Ship steel plate dynamic three-dimensional measuring system based on projection and multi-view vision

A three-dimensional measurement, multi-eye vision technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of lack of texture on the surface of steel plates, difficult visual measurement methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

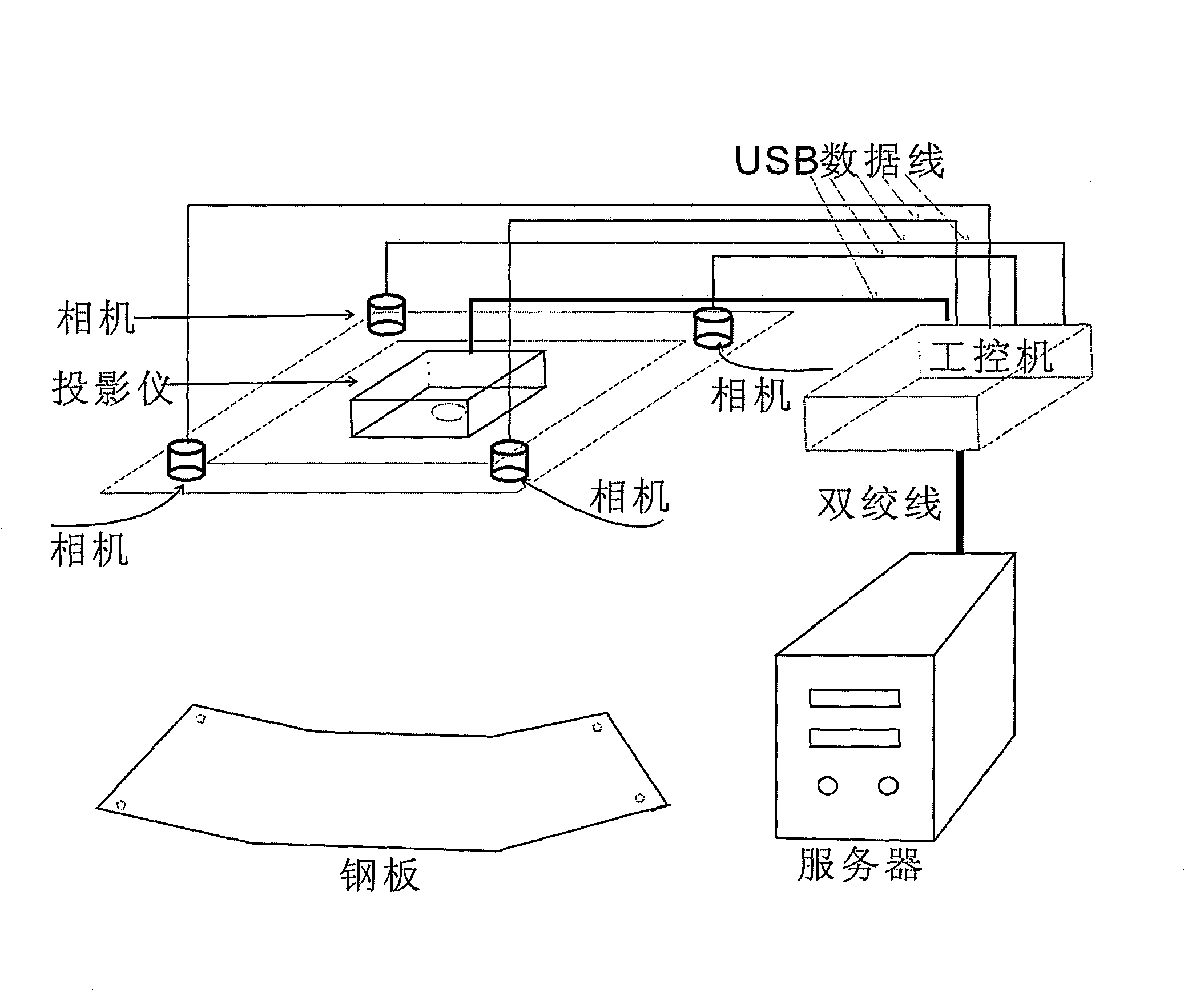

[0016] The hardware connection of the present invention is as figure 1 As shown, four 18-megapixel synchronous high-resolution industrial cameras and a projector with a brightness of 7,000 lumens are fixed above the steel plate to be measured. The four industrial cameras and the projector are connected to the industrial computer through USB data cables. The computer collects image data, and sends the image data to the server through the network cable, and the server performs three-dimensional measurement. The distance between the four cameras is 60cm. The projector is placed in the middle of the four cameras and is on the same plane as the four cameras. The camera, projector, and industrial computer are installed on the same measuring frame.

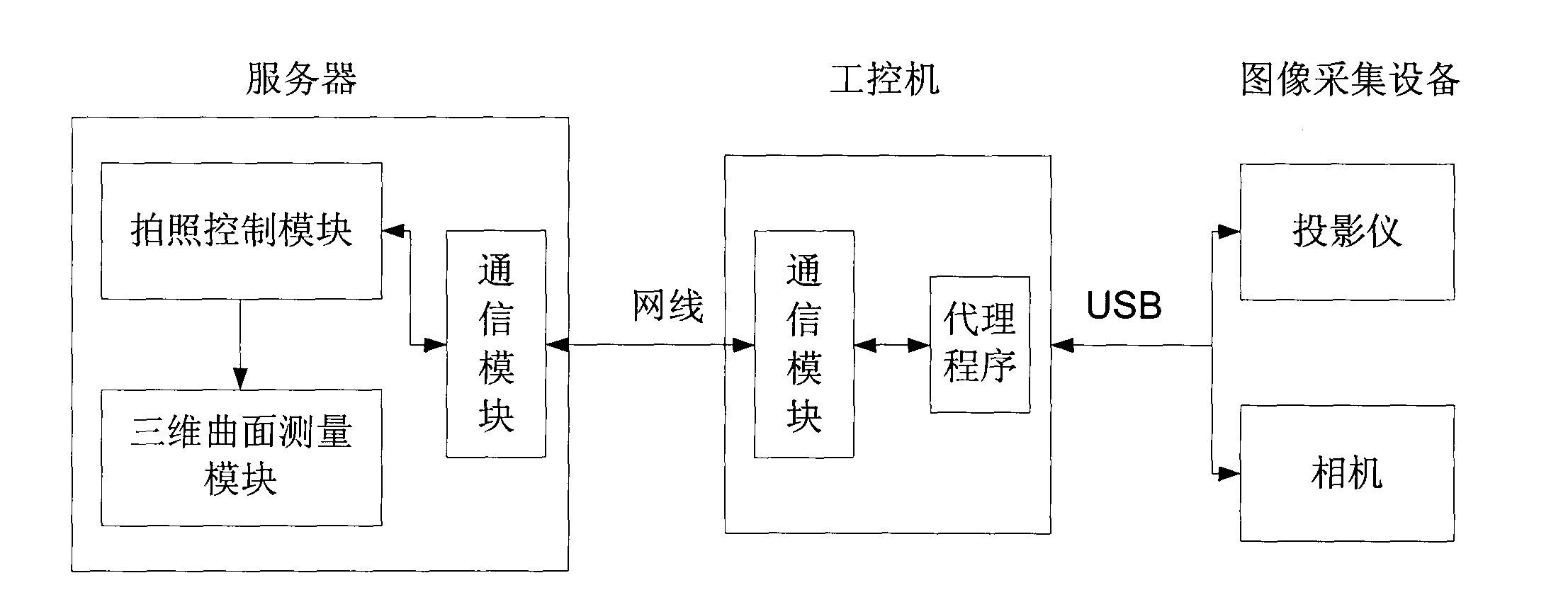

[0017] The software structure of the present invention is as figure 2 As shown, the camera control module and the three-dimensional surface measurement module are running in the server; an agent program is running on the industrial com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com