Pipe jacking project automatic measurement system and method thereof

A technology of automatic measurement and pipe jacking engineering, applied in the field of measurement systems, can solve the problems of poor measurement accuracy and slow wire measurement speed, and achieve the effects of improving accuracy, saving manpower and lowering operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

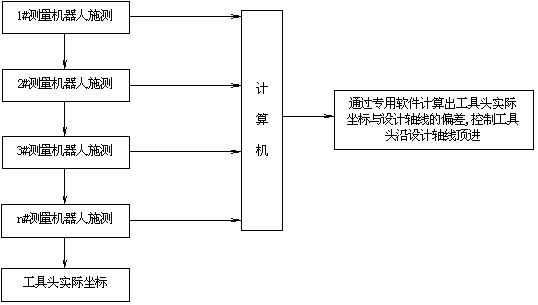

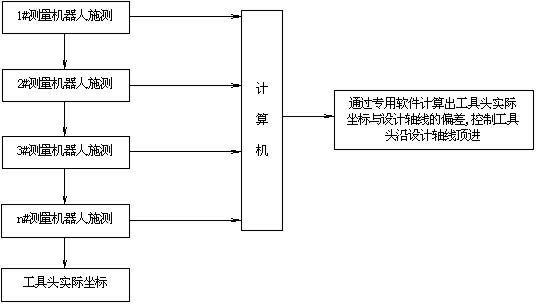

[0023] Such as figure 1 As shown, the automatic measurement system for pipe jacking engineering of the present invention includes auxiliary measuring stations established at the corners of pipe jacking construction, and is characterized in that each auxiliary measuring station is composed of an automatic leveling base and a total station. The data terminal of each measurement robot is connected to the data port of the computer through a shielded cable. The measurement data is processed by the computer, and each total station is controlled by the computer to carry out the measurement in an orderly manner.

[0024] The pipe jacking project automatic measuring method of the present invention, concrete steps are:

[0025] 1. Enter the starting point and end point of the design route, the coordinate values of the survey control points and the calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com