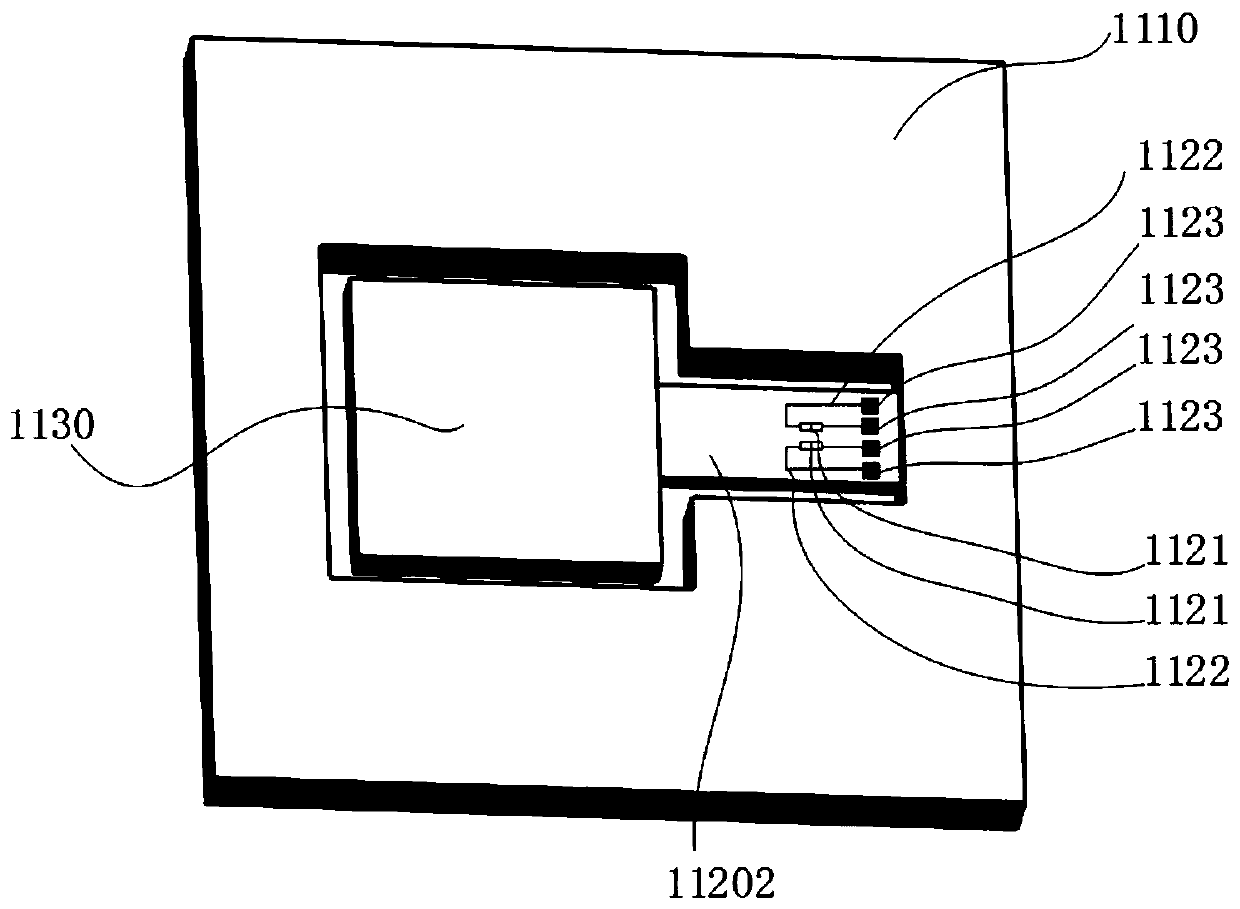

Inductive temperature measuring device and temperature measuring method, cooking device and electromagnetic device

PendingCN108414110ANo lossTimely measurementCooking-vessel materialsDomestic stoves or rangesMagnetic coreTest object

The invention relates to an inductive temperature measuring device which is characterized in that the inductive temperature measuring device comprises an electromagnetic device capable of generating an electromagnetic signal and a control unit which is connected to the electromagnetic device and can detect electrical parameters in the electromagnetic device. The electromagnetic device comprises amagnetic core and an electromagnetic coil, the magnetic core includes a magnetic core middle pillar, the electromagnetic coil is arranged at the periphery of the magnetic core, the electromagnetic device can generate an electromagnetic signal after being energized, and the inductive temperature measuring device further comprises a temperature sensing layer capable of sensing the electromagnetic signal generated by the electromagnetic device. According to the inductive temperature measuring device, a traditional temperature measuring method is changed, the temperature of a temperature sensing layer is detected by the action of the electromagnetic signal, according to the detection method of the invention, the heat transfer between a tested object and the electromagnetic device is not needed, the temperature of the tested object can be directly tested without the loss of heat and without a heat transfer process, and the temperature measurement is more timely and more accurate.

Owner:新兴县热点智能家居科技有限公司

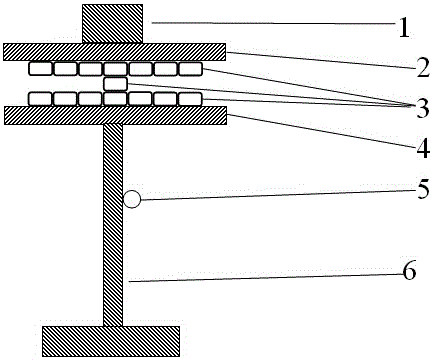

Silicon carbide high temperature vibration sensor with high sensitivity, high frequency response and anti-overload

ActiveCN109764954AHigh sensitivityAnti-overloadSubsonic/sonic/ultrasonic wave measurementUsing electrical meansCantileverHigh frequency

The invention discloses a silicon carbide high temperature vibration sensor with high sensitivity, high frequency response, and anti-overload. The silicon carbide high temperature vibration sensor comprises a silicon carbide chip, a silicon carbide bonding sheet, an insulation layer, a packaging shell, and a kovar pin; the silicon carbide chip comprises a supporting sheet body, a cantilever beam,and a mass block; the supporting sheet body and the silicon carbide bonding sheet form a bonding body; the mass block and the cantilever beam are arranged insidea cavity of the bondingbody, and the cantilever beam is provided with a chip circuit; and the kovar pin extends into a bonding material along through holes arranged on the package shell, the insulation layer and the silicon carbide bondingsheet, and is connected with the chip circuit. The high temperature vibration sensorhas the characteristics of high sensitivity, high frequency response and anti-overload, and the accurate and timelymeasurement of vibration signals in the high temperature environment can be realized.

Owner:XI AN JIAOTONG UNIV

Measuring device of friction coefficient of papilionaceous optical cable and measuring method of measuring device

InactiveCN105115890ASimplify manual operationsImprove test efficiencyUsing mechanical meansFibre mechanical structuresEngineeringProduct testing

The invention discloses a measuring device of the friction coefficient of a papilionaceous optical cable. The measuring device comprises a friction coefficient test bed, an electronic universal testing machine, a computer terminal and an electronic scale. The friction coefficient test bed comprises a base with a height adjusting knob, a cover plate and a bottom plate which are horizontally parallel and are placed in the vertical direction are arranged above the base, a tension arm and a pulley support with a fixed pulley are arranged on the electronic universal testing machine, and a clamp is mounted at the tail end of the tension arm. A measuring method comprises the steps that small tested optical cable segments equal in length are cut out, and are densely arranged and pasted on strong double sticky tapes on the cover plate and the bottom plate, the bottom plate and the lower edge of the fixed pulley are made to be horizontal, a large tested optical cable segment is taken and fixed, and a switch of the electronic universal testing machine is turned on to start testing. According to the measuring device, manual operation can be simplified, testing efficiency can be improved, and friction coefficient data at the initial stage of production or experiments can be measured and found in time, so that raw material waste of subsequent production can be reduced; besides, human and equipment errors are reduced to the maximum extent, and the accuracy and reliability of the product testing result are effectively guaranteed.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

Medium-frequency heat treatment system and heat treatment process for petroleum tool irregular materials

ActiveCN101824526AEven heating inside and outsideCompact structureFurnace typesIncreasing energy efficiencyThermodynamicsSprayer

The invention discloses a medium-frequency heat treatment system and heat treatment process for petroleum tool irregular materials. The heat treatment system comprises a medium-frequency heater, a discharge rack, a feed rack, a sprayer and a circulating air cooler, wherein the discharge rack and the feed rack are respectively arranged at the left end and the right end of the medium-frequency heater; the sprayer is arranged above the middle part of the medium-frequency heater; and the circulating air cooler cooperates with the sprayer for use. The heat treatment process comprises the following steps: (1) cleaning the petroleum tool irregular materials; (2) heating the petroleum tool irregular materials, soaking, and water-cooling and air-cooling at the same time; (3) heating the petroleum tool irregular materials, soaking, and air-cooling; and (4) inspecting before warehousing. The invention has the advantages of simple process steps, favorable process parameters, reasonable system structure, high heat treatment efficiency and simple control operation. The invention can effectively avoid the phenomena of cracking and laminating at the end of the petroleum tool irregular material, prevent cooling water from entering the inner bores and ensure that the inside and the outside thereof are uniformly heated. The whole treatment process does not have oxidation or decarbonization, thereby having no pollution.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com