Roller press roller surface abrasion detection method and device based on machine vision

A technology of machine vision and detection methods, which is applied in measuring devices, instruments, scientific instruments, etc., and can solve problems such as untimely detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

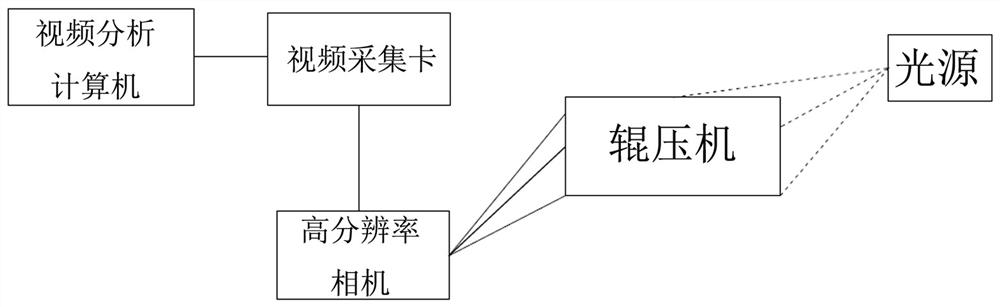

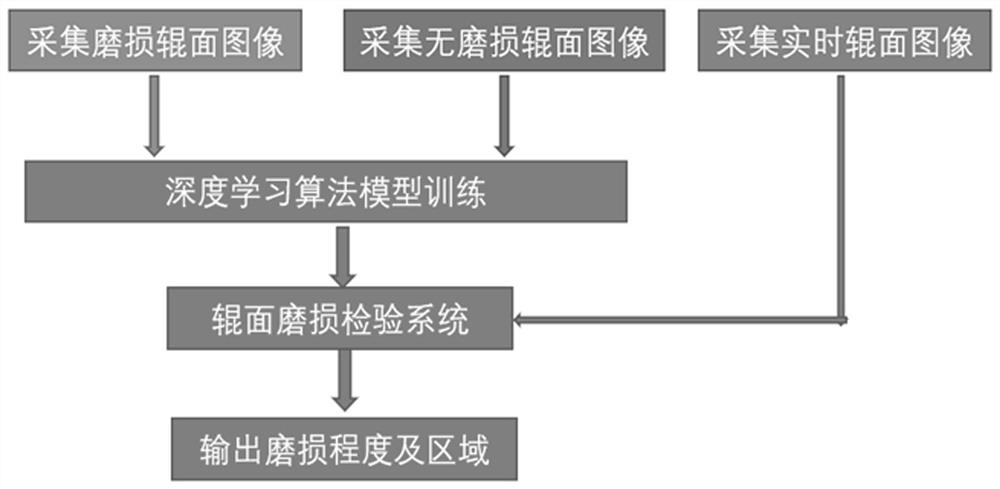

[0020] like figure 1 and 2 As shown, according to a specific embodiment of the present invention, the present invention first installs a high-resolution camera and an auxiliary light source at a suitable angle near the roller surface of the roller press, and sends the images captured by the camera to the video analysis computer after being processed by the video capture card. At the same time, a large number of images of the worn and unworn roller surfaces of the roller press are collected as input variables of the deep learning model, and the wear of the roller surface of the roller press is used as the output variable. The sample data is processed offline through the deep learning model based on the convolutional neural network. Training, in practical engineering applications, the steady-state input and output sample data can be updated at regular intervals according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com