Controlling device of flash butt welding position servo system

A servo system, flash butt welding technology, applied in the direction of digital control, electrical program control, etc., can solve the problem of low tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

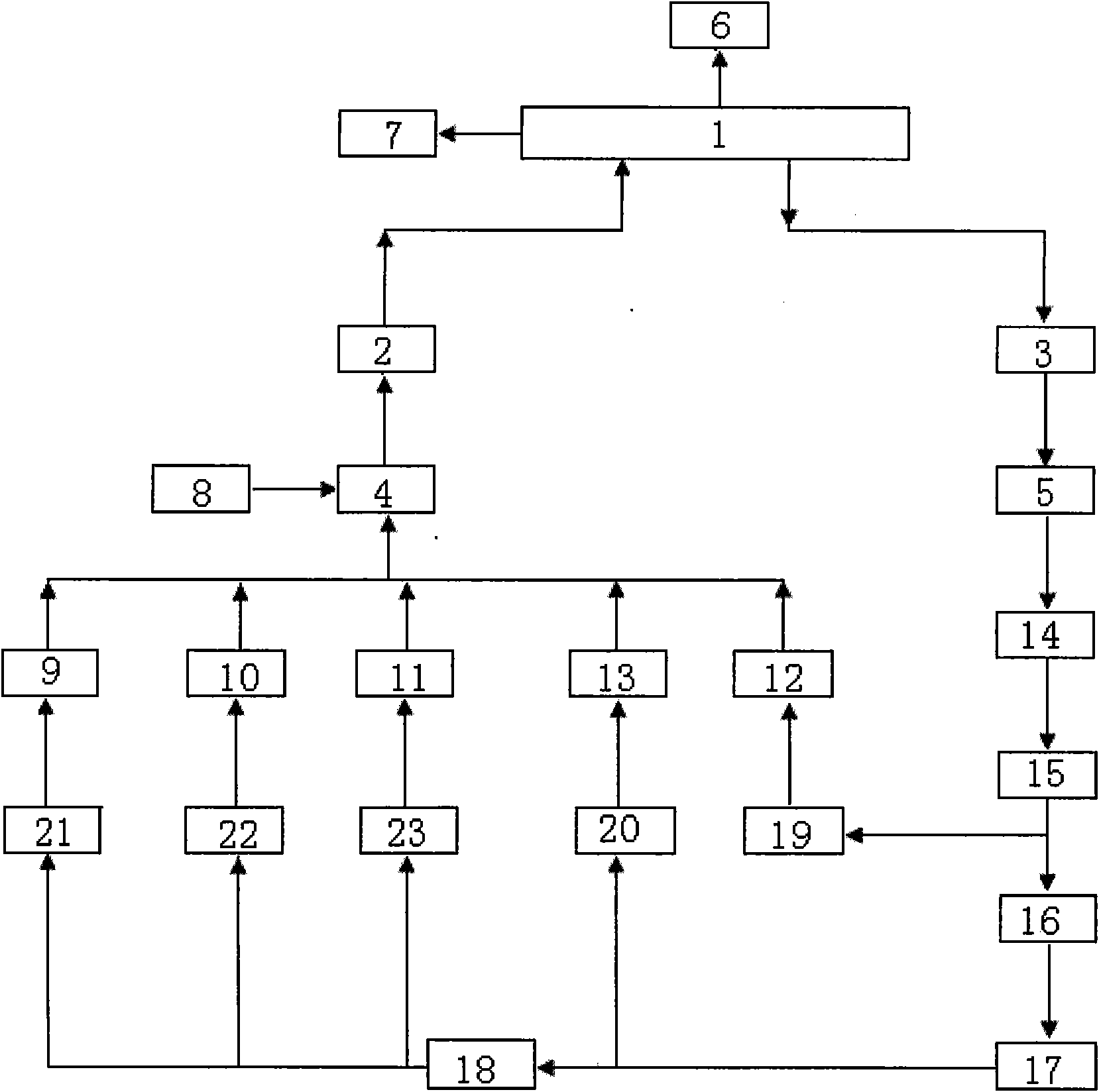

[0034] figure 1 The illustrated embodiment shows that the hardware part of the flash butt welding position servo system control device of the present invention includes an industrial control computer (1), a 16-channel programmable gain control single-ended A / D sampling board (2), and an 8-channel optically isolated D / A conversion board (3), photoelectric isolation module bottom board (4), D / A conversion board terminal board (5), man-machine interface (6), printer (7), DC24V power supply (8), hydraulic cylinder displacement input wiring Terminal board (9), hydraulic cylinder displacement speed input terminal board (10), hydraulic cylinder displacement acceleration input terminal board (11), electro-hydraulic servo valve current input terminal board (12), hydraulic cylinder pressure input terminal board (13), Electro-hydraulic servo valve output terminal board (14), servo amplifier (15), electro-hydraulic servo valve (16), hydraulic cylinder (17), load (18), servo amplifier curre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com