Micro-inductance sensor used for detecting metal fragments in oil liquid

A metal chip, micro-inductance technology, applied in the direction of using electrical devices, electromagnetic means, instruments, etc., can solve the problems of high cost, complicated operation, inability to diagnose the wear state of equipment in time, etc., to increase the number and measure in time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

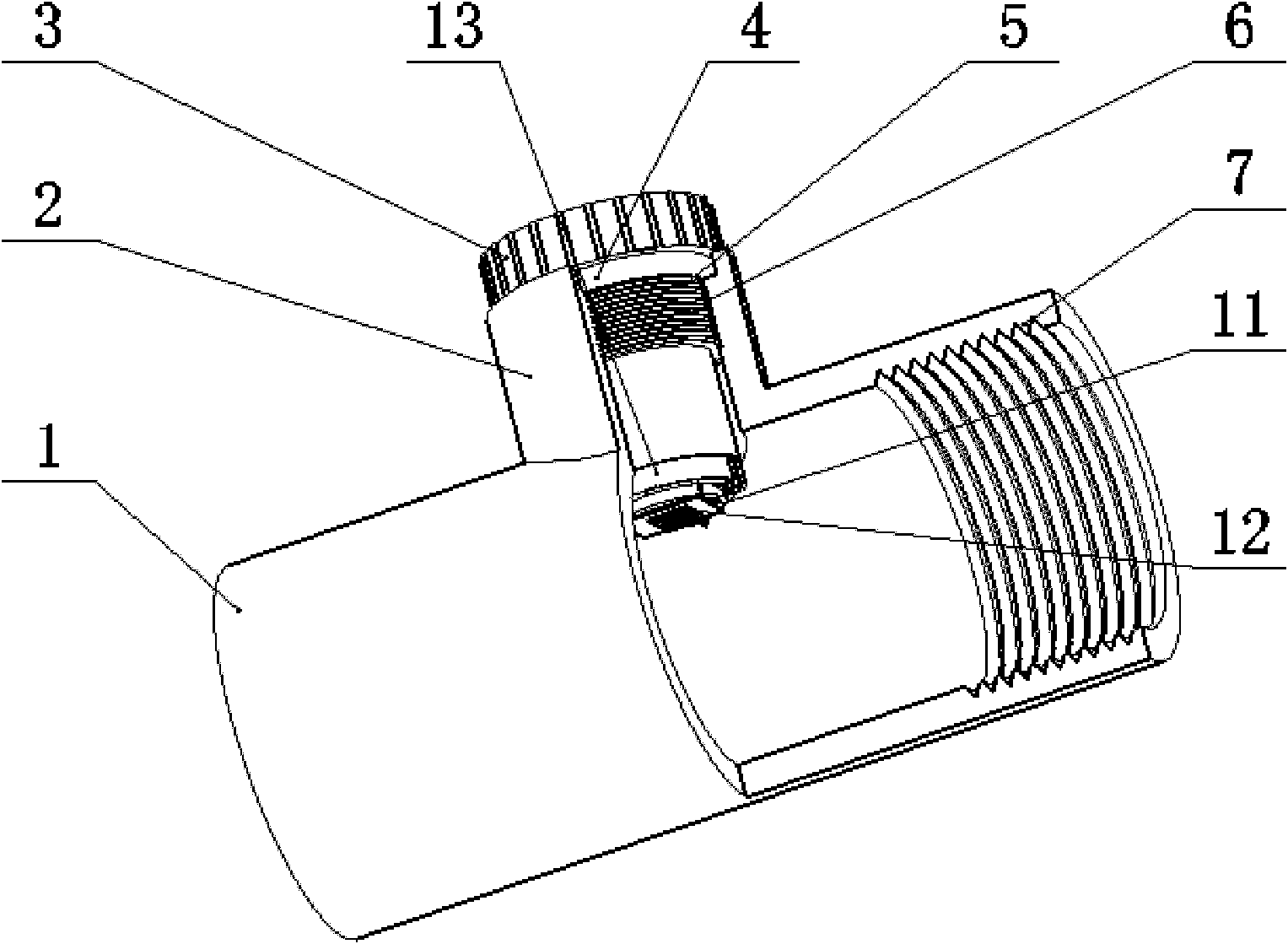

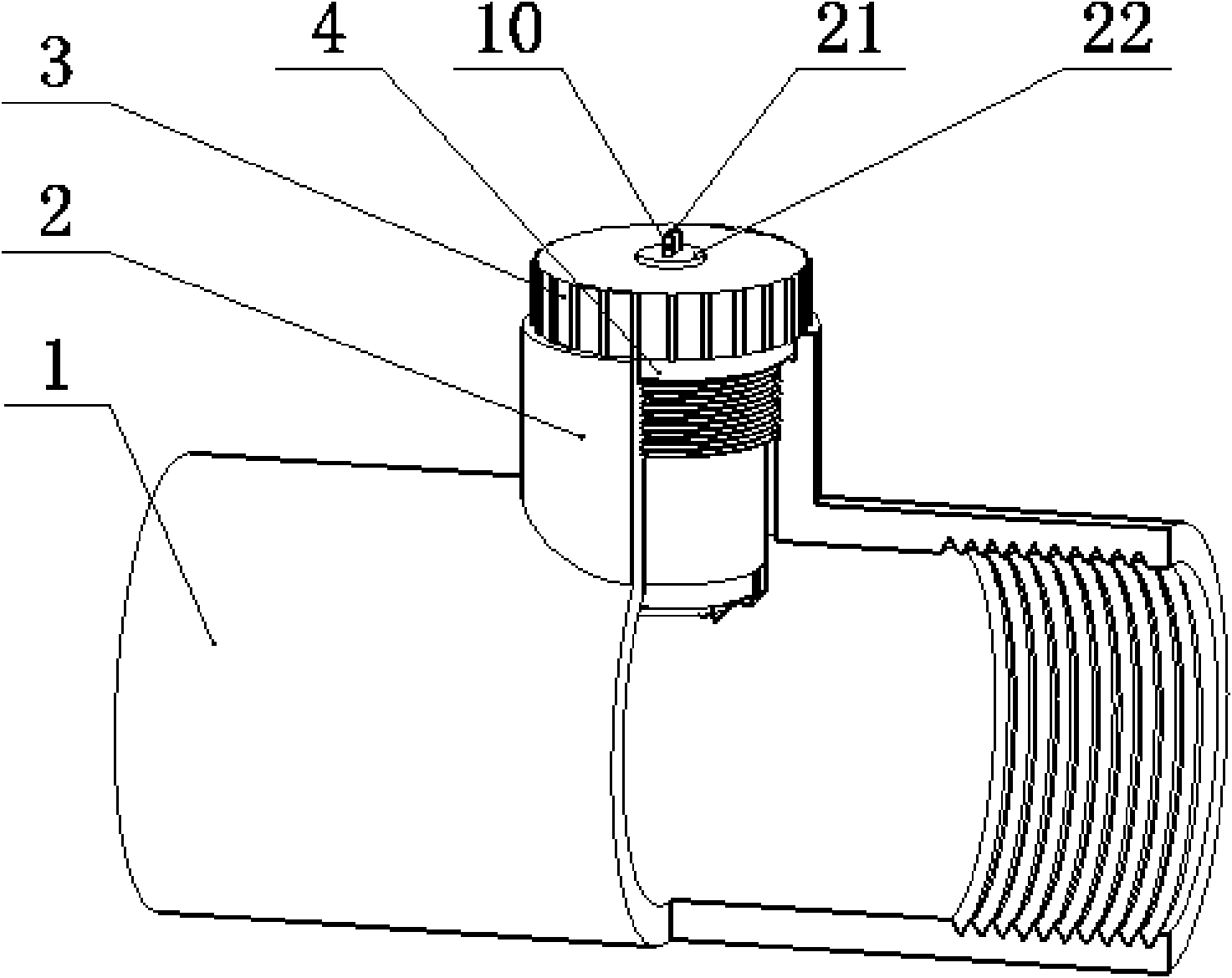

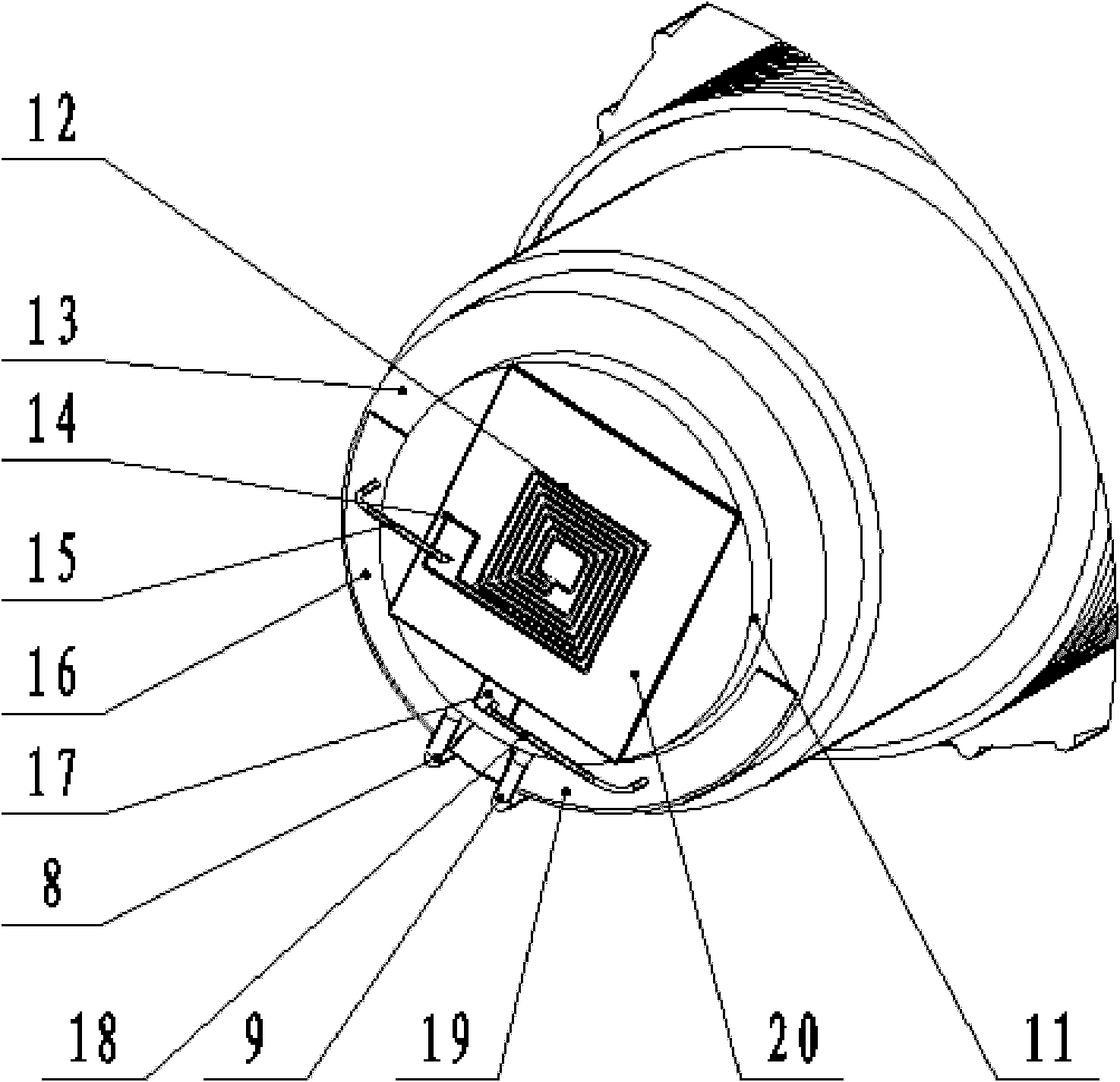

[0017] Attached below Figure 1~3 The present invention is described further:

[0018] In this embodiment, conventional machining, MEMS technology and PCB printing technology are adopted for design and installation.

[0019] The invention consists of a three-way pipe joint 1, a piston 3, a microcoil 12 and a PCB board.

[0020] Such as figure 1 The three-way pipe joint 1 of this embodiment shown can be made of non-magnetic stainless steel material but not limited to stainless steel, other non-magnetic conductive materials such as hard aluminum alloy, high-strength nylon, etc., and the three-way pipe joint 1 is at right angles to the main pipeline The joint is processed into a piston mounting joint 2, and the piston mounting joint thread is machined in the piston mounting joint inner hole, and a groove is processed at the outer end of the piston mounting joint 2 for installing the sealing ring 4. The two ends of the main pipeline of the three-way pipe joint 1 are processed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com