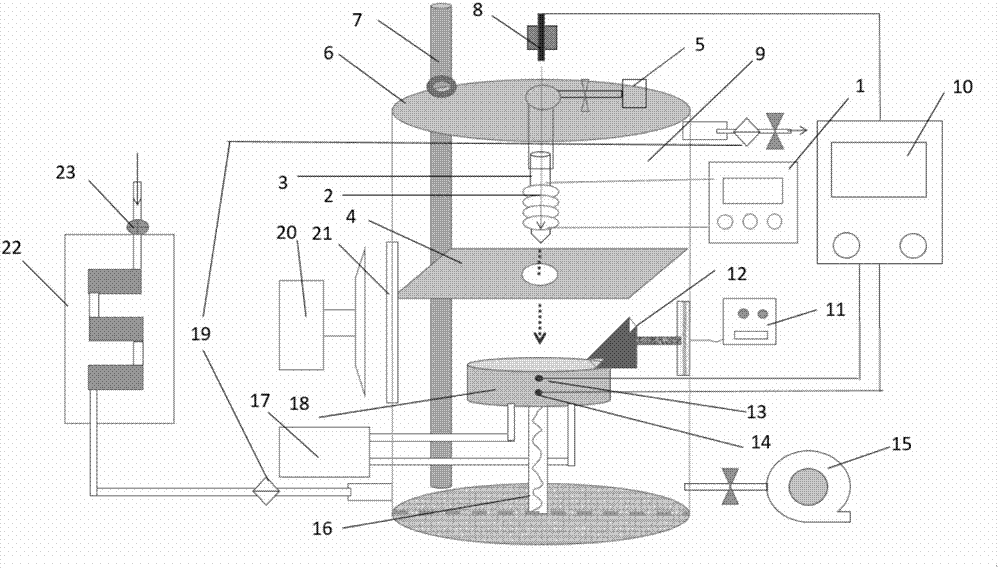

Method for testing rapid solidification behavior and solidification heat flow of metal material

A metal material and behavioral technology, applied in the field of rapid prototyping of metal materials, can solve the problems of not being able to observe and test heat flow changes, and achieve the effects of low test cost, high accuracy, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

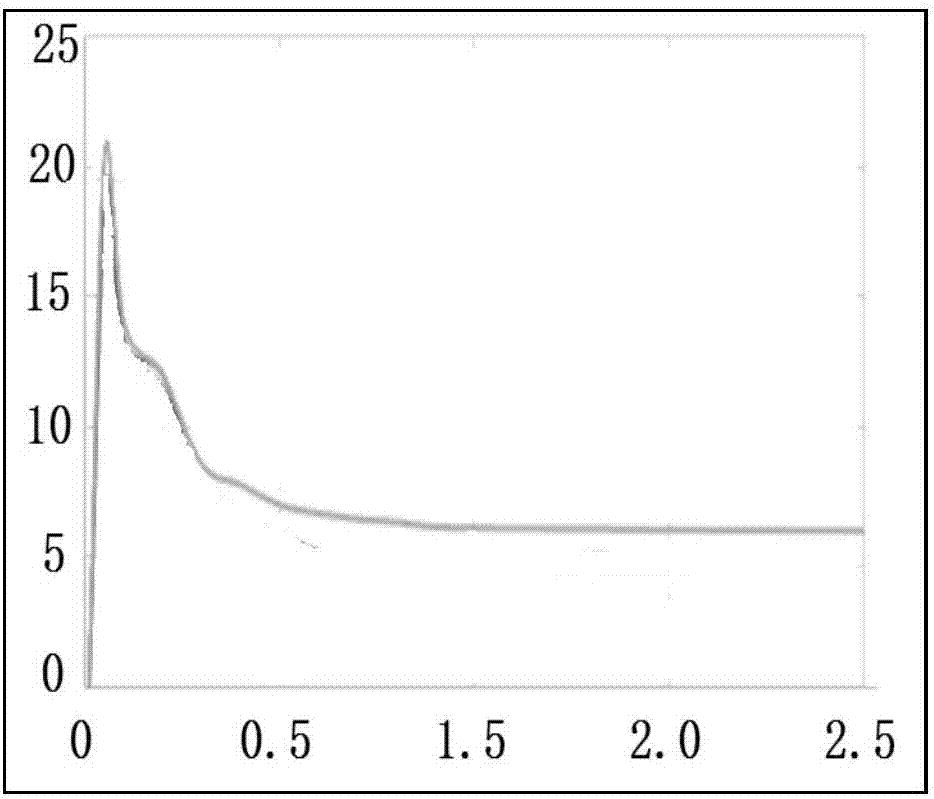

Examples

example 1

[0055] Example 1: Taking the test of non-magnetic steel as an example, the specific steps of determination are as follows:

[0056] 1. Obtaining metal droplets

[0057] (1) Loading: Open the cover of the protective gas cover, put 5g of steel sample at the bottom of the quartz tube with a hole diameter of 0.5mm, and close the cover of the protective gas cover.

[0058] (2) Vacuuming: Use a vacuum pump to evacuate the entire device for 30 minutes, and fill it with protective gas, oxygen partial pressure: PO 2 =10 -18 , and eventually its pressure reaches one atmosphere.

[0059] (3) Melting metal: adjust the power controller, heat the steel sample at the bottom of the quartz tube through the induction coil, set the target temperature to 1550°C, measure the temperature of the steel sample in real time with a precision thermometer, and stop heating when the predetermined temperature is reached.

[0060] 2. Spray molten droplets and collect data

[0061] (1) Turn on the cooling...

example 2

[0067] Example 2: Taking the test of ferroalloy as an example, the specific steps of determination are as follows:

[0068] 1. Obtaining metal droplets

[0069] (1) Loading: Open the cover of the protective gas cover, put 8g of steel sample at the bottom of the quartz tube with a hole diameter of 0.7mm, and close the cover of the protective gas cover.

[0070] (2) Vacuuming: Use a vacuum pump to evacuate the entire device for 45 minutes, and fill it with protective gas. Oxygen partial pressure: PO 2 =10 -20 , and eventually its pressure reaches one atmosphere.

[0071] (3) Melting metal: adjust the power controller, heat the steel sample at the bottom of the quartz tube through the induction coil, set the target temperature to 1600°C, measure the temperature of the steel sample in real time with a precision thermometer, and stop heating when the predetermined temperature is reached.

[0072] 2. Spray molten droplets and collect data

[0073] (1) Turn on the cooling water: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com