Static level monitoring system

A monitoring system and static leveling technology, applied in the direction of hydrostatic pressure, etc., can solve the problem of not being applicable to all-weather telemetry and automatic data acquisition, etc., and achieve the effects of high sensitivity, high measurement efficiency and large measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be discussed in detail below in conjunction with the accompanying drawings.

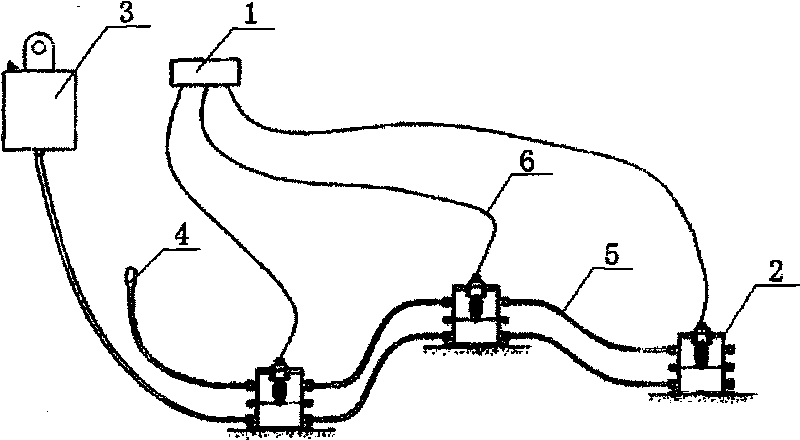

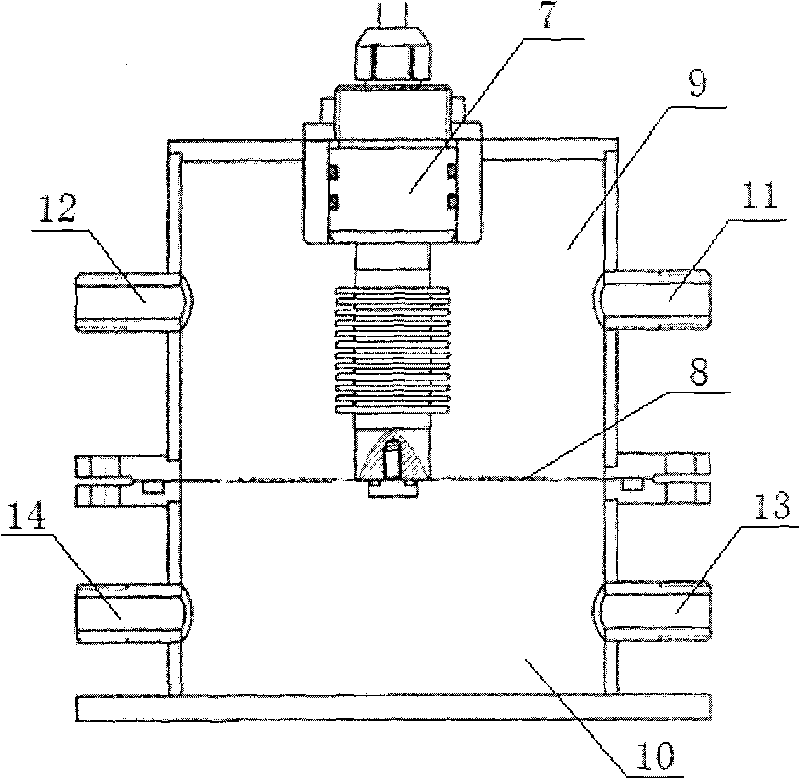

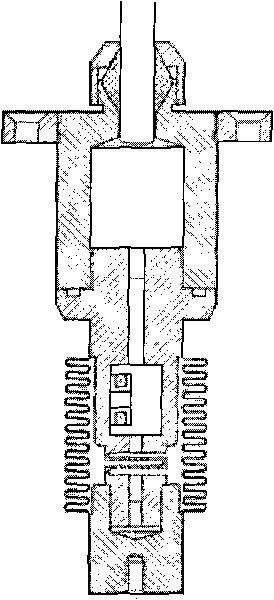

[0016] Such as figure 1 , figure 2 with image 3 As shown, a static level monitoring system in this embodiment includes a data acquisition system 1, a cable 6, a reference water tank 3, a static level 2, a connecting pipe 5 and a free water level end 4; the data acquisition system 1 adopts a GT-204 vibrator String reading instrument, or other vibrating wire frequency reading devices such as XTX-04 vibrating wire sensor measurement unit or other vibrating wire automatic measurement modules can be used to obtain monitoring data. The cable 6 uses an ordinary signal cable, and the data acquisition system 1 passes through the 6 is connected to the signal end of the static level 2, the reference water tank 3 adopts a stainless steel container that can store liquid, and the connecting pipe 5 adopts a nylon connecting pipe, or a conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com