Strip steel surface on-line inspection system and method based on embedded image processing system

An image processing and detection system technology, applied in character and pattern recognition, optical test flaws/defects, instruments, etc., can solve the problems of slow running speed, high system resource consumption, and many types of equipment in pure software detection methods, and achieve high Illumination output, saving system resources, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

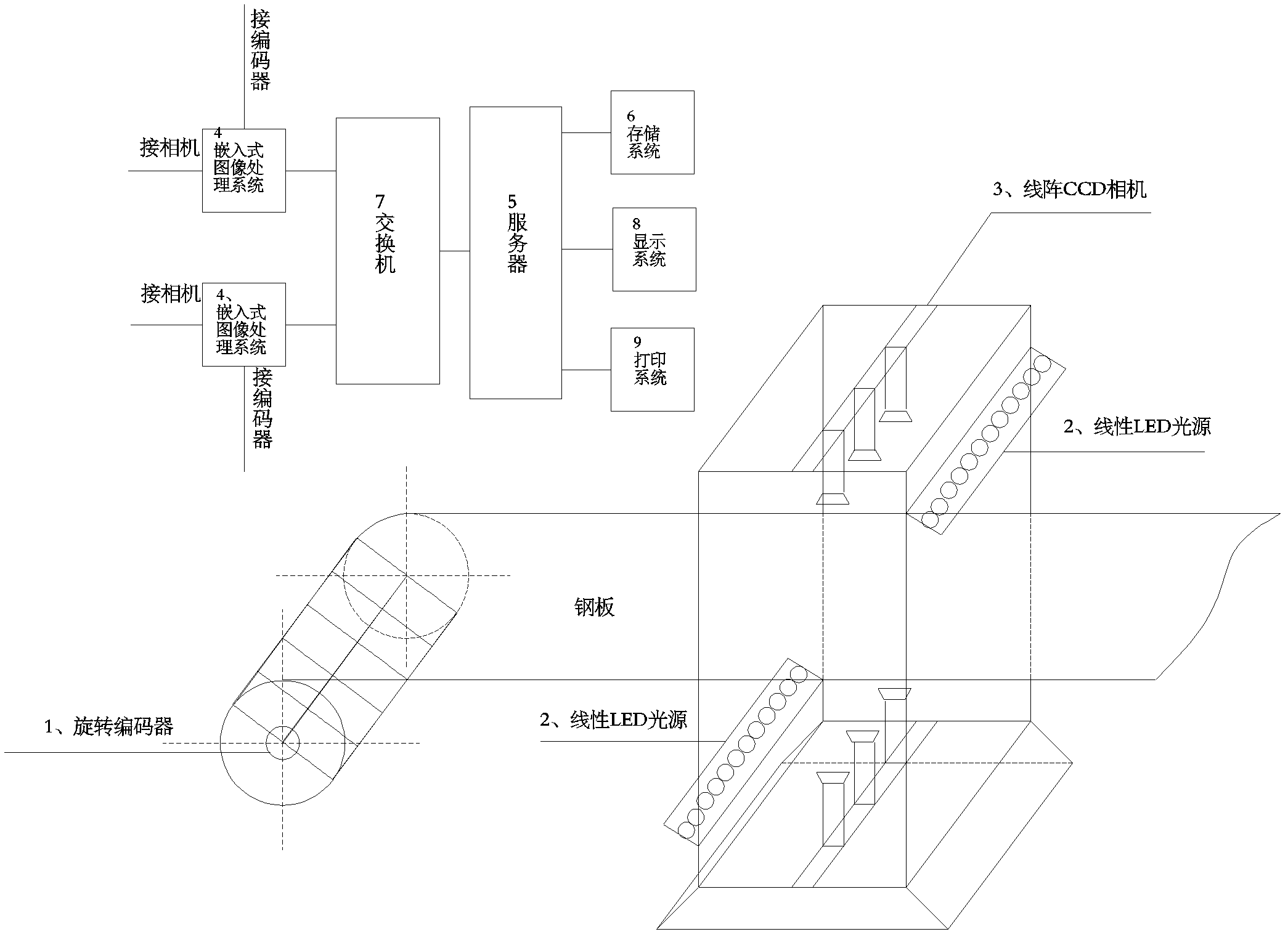

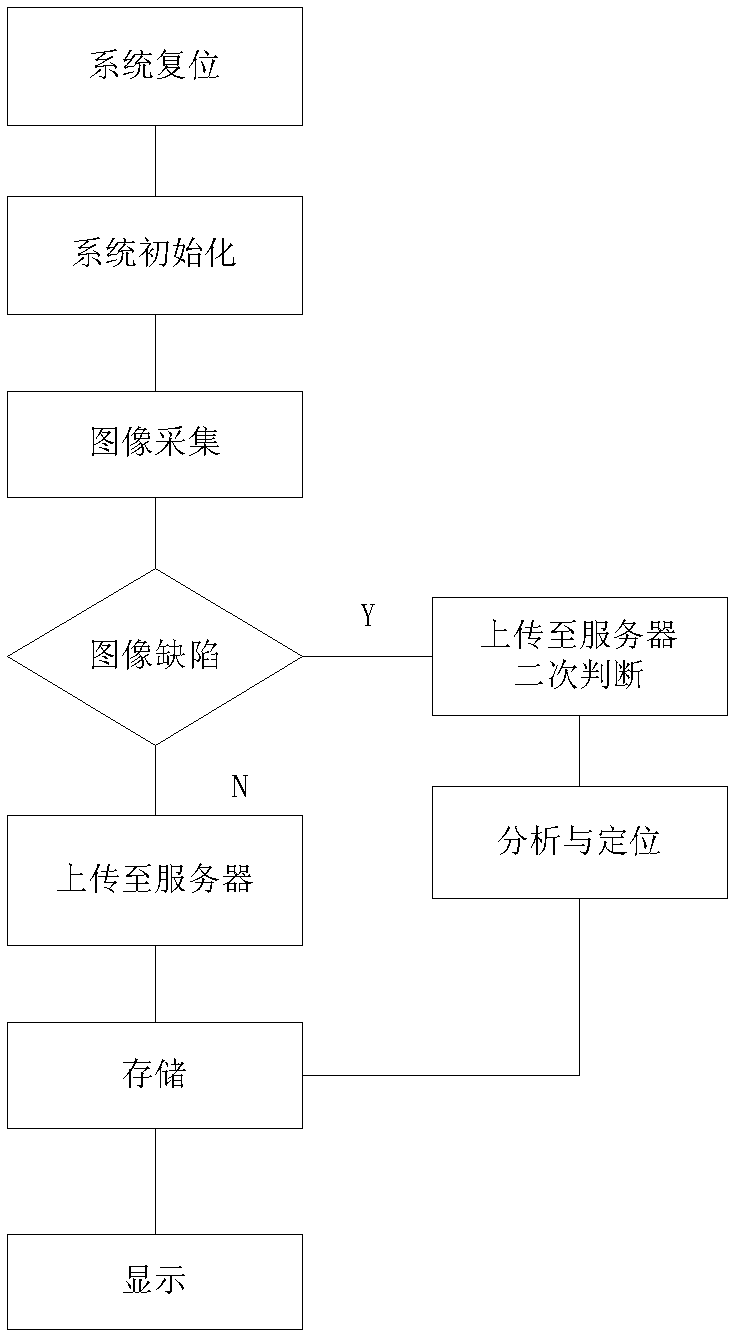

[0017] combine figure 1 Explain the specific real-time method: it consists of 1 speed measuring device rotary encoder, 2 linear LED light source, 3 linear array CCD camera, 4 embedded dedicated digital image preprocessing platform (DSP+FPGA), 5 servers, 6 storage systems, 7 switches, 8 display system, 9 printing system and 10 protection devices. The linear LED red light source is fixed on the upper part of the protection device through an angle-adjustable bracket, and the linear LED red light source is fixed to the best position by adjusting the knob to ensure that the linear array CCD camera can collect more complete and accurate cold in the bright market. Characterization of surface defects in rolled strip steel. The driving signal of the linear array CCD camera is provided by the programmable logic control device FPGA on the embedded image processing system, and the linear array CCD camera is controlled to collect the surface image information of the cold-rolled strip stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com