Patents

Literature

56results about How to "Data acquisition real-time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent oil well simulation experiment system and working method

InactiveCN102022112AEasy to operateFast and easy data collection and processingBorehole/well accessoriesTraffic volumeAutomatic control

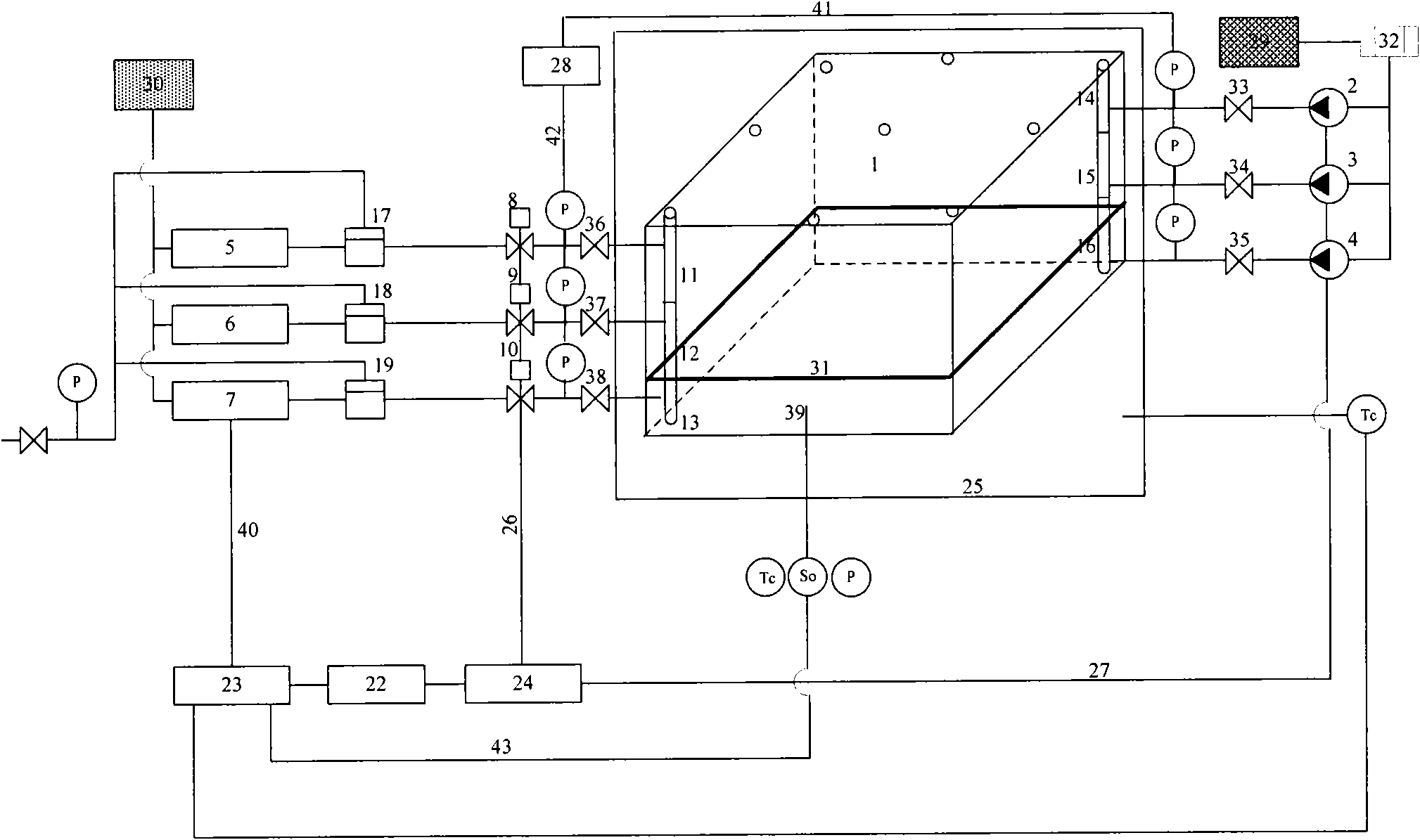

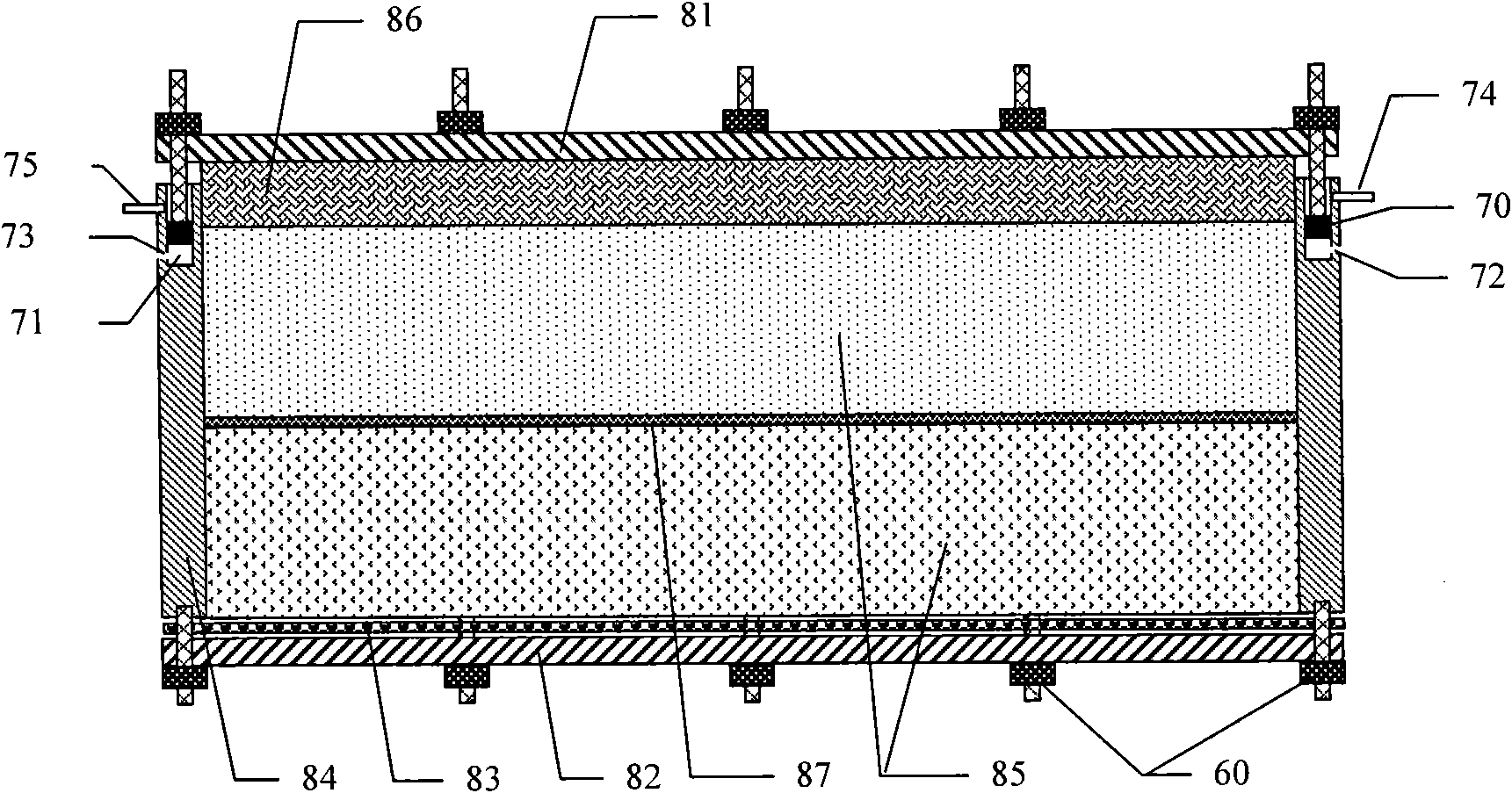

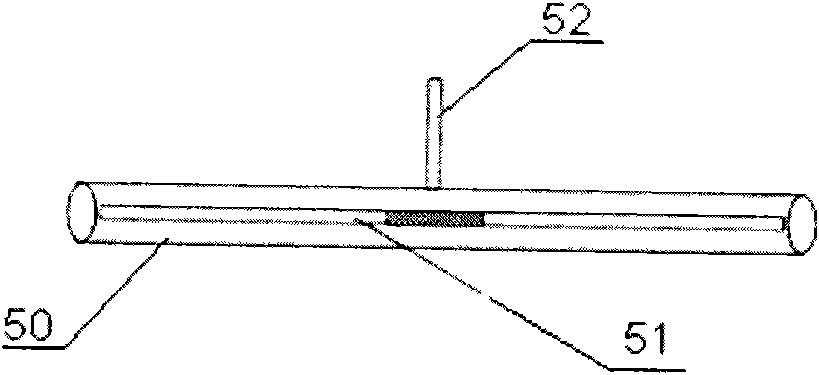

The invention discloses an intelligent oil well simulation experiment system and a experiment method. The intelligent oil well simulation experiment system comprises a three-dimensional heterogenous reservoir simulating box, a wellbore hole simulator, a fluid injecting module, a fluid generating module, a data acquiring module, an automatic control module, a constant temperature module, a saturation probe, a pressure sensor and a temperature sensor. The wellbore hole simulator is arranged in the three-dimensional heterogenous reservoir simulating box, the automatic control modules realizes the real-time extraction and injection on the wellbore hole simulator through controlling the fluid injecting module and the fluid generating module; and the data acquiring module is used for monitoringinjected and extracted fluid, and monitoring the saturation, the temperature and the pressure in the simulating box in real time, and a computer is used for optimizing and analyzing the monitoring data, controlling the injection and extraction flow in real time through the automatic control module, simulating and realizing multilayer comingling production, sectional extraction of a horizontal well, extraction of a multi-branch well and control strategy of an injection and extracting well, and perfecting the researches of real-time optimization, real-time regulation and the like of the production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

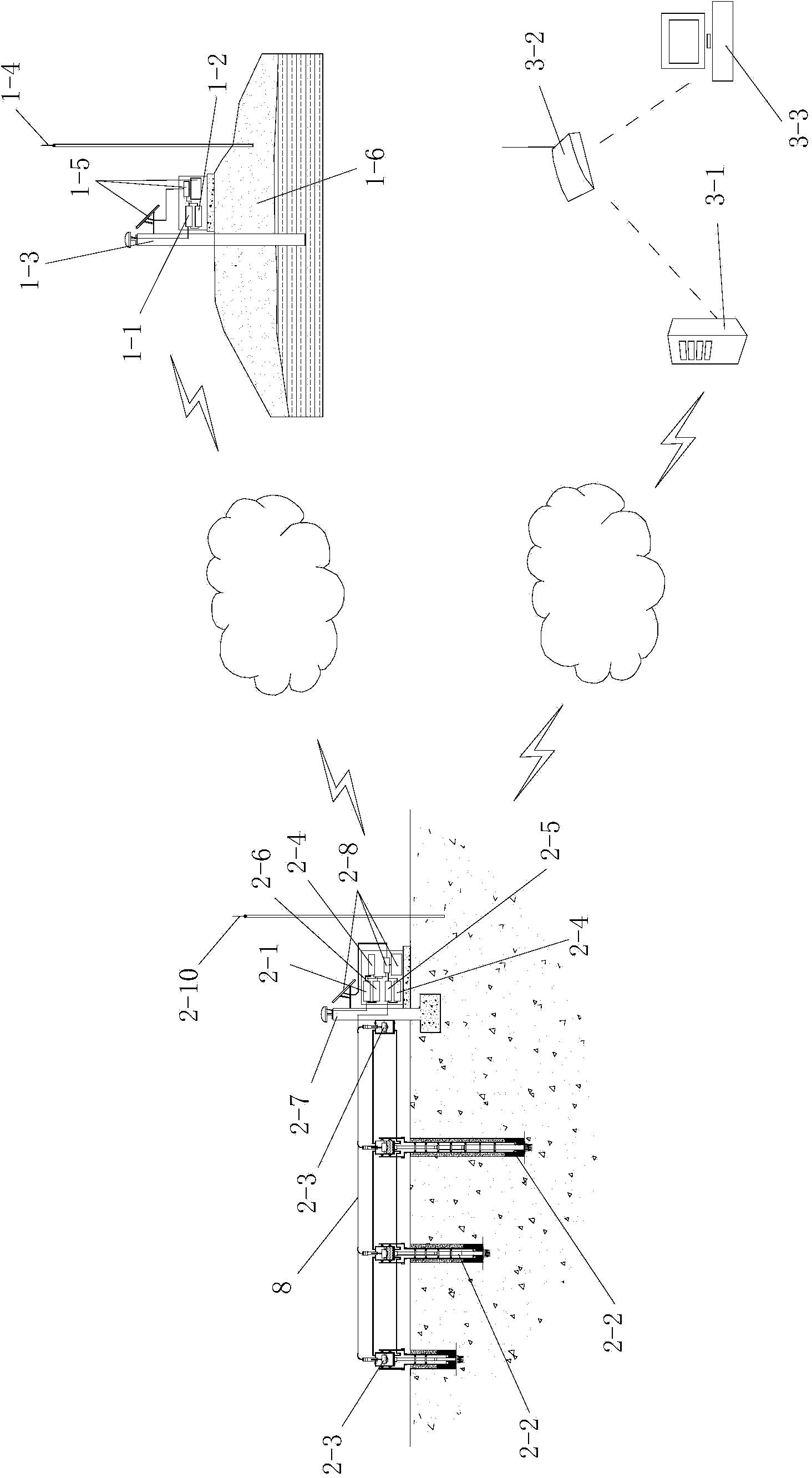

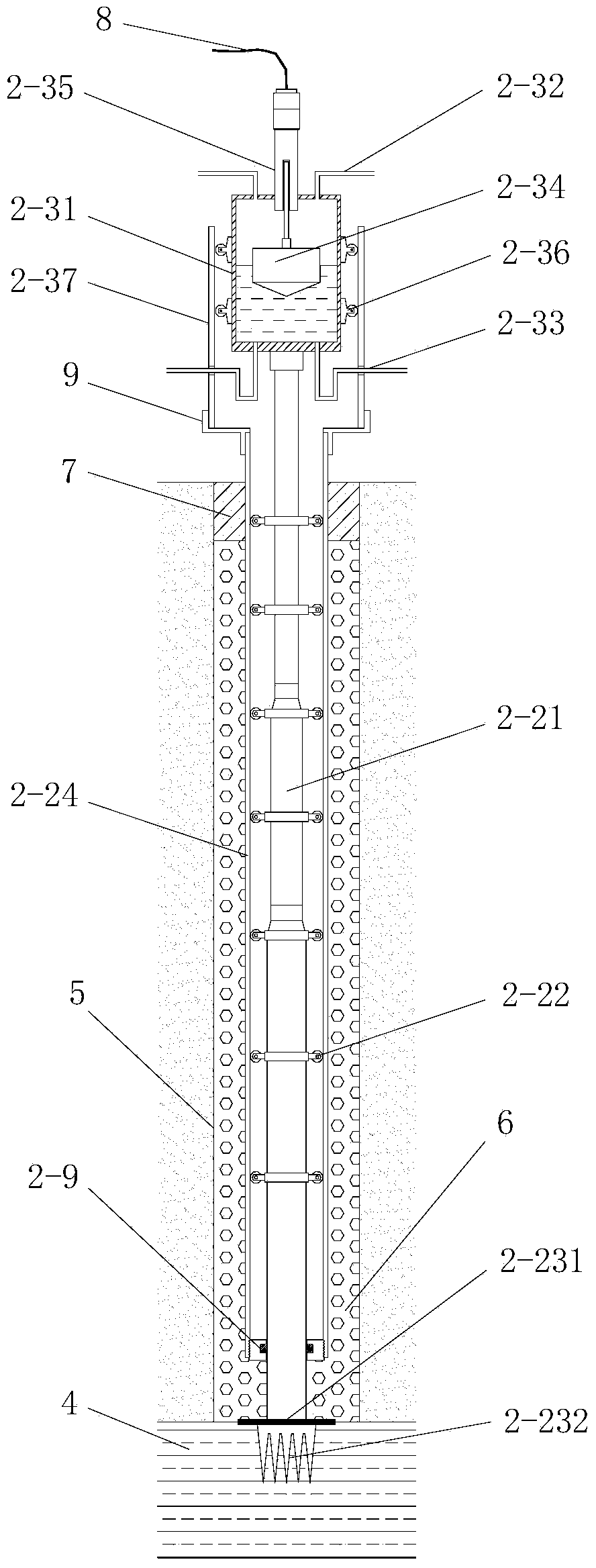

Satellite positioning and static leveling-based layered settlement monitoring system and method

ActiveCN104296721ASimple structureReasonable designHydrostatic levellingData transmissionEngineering

The invention discloses a satellite positioning and static leveling-based layered settlement monitoring system and method. The system comprises a base station, a monitoring station which is arranged in a settlement monitoring area and a monitoring center which communicates with the monitoring station, wherein the base station communicates with the monitoring station; the monitoring station comprises an observation pillar, a second Beidou satellite signal receiver mounted on the observation pillar, a data transmission unit, a plurality of layered settlement marks and a static level system; the static level system comprises a plurality of static level gauges; each layered settlement mark is provided with one static level gauge; one of the static level gauges is arranged on the observation pillar. The method comprises the following steps: I, setting of the monitoring system; II, data acquisition and transmission; III, data processing and analysis. According to the satellite positioning and static leveling-based layered settlement monitoring system and method, the calibration and correction problems of the instable working base points during the static leveling can be effectively solved, and the long-term, remote and real-time monitoring for the layered settlement deformation of the geologic bodies can be realized.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

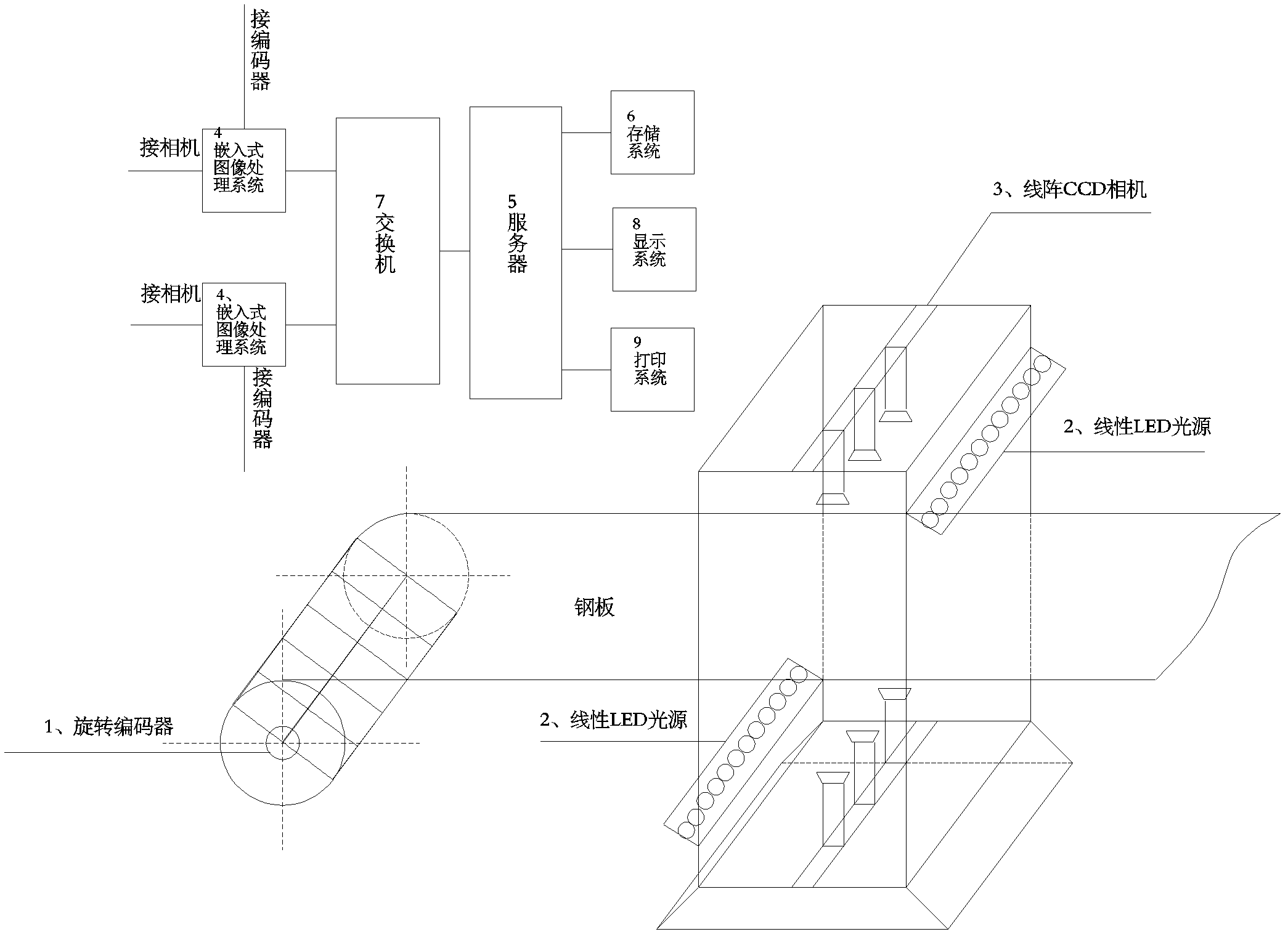

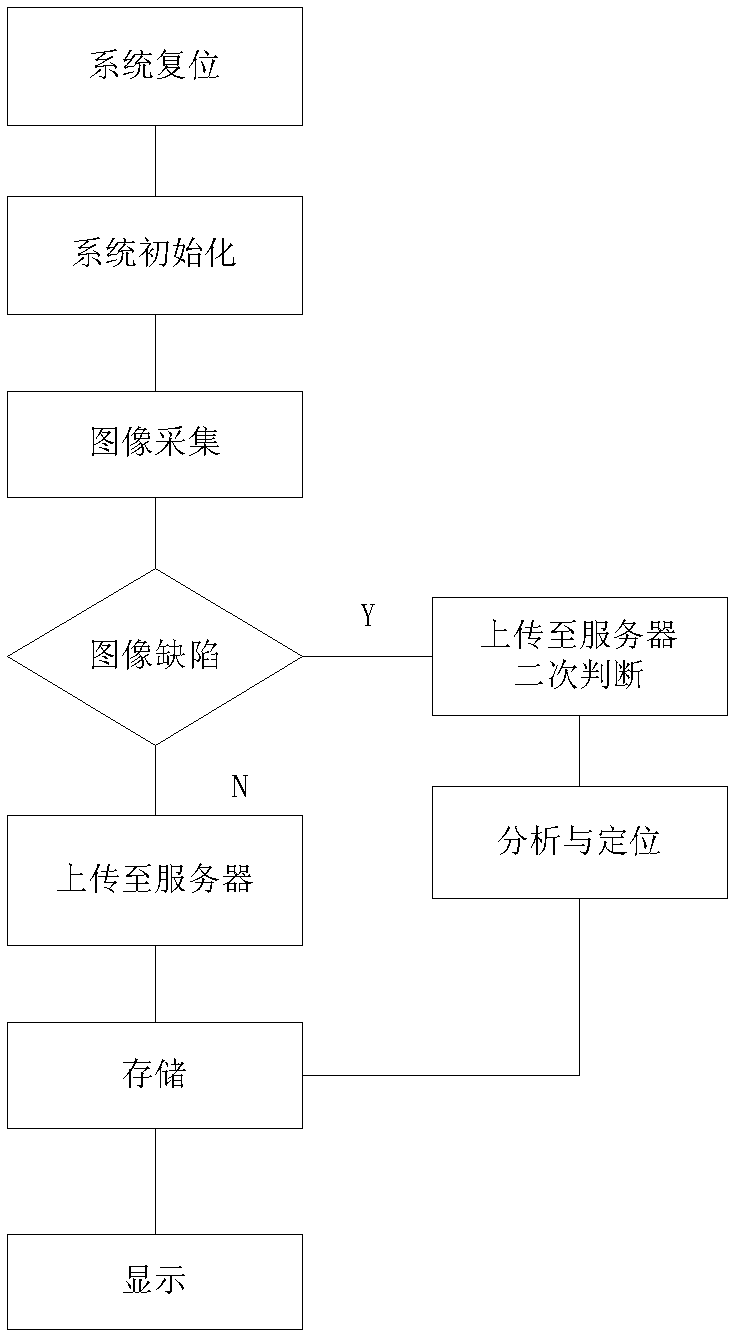

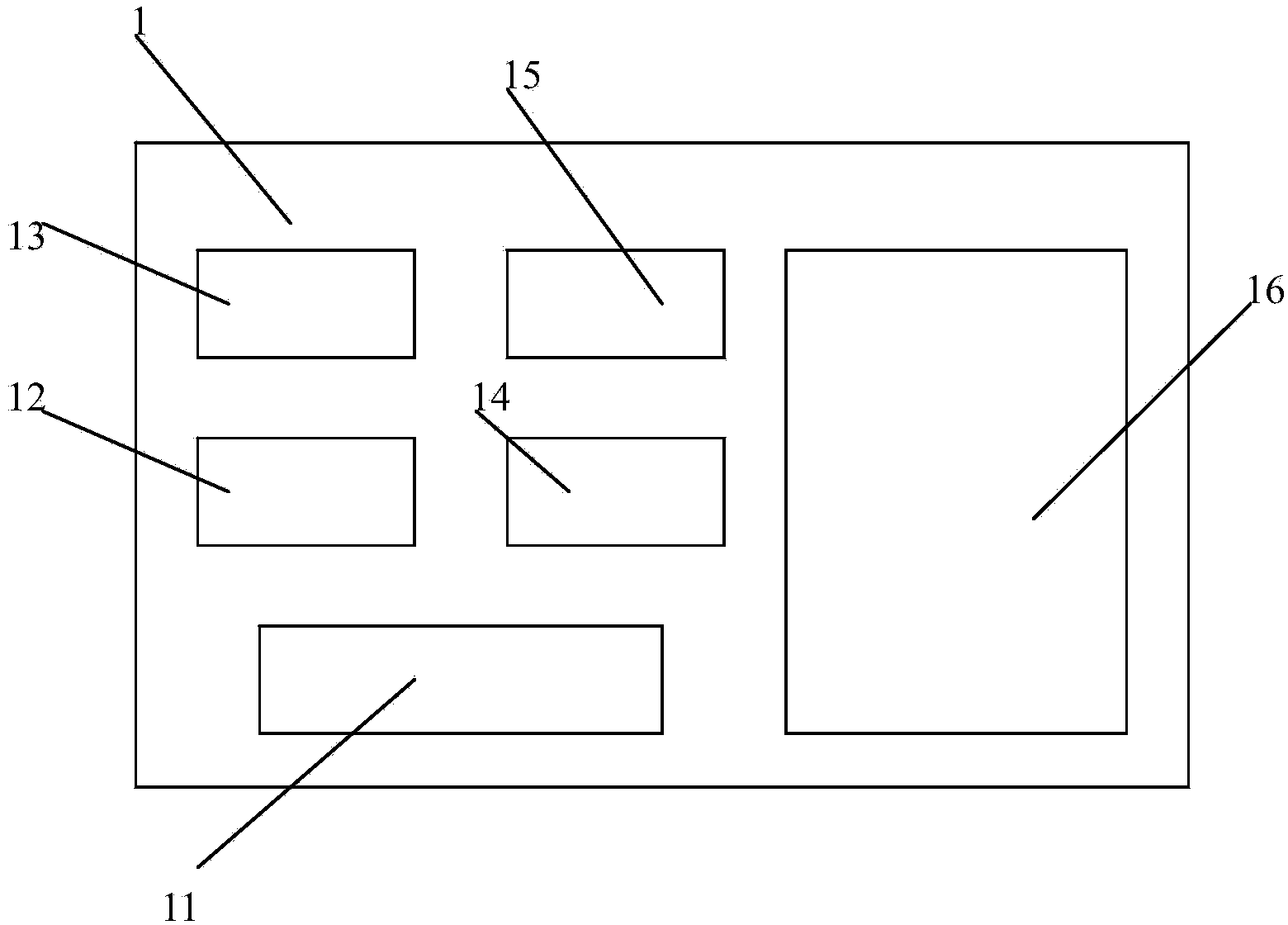

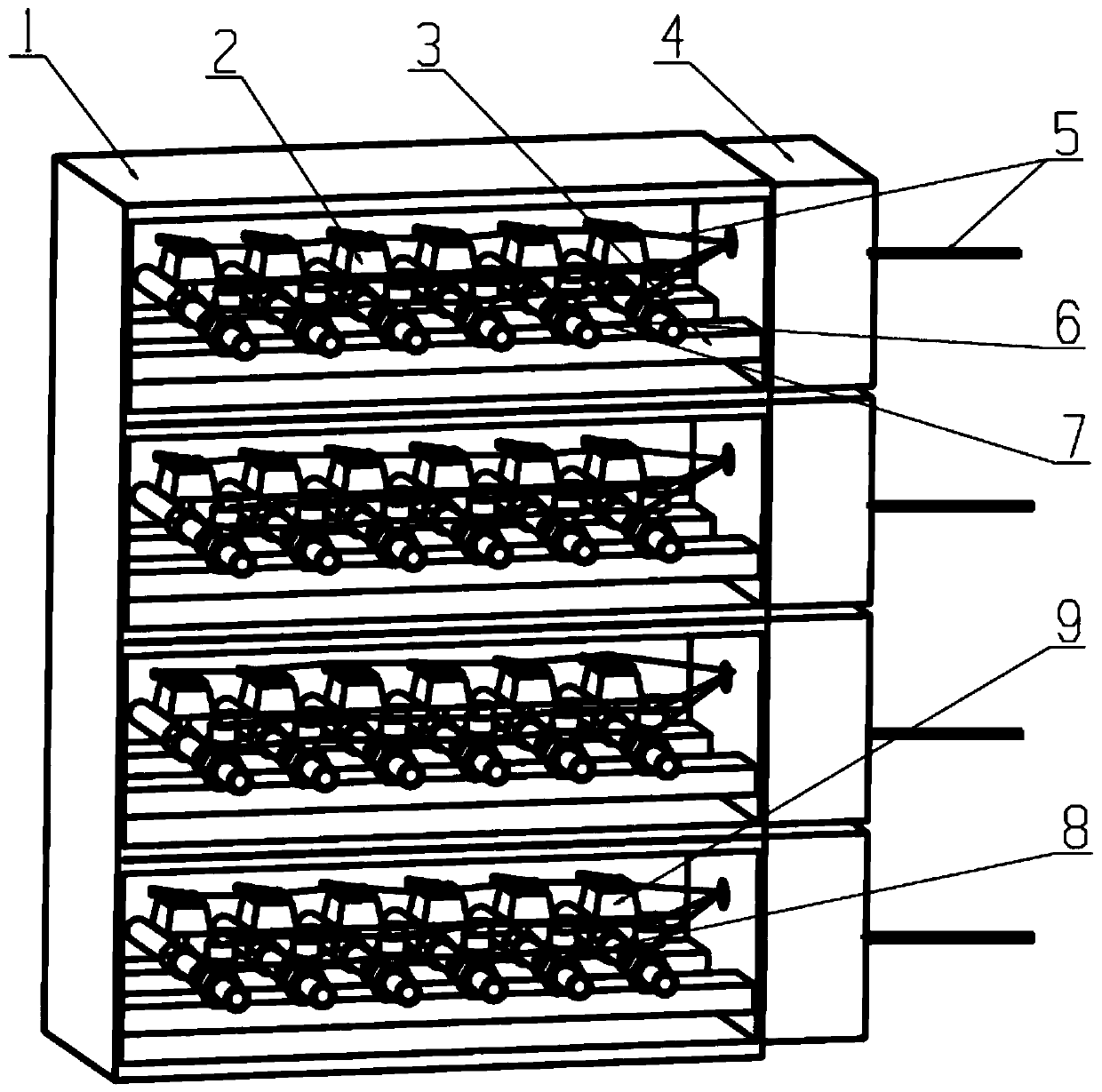

Strip steel surface on-line inspection system and method based on embedded image processing system

InactiveCN103163141AImprove light outputImprove uniformityCharacter and pattern recognitionOptically investigating flaws/contaminationData acquisitionDisplay device

The invention provides a strip steel surface on-line inspection system and method based on an embedded image processing system. The inspection system mainly comprises an encoder (1) installed on an S roller, a fixed frame (10) located above and below a transmission strip steel be detected, a linear LED light source (2) mounted on the fixed frame, a linear array CCD camera (3), an embedded image processing system connected to the encoder and the CCD camera through Gigabit Ethernet, a server (5) connected to the embedded image processing system (4) through a switchboard (7), a storage (6) and a display (8). The invention uses a small amount of equipment and devices, and a bus mode to ensure real-time and accurate data acquisition of surface quality information of a cold-rolled strip steel, saves a large amount of system resources, and has the advantages of simple structure and convenient maintenance. Besides, the invention solves the problem of low running speed of a PC based pure software detection method and the problems of complex system and high cost of multiple DSP parallel processing of data.

Owner:ANGANG STEEL CO LTD

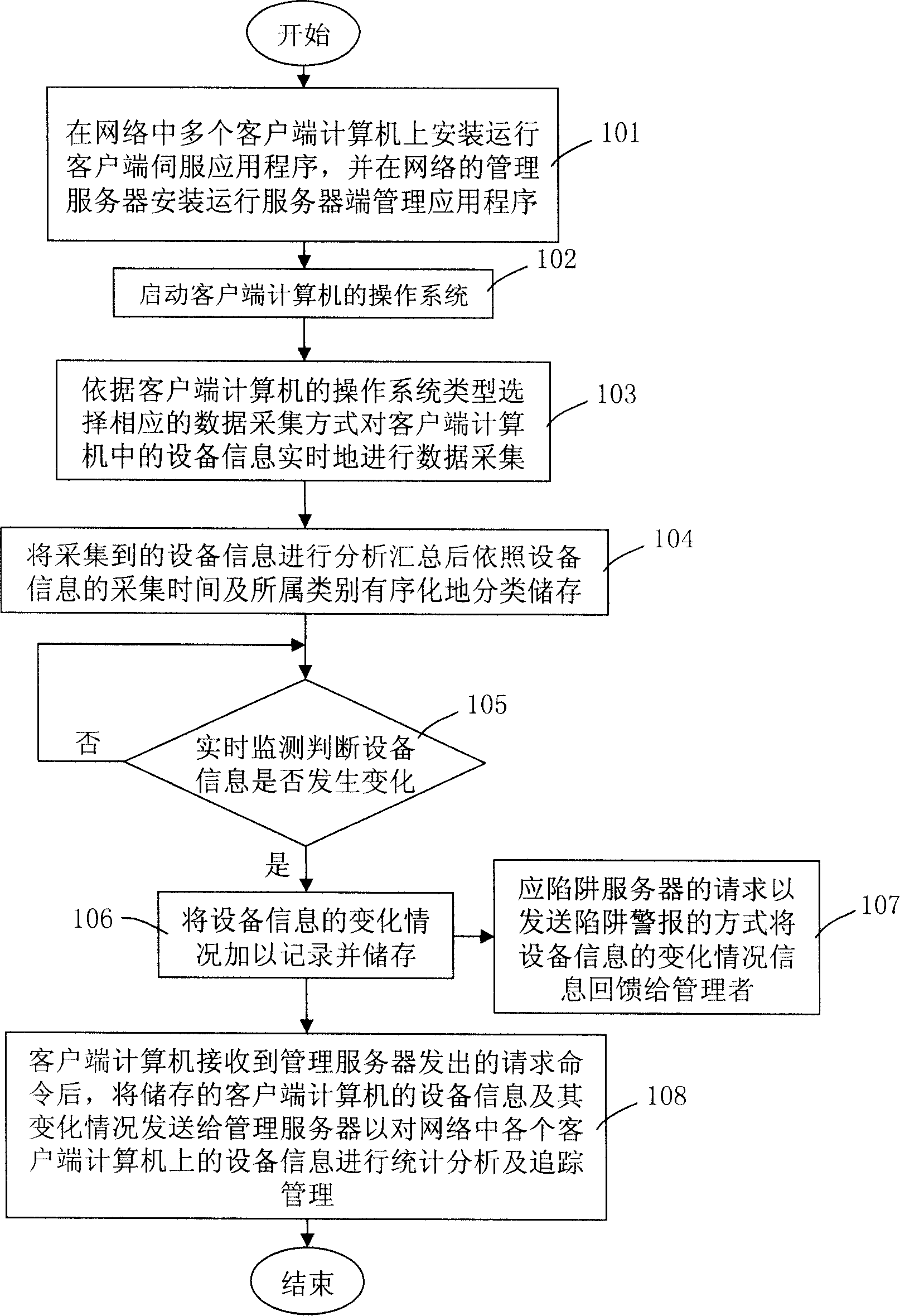

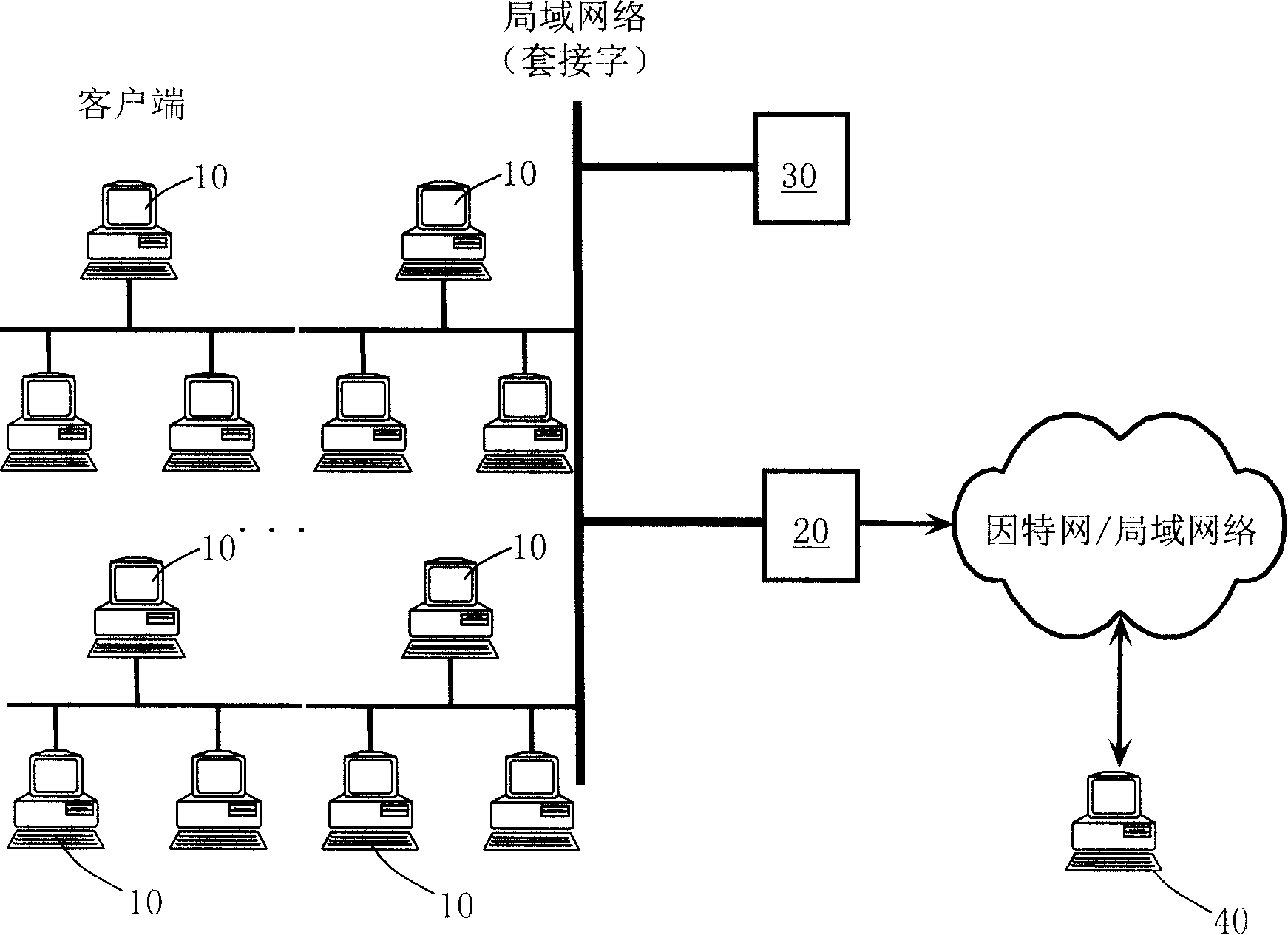

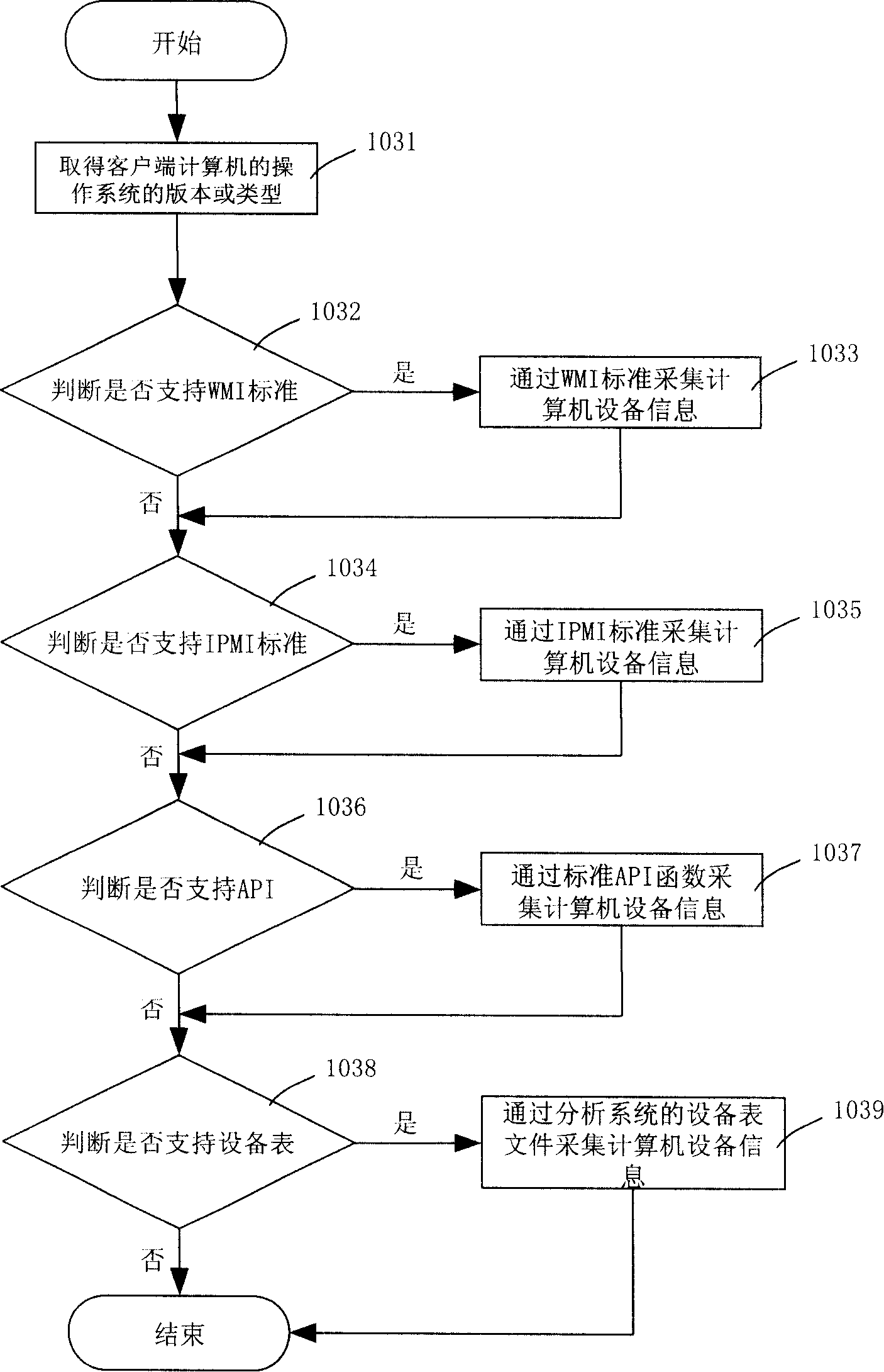

Method for collecting and managing equipment information

InactiveCN101202649AData acquisition real-timeIncrease coverageData switching networksReal-time dataOperational system

The invention relates to a method for collecting and managing the information of a computer device, which carries through information collecting, analyzing and management on the device information of a multi-client computer that runs in a normal network through service terminal / client application program; wherein, the method includes the following steps: client service application program is installed on the multi-client computer to run and management application program of a server is installed at a the server terminal to run; after the system of the client computer is started, the corresponding data collecting mode is selected to carry through real time data collecting to the device information in the computer according to the operation system type of the computer; after being analyzed and gathered, the collected device information is classified and stored in sequence; the changing situation of the device information is monitored and recorded in real time; and the stored device information and the changing situation of the device information are transmitted to the server terminal to carry through statistical analysis and tracing management.

Owner:INVENTEC CORP

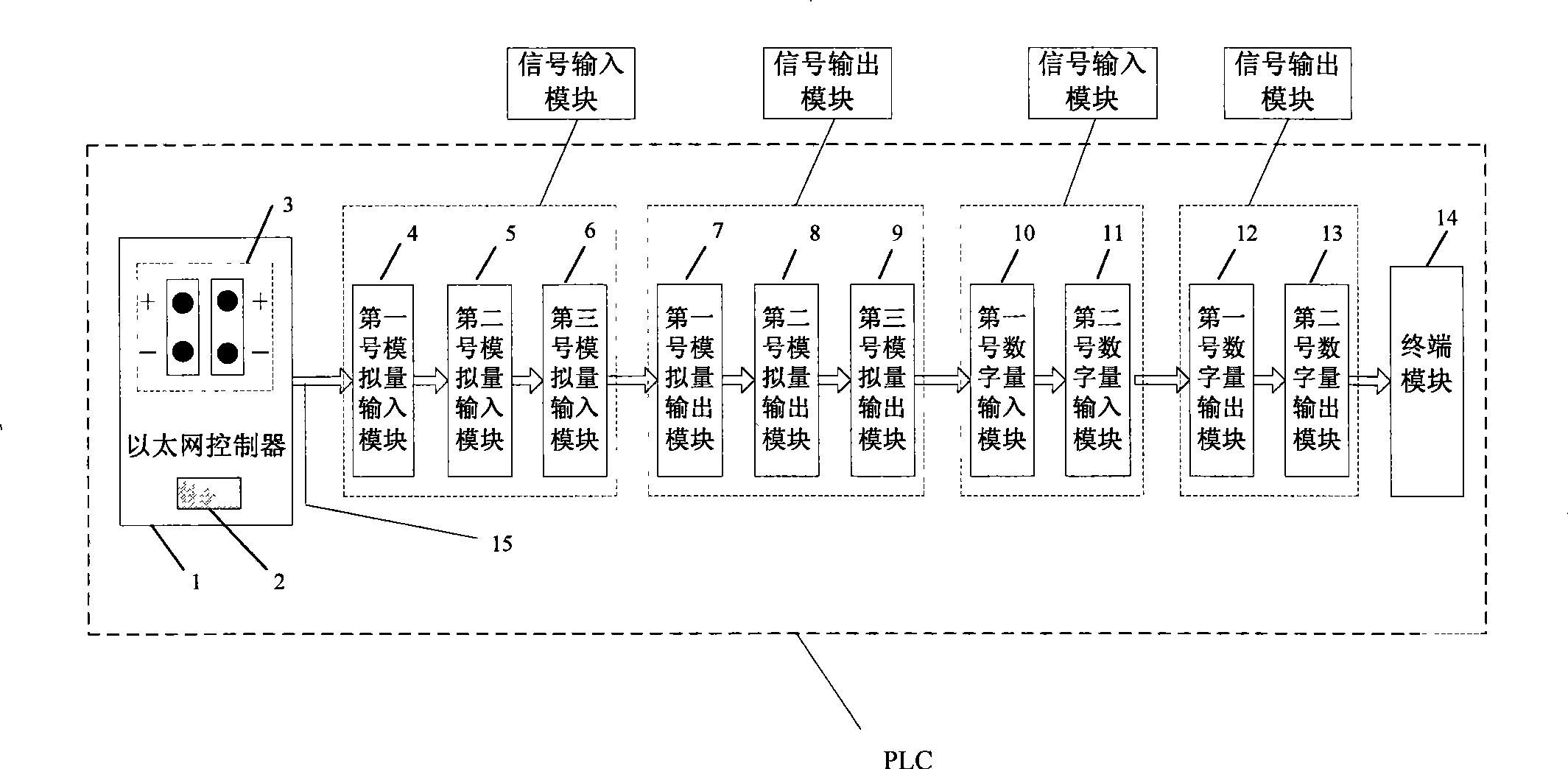

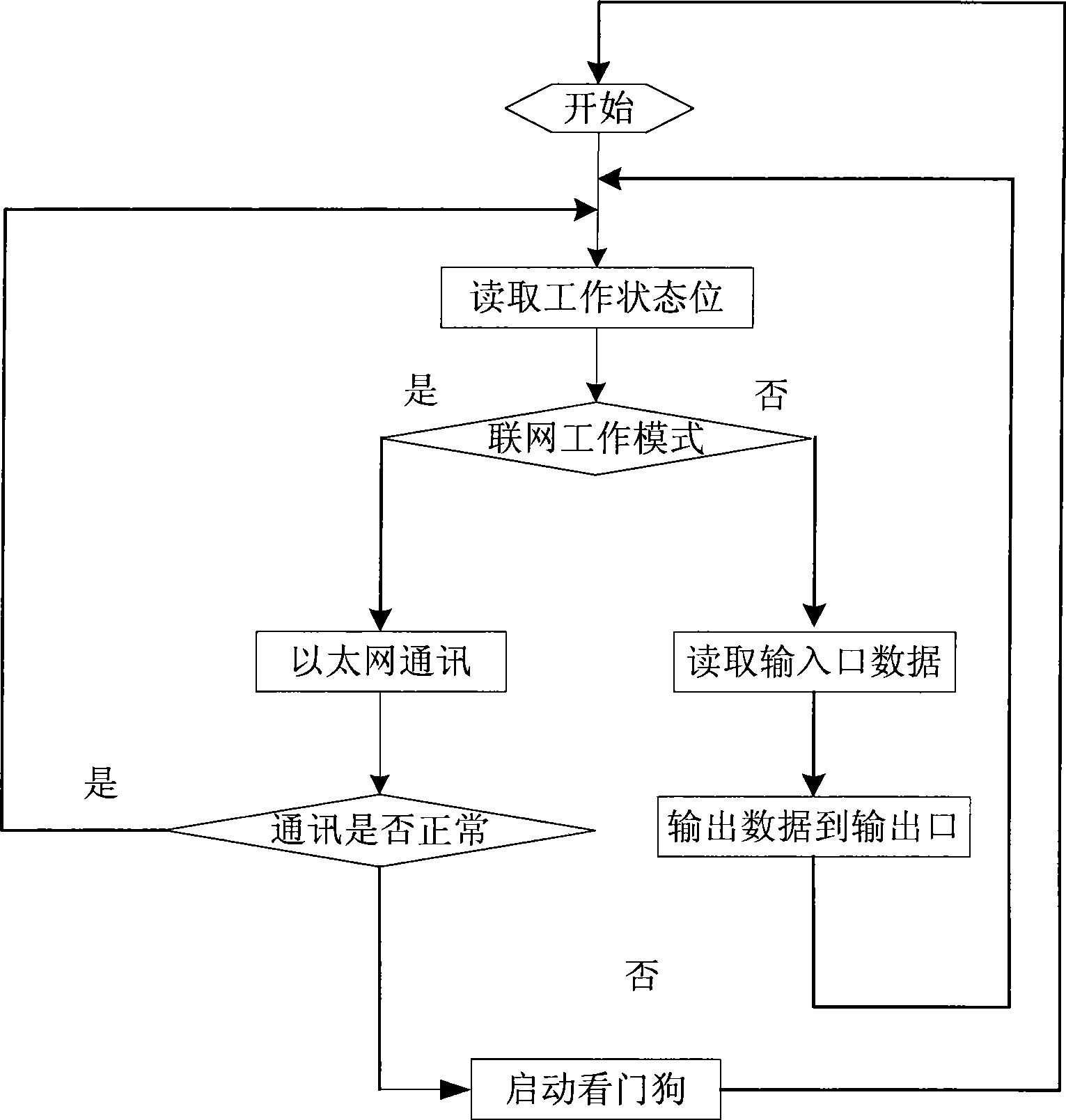

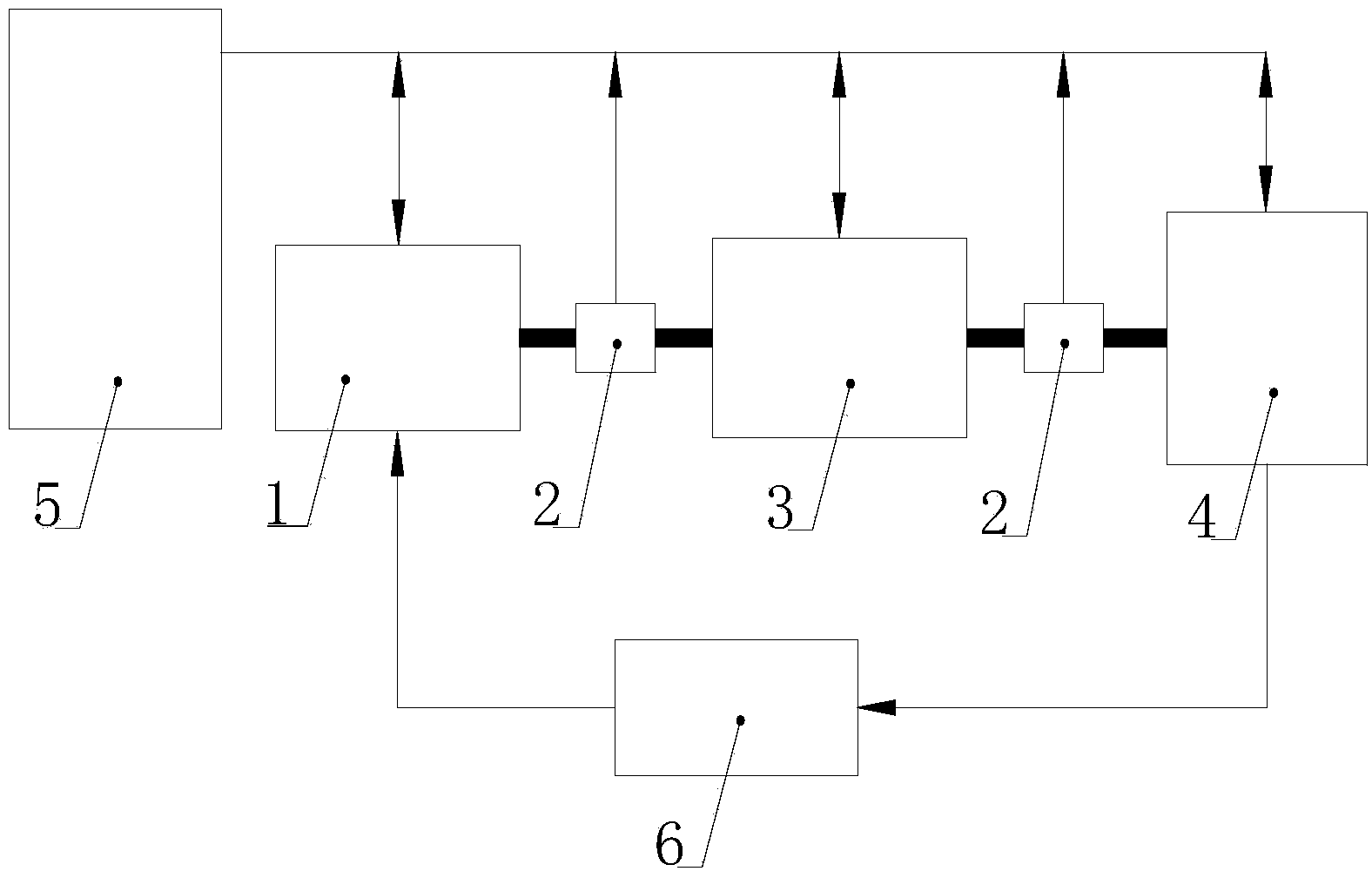

Ethernet network data acquisition and transmission method and system

InactiveCN101452639AStrong stabilityStrong signal reliabilityElectric signal transmission systemsTransmissionReal time acquisitionEthernet communication

The invention relates to real-time data acquisition technology, in particular to a distributed, networking and expandable Ethernet data acquisition and transmission method and a distributed, networking and expandable Ethernet data acquisition and transmission system which acquire and transmit data in real time and are based on Ethernet and programmable controller PLC technology. The Ethernet data acquisition and transmission system takes a programmable controller as a control device for data acquisition and communication, is provided with an Ethernet controller, is in Ethernet communication with a host computer by adoption of an Ethernet / IP communication mode and a Modbus transport protocol, and also comprises an I / O module which is connected with the Ethernet controller and connected with a terminal module through a final level digital quantity output module; and the programmable controller receives digital quantity signals or analog quantity signals from a sensor through the I / O module, is communicated with the host computer through a system program, selects a working model, and transmits the digital quantity signals or the analog quantity signals to a controlled device. The Ethernet data acquisition and transmission system has strong communication ability, wide application scope and a plurality of acquisition points, and a data acquisition system capable of being suitable for complex operating condition requirements is an urgent requirement of industrial fields.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

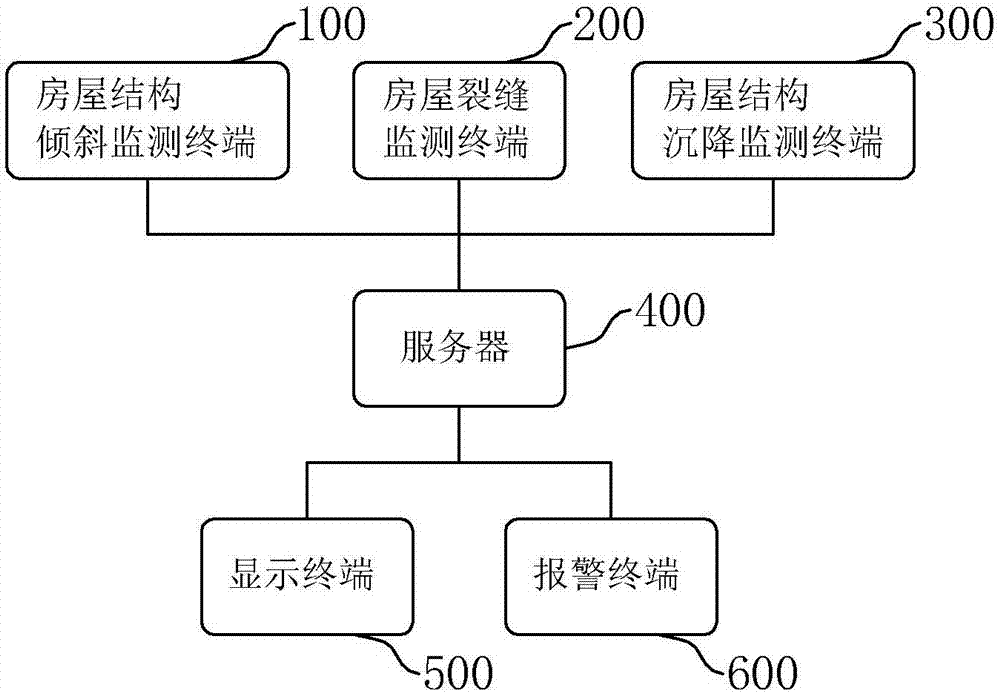

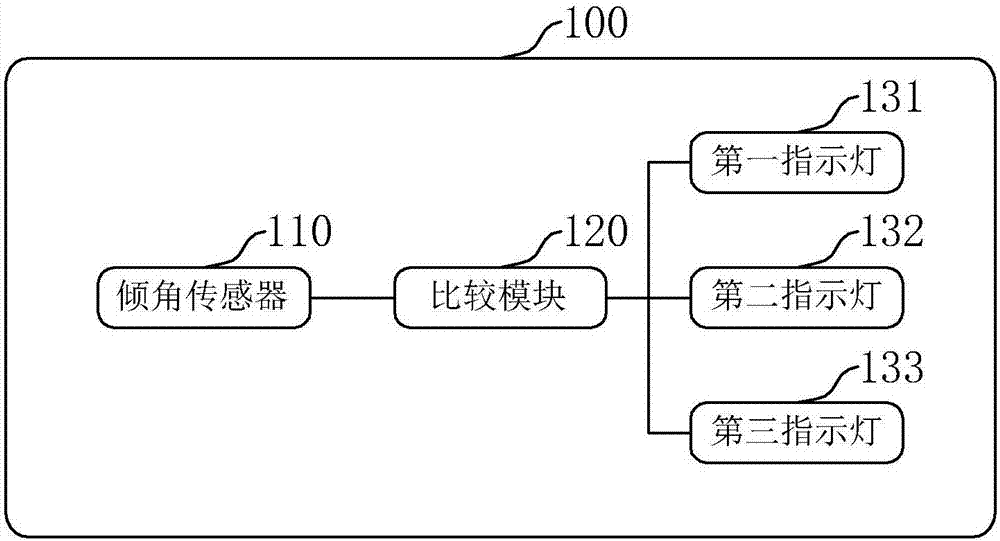

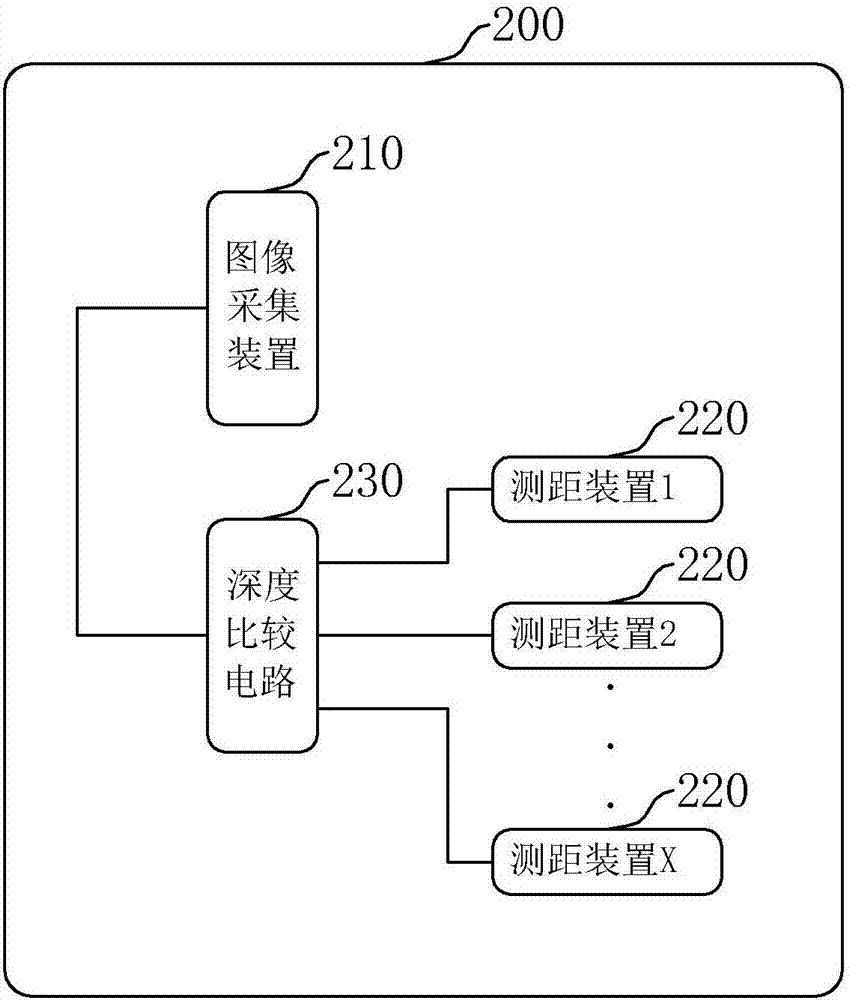

Automatic monitoring system of old and dilapidated house

ActiveCN107167114AData acquisition real-timeHeight/levelling measurementUsing optical meansTerminal serverMonitoring system

The invention discloses an automatic monitoring system of an old and dilapidated house. The system includes a house structure inclination monitoring terminal, a house crack monitoring terminal, a house structure settlement monitoring terminal, a server and a display terminal. The automatic monitoring system of the old and dilapidated house monitors the inclination angle of a house through the house structure inclination monitoring terminal, monitors the wall crack of the house through the house crack monitoring terminal, monitors the settlement height of the house through the house structure settlement monitoring terminal, and finally displays through the display terminal. The system using an Internet-of-things technology has the advantages of realization of monitoring, real-time data acquisition, and knowing of the scene situation for the first time.

Owner:RUIAN MAITIAN NETWORK TECH

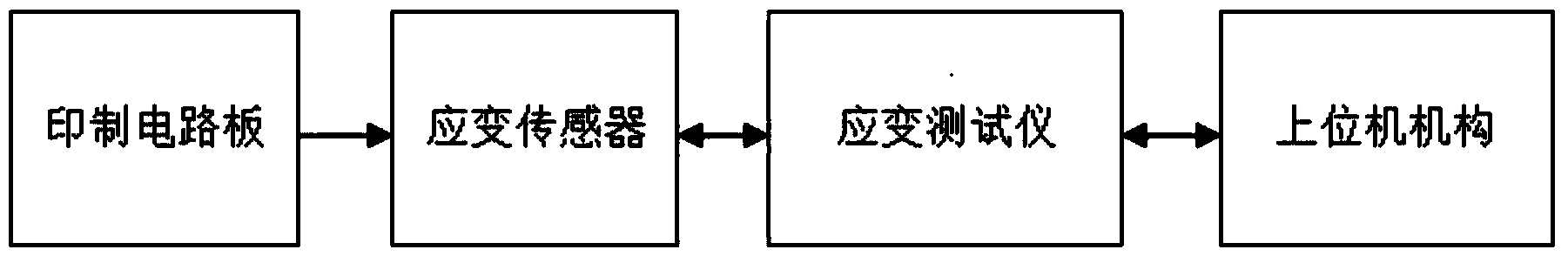

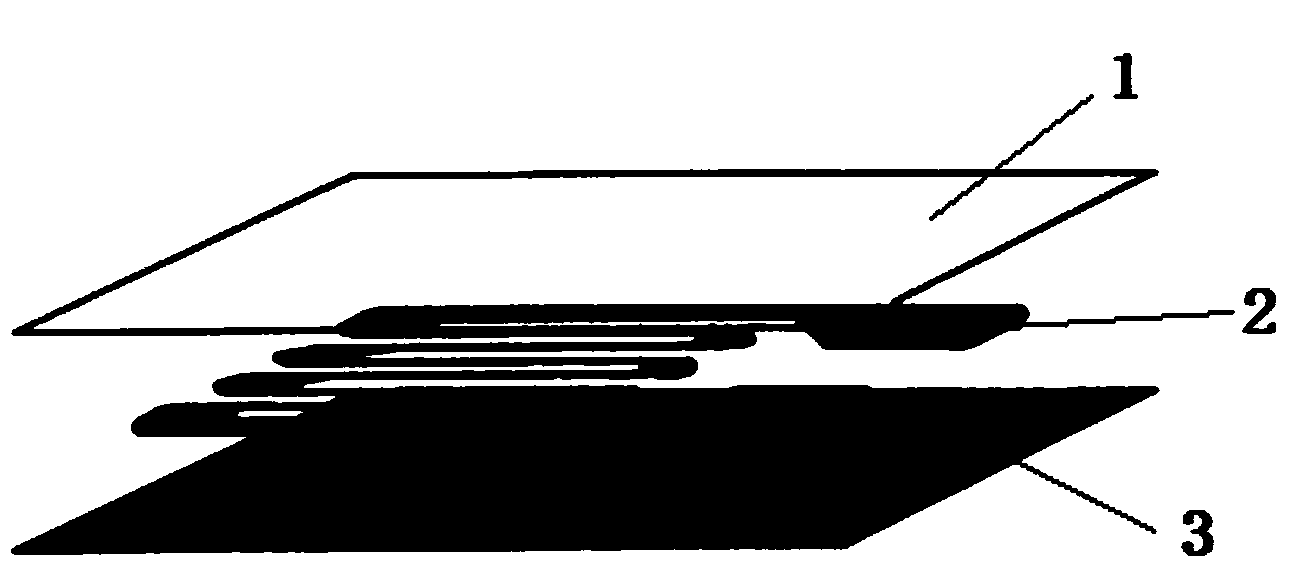

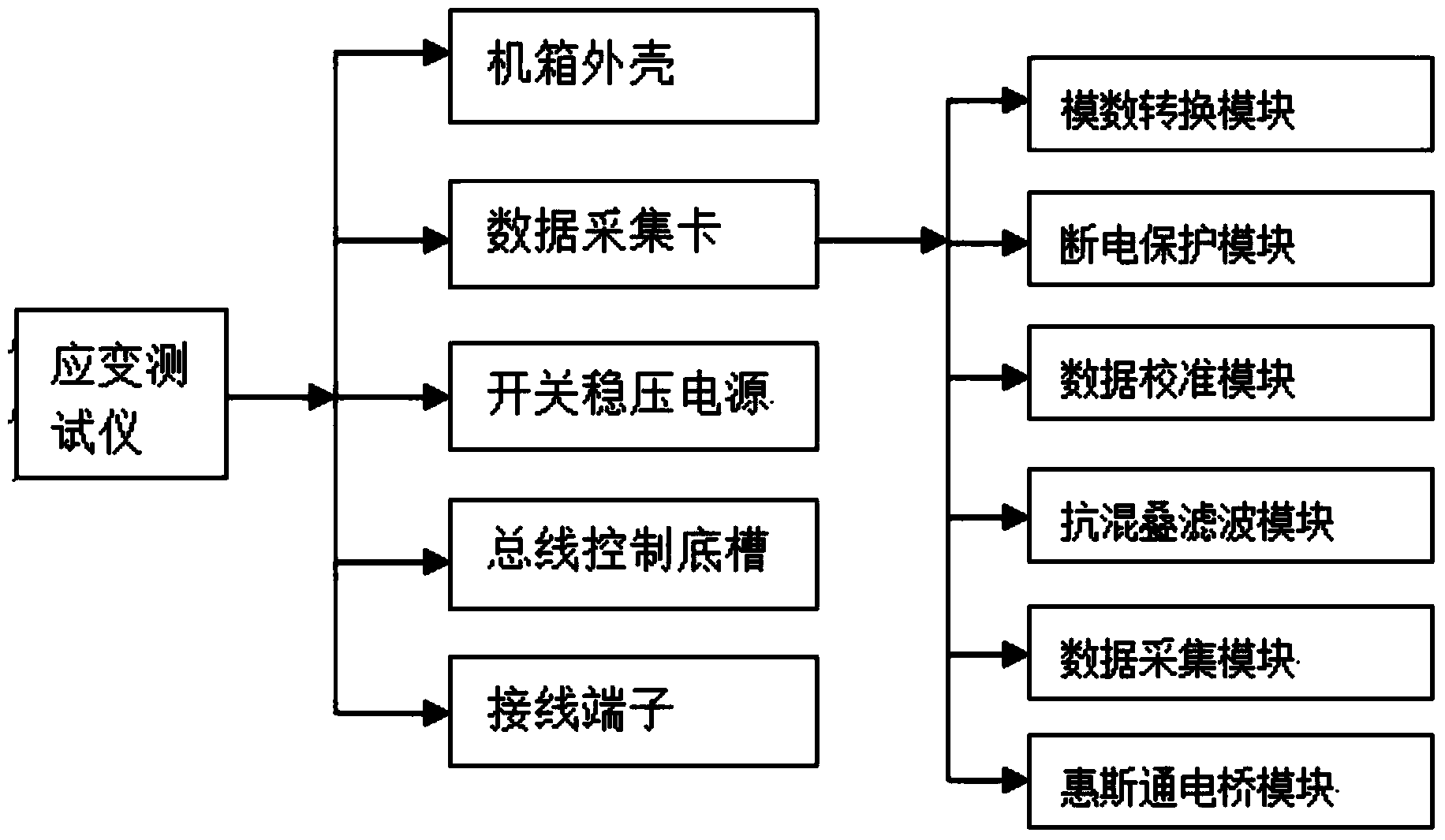

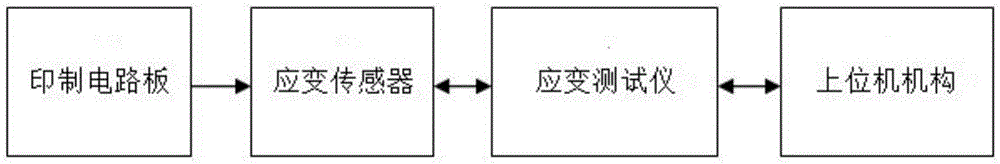

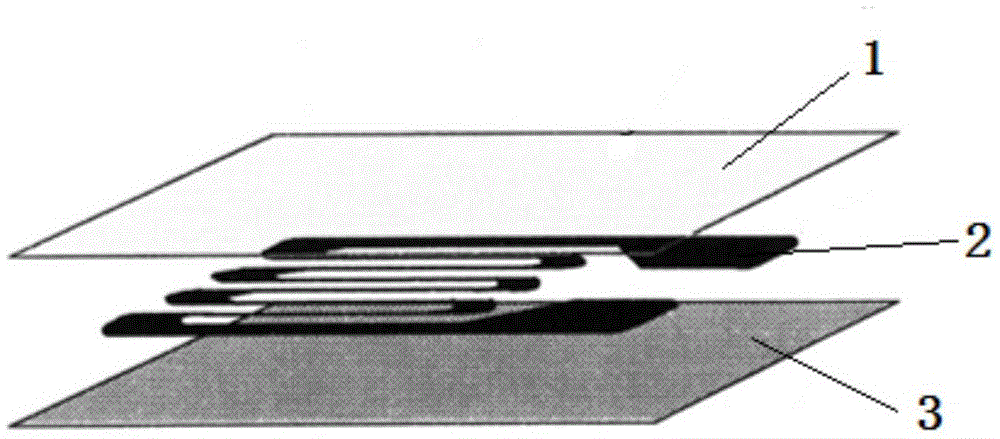

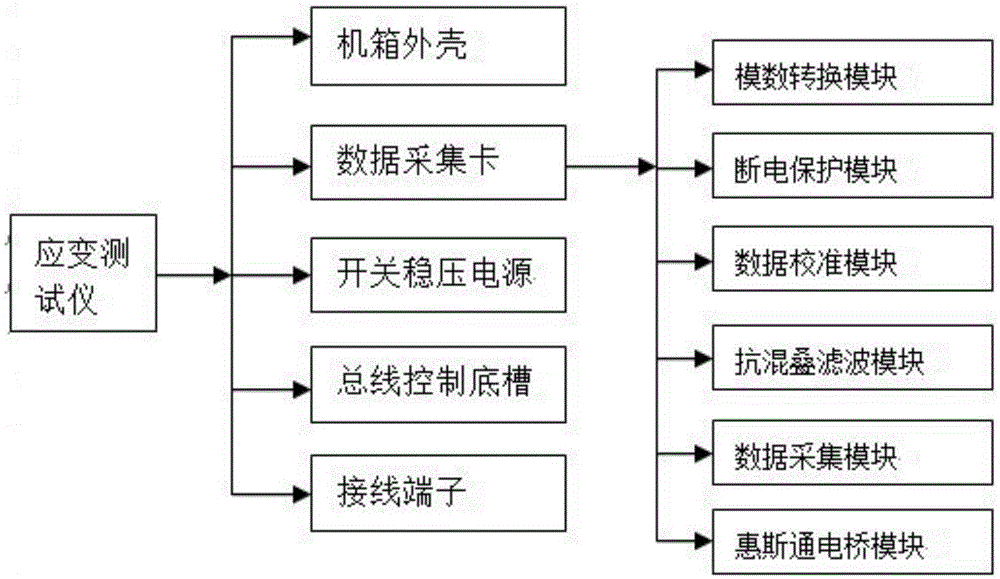

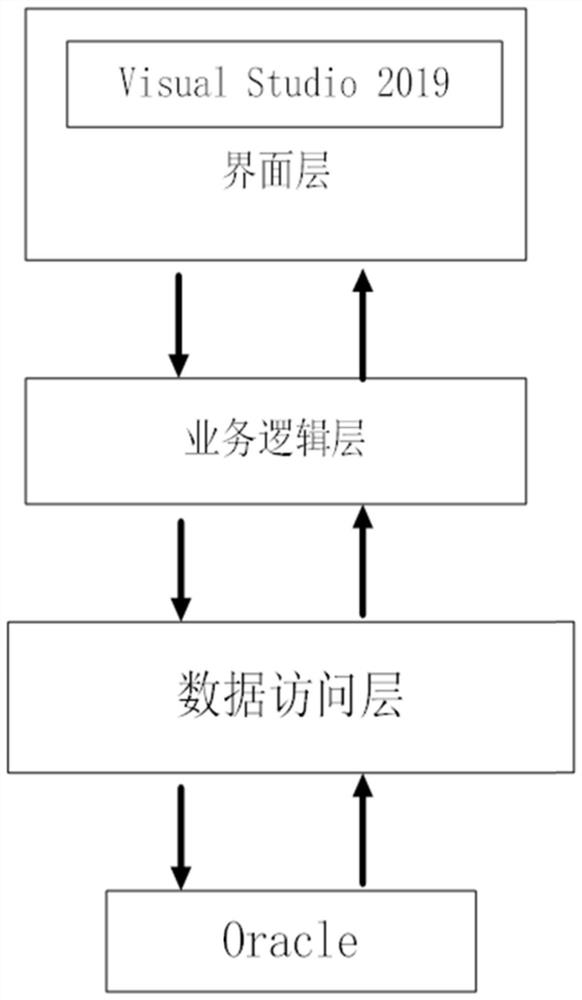

Stress-strain test system for printed circuit board

ActiveCN103528493AData acquisition real-timeReal time monitoringElectrical/magnetic solid deformation measurementStrain sensorStrain rate

The invention discloses a stress-strain test system for a printed circuit board. The stress-strain test system comprises a strain sensor, a strain tester and an upper computer mechanism; the strain sensor is attached to the printed circuit board and is connected with the strain tester which is connected with the upper computer mechanism. Compared with the prior art, the stress-strain test system for the printed circuit board has the advantages of capability of monitoring the strain condition of the circuit board in real time, good dynamic responding, high precision and the like.

Owner:章和技术(广州)有限公司

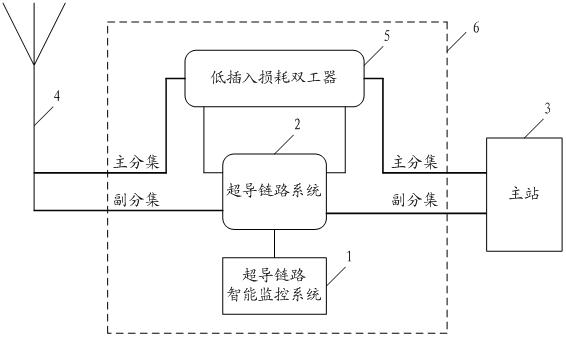

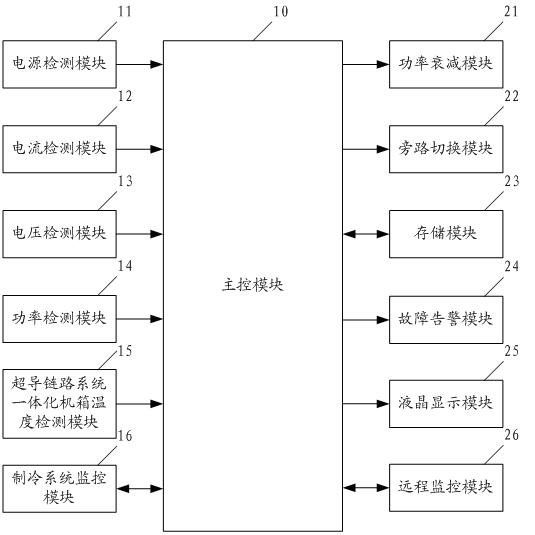

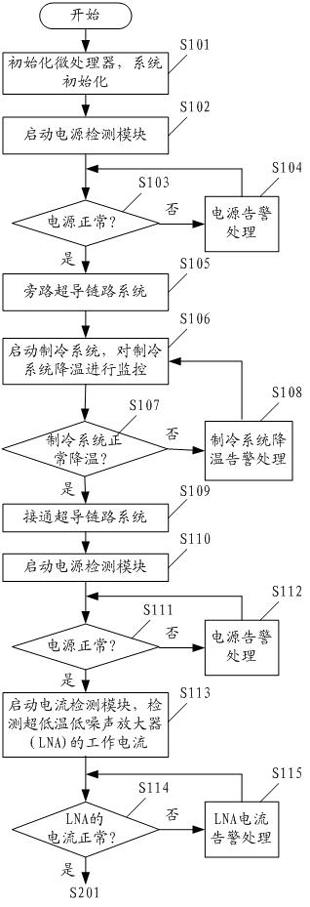

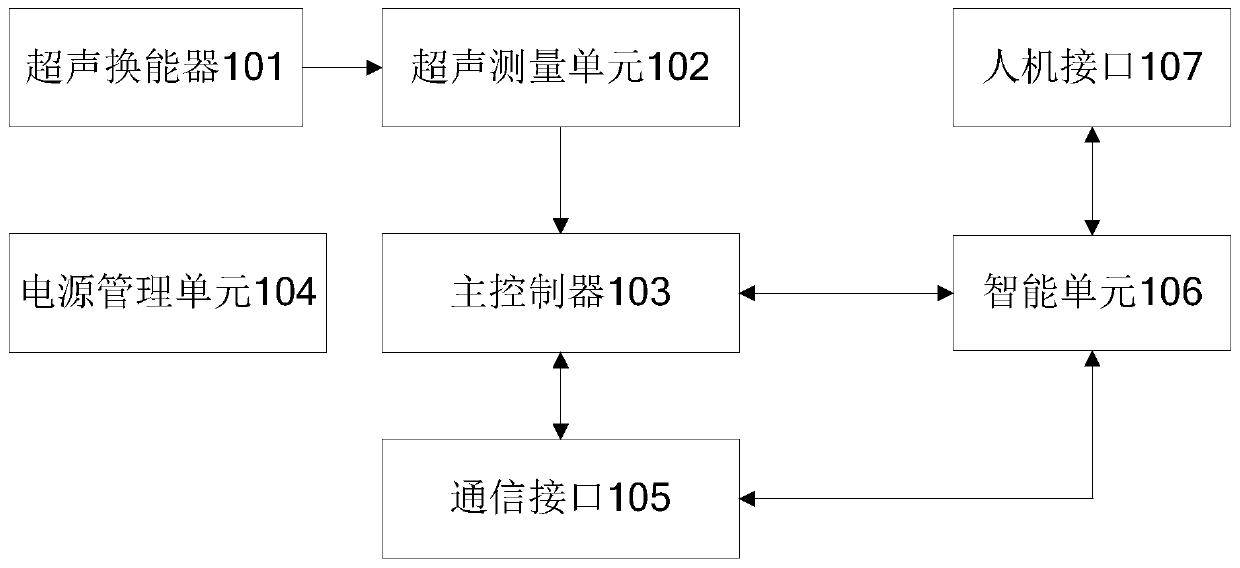

Intelligent monitoring system for superconducting link

ActiveCN102026248AReduce power consumptionData acquisition real-timeWireless communicationIntelligent lightingHuman–machine interface

The invention discloses an intelligent monitoring system for a superconducting link. The system mainly comprises a main control module, a power detection module, a power attenuation module, a bypass switching module and a liquid crystal display module. The system has the main functions of performing data acquisition, visual man-machine interface display, alarming and processing, historical information recording and system maintenance on the temperature, a radio frequency circuit and a power supply system of a superconducting link system in real time. The system can ensure the normal operationof the superconducting link system, prevent a too intense signal input into a master station from causing the abnormal operation even damage of the master station, and ensure the normal operation of a network link between an antenna and the master station.

Owner:广州特信网络技术有限公司

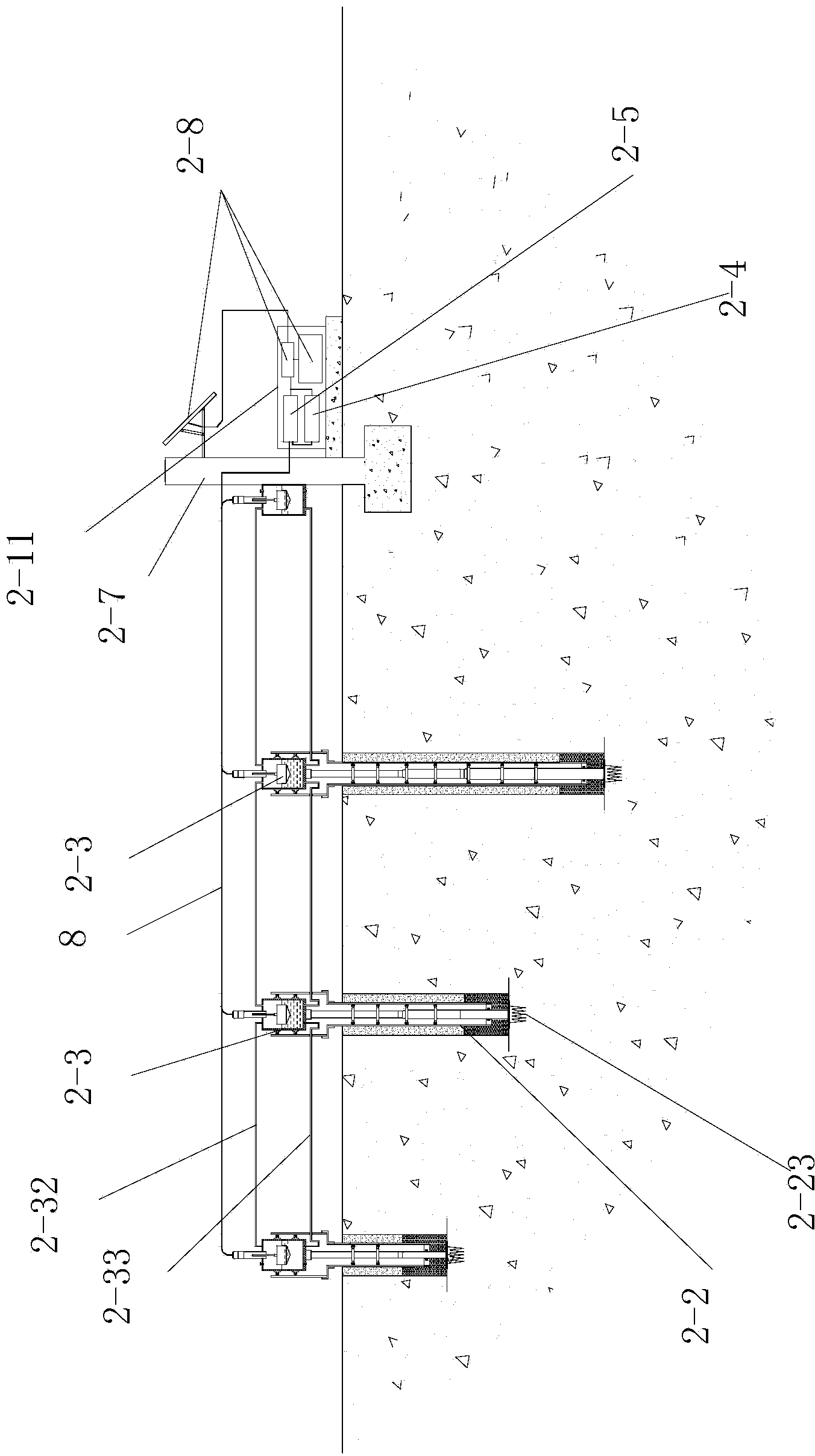

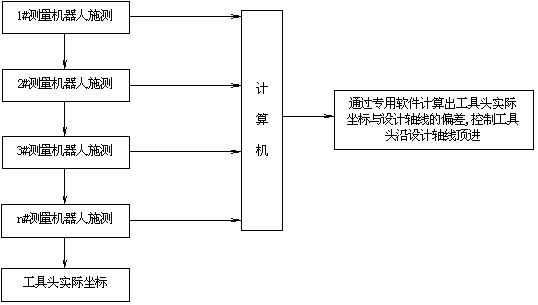

Pipe jacking project automatic measurement system and method thereof

InactiveCN102564389AHigh precisionEliminate or reduce error factorsAngle measurementOptical rangefindersData terminalShielded cable

The invention relates to a pipe jacking project automatic measurement system and a method thereof. The pipe jacking project automatic measurement system comprises auxiliary observation stations established at the turning positions in the pipe jacking construction. Each auxiliary observation station consists of an automatic leveled base and a measurement robot total station. A data terminal of each measurement robot total station is connected with a data port of a computer by a shielded cable. Measurement data is processed by the computer. Each total station is sequentially controlled by the computer to orderly carry out transfer measurement. According to the invention, measurement robots are adopted to be connected with the programmed computer and the computer commands each measurement robot to carry out automatic tracking measurement according to a program. The system and the method thereof can be used for conveniently and timely measuring actual coordinate values of a tool head in various curve pipe jacking projects.

Owner:SHANGHAI FOUND ENG GRP

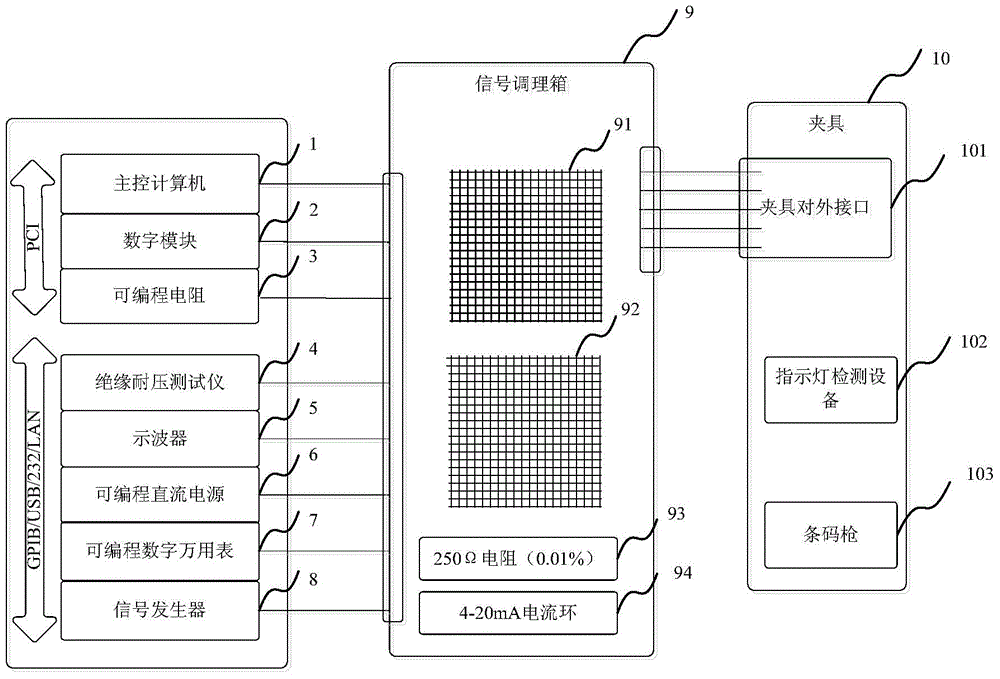

Analog quantity automatic check system based on safety instrument

ActiveCN104090186AEasy to disassembleFlexible combinationTesting dielectric strengthDielectricResistor

The invention provides an analog quantity automatic check system based on a safety instrument. The system comprises a master control computer, a digital module, a programmable resistor, a dielectric withstand voltage tester, an oscilloscope, a programmable direct-current power source, a programmable digital multimeter, a signal generator, a signal conditioning box and a clamp. The master control computer, the digital module, the programmable resistor, the dielectric withstand voltage tester, the oscilloscope, the programmable direct-current power source, the programmable digital multimeter and the signal generator are all connected with the signal conditioning box, and the signal conditioning box is connected with the clamp through a flexible cable. A modularized structure is adopted for the analog quantity automatic check system based on the safety instrument, so that the system is convenient to detach, the measurement range can be expanded, and the system can adapt to different occasions; the check standards are objective and unified, and real-time data acquisition, processing, display and record playback can be achieved; uncontrollable human factors are reduced, and the production quality is guaranteed more reliably due to automation.

Owner:SHANGHAI CHENZHU INSTR

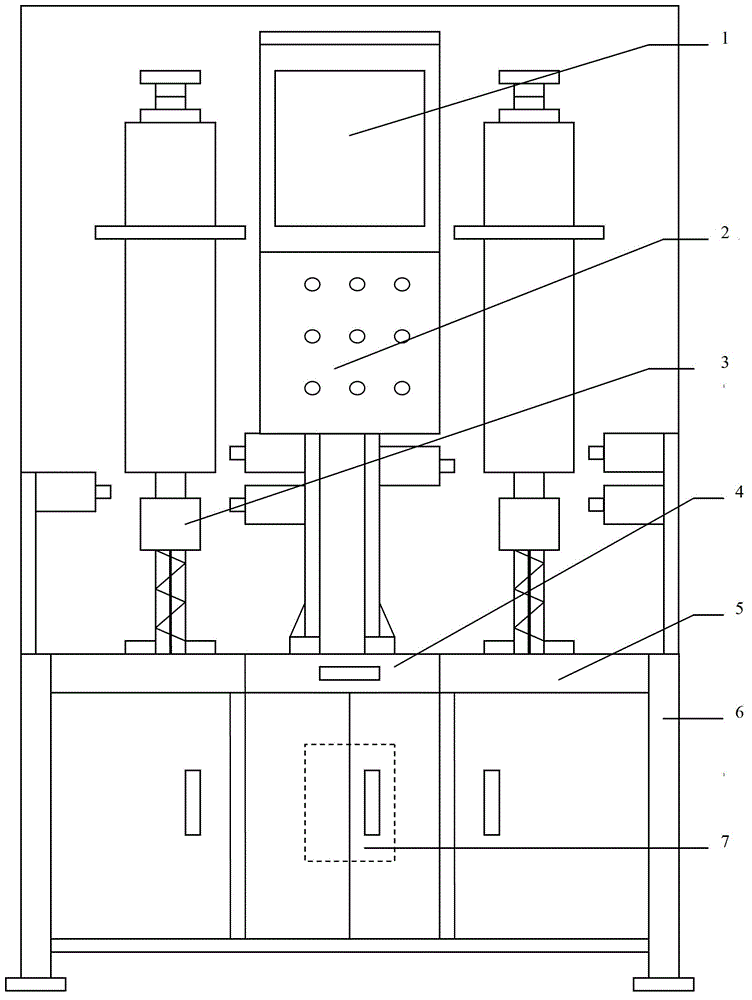

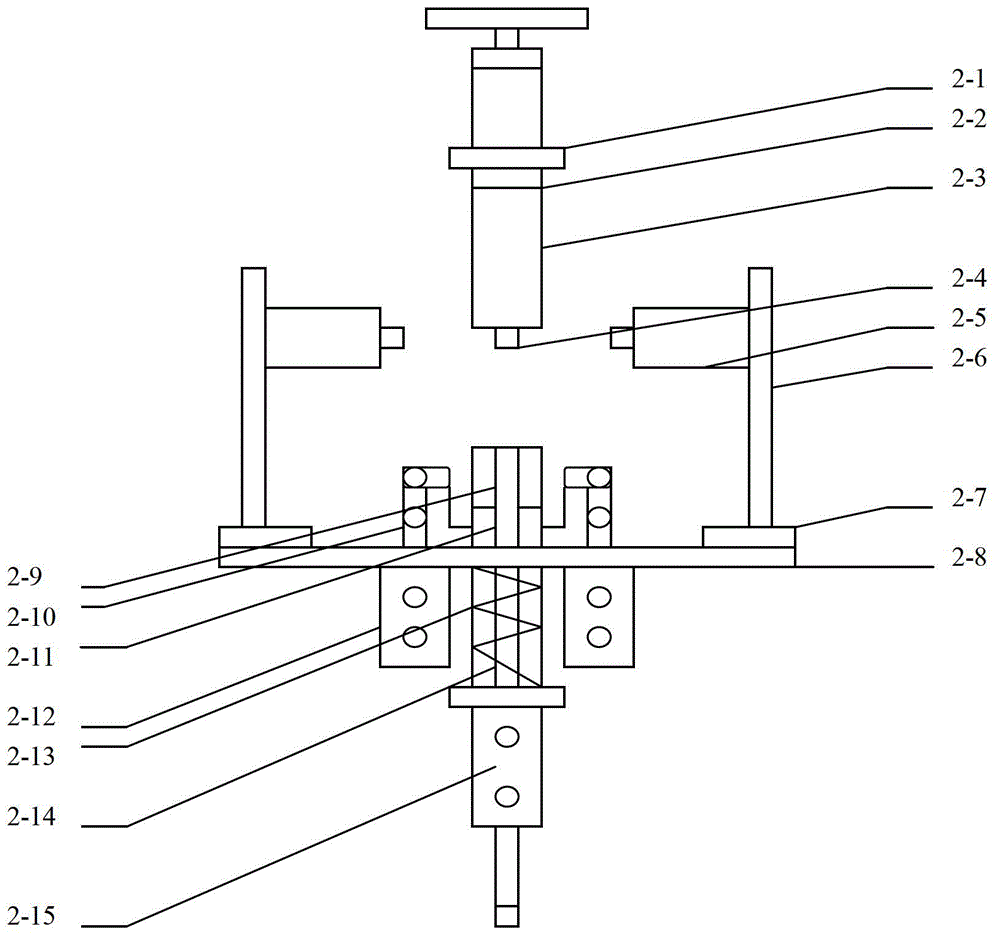

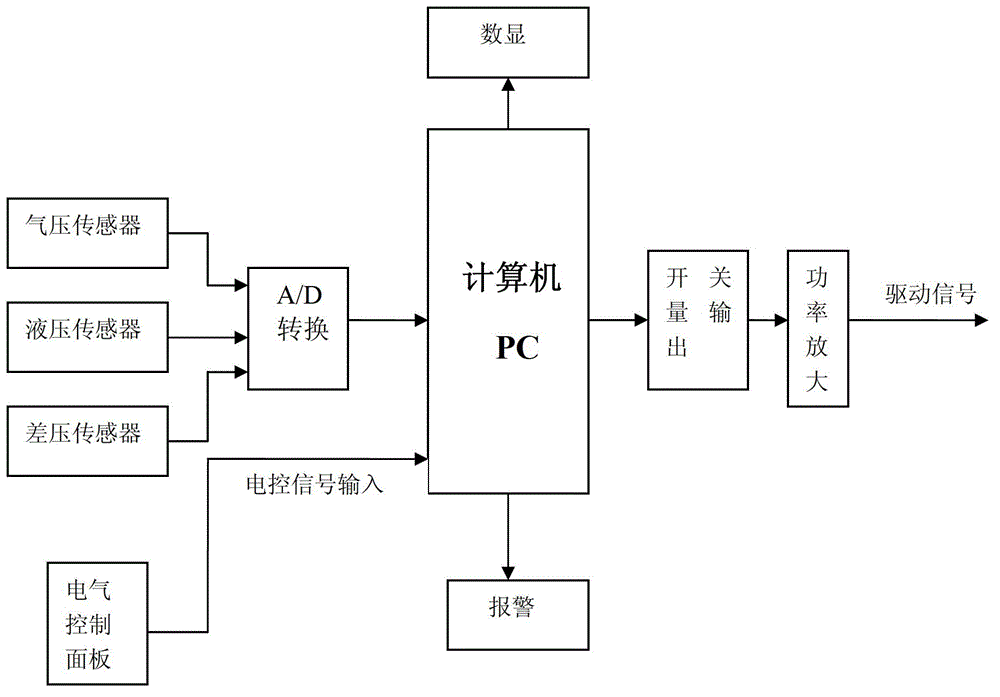

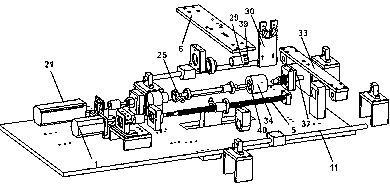

Double-station online detection platform for tightness of clutch booster

ActiveCN102865975AImprove general performanceRealize double-station online monitoringMeasurement of fluid loss/gain rateLiquid-crystal displayTest-and-set

The invention discloses a double-station online detection platform for the tightness of a clutch booster. The conventional apparatus is low in stability and test accuracy. The double-station online detection platform comprises a liquid crystal display, a fast insertion box, clamping and test devices, a keyboard area, a control box, a rack and a personal computer (PC). The PC, the keyboard area and the control box are arranged in the rack. The liquid crystal display is arranged at a central position above the rack. The quick insertion box is arranged below the liquid crystal display. A plurality of fast insertion joints are arranged on the fast insertion box, comprise interfaces for controlling the advance and retreat of downward pressing cylinders and side sealing cylinders, and are connected with corresponding advance and retreat interfaces of the downward pressing cylinders and the side sealing cylinders respectively. A plurality of control switches are arranged in the control box, and control the opening and closing states of a plurality of electromagnetic valves respectively. The clamping and test devices are arranged on the two sides of the liquid crystal display. The keyboard area is used for controlling the PC to operate, selecting contents to be tested and setting the time of a test flow. A detection process of the double-station online detection platform is automatic, the clutch booster can be fast clamped, a judgment of qualification is automatically made, and a sound and light alarm is automatically given.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

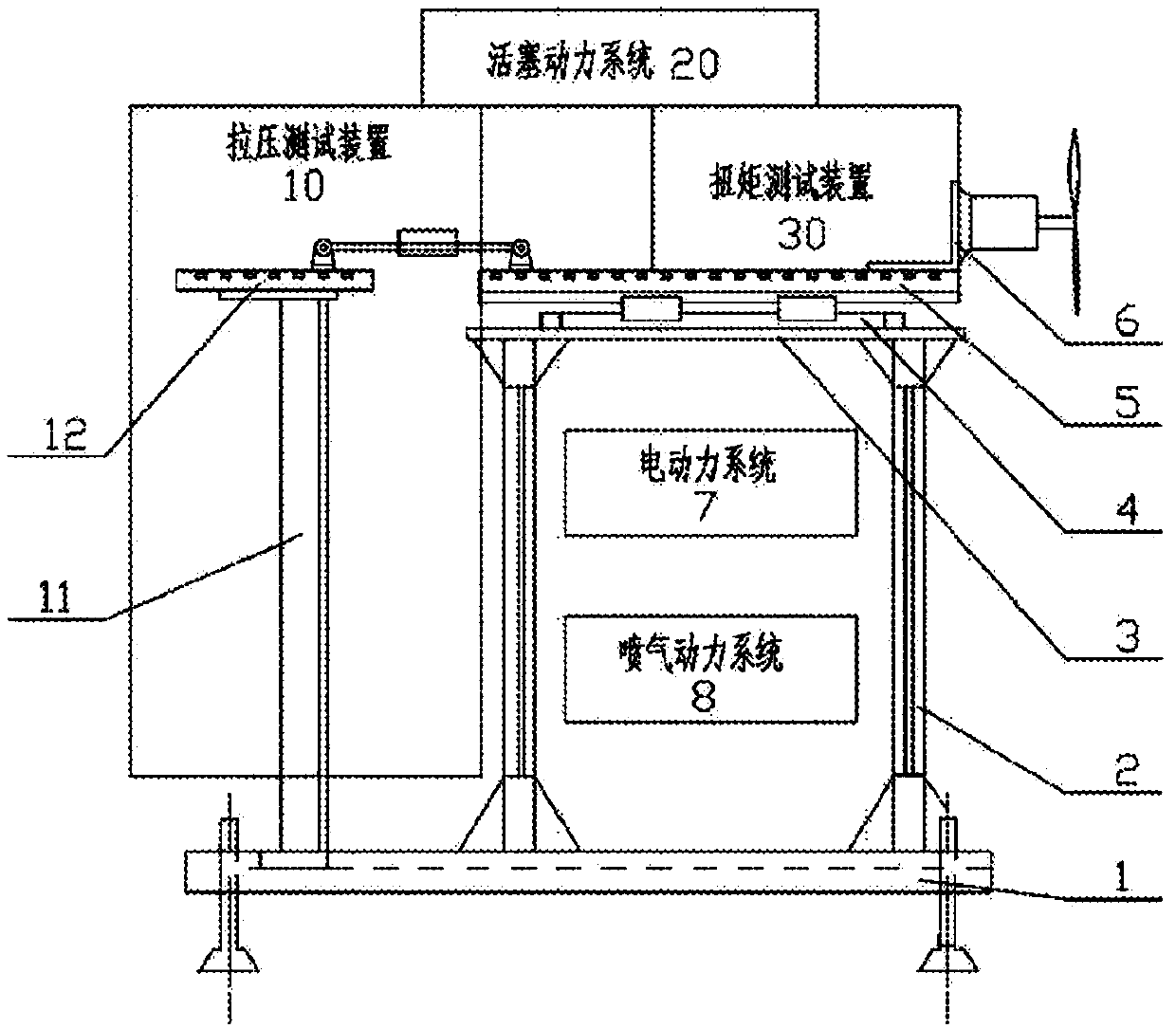

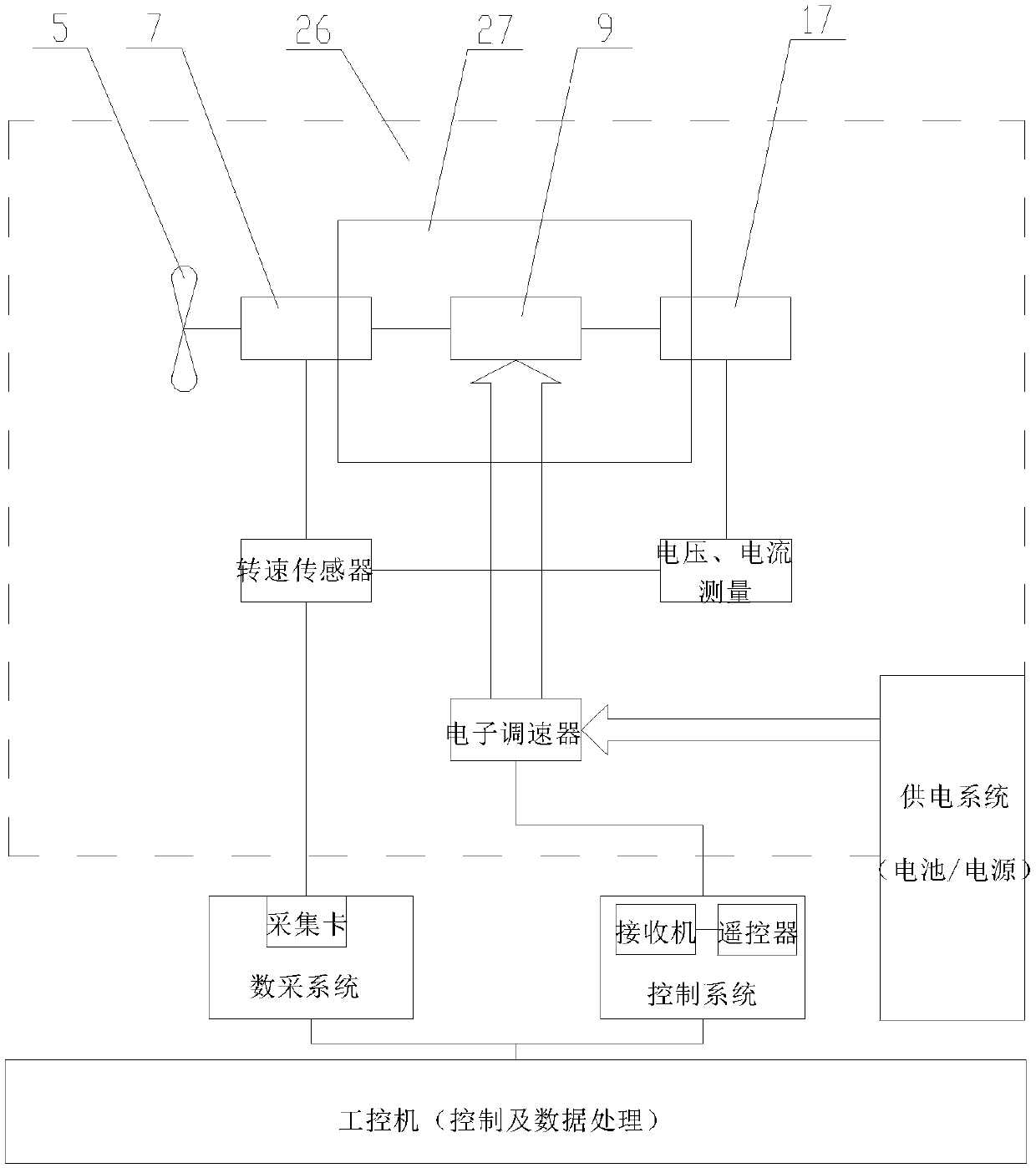

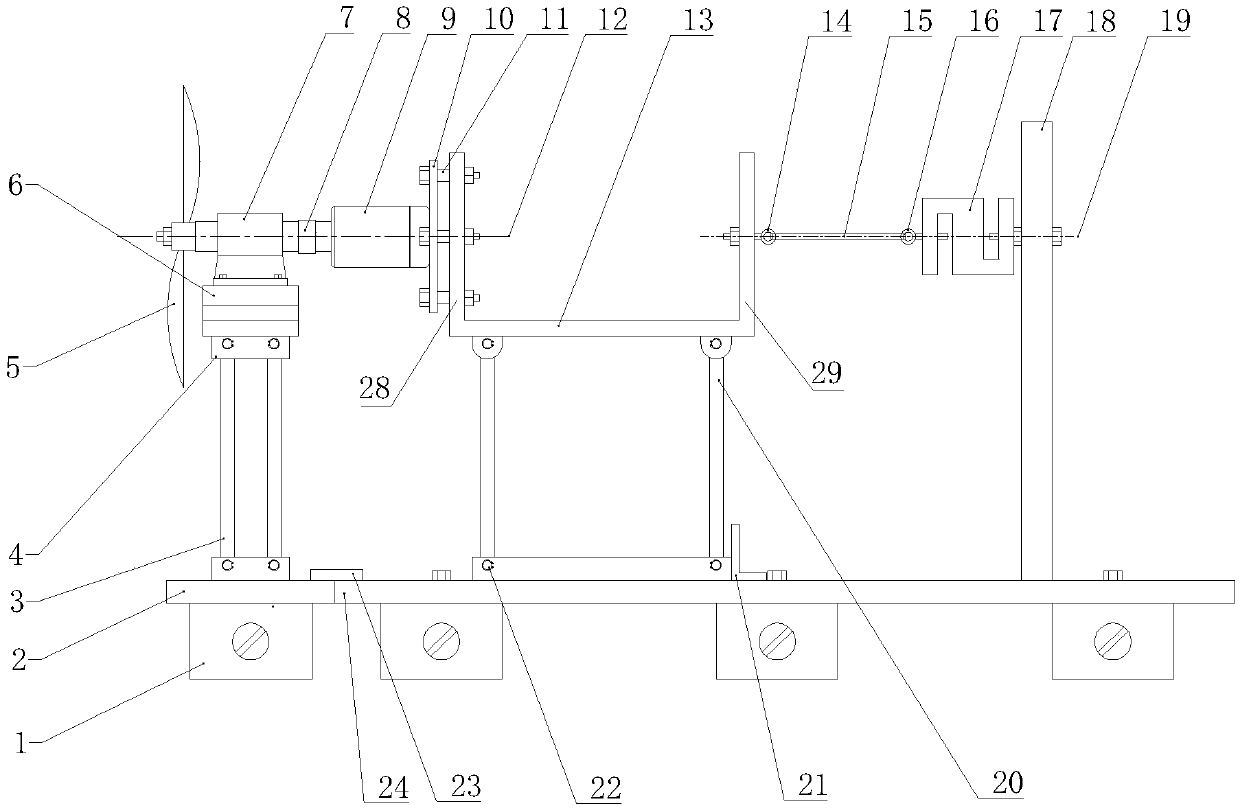

Electric unmanned aerial vehicle power system multifunctional testing stand

ActiveCN107588957AMeet the test itemsMeet the precision requirementsInternal-combustion engine testingDynamo-electric machine testingStanding frameControl system

The invention discloses an electric unmanned aerial vehicle power system multifunctional testing stand. The electric unmanned aerial vehicle power system multifunctional testing stand is multifunctional, is high in safety and reliability, is low in cost, and is convenient to use. The electric unmanned aerial vehicle power system multifunctional testing stand includes a testing stand frame assembly, a power supply assembly, a data measuring assembly, and a safety protection system assembly, wherein the data measuring assembly at least includes a torque measuring module, a tension / pressure measuring module, a non force cell sensor module, and a data acquisition and control system assembly; and the data acquisition and control system assembly is used for acquiring feedback signals of the datameasuring assembly, and transmitting the acquired feedback signals to a host computer in real time. The electric unmanned aerial vehicle power system multifunctional testing stand can realize groundstatic tension test and movable tension test of the power system, and the stand frame is provided with a ground working table and a vehicle running test general interface, so that the movable tensiontest function can successfully avoid the defects that a traditional ground static tension test has too big error and too high wind tunnel test cost.

Owner:CHANGGUANG SATELLITE TECH CO LTD

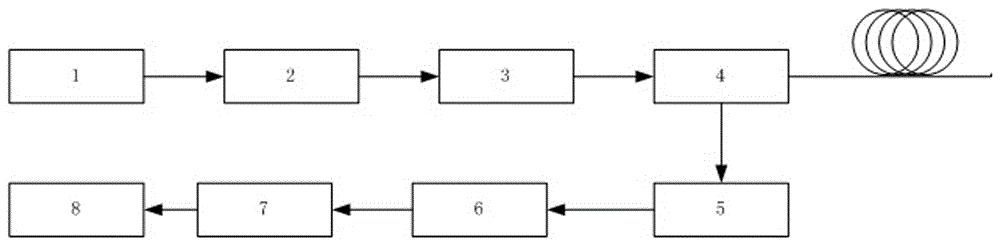

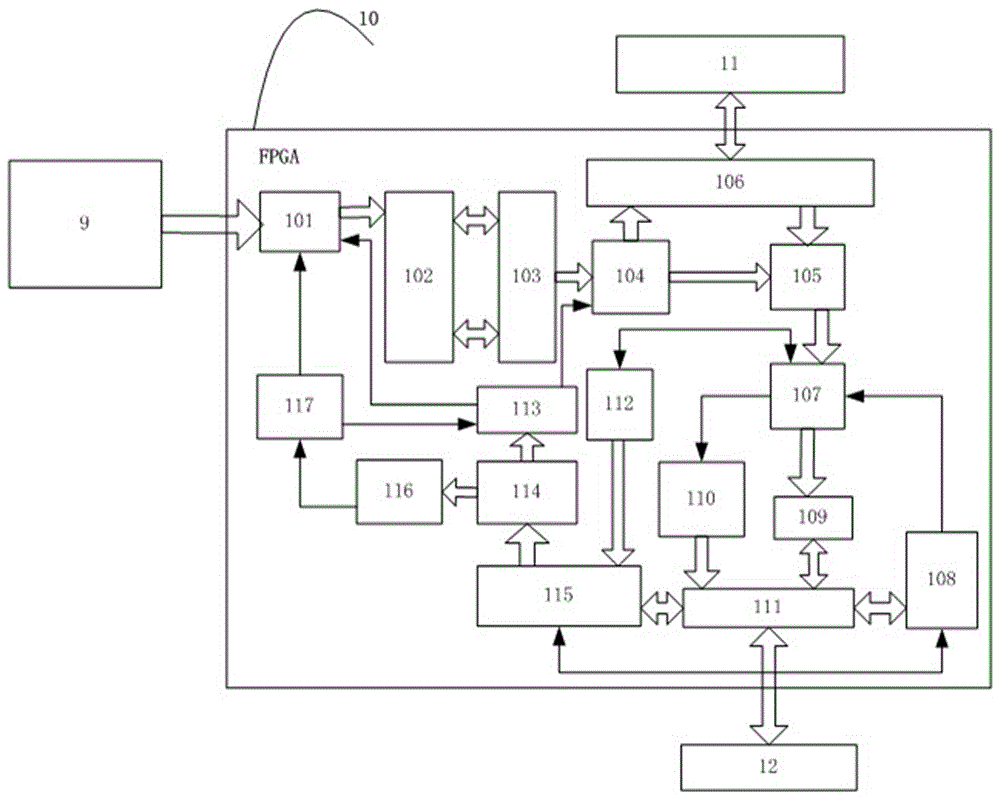

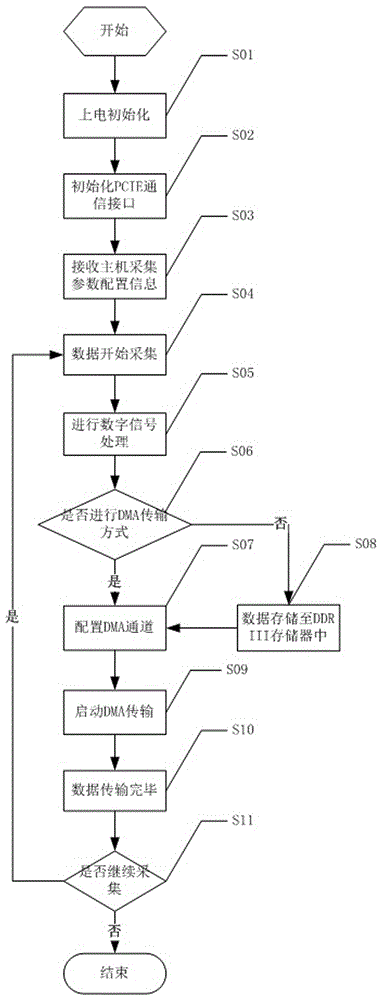

Optical fiber vibration interference signal real-time data acquisition and transmission device and application thereof

InactiveCN106197648AOvercome the disadvantage of slow communication rateImprove signal-to-noise ratioProgramme controlSubsonic/sonic/ultrasonic wave measurementDigital signal processingLine width

The invention belongs to the field of optical fiber sensing, relates to the technology of high-speed data acquisition and provides a large-data-size optical fiber vibration interference signal real-time data acquisition and transmission device for a distributed optical fiber vibration sensing system and application of the device. The device is characterized by comprising an ultra-narrow line-width laser device, light modulator, a light amplifier, a circulator, a sensing optical fiber, a filter, a photoelectric detector, an acquisition and transmission device and a PC. The device has the advantages that a PCIE interface is adopted for communication with a host, and the defect that a traditional acquisition device is low in communication speed is overcome; a digital signal processing module is adopted to inhibit noise in acquired data, and the signal-to-noise ratio of the acquisition device is increased; a DDR III storage is adopted, and large-scale real-time data acquisition can be achieved.

Owner:WEIHAI BEIYANG PHOTOELECTRIC INFORMATION TECH

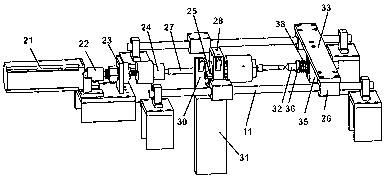

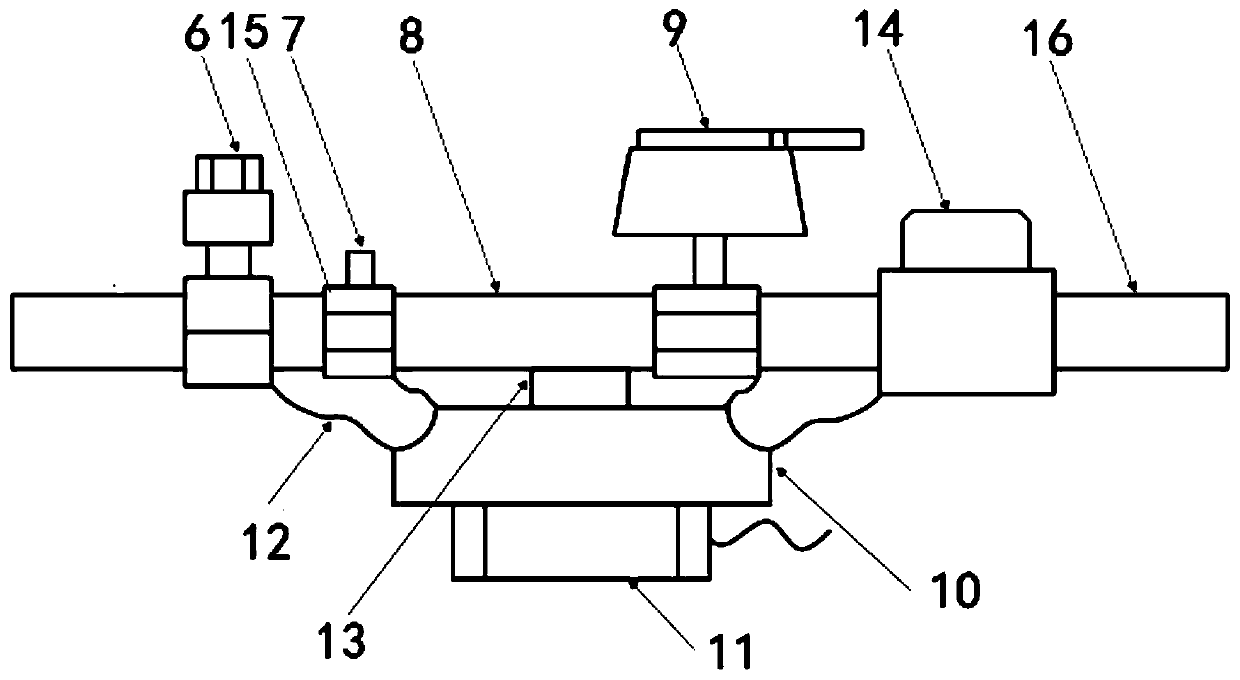

Testing system and method of high-power automatic transmission control strategy

InactiveCN103529828AEasy to controlFacilitate parameter calibrationElectric testing/monitoringConstant torqueControl system

The invention discloses a testing system of a high-power automatic transmission control strategy. The system comprises a control system, a fixing rack, a variable-frequency motor, a high-power automatic transmission and an electric power loading device, wherein the electric power loading device is in transmission connection with an output of the high-power automatic transmission; torque and rotation speed sensors are arranged between the variable-frequency motor and the high-power automatic transmission and between the high-power automatic transmission and the electric power loading device respectively; and the torque and rotation speed sensors, the variable-frequency motor, the high-power automatic transmission and the electric power loading device are connected with the control system respectively. At the same time, the invention further discloses a testing method using the testing system, a power device is the variable-frequency motor, an engine is not taken as a power source, the variable-frequency motor can realize constant rotation speed control and constant torque control and is easy to control; accurate control of control strategies such as shift rules and the like can be realized, and parameter correction is facilitated.

Owner:MILITARY TRANSPORTATION UNIV PLA

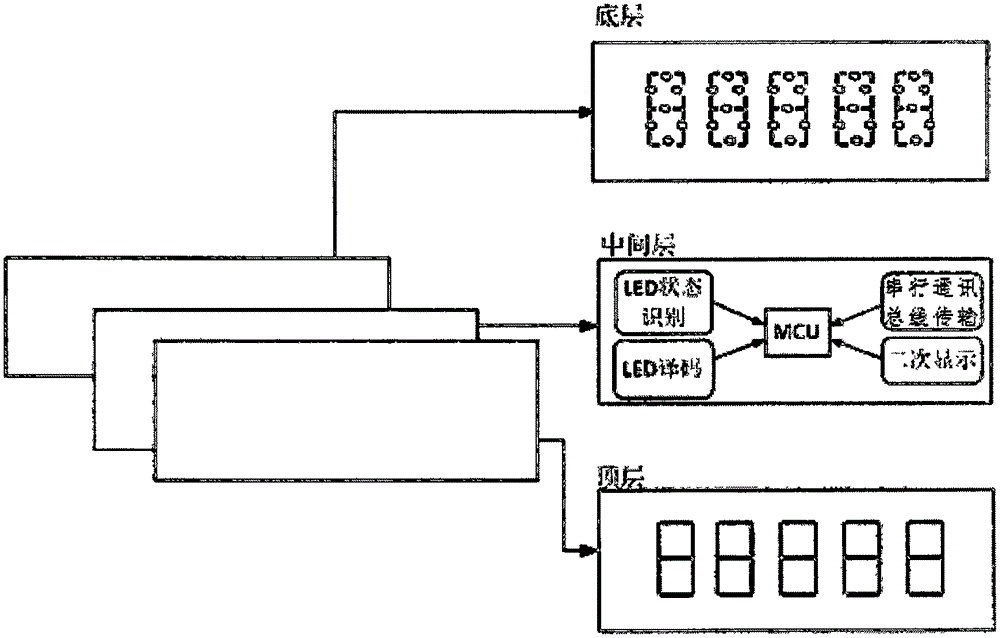

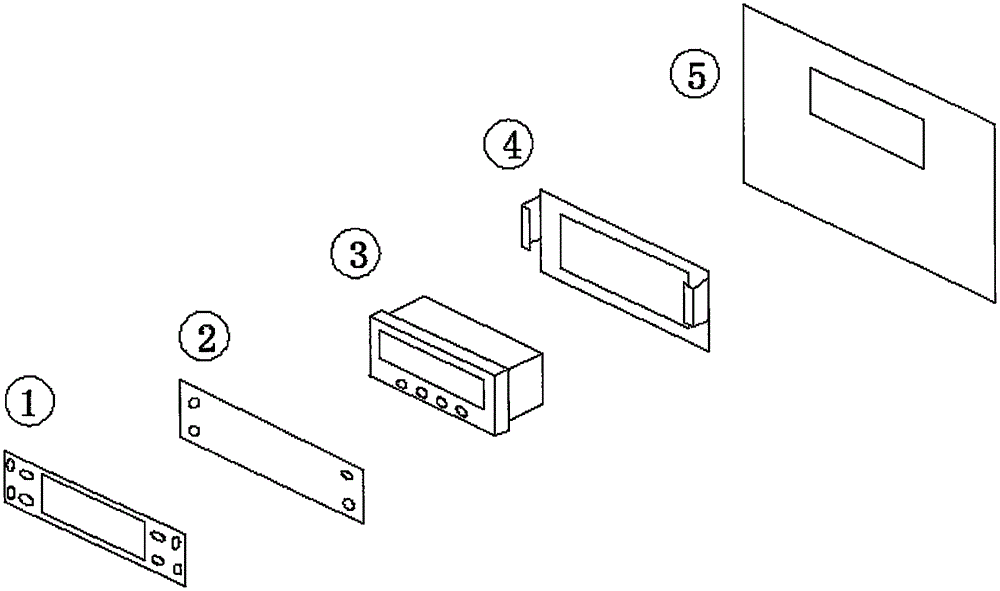

Intelligent terminal for timely and automatically collecting LED digital display data

InactiveCN105259842AReduce workloadReduce manual involvementProgramme controlComputer controlCollections dataEngineering

The invention discloses an intelligent terminal for timely and automatically collecting LED digital display data. The intelligent terminal comprises a bottom layer, a middle layer and a top layer. The bottom layer adopts an LED nixie tube light emitting state detection device arranged on a PCB, small holes, corresponding to centers of LED nixie tubes, are formed in the PCB, and photodiodes are welded on the small holes. The middle layer adopts a MCU as a controller, and the MCU is connected with an LED state identification module, an LED decoding module, a secondary display module and a serial communication bus transmission module. The top layer adopts the form of LED nixie tubes for secondary display of readings on the LED nixie tubes. The intelligent terminal automatically achieves data collection in the operation process of equipment and omits links such as manual data recording and data logging, thereby reducing workload of operators. The accuracy and reliability of data is greatly improved, the timeliness of data collection is greatly improved, and automatic collection is achieved.

Owner:CHEUNG KONG UNION BEIJING TECH CO LTD

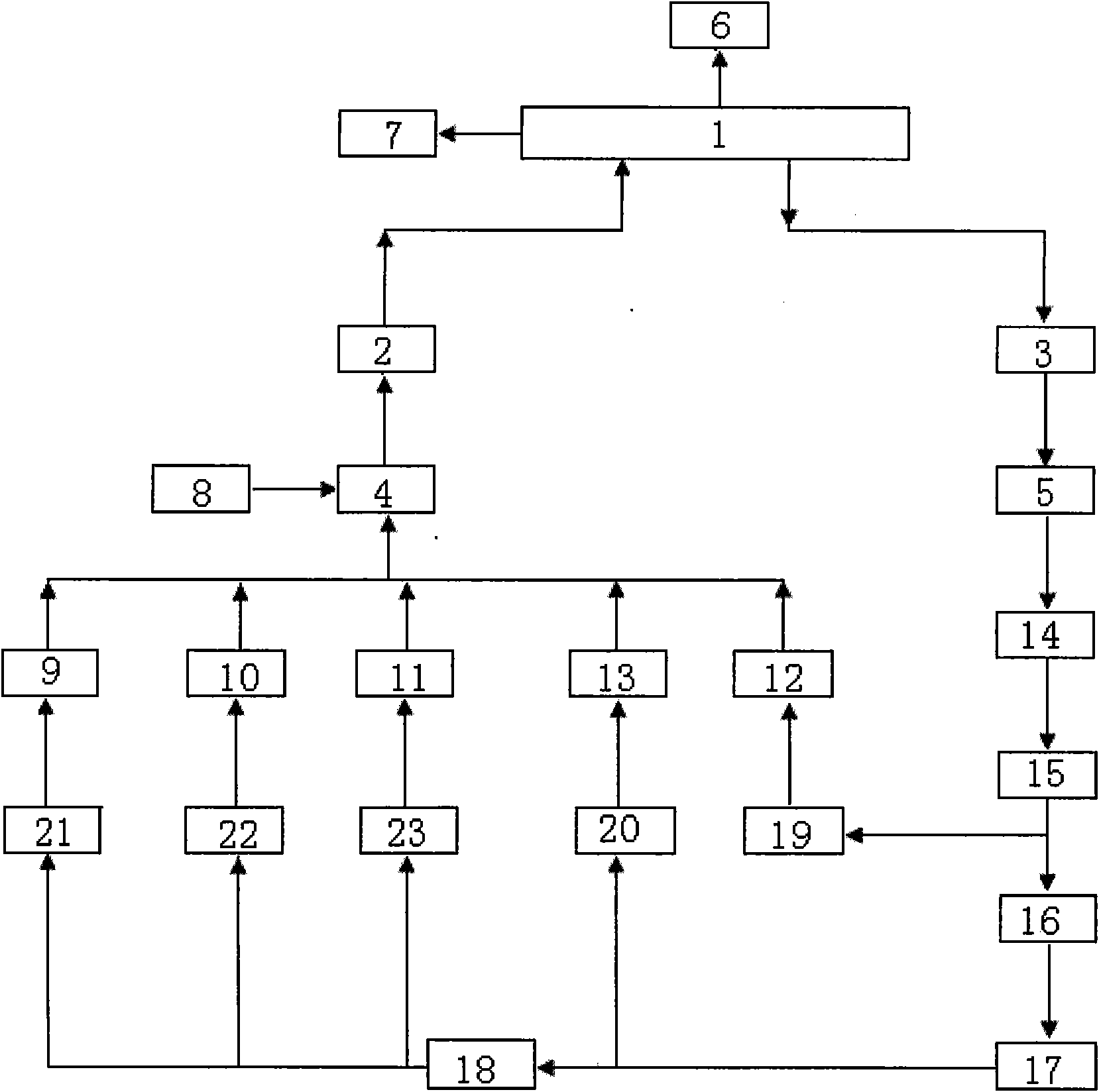

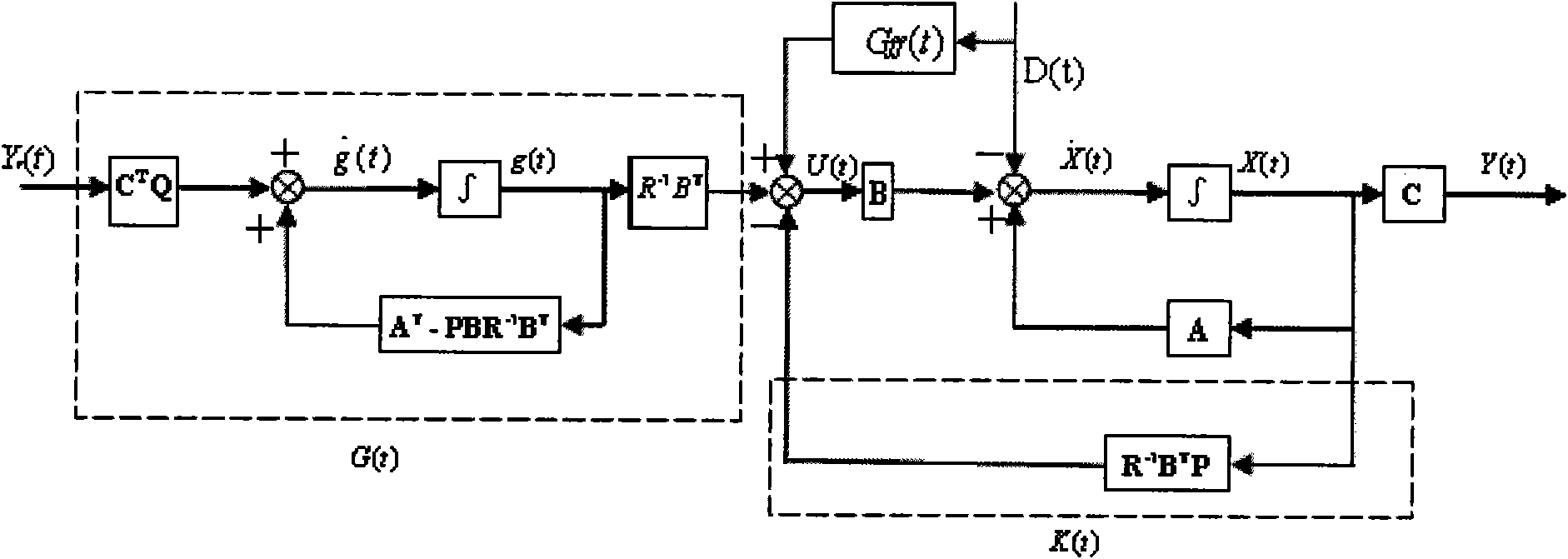

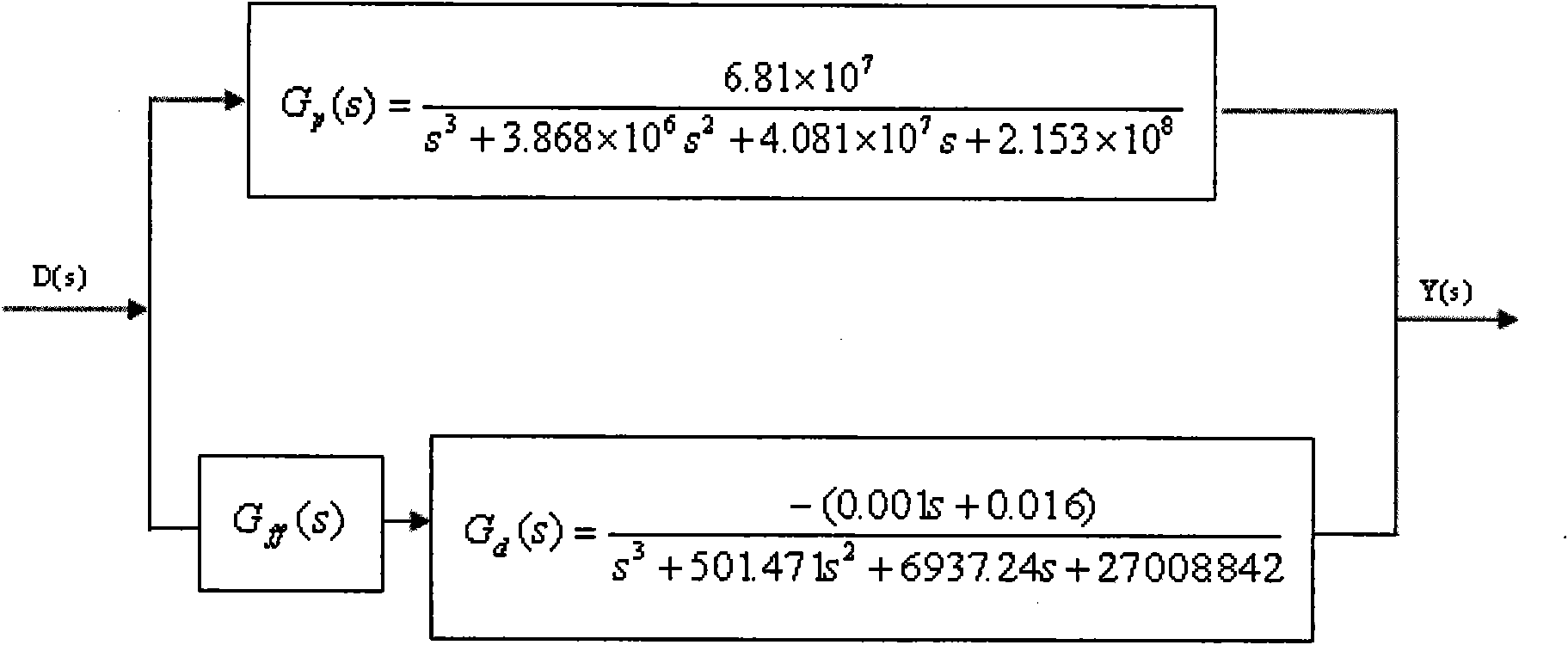

Controlling device of flash butt welding position servo system

InactiveCN101592937AImprove welding qualityGuaranteed real-timeNumerical controlButt weldingControl system

The invention discloses a controlling device of a flash butt welding position servo system and relates to a program controlling system. The device consists of a hardware part and a program control part, wherein the program control part is that: the linear feedback of quadratic optimal control is applied to a control loop of a hydraulic position servo system of the controlling device of the flash butt welding position servo system and a prefilter function and a disturbance feedforward compensator function are calculated on the basis of the linear feedback. The quadratic optimal controlling method with disturbance feedforward is applied to the hydraulic position servo system of a flash butt welding process, so that the hydraulic position servo system has rapider response speed, shorter regulating time, higher tracking precision and stronger antijamming capacity than a conventional PID controlling method; the problem of low tracking precision of the prior PID controlling method is solved; the error of real-time dynamic position tracking precision is increased to 2.2 percent from 13.3 percent of the PID controlling method; and the requirement of the tracking precision of the hydraulic position servo system is met.

Owner:HEBEI UNIV OF TECH

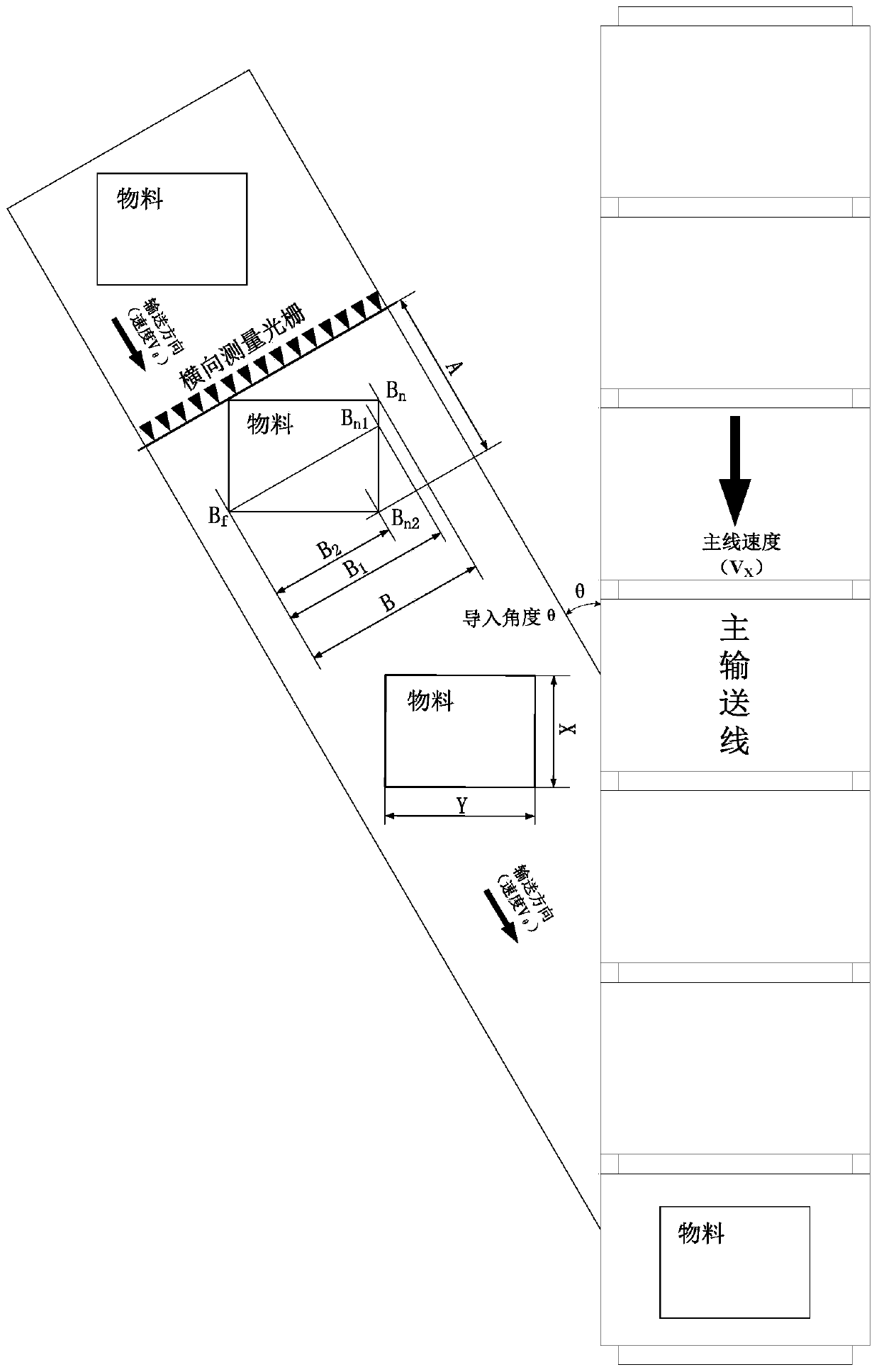

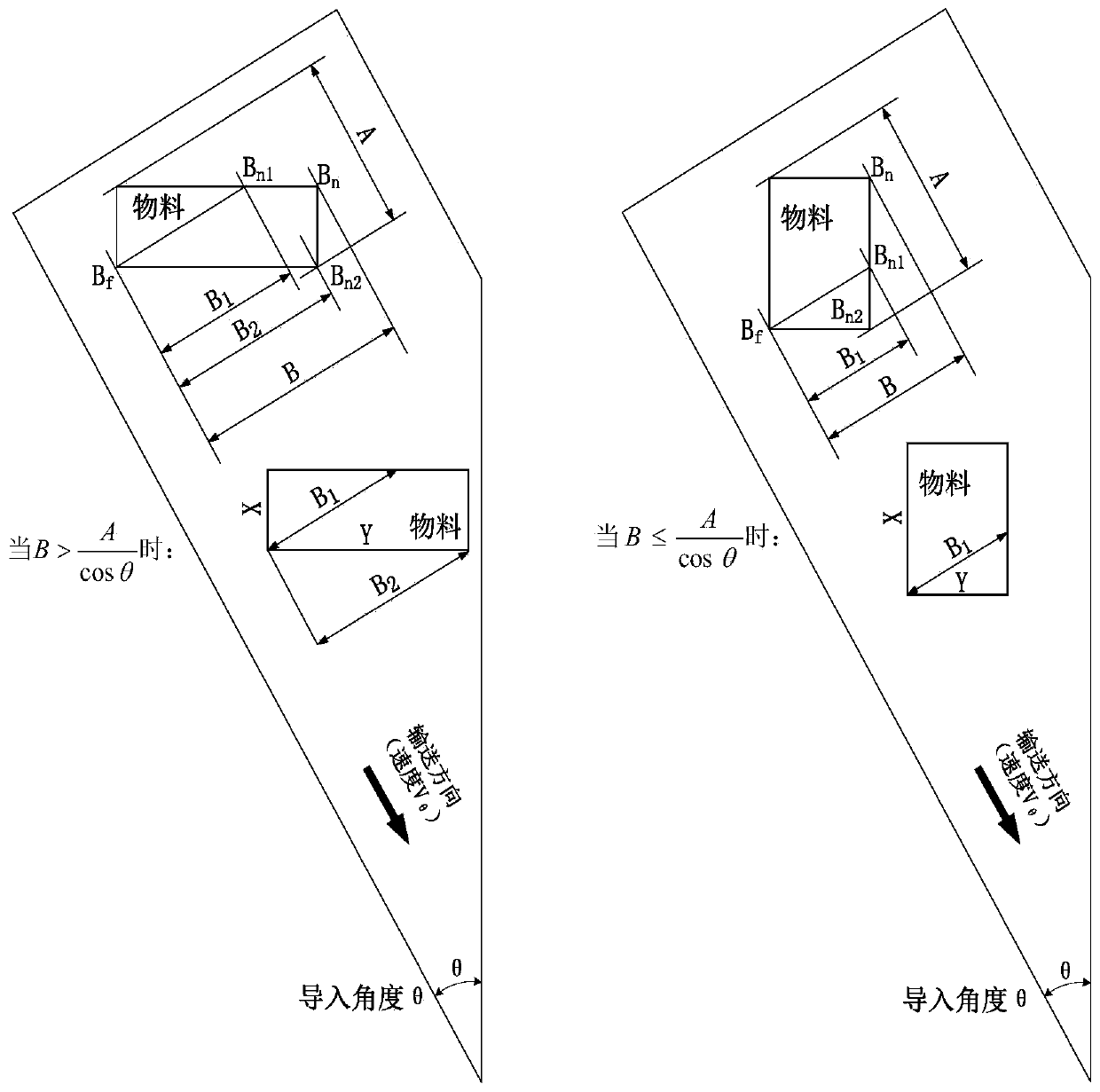

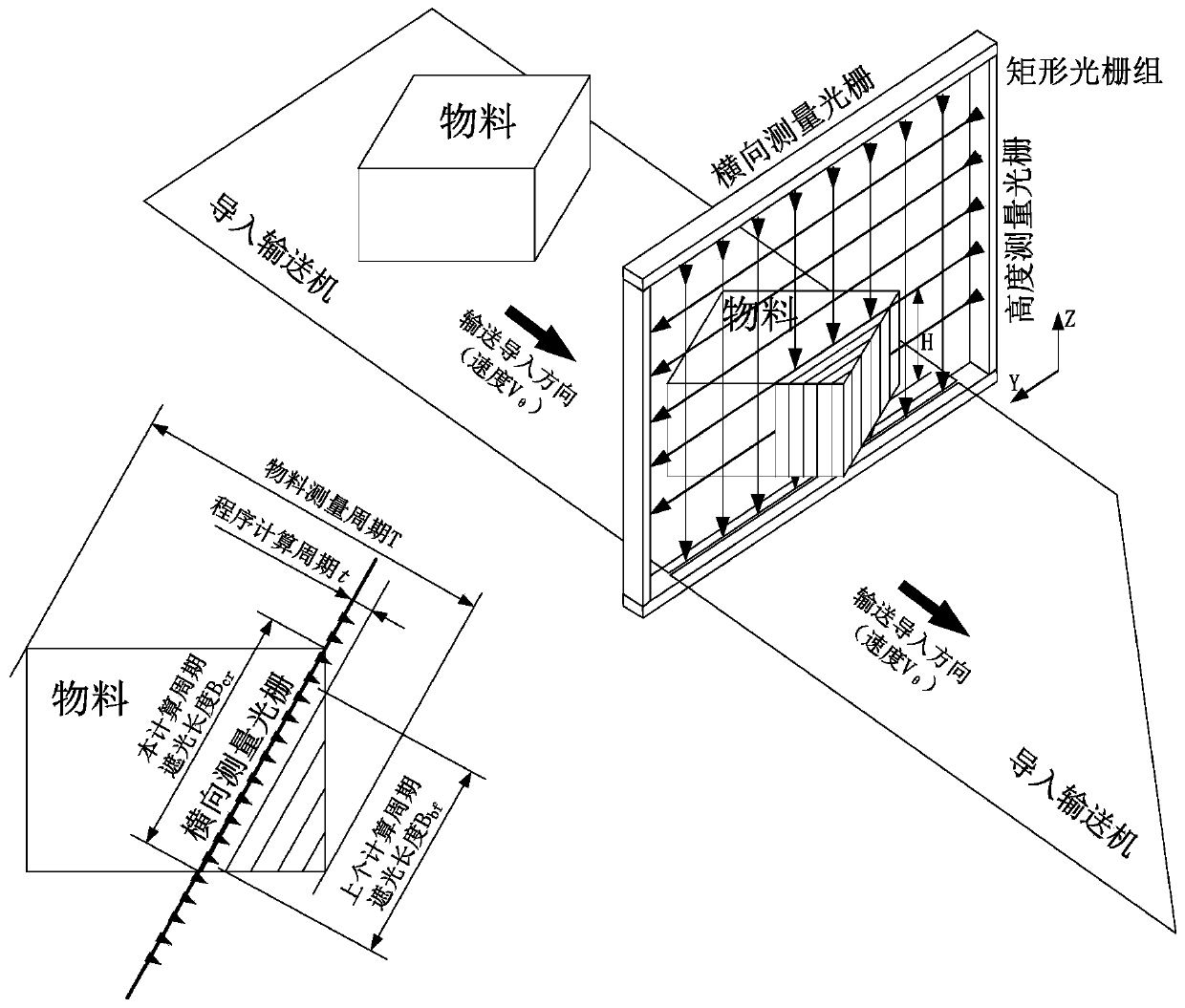

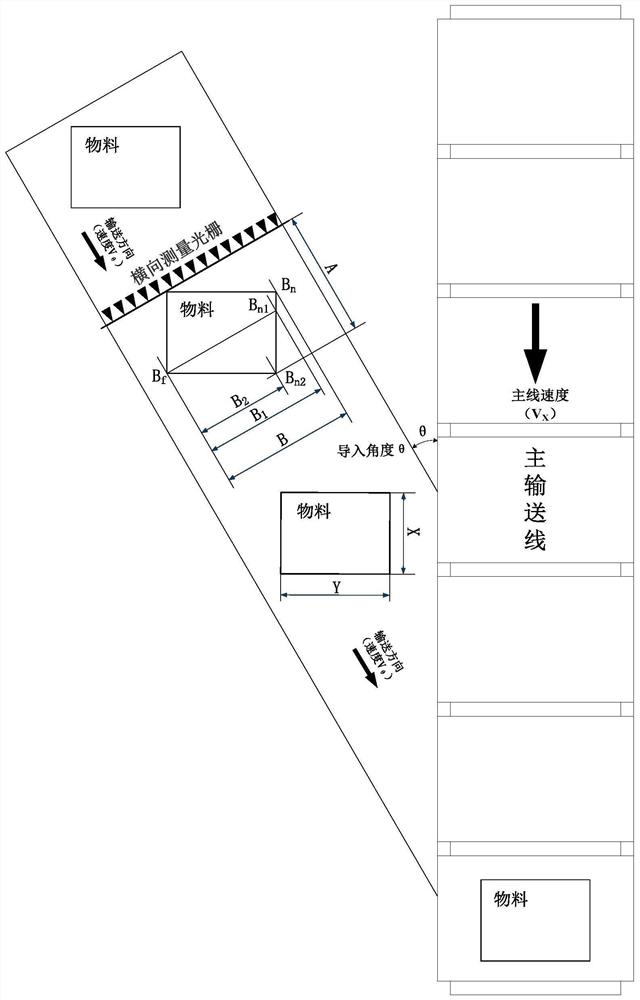

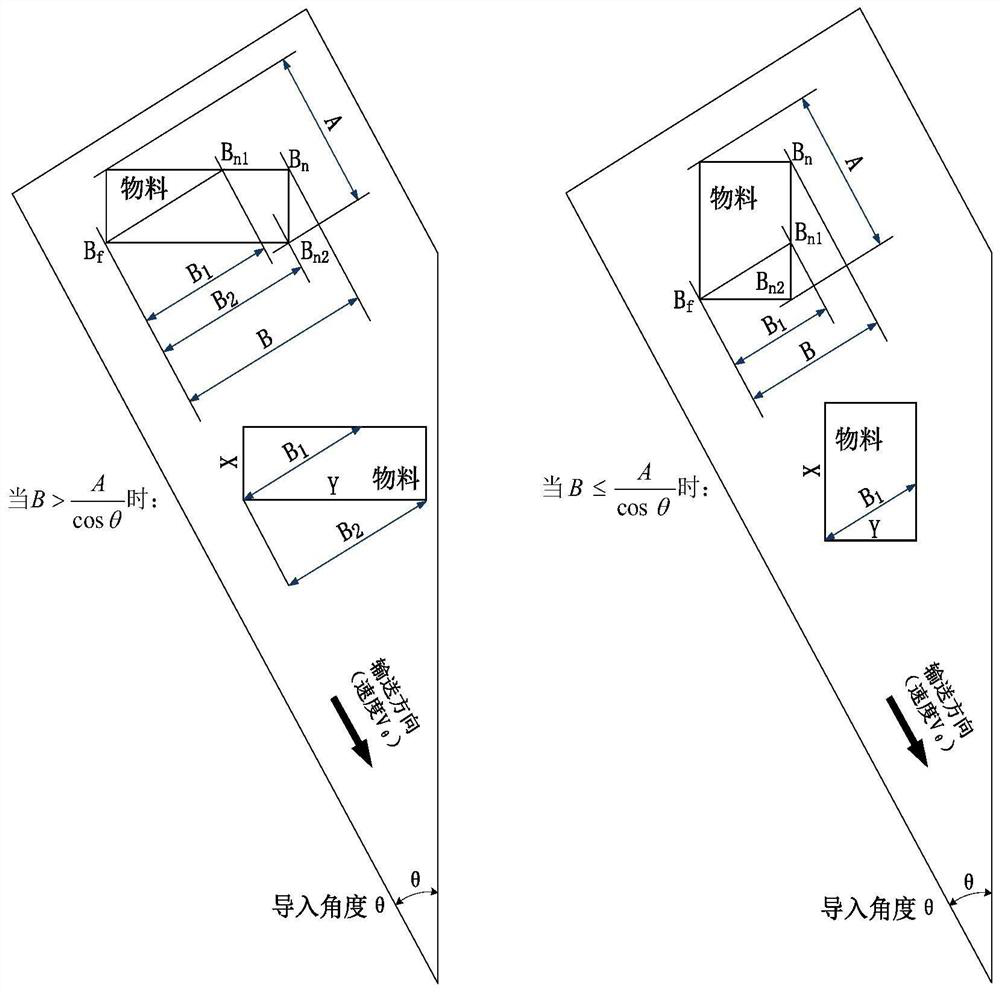

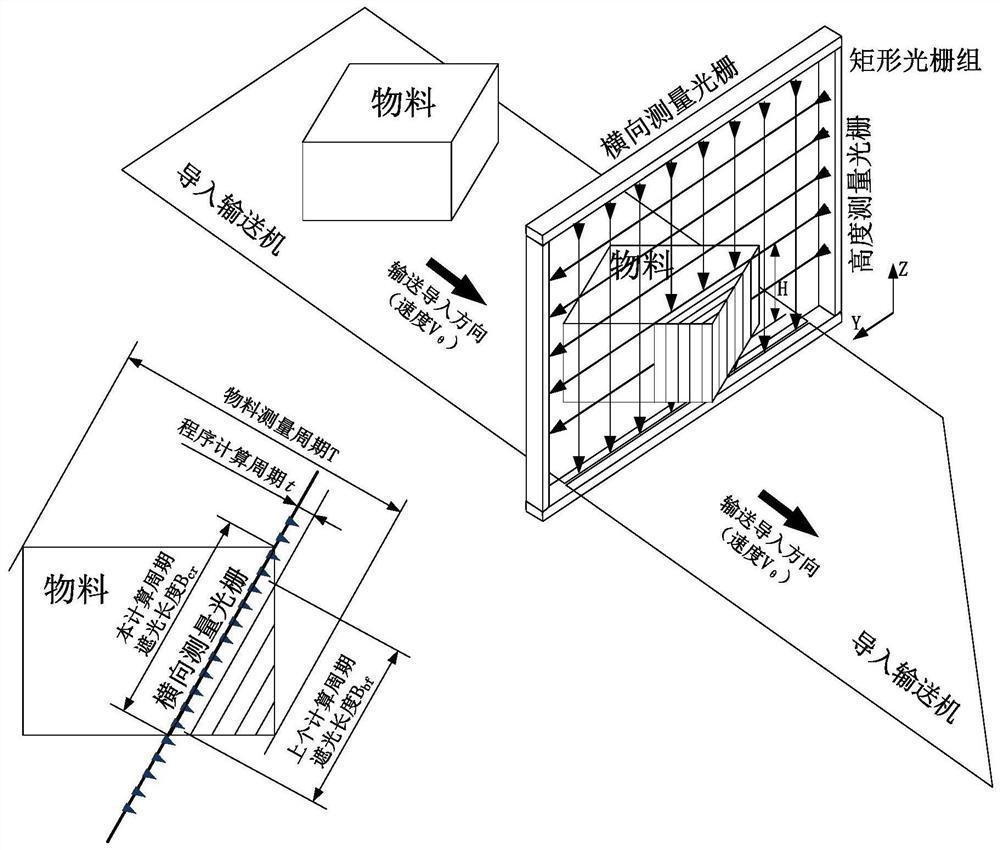

Method for measuring and calculating length, width and approximate volume of imported materials and program product

The invention discloses a method for measuring and calculating the length, width and approximate volume of an imported material and a program product. The length and the width of a material are measured, the shielding size of the material in the direction perpendicular to the conveying direction is measured through a transverse measuring grating installed at the position of a guide-in conveyor, and the length and the width of the material are measured and calculated according to the maximum value of the material outline, size feature points, length-width ratio relation judgment and the like. Aheight measuring grating is added to form a rectangular grating group; tomography measurement is carried out on the section sections in the Y direction and the Z direction to obtain the projection area and the shading height H of the material passing through a small-section section on the conveyor belt surface in the calculation period, the volume of the small section-section - where the materialpasses through in the period is calculated, and the small-section section- in the material measurement period T is accumulated to calculate the approximate volume. Program products of the calculationmethod are executed by a processor in the controller, the size and approximate volume of the materials can be reliably obtained, and guarantee is provided for accurate and efficient operation of thewhole sorting conveying line.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

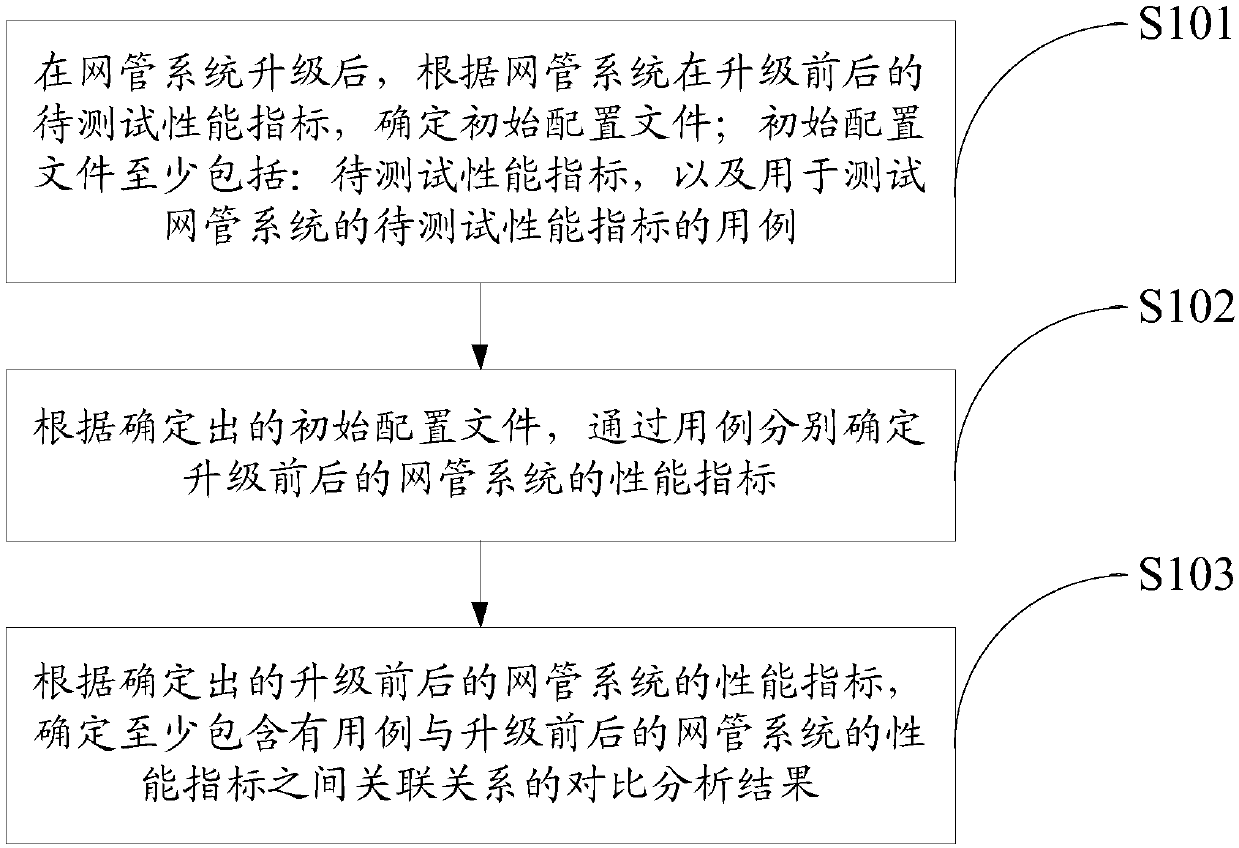

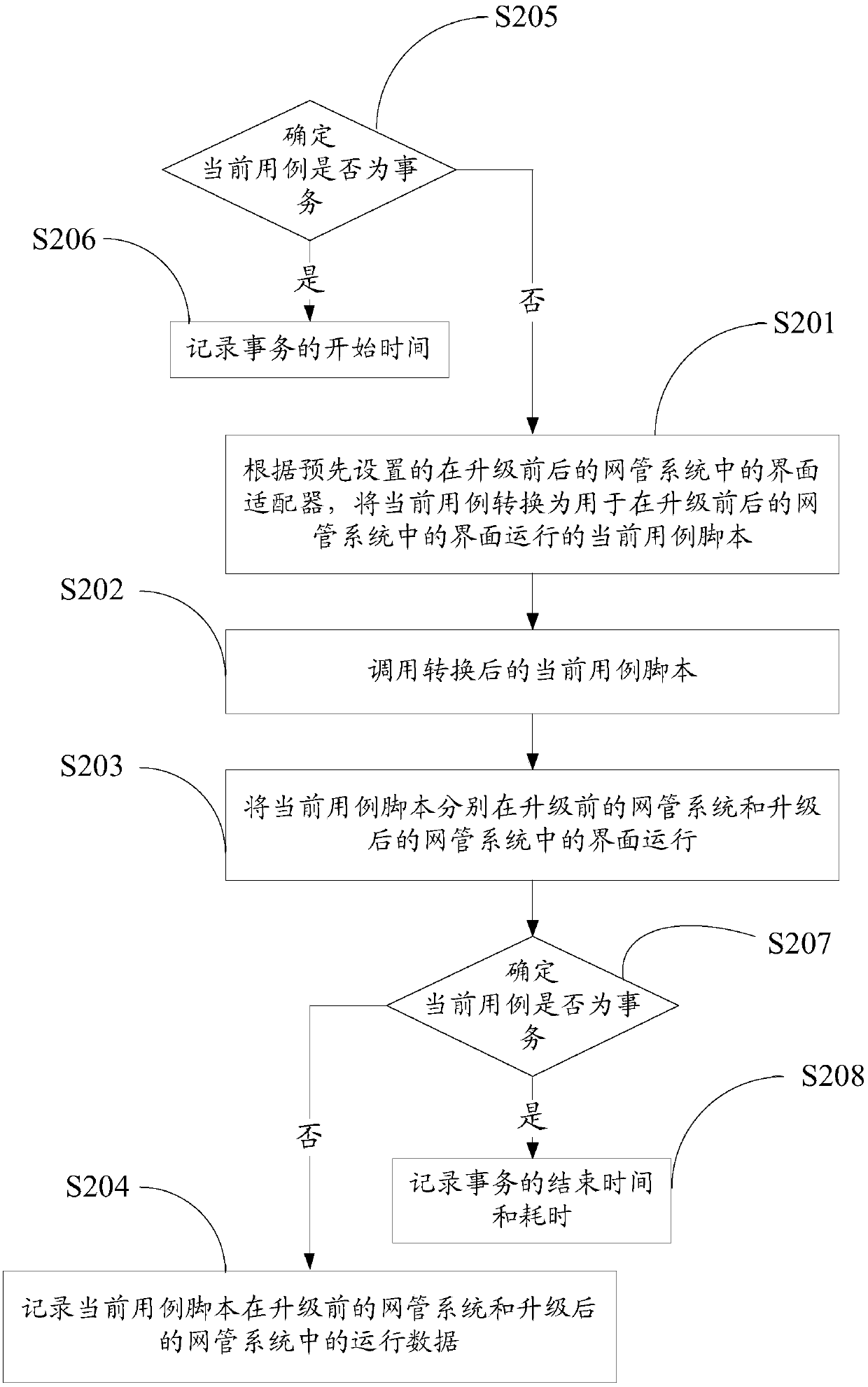

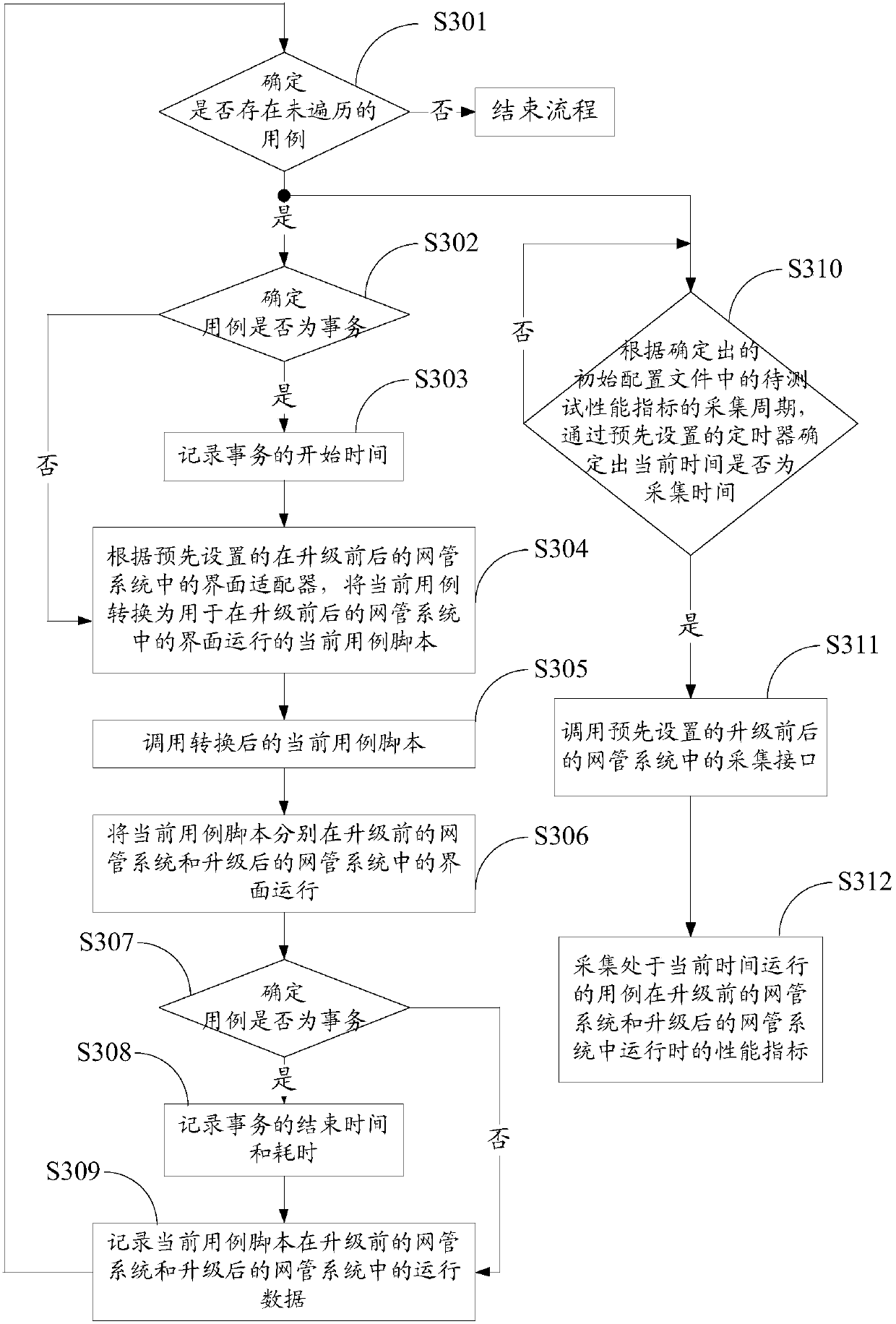

Performance testing method, performance testing device and performance testing system for network management system

ActiveCN107872352AImprove practicalityReal-time managementData switching networksData acquisitionPerformance index

The invention discloses a performance testing method, a performance testing device and a performance testing system for a network management system. After the network management system is upgraded, performance indexes of the network management system before and after upgrade can be determined by operating a use case in the network management system before and after upgrade, so that a comparison and analysis result at least including the incidence relation between the use case and the performance indexes of the network management system before and after upgrade can be determined, performance merits and demerits of the network management system before and after upgrade can be determined visually, and direction is pointed for optimization of the network management system. No manual interference is needed, so that labor cost can be reduced greatly, engineers who do not contact performance tests before can also use the performance testing system, and practicability of the performance testing system is improved. Data can be collected in real time to guarantee real-time, accurate and efficient management of the network management system.

Owner:RAISECOM TECH

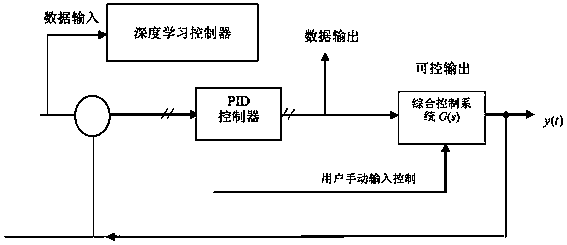

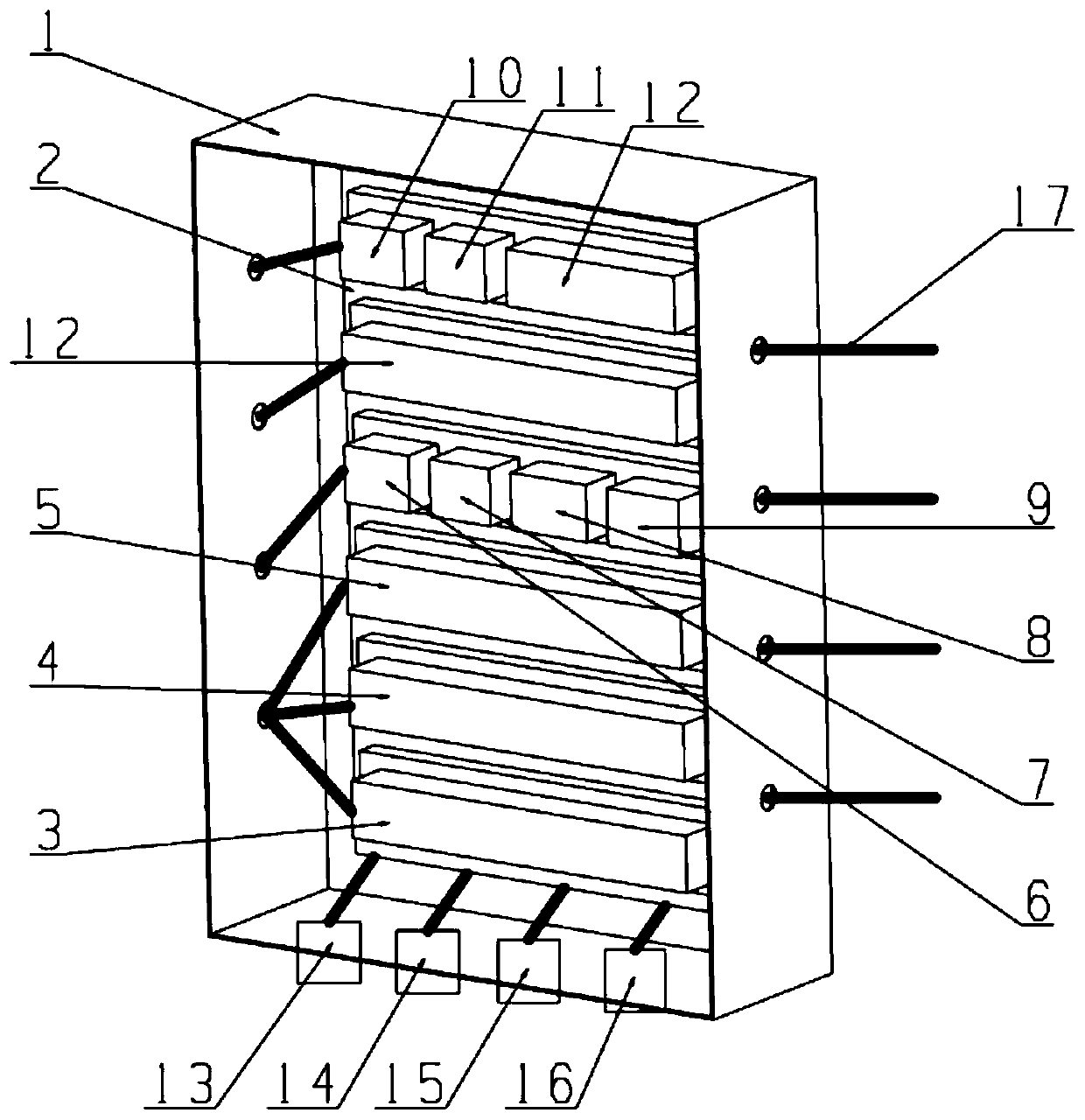

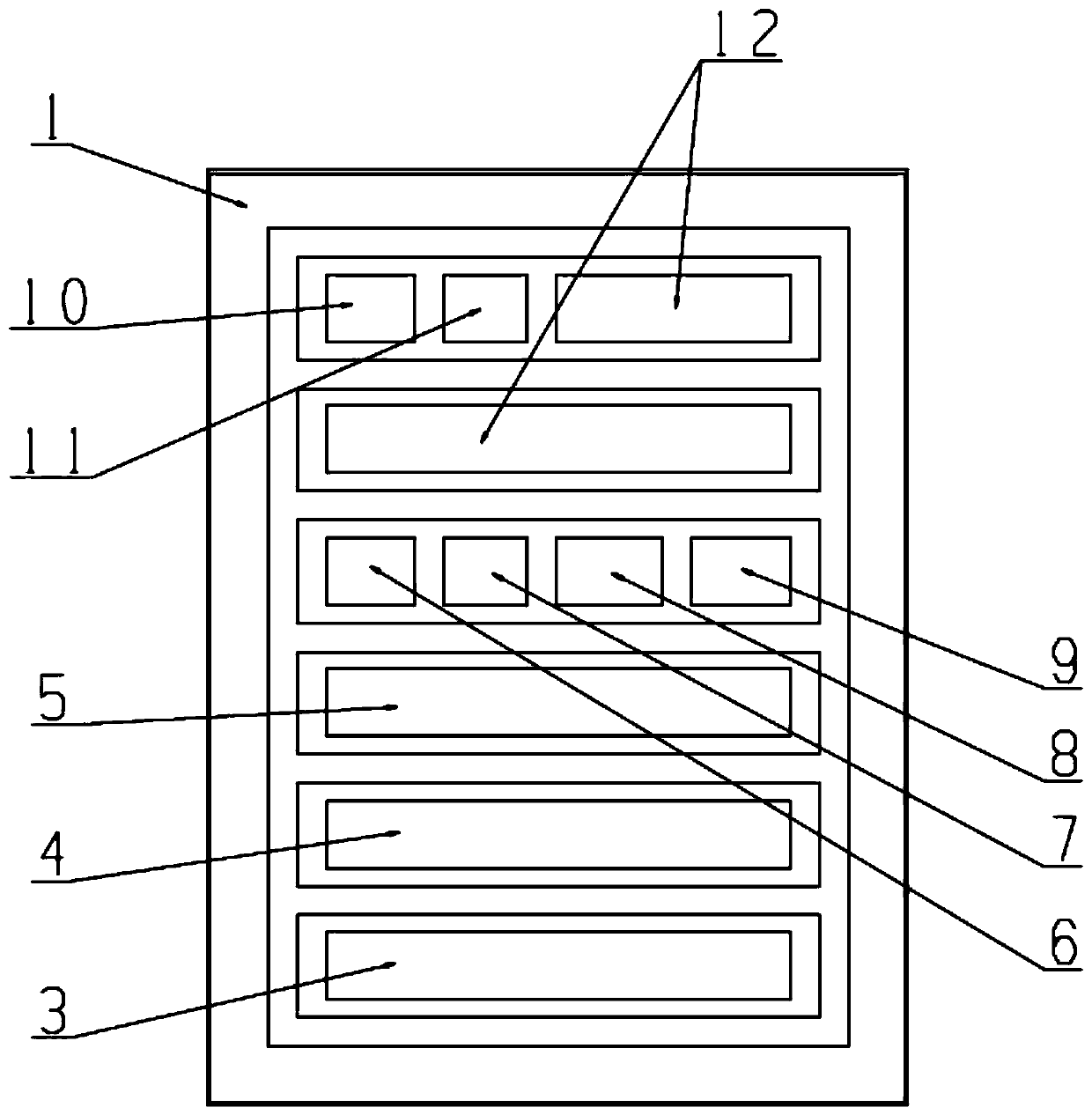

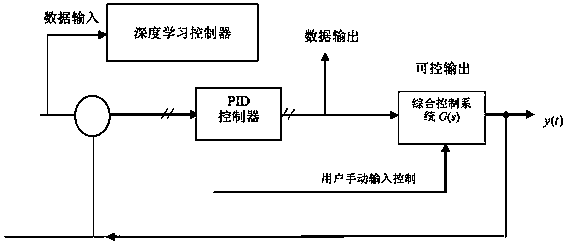

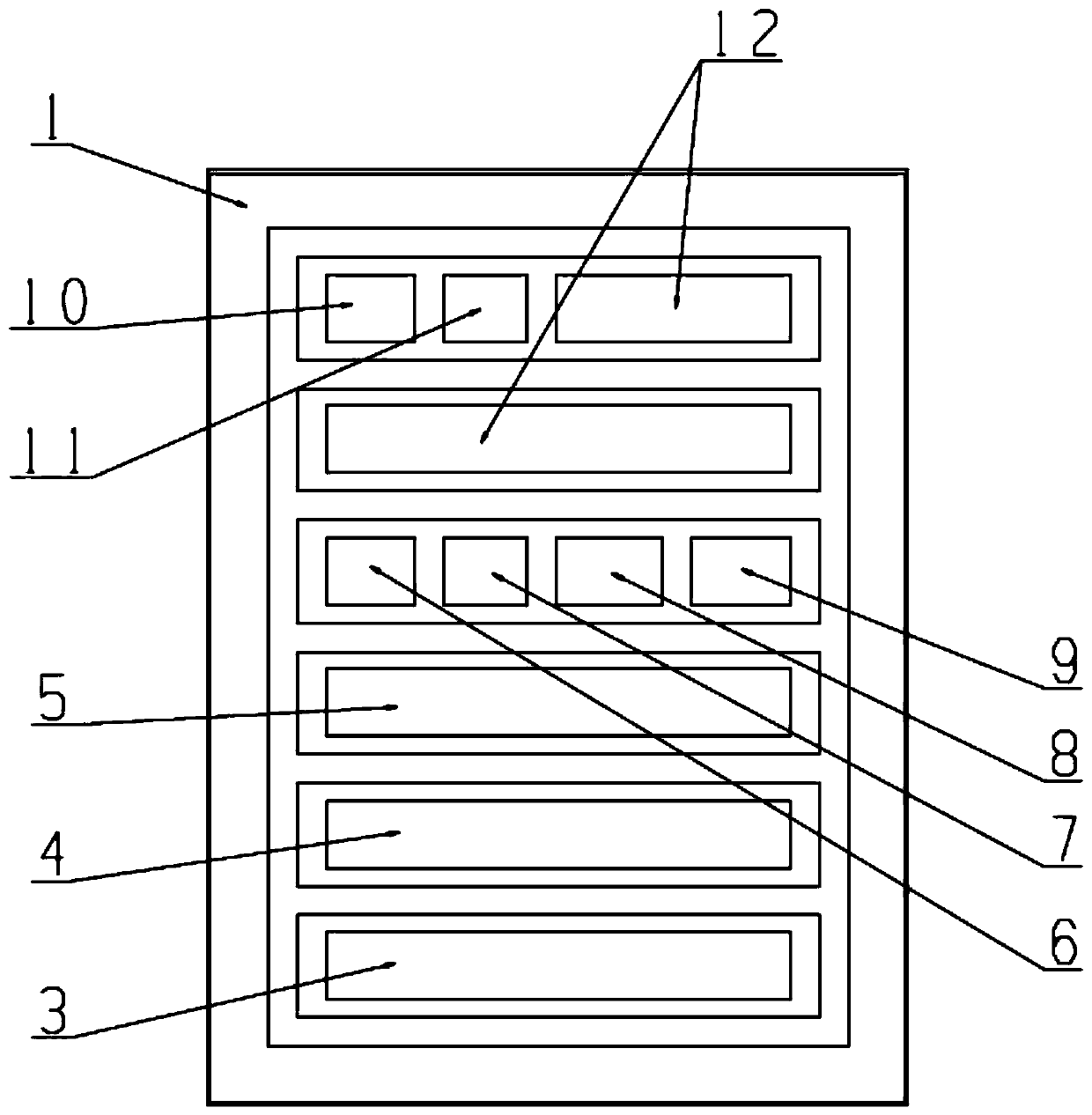

Data collection cabinet

ActiveCN109946960AData collection continuesData acquisition real-timeTemperature control using electric meansControllers with particular characteristicsTemperature controlData acquisition

The invention belongs to the technical field of the intelligent water supply temperature control construction of the water resources and hydropower engineering, and provides a data collection cabinet.The data collection cabinet comprises a cabinet body, a wiring device, a collection module, a central processing module and an external module; the wiring device is used for mounting the collection module, the central processing module and the external module; the collection module is used for collecting flow of a heat exchange medium, the temperature of the inlet-outlet heat exchange medium andthe concrete block temperature in an integrated control cabinet; the central processing module uploads the collected data to a cloud server to perform data interaction; and the central processing module controls the flow of the heat exchange medium by adopting a gradient intelligent closed-loop learning control method, thereby realizing the controlling on the highest temperature, the adjusting onthe cooling rate and the diagnosis on the abnormal temperature of a controlled object. The data collection cabinet disclosed by the invention has the advantages of being anti-interference, capable ofcontinuously, stably and efficiently running, and performing the data collection, analysis and control in real time.

Owner:TSINGHUA UNIV +1

A printed circuit board stress and strain testing system

ActiveCN103528493BData acquisition real-timeReal time monitoringElectrical/magnetic solid deformation measurementTester devicePrinted circuit board

The invention discloses a stress-strain test system for a printed circuit board. The stress-strain test system comprises a strain sensor, a strain tester and an upper computer mechanism; the strain sensor is attached to the printed circuit board and is connected with the strain tester which is connected with the upper computer mechanism. Compared with the prior art, the stress-strain test system for the printed circuit board has the advantages of capability of monitoring the strain condition of the circuit board in real time, good dynamic responding, high precision and the like.

Owner:章和技术(广州)有限公司

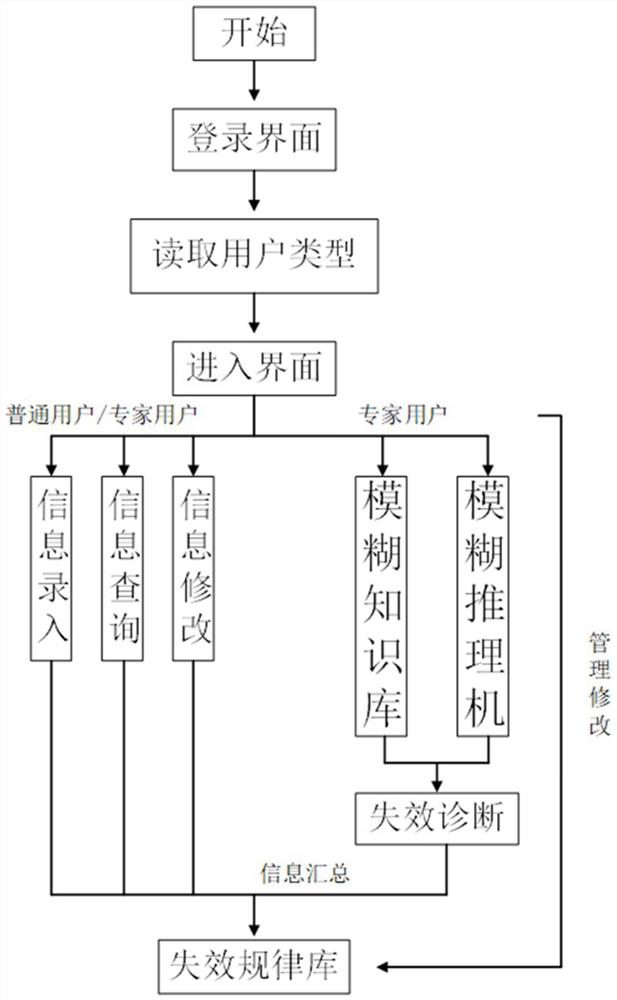

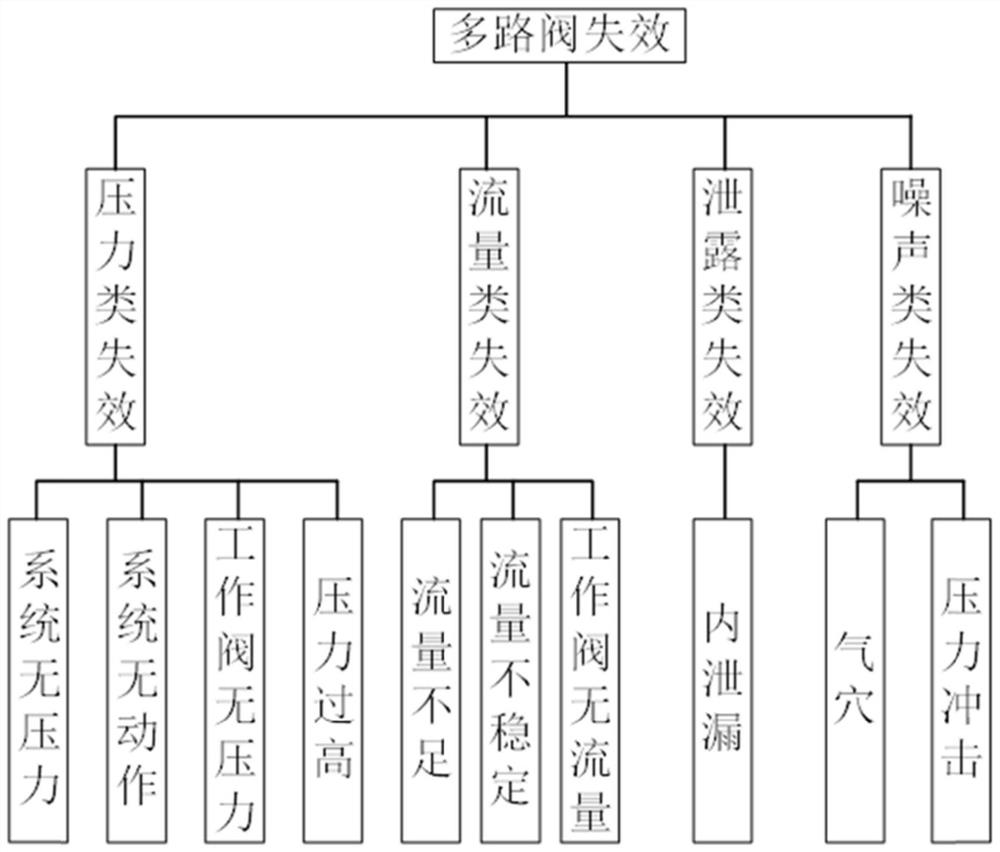

Multi-way valve failure data management and failure mode automatic diagnosis system

PendingCN112231352AReduce investmentRealize managementDigital data information retrievalNeural architecturesFault analysisComputer science

The invention provides a multi-way valve failure data management and failure mode automatic diagnosis system. The multi-way valve failure data management and failure mode automatic diagnosis system comprises a user information login management module, a failure case information management module, a failure information query module, a part information management module, a failure mode automatic diagnosis module and a failure case rule base module. According to the invention, previous scattered multi-way valve failure case data are combined and classified through advanced network and database technologies, the data are stored in the database in a certain mode, rules can be summarized and found in numerous failure cases, and the possibility of faults is pre-judged on the basis of the rules; an engineer can have references when dealing with the failure of the multi-way valve, the fault case analysis process is simplified, the fault analysis and processing efficiency is improved, the working time is shortened, unnecessary waste and repeated work are avoided, and faults can be prevented in advance.

Owner:NANJING UNIV OF TECH

Carbon emission intensity monitoring sensor installation device

ActiveCN105004840ALow costData acquisition real-timeTransmission systemsPosition/course control in two dimensionsMotor driveWireless transmission

The invention discloses a carbon emission intensity monitoring sensor installation device including a guide rail; a motor-driven carrier is arranged on the guide rail and is provided with a greenhouse gas monitoring sensor, a storage battery, a solar cell panel, a wind power generator and a wireless transmission module; the solar cell panel and the wind power generator are both connected to the storage battery; the guide rail is provided with N deceleration zones each internally provided with a deceleration plate, and the deceleration plates are connected with the side faces of the guide rail and are provided with magnets; wheels of the motor-driven carrier are made of metal magnetic materials; the technical effects of reasonable equipment design, relatively low cost, energy conservation and environmental protection are achieved.

Owner:CHENGDU HANKANG INFORMATION IND

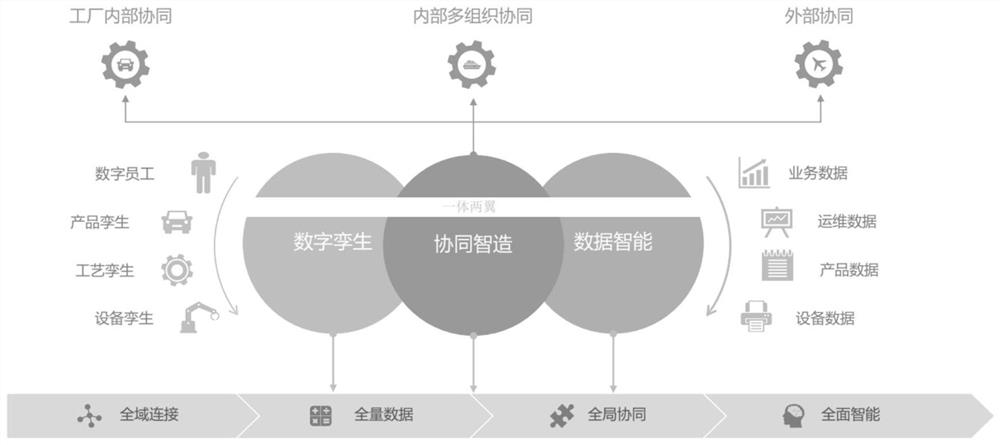

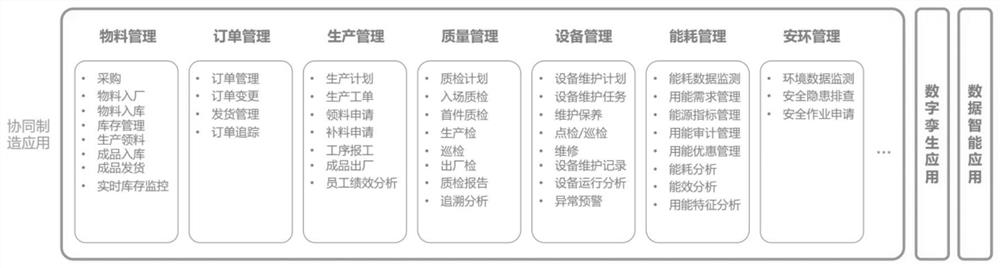

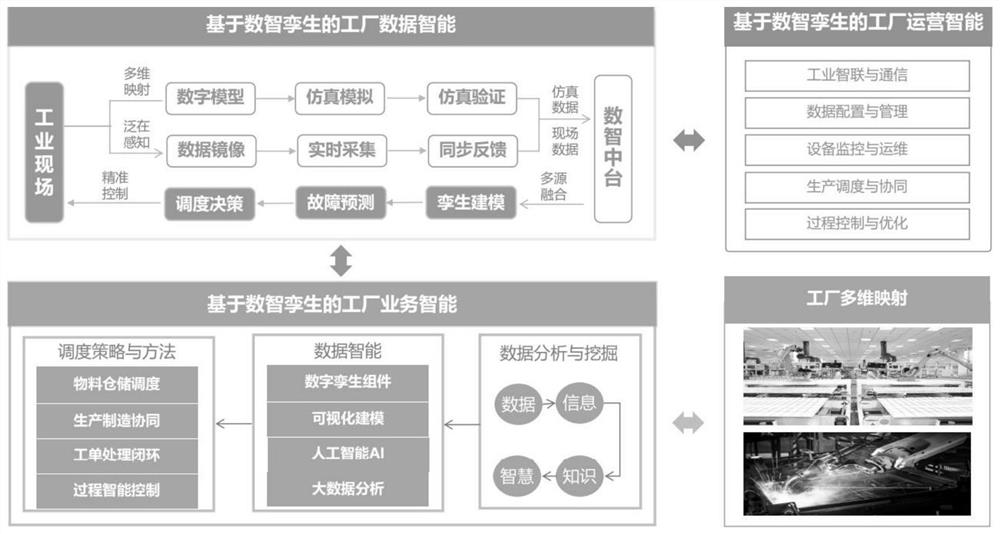

Cloud service system based on industrial internet platform

PendingCN113673952ATraceable managementFully automatic data collectionOffice automationManufacturing computing systemsThe InternetIndustrial Internet

The invention relates to a cloud service system based on an industrial internet platform, and the system comprises an internal multi-organization cooperation platform, an external cooperation platform, and a factory internal cooperation platform which carry out networking interaction based on the industrial internet platform. The internal multi-organization collaboration platform comprises a collaboration manufacturing application platform, a digital twinborn platform built based on the collaboration manufacturing application platform, and an intelligent data integration platform for integration and statistics of intelligent data based on the collaboration manufacturing application platform and the digital twinborn platform. The external collaboration platform and the factory internal collaboration platform are in communication connection with the internal multi-organization collaboration platform through the intelligent data integration platform. According to the invention, intelligent collaboration is taken as a body, a lightweight and innovative digital capability platform is provided, online factory equipment, collaborative online, business online and digital intelligent online are realized, the core problem of mutual collaboration of material flow, information flow, equipment and people inside and outside a factory is solved, and a new mode of flexible 'intelligent manufacturing' of the factory is realized.

Owner:太仓月球云科技有限公司

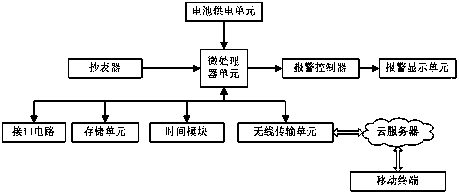

Meter reading system based on wireless transmission

InactiveCN108417005AAccurate data collectionData acquisition real-timeTransmission systemsWireless transmissionComputer terminal

The invention discloses a meter reading system based on wireless transmission. The meter reading system comprises a microprocessor unit, an image collection unit, an image recognition unit, a batterypower supply unit, an alarm controller, an alarm display unit, a wireless transmission unit, a storage unit, a time module, a cloud server, a mobile terminal and an interface circuit, wherein the image collection unit is connected with the input end of the microprocessor unit through the image recognition unit; the output end of the microprocessor unit is connected with the alarm display unit through the alarm controller; the microprocessor is connected with the wireless transmission unit, the storage unit, the interface circuit and the time module; the mobile terminal is in network connectionwith the cloud server; the cloud server is used for charging and storage; the microprocessor unit is connected with the cloud server through the wireless transmission unit and is used for uploading meter reading data.

Owner:成都巴哈极上科技有限公司

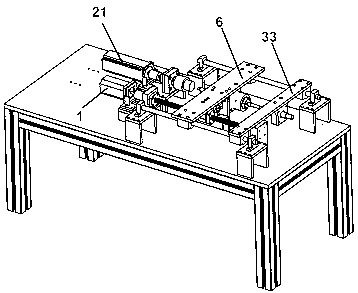

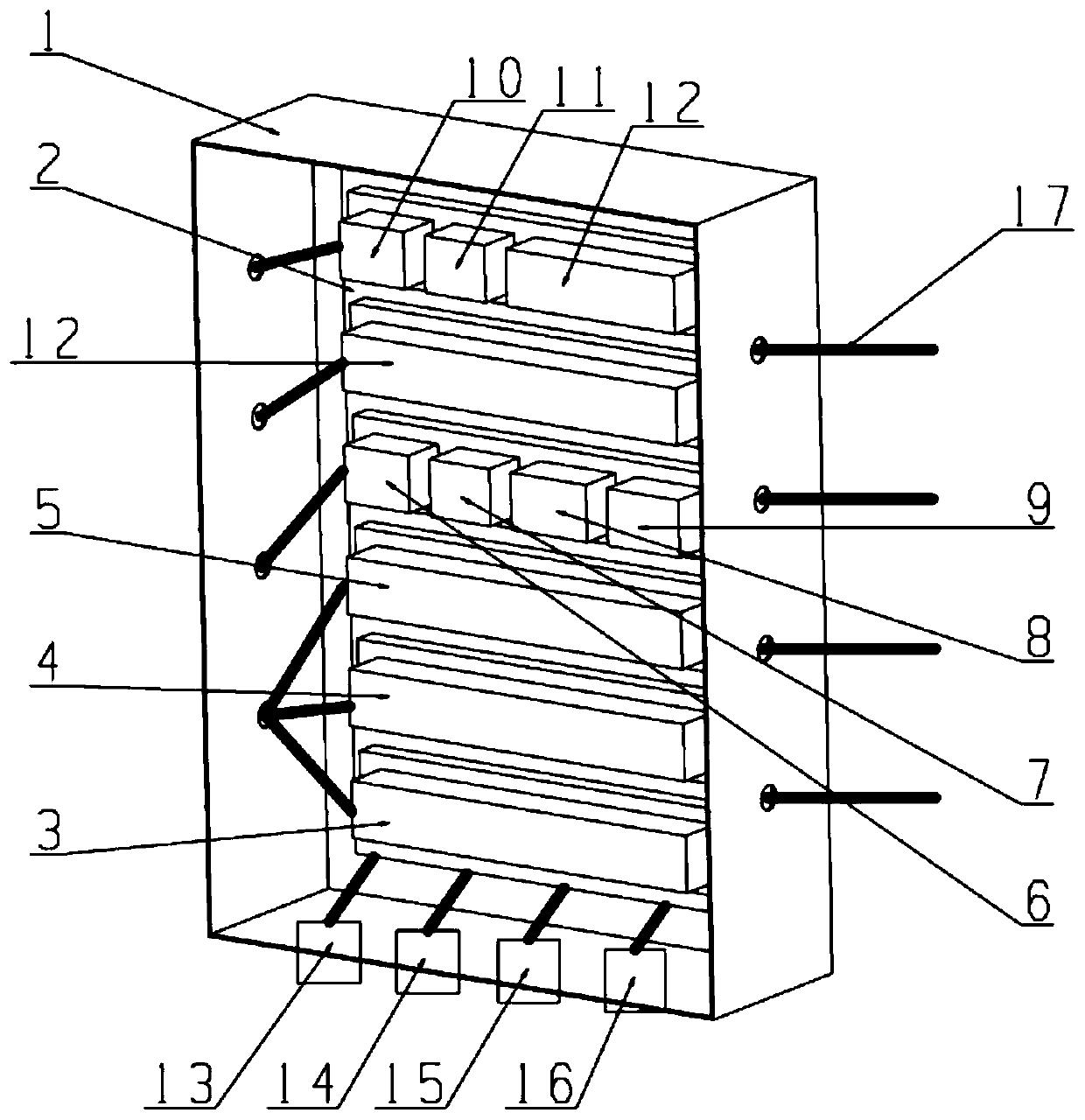

Ball screw torsion test device

ActiveCN110320029AData acquisition real-timeImprove detection accuracyMachine part testingMeasurement of torque/twisting force while tighteningTorsion testBall screw

The invention provides a ball screw torsion test device, comprising: a base, a driving mechanism disposed on the base, a fixing and clamping mechanism, a measuring mechanism and a translation mechanism. The driving mechanism is used for driving a ball screw to rotate. The fixing and clamping mechanism is used for clamping the ball screw and fixing the same to the base. The measuring mechanism is used for testing torsion of the ball screw and comprises a measured screw nut chuck and a force measuring device. The translation mechanism is used for controlling the force measuring device and the measured screw nut chuck relatively static.

Owner:苏州斯科勒自动化设备有限公司

A data collection cabinet

ActiveCN109946960BData collection continuesData acquisition real-timeTemperature control using electric meansControllers with particular characteristicsCollection analysisData acquisition

The invention belongs to the technical field of the intelligent water supply temperature control construction of the water resources and hydropower engineering, and provides a data collection cabinet.The data collection cabinet comprises a cabinet body, a wiring device, a collection module, a central processing module and an external module; the wiring device is used for mounting the collection module, the central processing module and the external module; the collection module is used for collecting flow of a heat exchange medium, the temperature of the inlet-outlet heat exchange medium andthe concrete block temperature in an integrated control cabinet; the central processing module uploads the collected data to a cloud server to perform data interaction; and the central processing module controls the flow of the heat exchange medium by adopting a gradient intelligent closed-loop learning control method, thereby realizing the controlling on the highest temperature, the adjusting onthe cooling rate and the diagnosis on the abnormal temperature of a controlled object. The data collection cabinet disclosed by the invention has the advantages of being anti-interference, capable ofcontinuously, stably and efficiently running, and performing the data collection, analysis and control in real time.

Owner:TSINGHUA UNIV +1

Import the measurement and calculation methods and program products of length, width and approximate volume of materials

The invention discloses a method for measuring and calculating the length, width and approximate volume of imported materials and a program product. Measure the length and width of the material, use the horizontal measurement grating installed at the position of the import conveyor to measure the occlusion size of the material perpendicular to the conveying direction, and judge the material according to the maximum value of the material contour, size feature points, and aspect ratio relationship The length and width dimensions are measured and calculated. By increasing the height measurement grating to form a rectangular grating group, the tomographic measurement of the section section in the Y and Z directions is carried out, and the projected area and the shading height H of the material passing through the small section section on the conveyor belt surface within the calculation period are obtained, and the calculation is made. The volume of the small cross-section section that the periodic material passes through, and it is accumulated in the material measurement period T to calculate the approximate volume. The program product of the calculation method is executed by the processor in the controller, which can reliably obtain the size and approximate volume of the material, and provide guarantee for the accurate and efficient operation of the entire sorting conveyor line.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

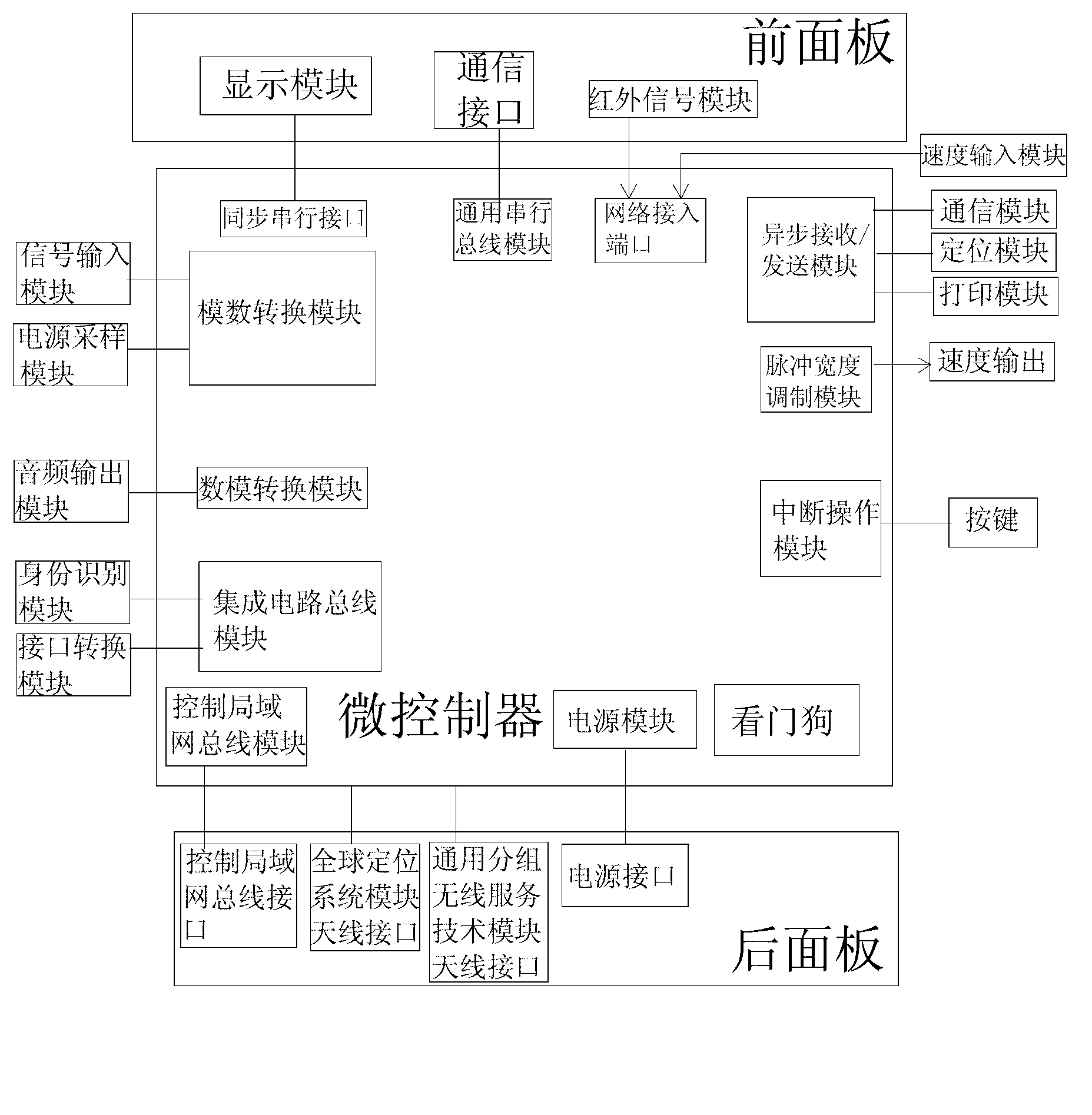

Vehicle-mounted terminal

InactiveCN103023524AData acquisition real-timeFunctionalWireless commuication servicesTransmissionData informationComputer science

The invention discloses a vehicle-mounted terminal. The vehicle-mounted terminal comprises a controller, a communication module, a positioning module, a printing module, a speed output module, a speed input module, a power module, a display module and a storage module, wherein the communication module is used for interactively transmitting data, the positioning module is used for recording coordinate positioning data in real time, the printing module is used for printing self internal data information, the controller is connected with the communication module, the positioning module and the printing module, the speed output module and the speed input module are used for monitoring travelling speed, the controller is respectively connected with the speed output module and the speed input module, the power module is connected with the controller and used for providing working power supply for the vehicle-mounted terminal, and the display module and the storage module are connected with the controller. The vehicle-mounted terminal has multi-functions, thereby being more convenient for use of vehicle travelling. In addition, vehicle performance is improved.

Owner:SHANGHAI HANGSHENG IND

Intelligent control system and method for medium heat exchange

ActiveCN110006284AStrong process controllabilityAchieve batchFoundation engineeringControllers with particular characteristicsTemperature controlData acquisition

The invention belongs to the technical field of intelligent medium heat exchange and temperature control construction of civil engineering, and provides an intelligent control system and method for medium heat exchange. The intelligent control system for the medium heat exchange comprises a heat exchange device, a heat exchange auxiliary device and control devices; a plurality of integrated flow temperature control devices are arranged in a flow temperature medium integrated control cabinet; the flow temperature medium integrated control cabinet and a data acquisition, analysis and feedback intelligent control cabinet are arranged in a heat exchange medium loop; the control devices are used for controlling heat exchange media to finish heat exchange with a target area through the loop, theheat exchange auxiliary device and the heat exchange device. The intelligent control system has the beneficial effects that, by adopting intelligent PID algorithm control, the maximum temperature control in the heat exchange process, coordinated gradient control over the spatial temperature variation rate in the whole process of heat exchange of the target area, and control over the abnormal temperature control conditions in the heat exchange process of the target area are performed through a gradient closed-loop intelligent learning control method, and various emergencies and abnormalities can be handled effectively.

Owner:TSINGHUA UNIV +1

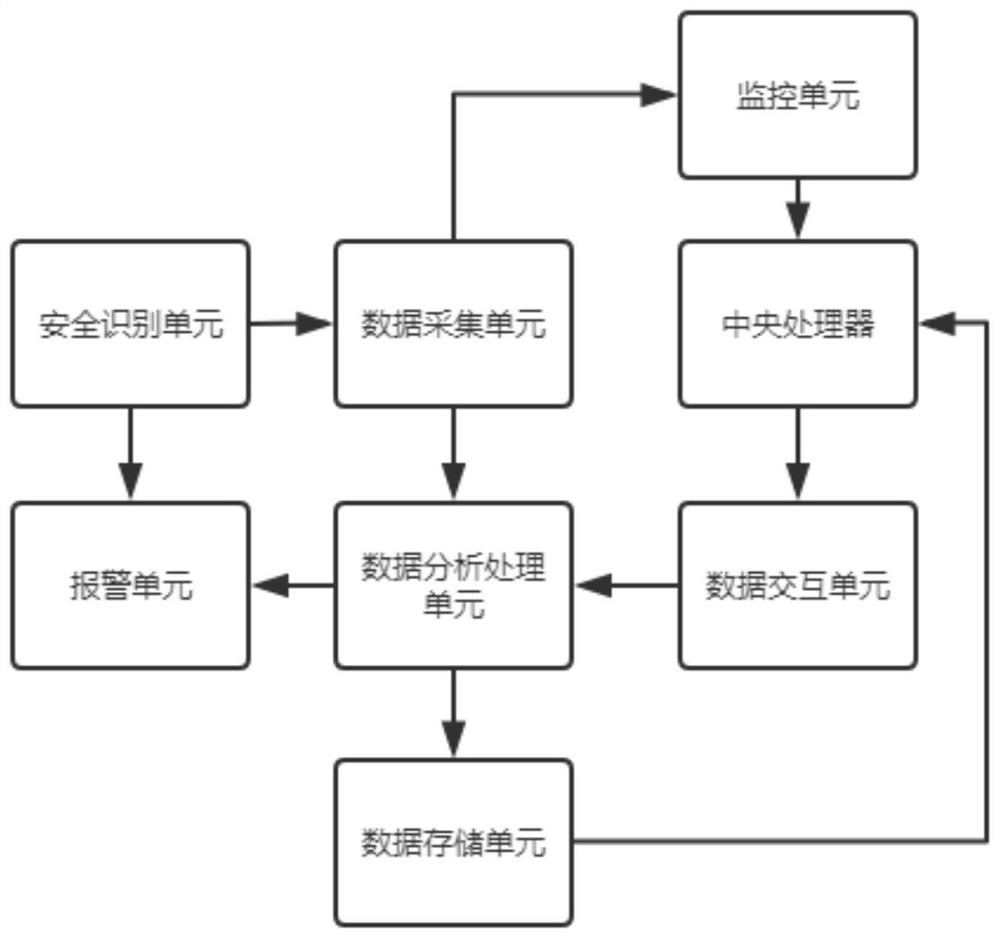

Safety management system for industrial Internet-of-things data acquisition terminal

InactiveCN112200988AData acquisition real-timeGuaranteed safety managementAlarmsElectric transmission signalling systemsRadio frequencyIndustrial Internet

The invention discloses a safety management system for an industrial Internet-of-things data acquisition terminal, and relates to the technical field of information management. The problem that collected data is inaccurate is solved. The system specifically comprises a central processing unit, a safety identification unit, a data acquisition unit, a data analysis processing unit, a data storage unit, a data interaction unit, a monitoring unit and an alarm unit. The central processing unit is in communication connection with the signal input end of the data interaction unit; the signal output end of the safety identification unit is in communication connection with the alarm unit; and the signal input end of the data acquisition unit is electrically connected with the safety identificationunit. A material positioning module is sequentially arranged on the produced materials, in the material moving process, the material positioning module sends radio frequency information to a positionpositioning modules, a sensor module continuously collects radio frequency identification information sent by the positioning module, and real-time and high-precision data collection in industrial production is achieved.

Owner:衡阳市华毅自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com