Silicon carbide high temperature vibration sensor with high sensitivity, high frequency response and anti-overload

A vibration sensor, silicon carbide technology, used in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of low use temperature of sensors and limitations of sensor temperature resistance, achieve good high temperature stability, prevent fracture or Destruction, effect of good bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The examples are only used to explain the present invention, not to limit the protection scope of the present invention.

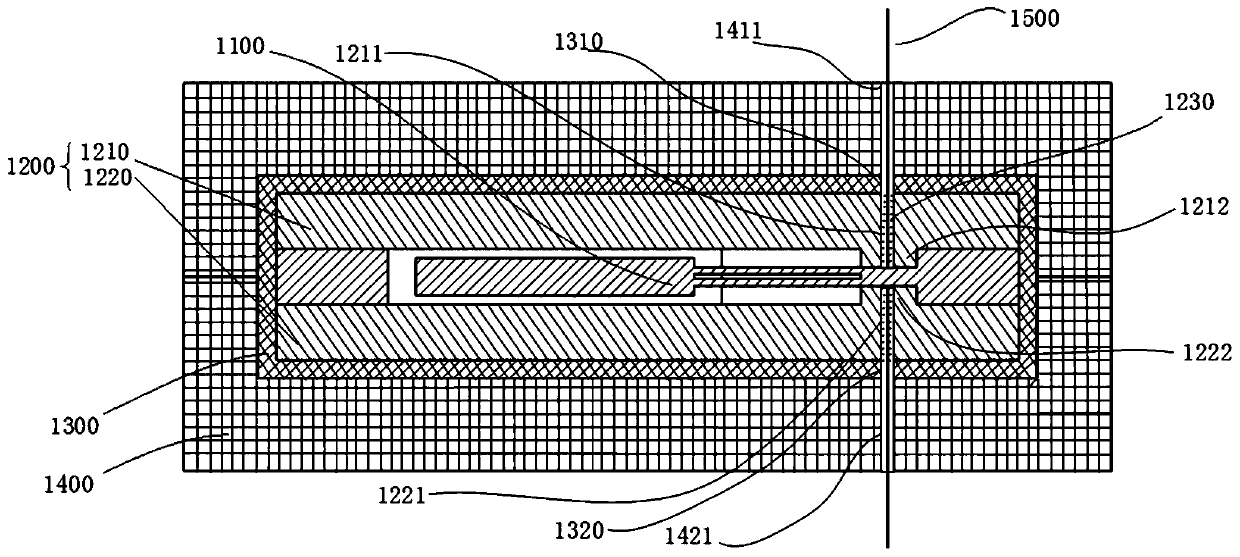

[0039] figure 1 The structure of the high-sensitivity, high-response, and overload-resistant silicon carbide high-temperature vibration sensor provided by the embodiment of the present invention is shown. The silicon carbide high-temperature vibration sensor includes: a silicon carbide chip 1100, a bonding sheet 1200, a heat insulating layer 1300, and a package Housing 1400 and Kovar pin 1500.

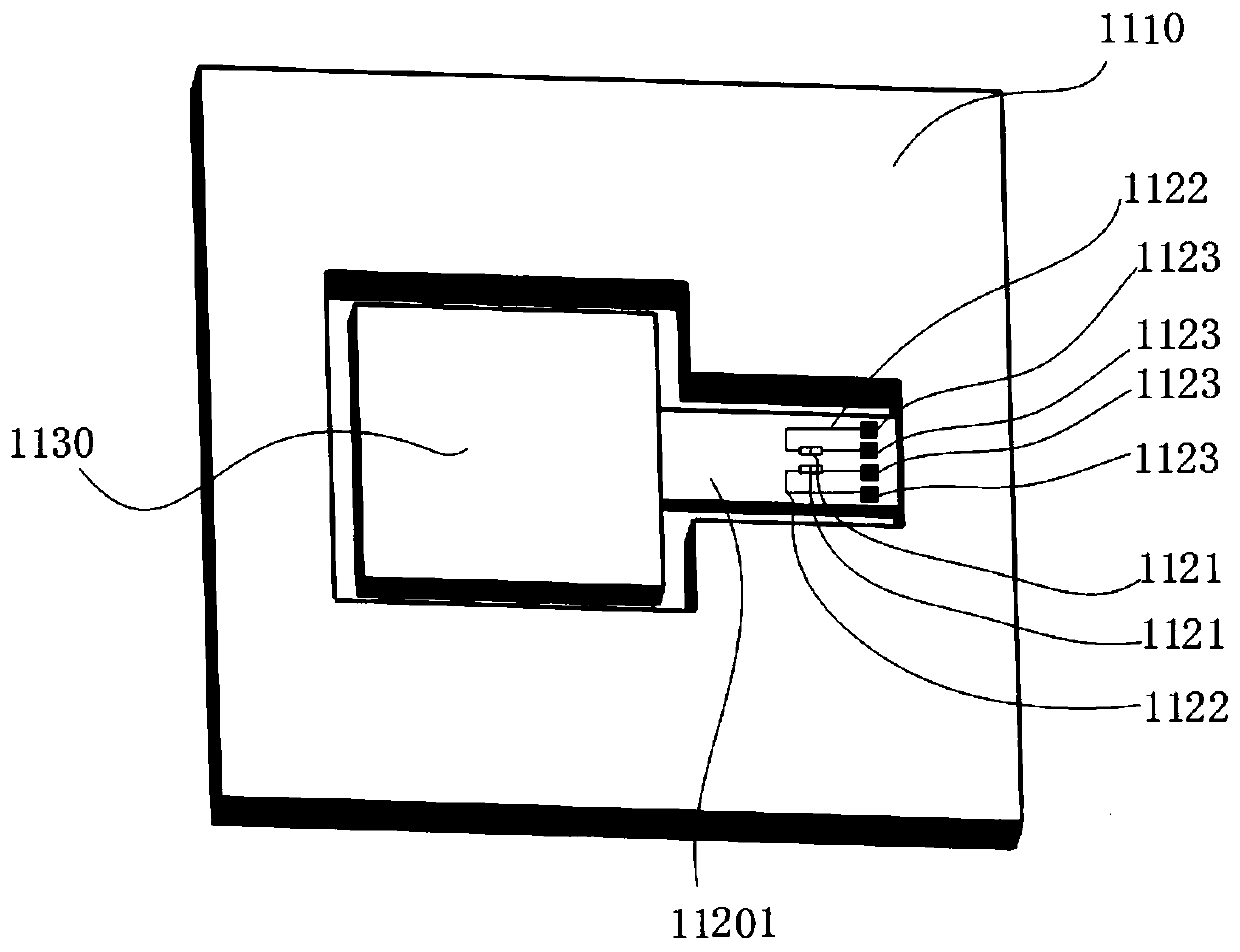

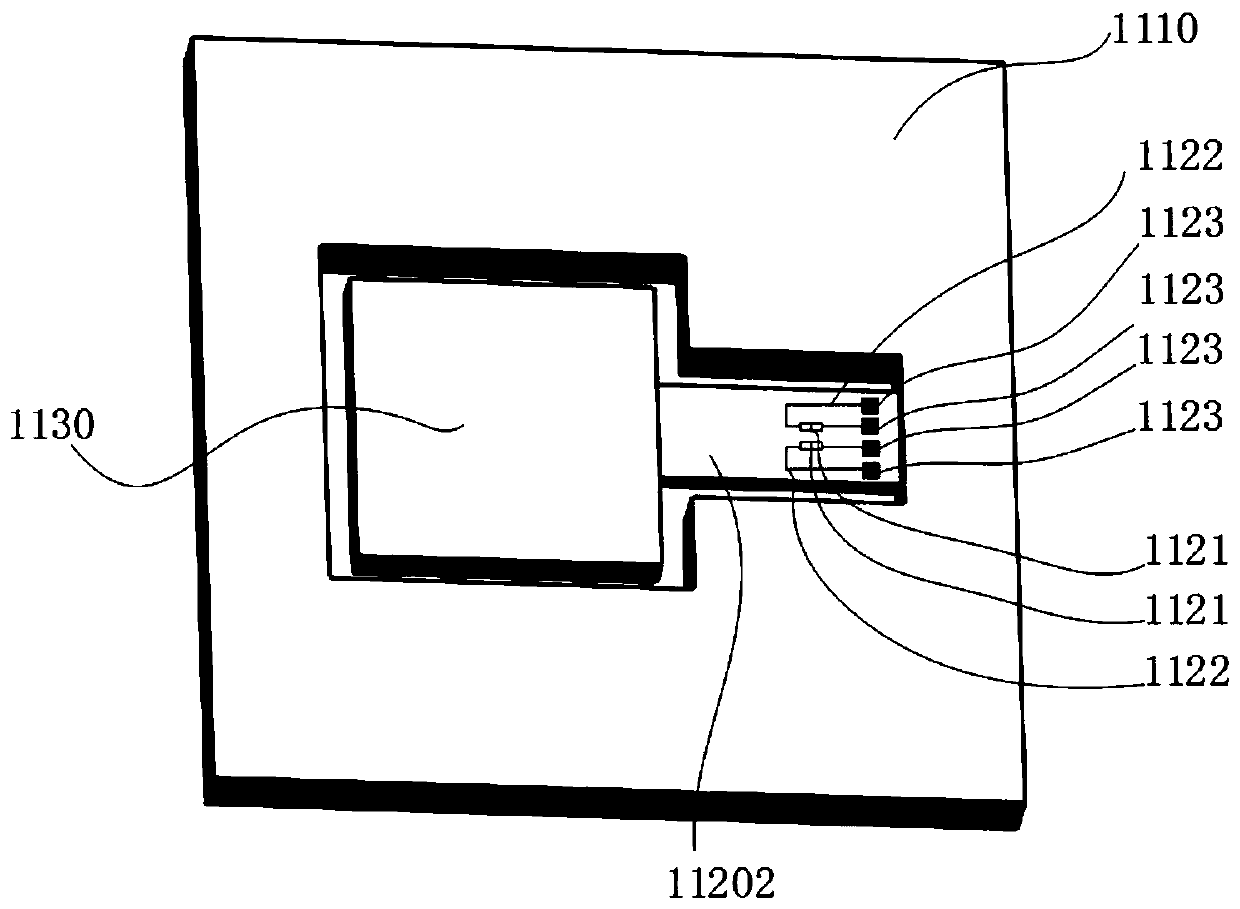

[0040] It should be understood that figure 1 It is a schematic cross-sectional view of the high-sensitivity, high-response, and overload-resistant silicon carbide high-temperature vibration sensor structure. The silicon carbide chip 1100 includes a supporting sheet 1110 , a cantilever beam 1120 and a proof mass 1130 . Wherein, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com