Patents

Literature

79results about How to "Achieve batch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

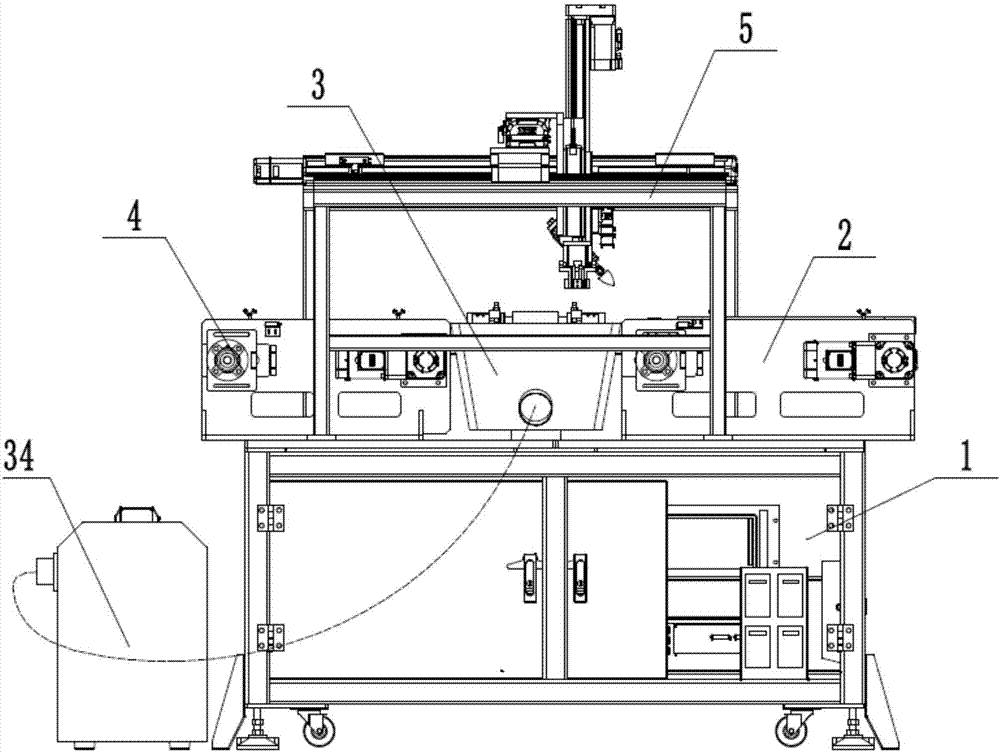

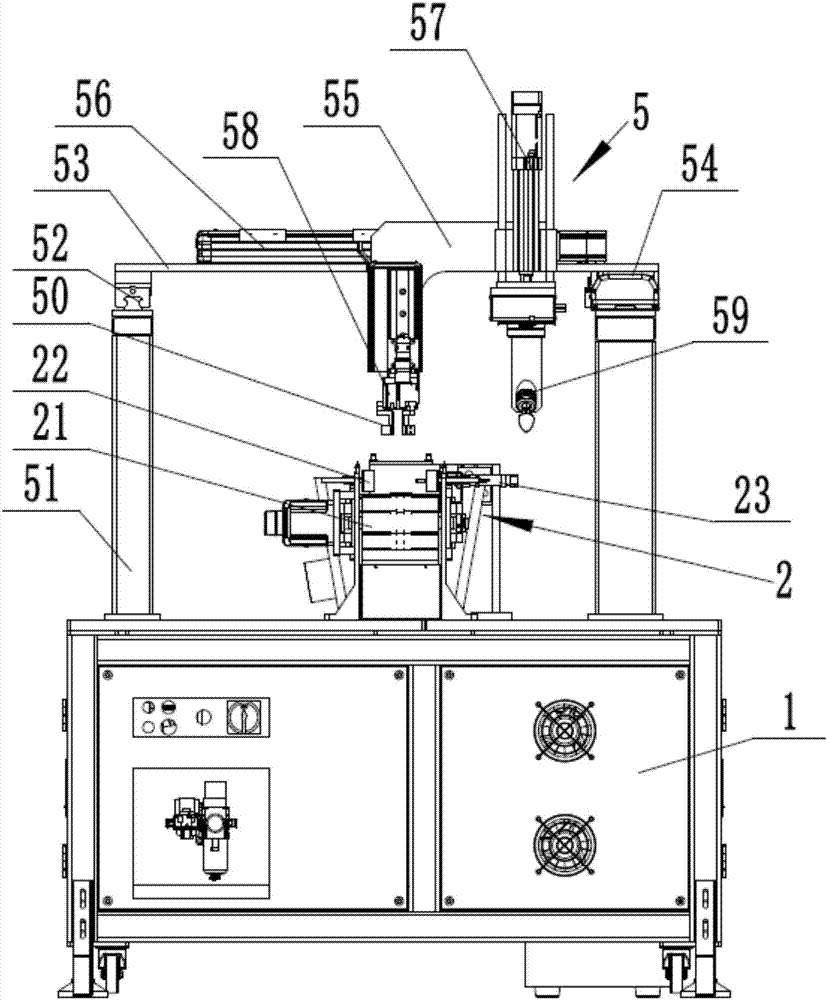

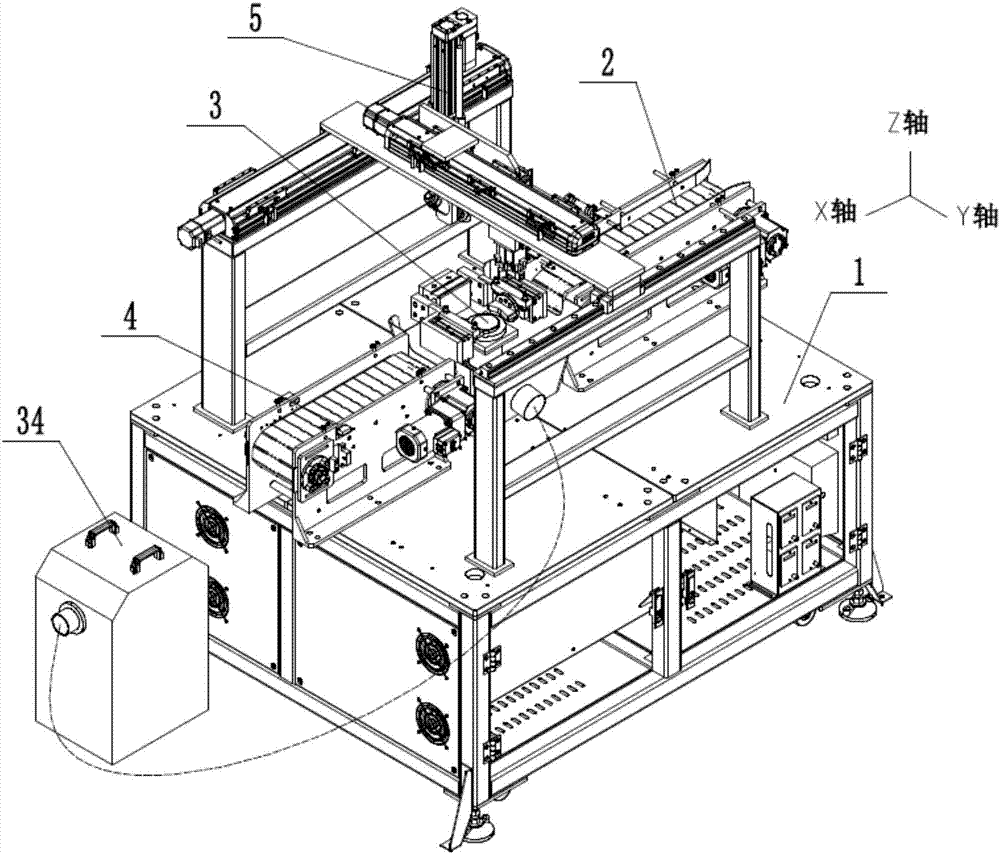

Automobile hub double-face full-automatic polishing production line

InactiveCN108000273AAccurate capturePrecise positioningEdge grinding machinesGrinding carriagesProduction lineManipulator

The invention discloses an automobile hub double-face full-automatic polishing production line which comprises a rack and a polishing mechanism. The rack is sequentially provided with a feeding mechanism, a hub polishing rotary table and a discharging mechanism, the polishing mechanism is located above the polishing mechanism, and the characteristics are that the feeding mechanism comprises a first chain plate conveyor, two guide plates and a stopping air cylinder; the hub polishing rotary table comprises a grinding collecting box, a hub polishing jacking table and an overturning tool; the overturning tool comprises a vertical plate, a wide type gas claw, two clamping connecting plates, two rotary air cylinders and two clamping blocks; the polishing mechanism comprises a support, an X-axisguide rail, an X-axis sliding base, a Y-axis sliding base, an X-axis electric cylinder, a Y-axis electric cylinder, a Z-axis electric cylinder, a Z-axis stretchable cylinder, an electric polishing head and a carrying mechanical arm; and the discharging mechanism at least comprises a second chain plate conveyor. The automobile hub double-face full-automatic polishing production line is used for automobile hub full-automatic polishing production, the front and back faces of a hub can be switched at will, and the reliability and the stability can be improved.

Owner:李茂菊

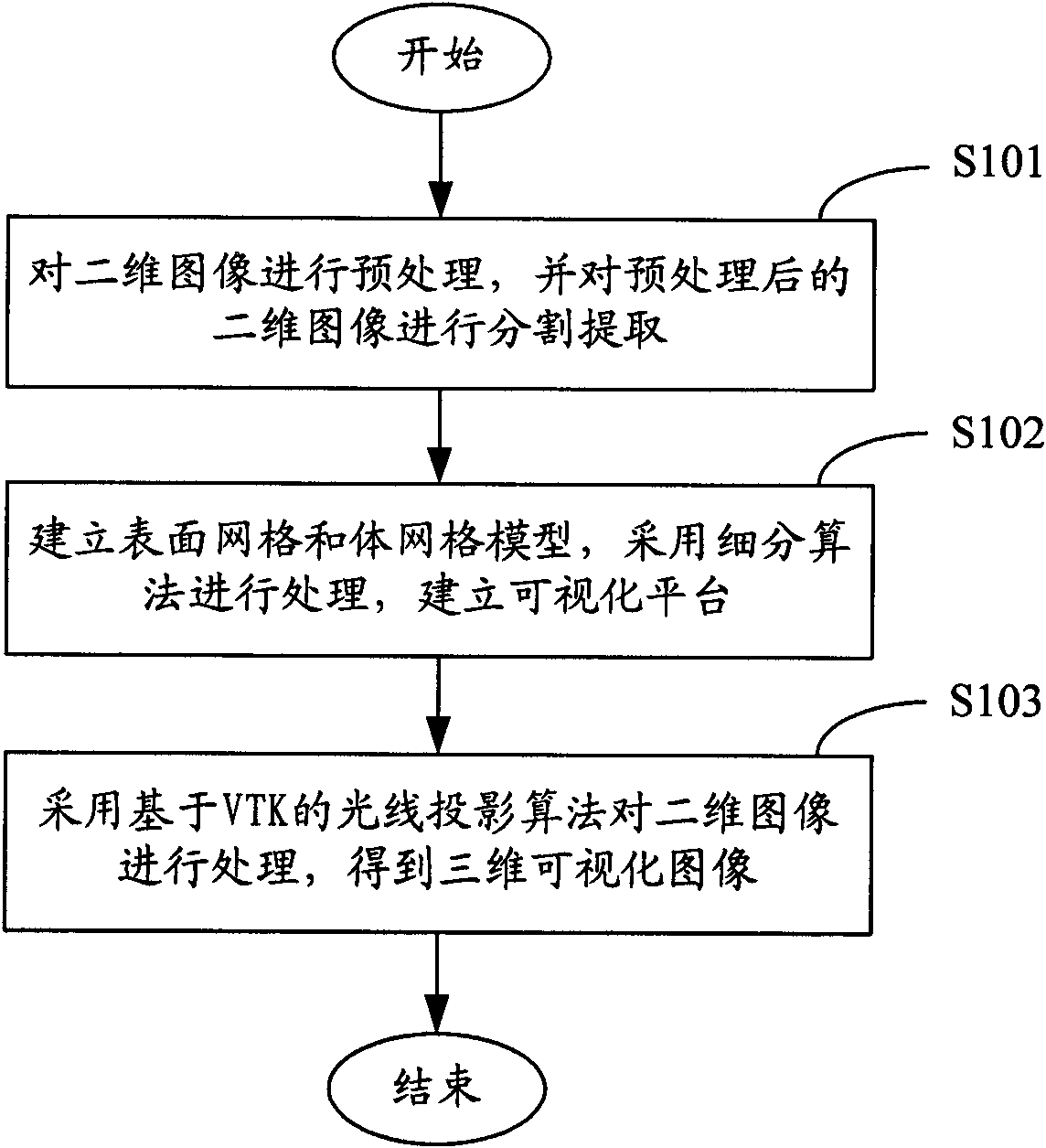

Method for processing medical images

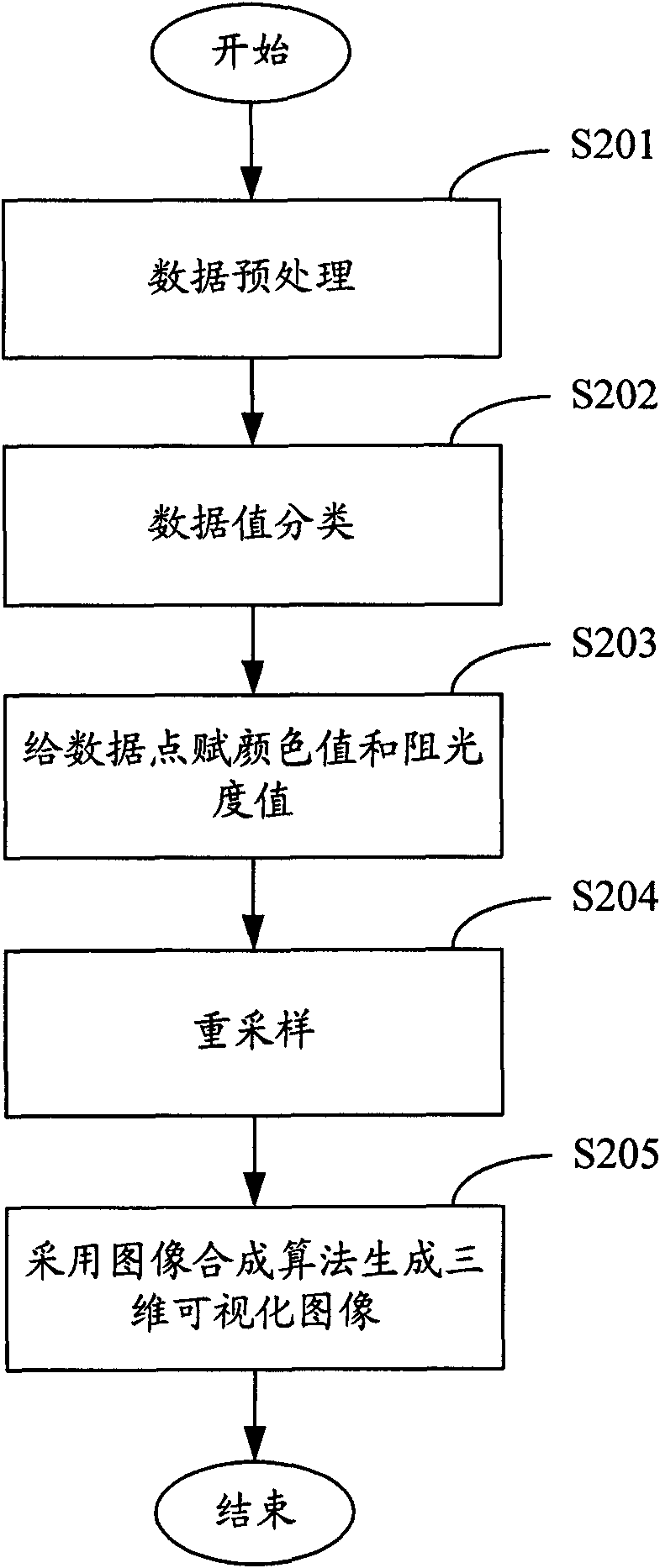

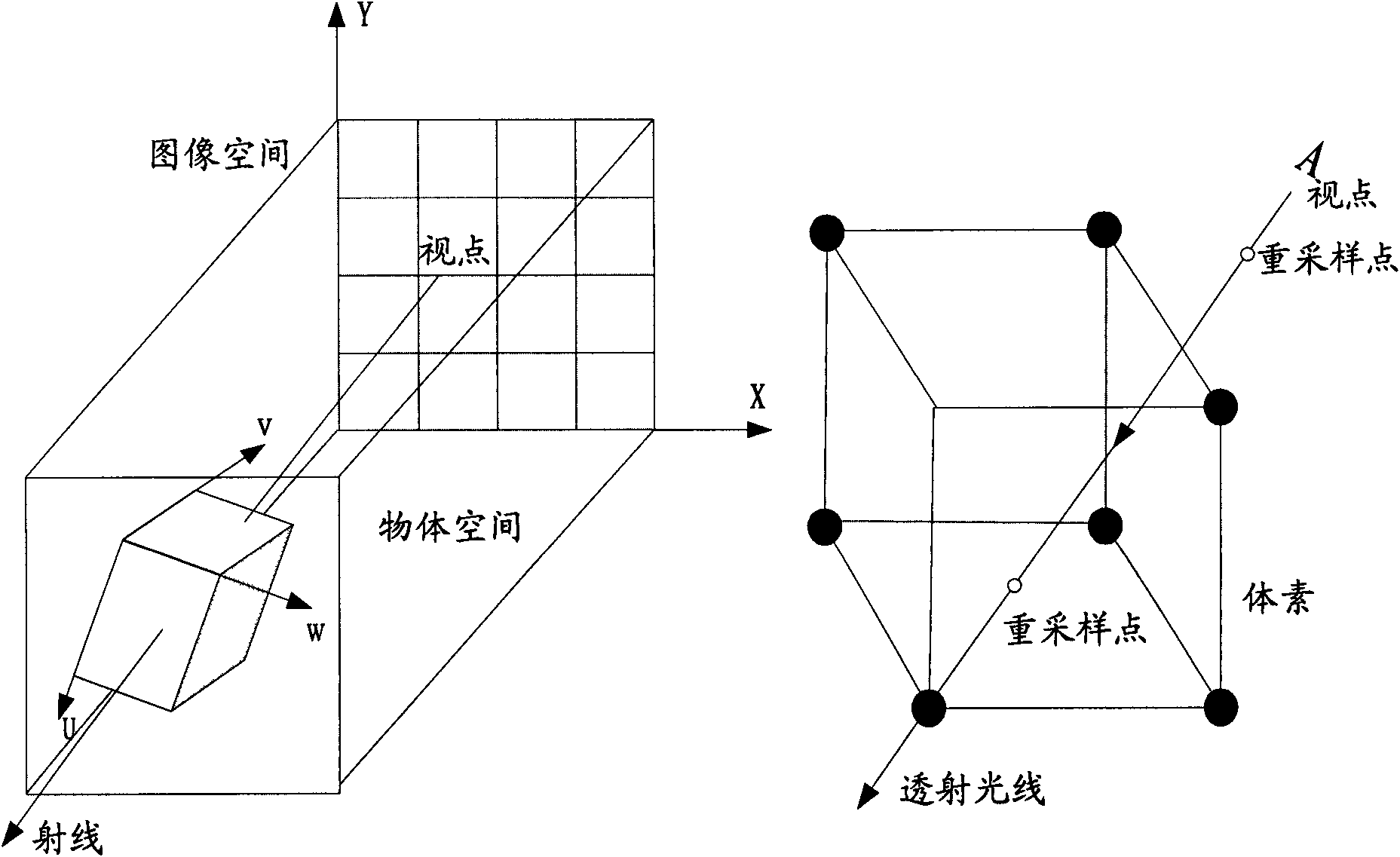

InactiveCN101625766AAchieve batchQuick and automatic processingImage analysis3D-image renderingBatch processingMesh model

The invention provides a method for processing medical images, comprising the following steps: A. c preprocessing two-dimensional images, and partitioning and extracting the preprocessed two-dimensional images; B. establishing surface mesh and body mesh moulds, adopting a subdivision algorithm for processing, and establishing a visualization platform; and C. adopting a light projection algorithm based on VTK for processing the two-dimensional images, and obtaining three-dimensional visualization images. When the method for processing medical images provided by the invention is adopted, fast batch processing can be carried out on the medical two-dimensional images, and three-dimensional visualization of the two-dimensional images can be realized.

Owner:SHENZHEN INST OF ADVANCED TECH

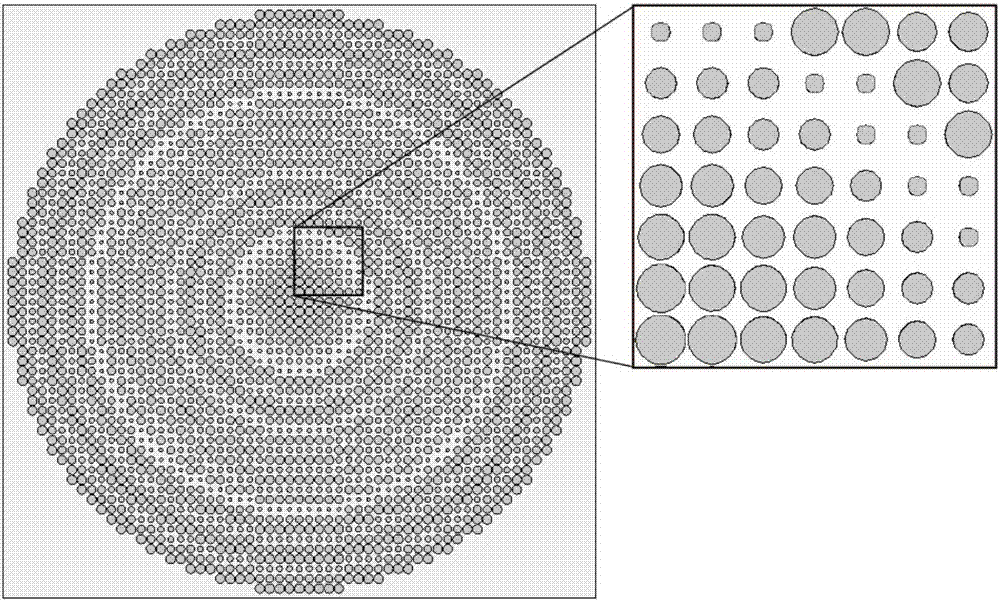

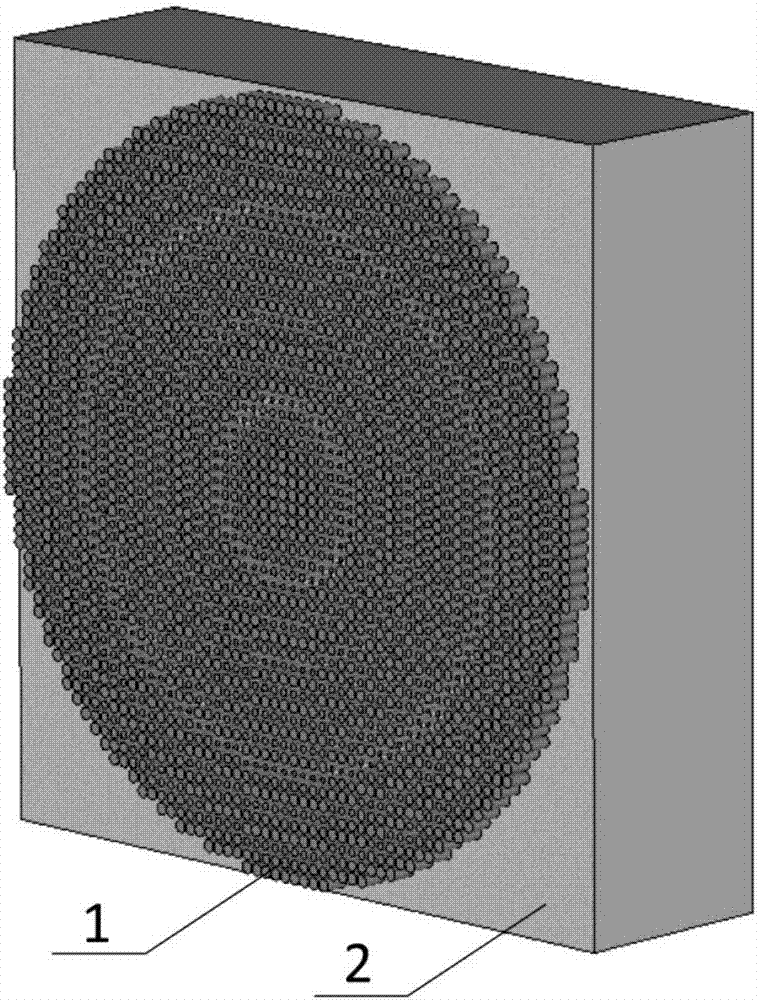

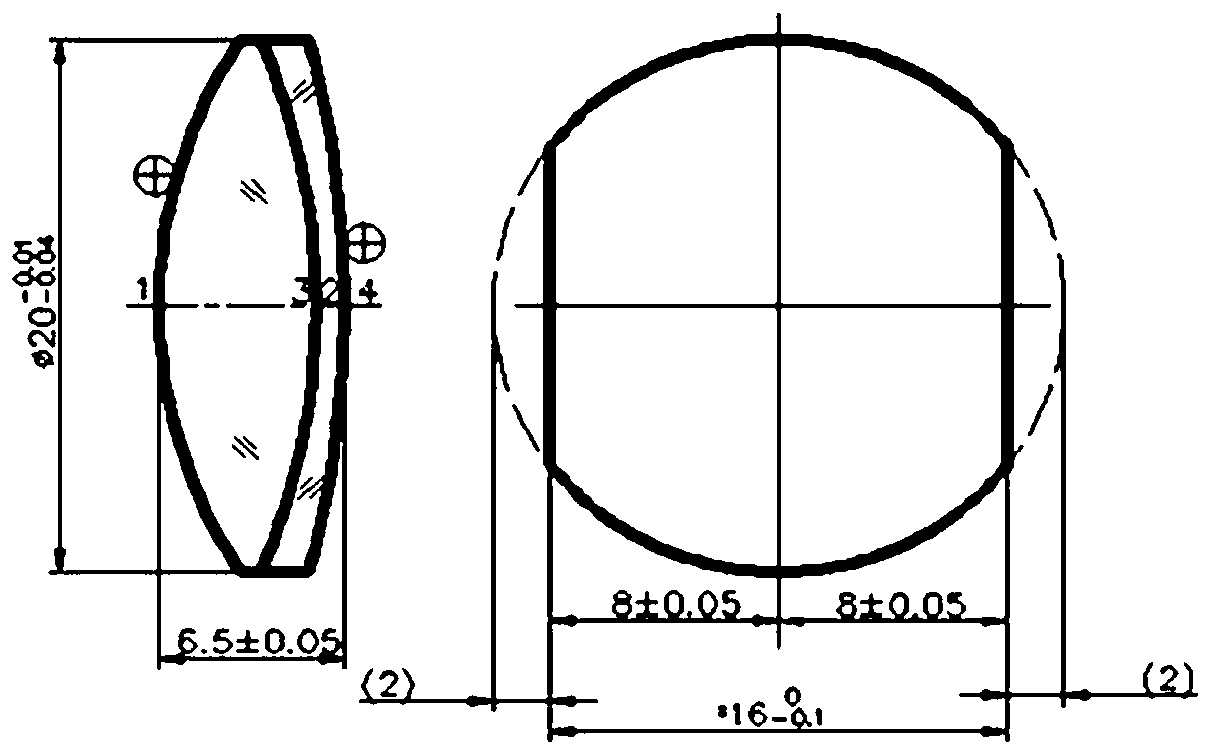

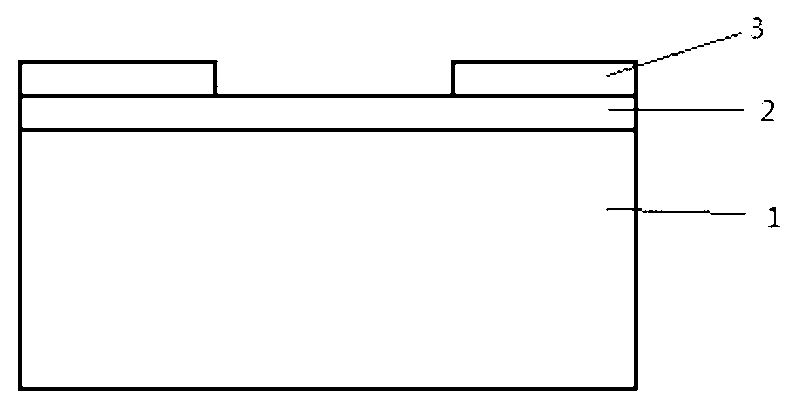

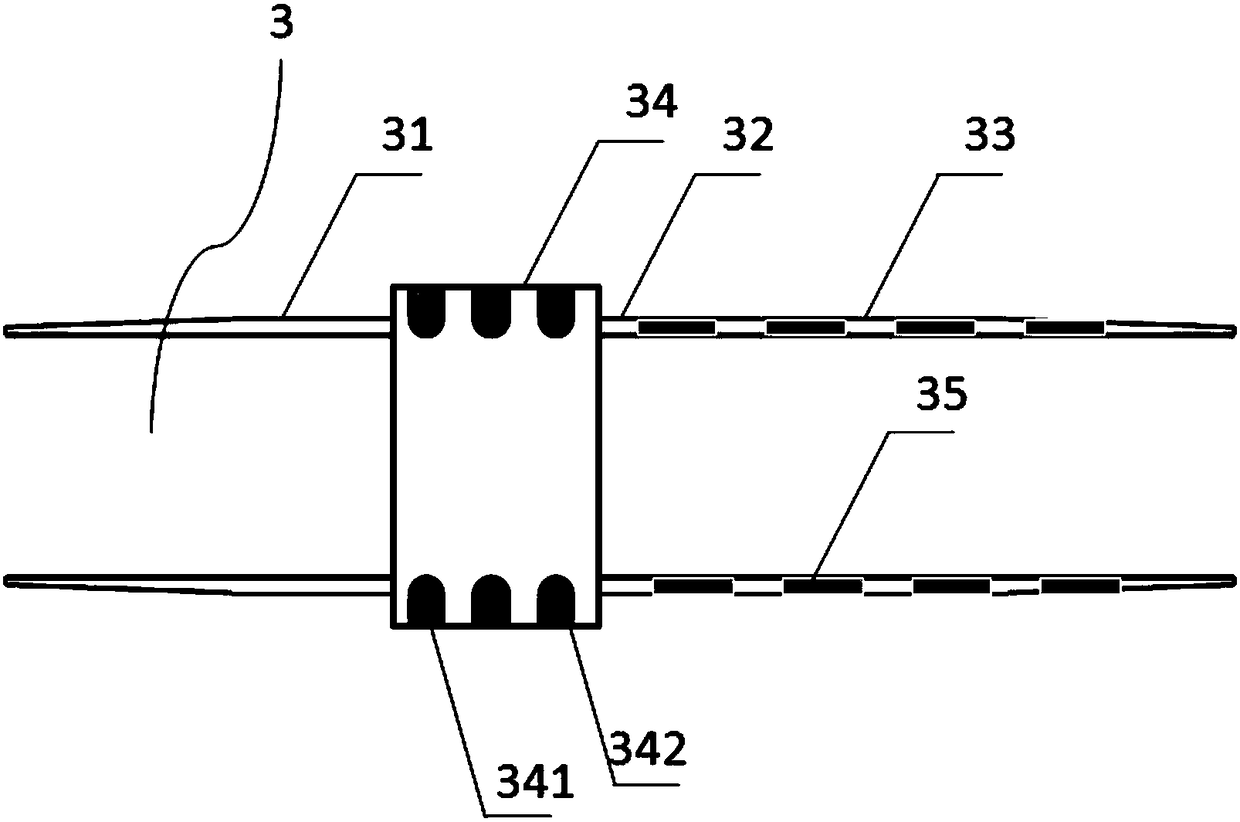

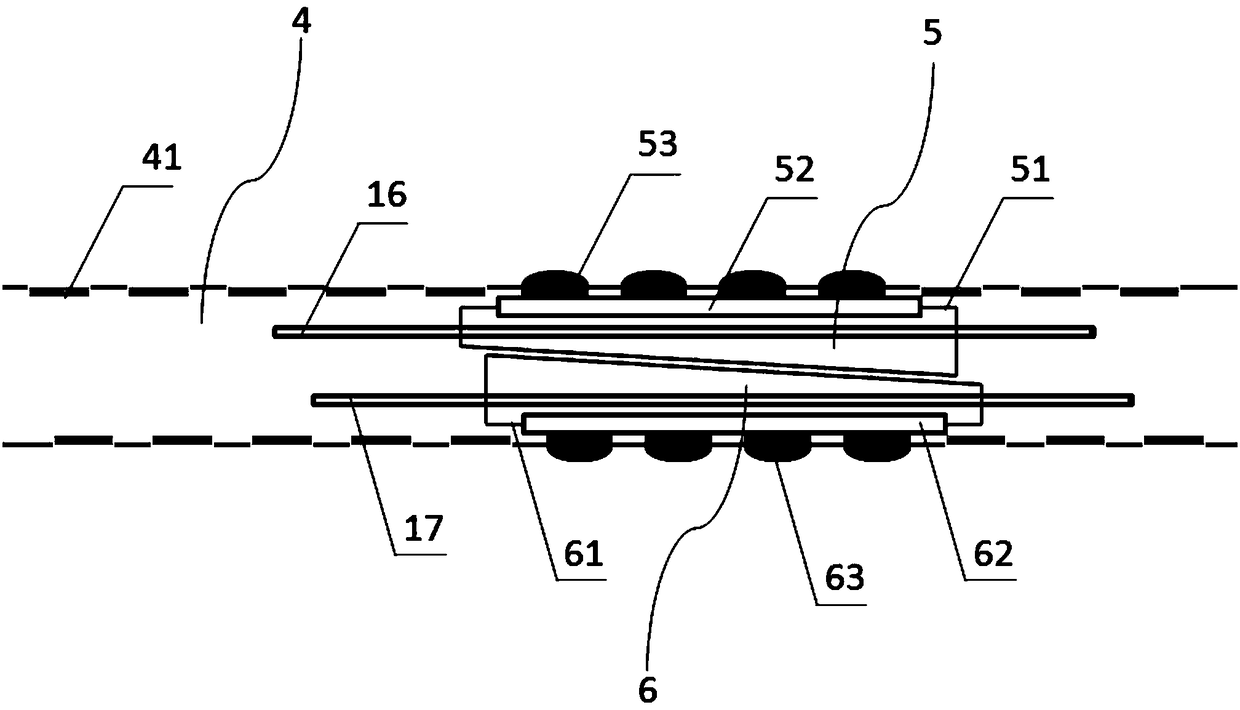

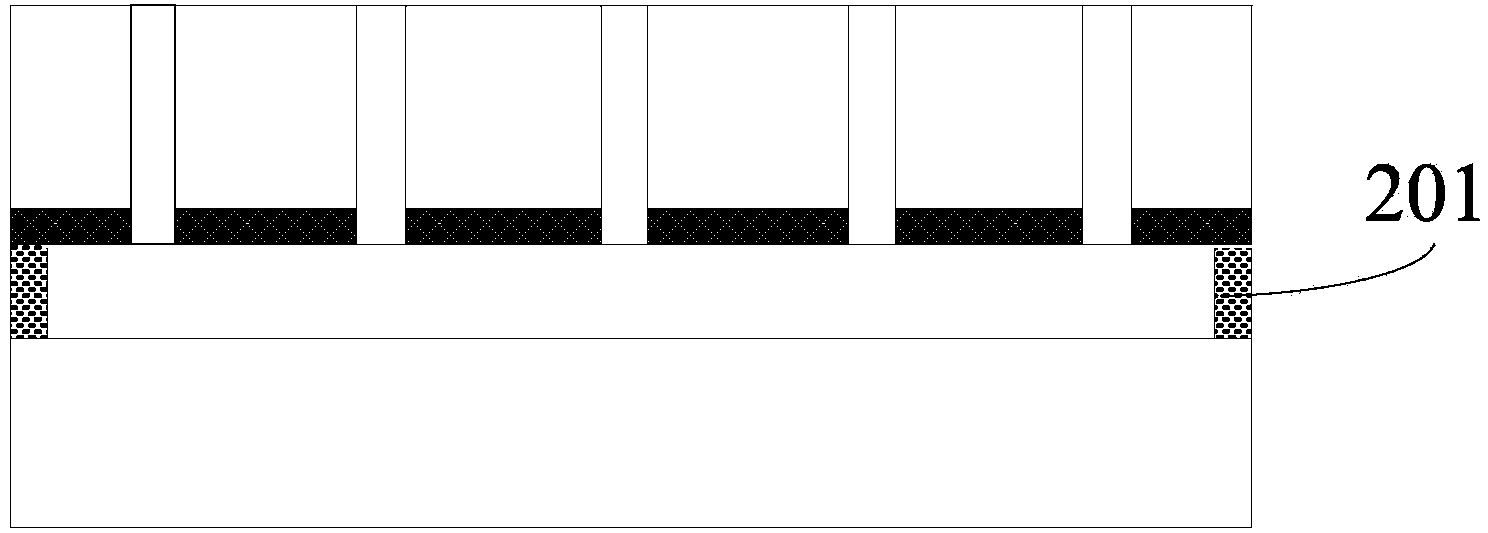

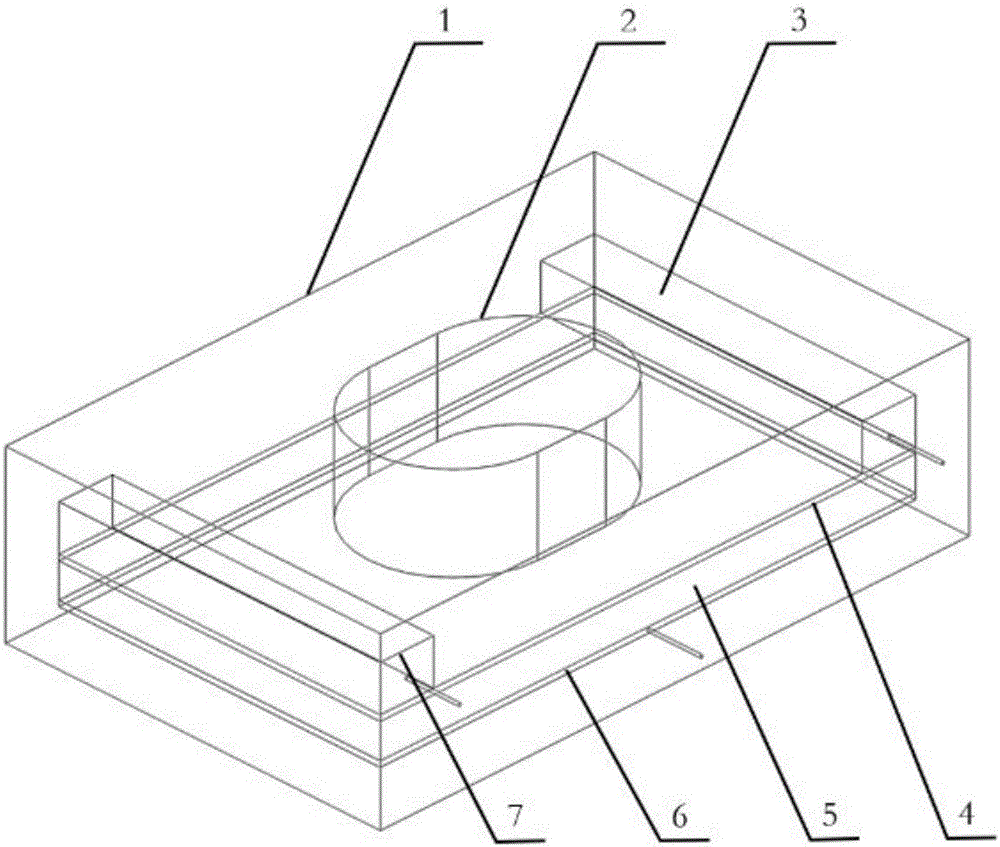

Dielectric metasurface collimating lens matched with terahertz photoconductive antenna in use

InactiveCN107317117AImprove transmittanceReduce complexity and cumbersomenessAntennasMicrostructurePhason

The invention relates to a terahertz waveband dielectric metamaterial, and aims to design and produce a device with a small size, easy integration and higher transmission efficiency for improving the flexibility of a photoconductive antenna-based terahertz time-domain spectral system, so as to replace a silicon lens and a paraboloidal mirror or a silicon lens and a terahertz lens. A technical scheme is adopted as follows: a dielectric metasurface collimating lens matched with a terahertz photoconductive antenna in use consists of two parts: a substrate layer and a two-dimensional microstructure layer, wherein the substrate layer is an isotropous high-resistance silicon layer with uniform thickness; the substrate layer is used for providing mechanical support for the two-dimensional microstructure layer, and the two-dimensional microstructure layer is also made from high-resistance silicon; the two-dimensional microstructure layer is formed by tetragonal lattices of cylindrical structures in arrangement similar to a concentric annulus way; and the cylindrical structures of different diameters have different modulation depths on phases, and the cylindrical structures on the same ring of the concentric annulus are the same in diameters. The dielectric metasurface collimating lens is mainly applied to design and manufacturing of the device with higher transmission efficiency.

Owner:TIANJIN UNIV

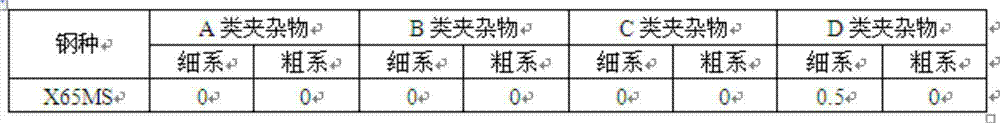

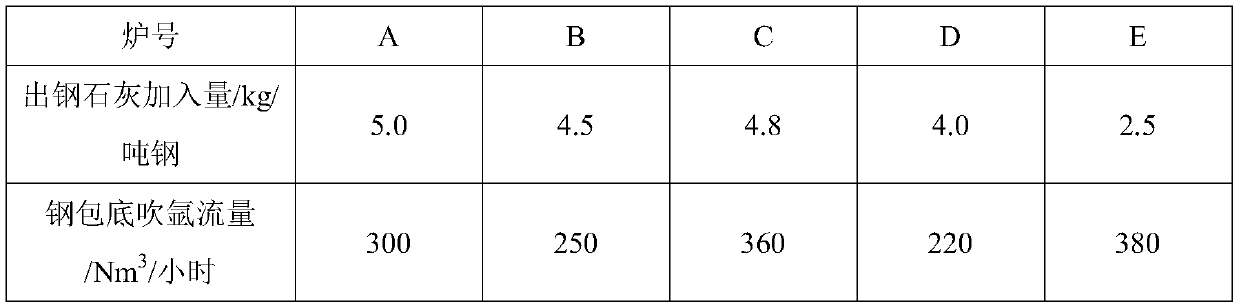

Method for controlling non-metallic slag inclusion in medium and heavy plate of hydrogen-induced cracking resistance pipe line steel

InactiveCN102732666ARealize industrializationAchieve batchManufacturing convertersSteelmakingCrack resistance

The invention provides a method for controlling non-metallic slag inclusion in a medium and heavy plate of a hydrogen-induced cracking resistance pipe line steel, belonging to a technical field of steel-making. Process route of the method is: converter steelmaking, ladle furnace refining RH vacuum refining, Ca processing, soft blow and killing, and continuous casting. Characteristics of the technology are: controlling contents of carbon and oxygen at a smelting end-point of the converter, adding a strong aluminum deoxidizer in a tapping process; adding high alkalinity refining slag in the ladle furnace refining process, and controlling flow and time of bottom-blowing argon and components of the refining slag; controlling increase of the argon flow and vacuum treatment time in the RH vacuum refining process; controlling [Ca] content in steel in the Ca processing process; controlling the flow and time of the soft blow liquid steel and the killing time; and adopting full protection casting in the continuous casting process. The method provided in the invention has the advantages that: by adopting the technology, requirement of the non-metallic slag inclusion in the hydrogen-induced cracking resistance pipe line steel is satisfied; according to GB / T10561-2005 criterion for the non-metallic slag inclusion in the steel, various non-metallic slag inclusions in the steel are controlled within 0.5 grade; adopting a NACE standard A solution to carry out a detection of anti-HIC performance to the medium and heavy plate rolled by the casting blank, and the detection result of anti-HIC performance is qualified; and realizing batch and stable production of the medium and heavy plate in the hydrogen-induced cracking resistance pipe line steel.

Owner:SHOUGANG CORPORATION

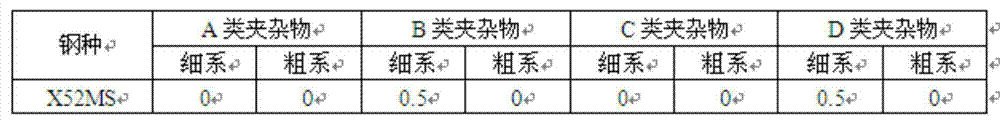

Smelting process of hydrogen-induced cracking resistant vessel steel

ActiveCN104498663AStable productionRealize industrializationManufacturing convertersProcess efficiency improvementSteel platesPre treatment

The invention discloses a smelting process of hydrogen-induced cracking resistant vessel steel, and belongs to the technical field of steelmaking. The process route is molten iron pretreatment, converter smelting, ladle furnace refining, RH vacuum refining and continuous casting. The process has the characteristics that key factors for affecting the hydrogen-induced cracking resistance of the vessel steel are successfully controlled through control on various links of in the smelting process; according to the final product, the target carbon content is stably controlled at + / -0.01%; the super-low sulfur content [S] is smaller than or equal to 0.0010%; the low-hydrogen content [H] is smaller than or equal to 1.5ppm; the rating control of various occluded foreign substances is smaller than or equal to 0.5; and the center segregation level of a continuously cast bloom is not higher than class C 1.0. The smelting process has the advantages that smelting of the hydrogen-induced cracking resistant vessel steel is achieved; the target carbon content is stably controlled at + / -0.01%; the super-low sulfur content [S] is smaller than or equal to 0.0010%; the low-hydrogen content [H] is smaller than or equal to 1.5ppm; the rating control of various occluded foreign substances is smaller than or equal to 0.5; the center segregation level of a continuously cast bloom is not higher than class C 1.0; according to a steel plate rolled by a casting blank, the hydrogen-induced cracking resistance is qualified in detection by virtue of an NACE standard; and industrialized, massive and stable production of the hydrogen-induced cracking resistant vessel steel is achieved.

Owner:SHOUGANG CORPORATION

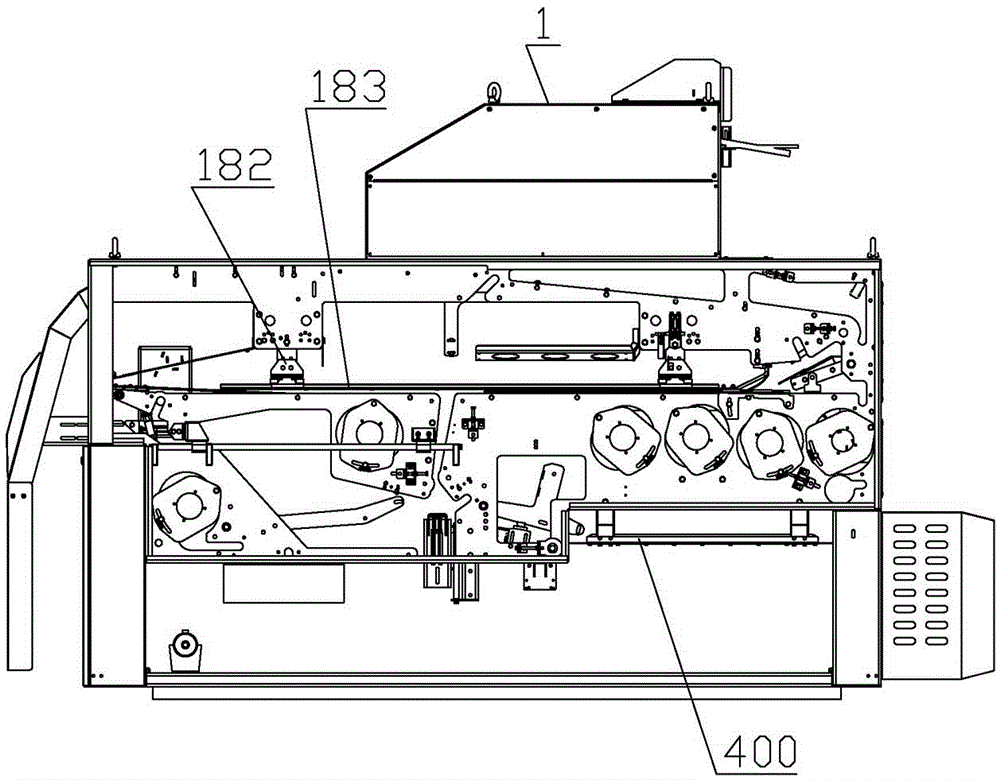

Working clothes folding machine

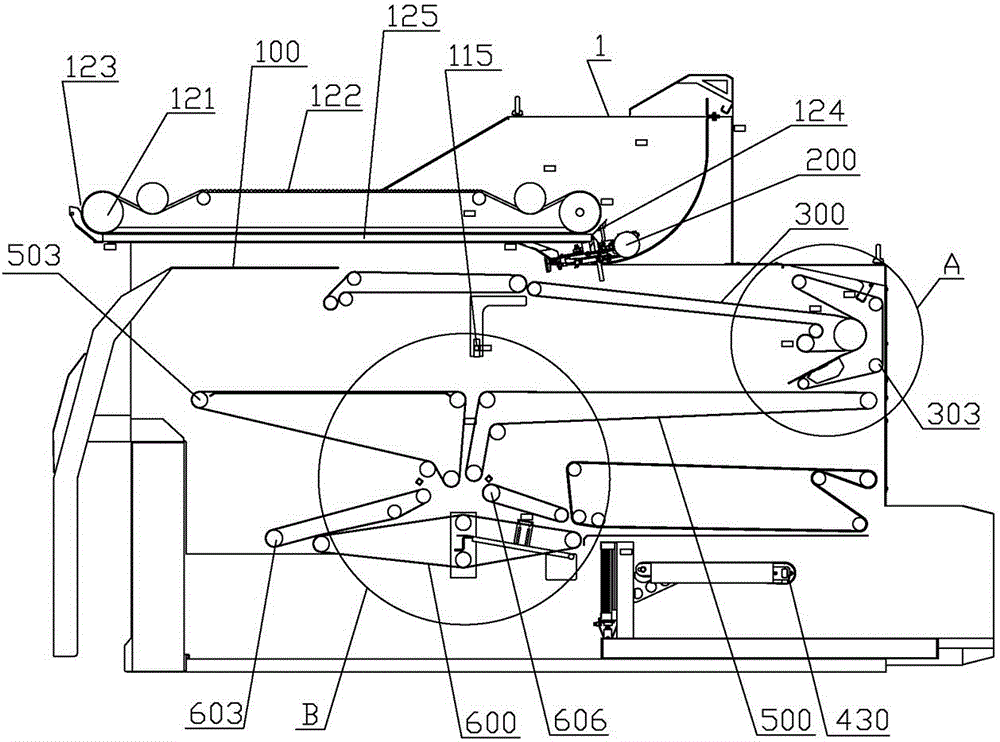

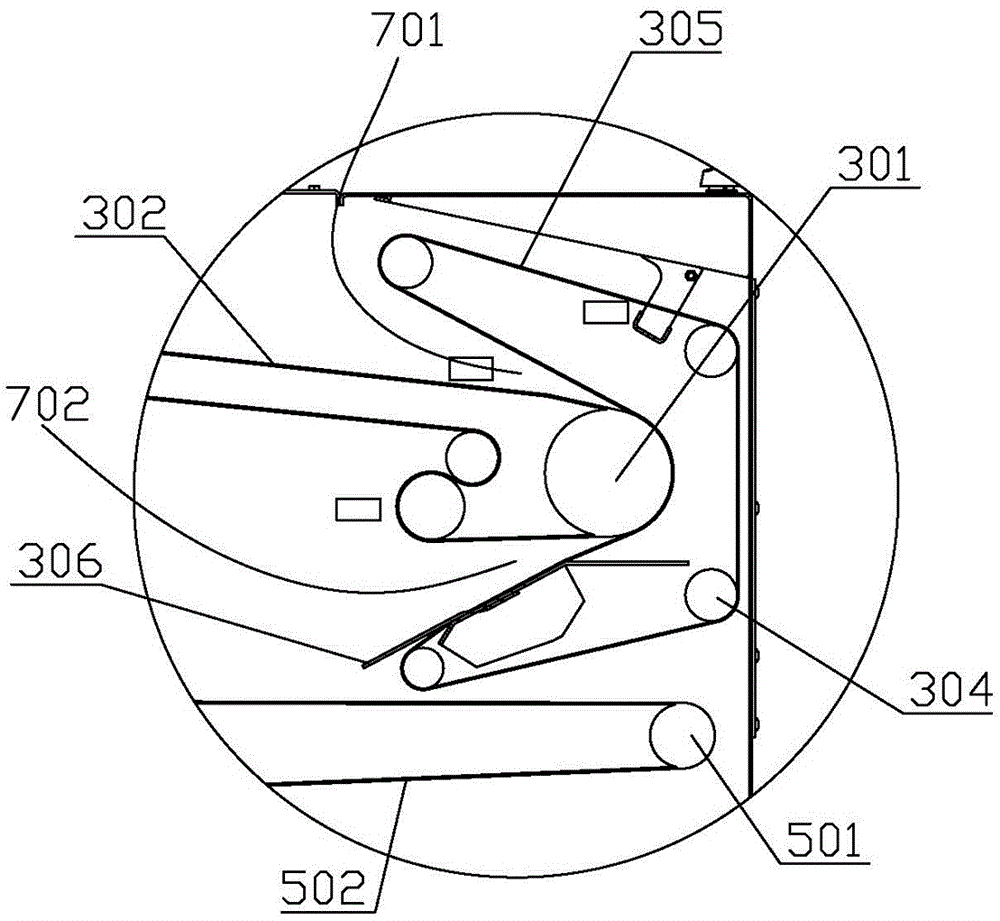

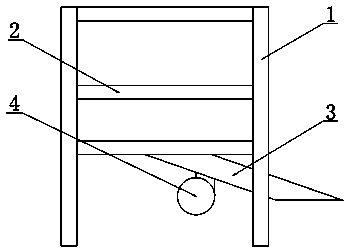

ActiveCN105586762AImprove flatnessEnsure consistencyIroning apparatusFolding thin materialsClothes hangerMechanical engineering

The invention discloses a working clothes folding machine. A sleeve folding device capable of crosswise folding two sleeves of working clothes at the back of the working clothes is arranged at the feeding place of a rack body, the back side of the sleeve folding device is provided with a first conveying device, a clothes hanger separating device for separating a clothes hanger in the working clothes from the working clothes is arranged between the sleeve folding device and the first conveying device, the first conveying device can receive the working clothes output from the sleeve folding device, and a multi-folding conveying device is arranged under the first conveying device and can fold the working clothes for at least one time; the back side of the first conveying device is provided with a transfer device for transferring the working clothes output from the first conveying device to the multi-folding conveying device. The working clothes folding machine can automatically folding the working clothes and ensure the flatness and uniformity of the folded working clothes.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

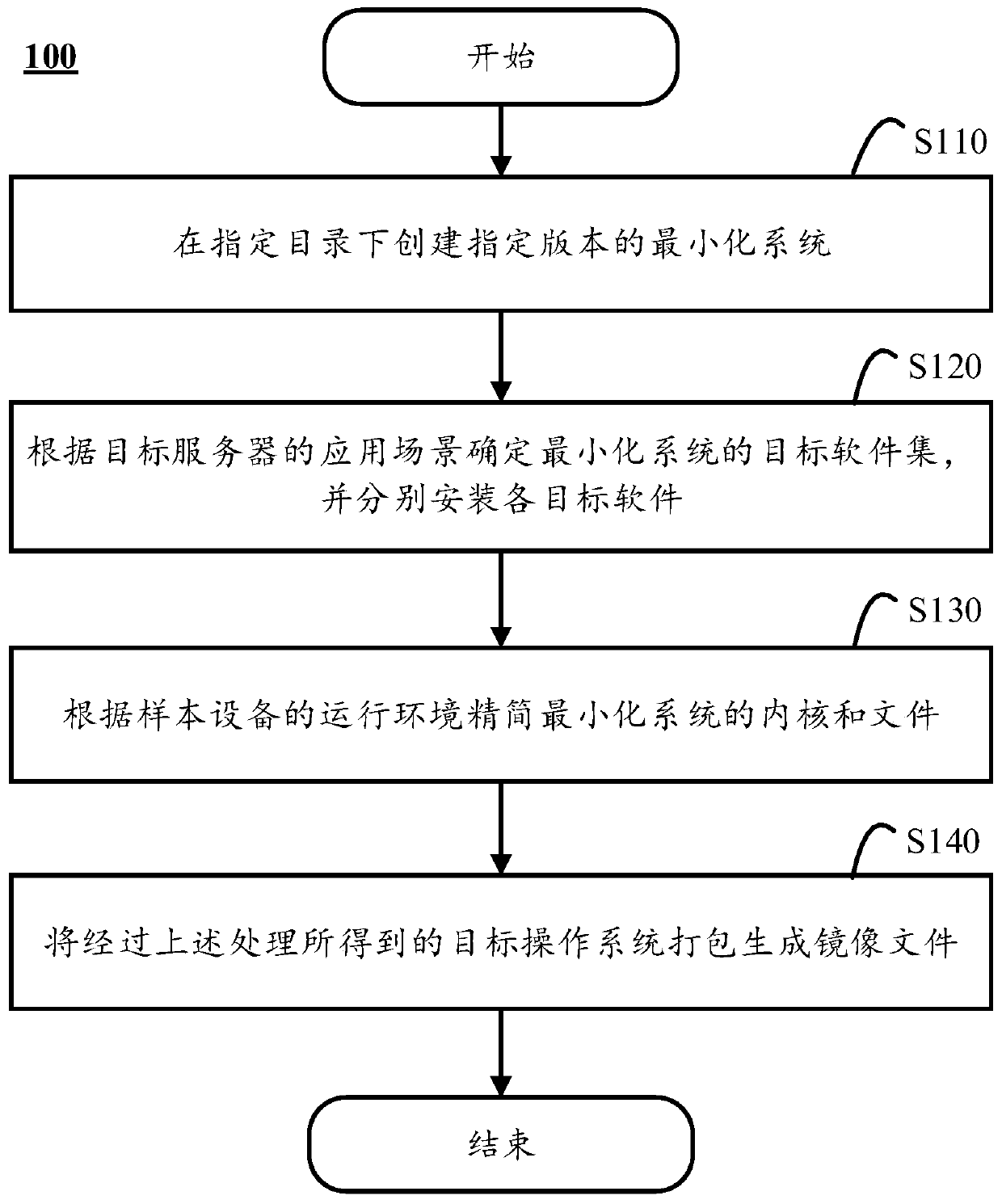

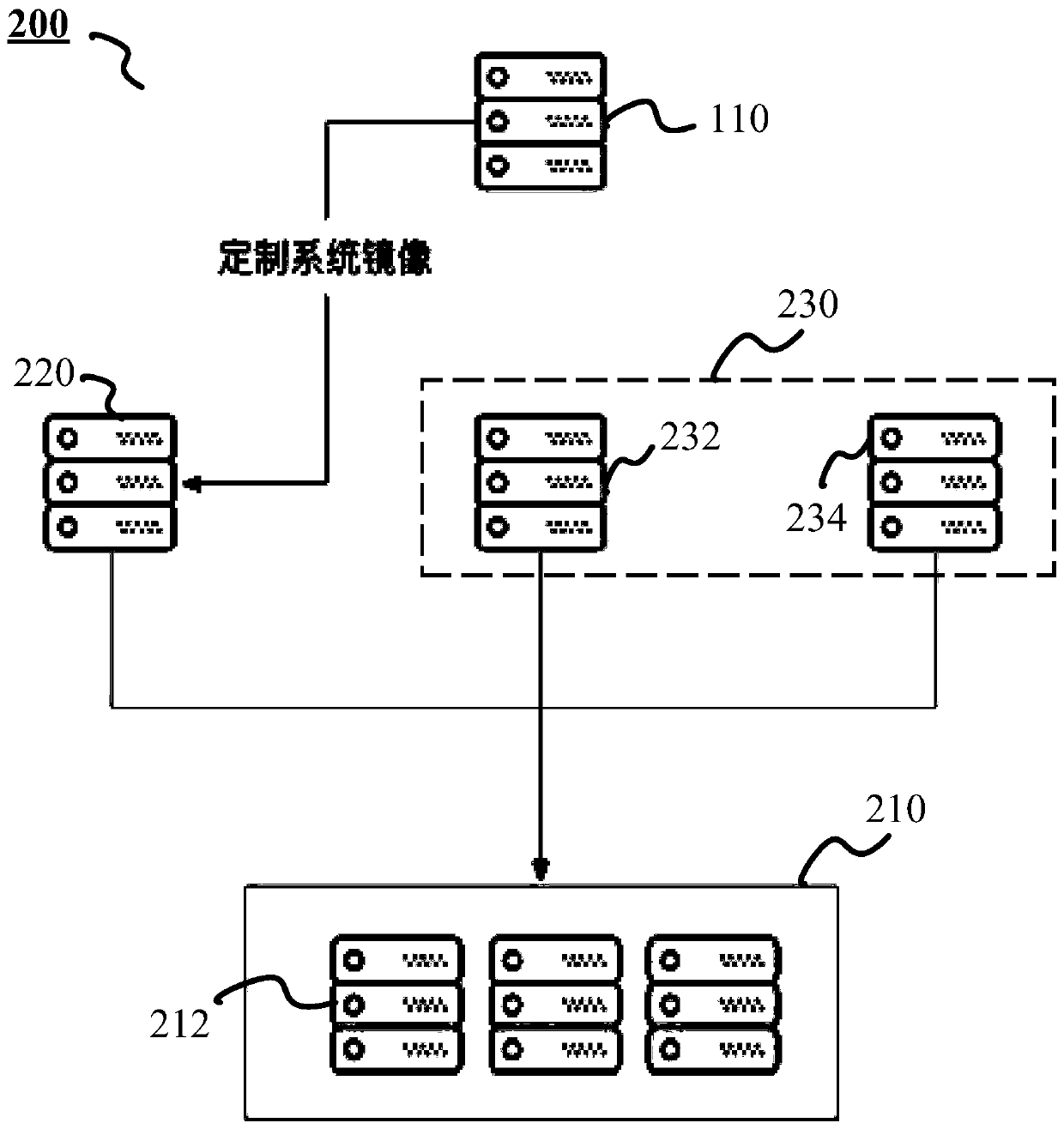

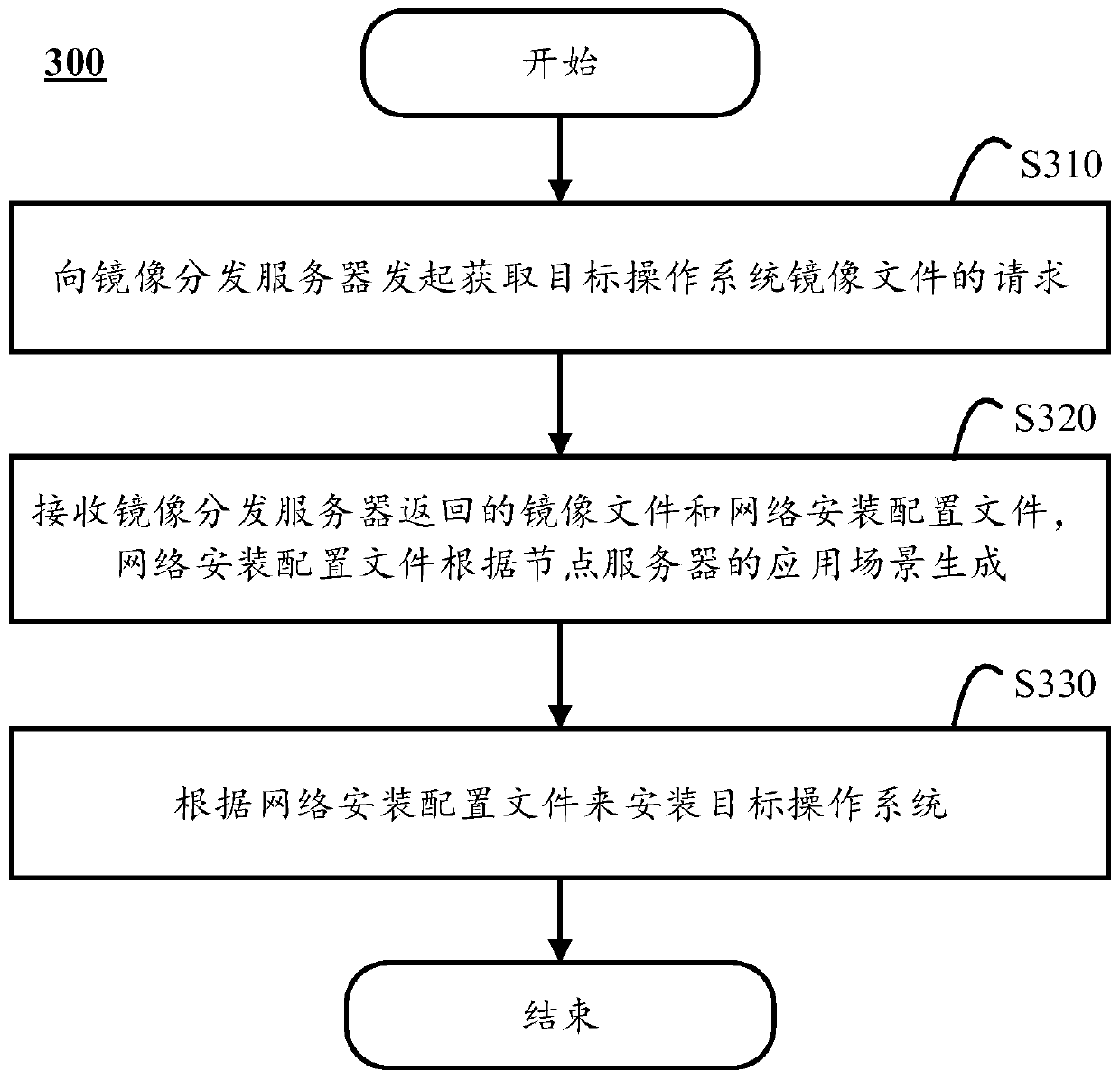

Operating system customization method, batch deployment method and batch deployment system

ActiveCN110825392AReduce customization complexityImprove customization efficiencyBootstrappingProgram loading/initiatingOperational systemDirectory

The invention discloses an, which is executed in sample equipment and is suitable for generating a target operating system suitable for a target server, the similarity of hardware environments of thesample equipment and the target server is greater than a threshold value, and the method comprises the following steps of: creating a minimization system of a specified version under a specified directory; determining a target software set of the minimization system according to the application scene of the target server, and respectively installing the target software; simplifying a kernel and afile of the minimization system according to the running environment of the sample equipment; and packaging the target operating system obtained by the processing to generate a mirror image file. Theinvention also discloses a corresponding batch deployment method and a batch deployment system of the operating system.

Owner:中国人民解放军战略支援部队第五十六研究所 +1

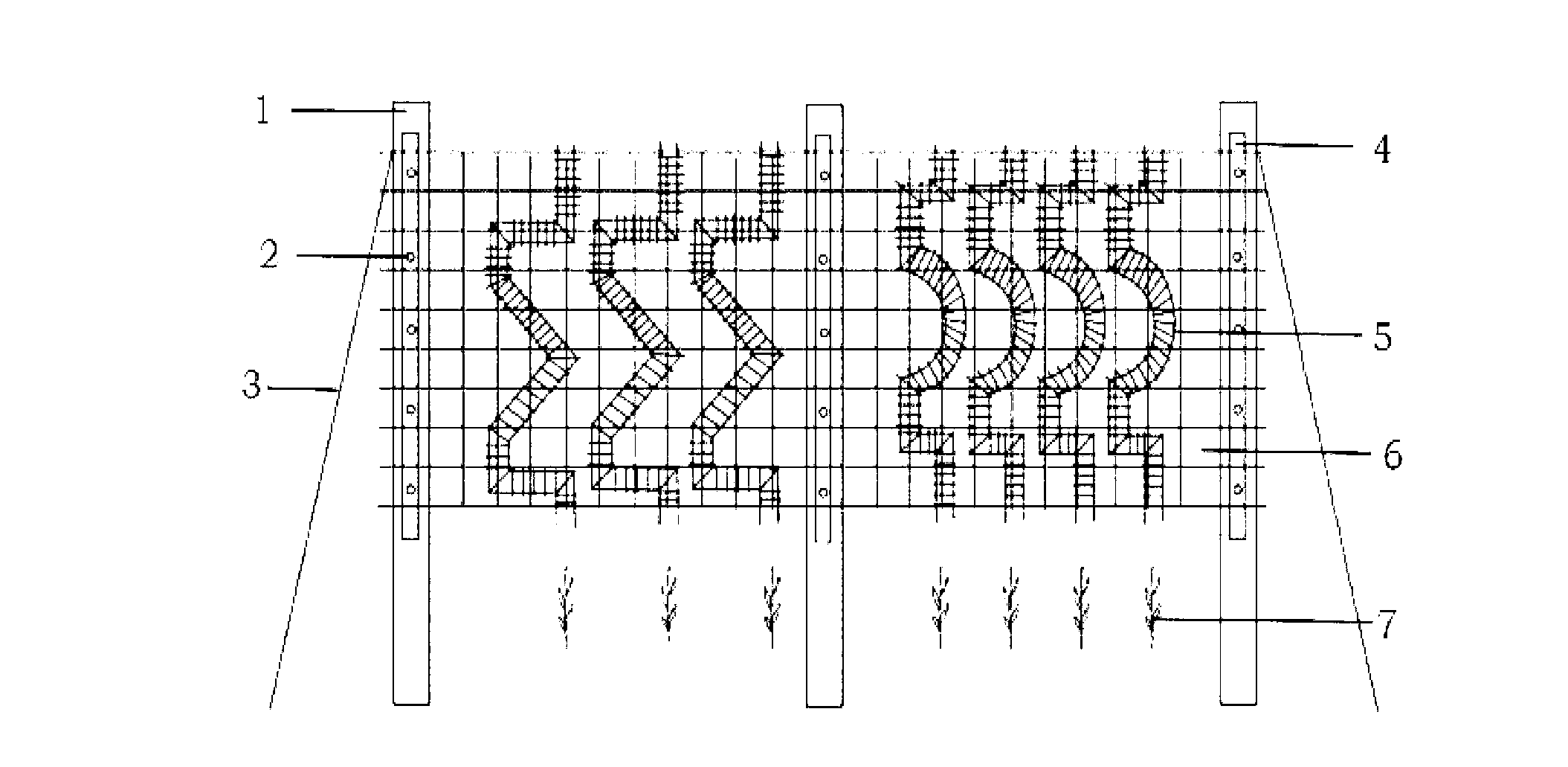

Method for shaping scaling ladder type plastic-dipped metal rack tree

ActiveCN103009907AEasy to operateEasy to shapeSpecial ornamental structuresRetention periodEngineering

The invention discloses a method for shaping a scaling ladder type plastic-dipped metal rack tree. The method mainly comprises the following steps of: (1) designing special parameters of a tree shape, destructing a certain quantity of single plants according to corresponding parameters, and manufacturing a tree cultivation shape technical pattern of the corresponding single plants; (2) manufacturing and mounting a scaling ladder type plastic-dipped metal rack and a supporting frame, so as to manufacture a tree cultivation template; (3) planting shaped nursery stocks in a nursery cultivation field below the scaling ladder type plastic-dipped metal rack; (4) when a tree grows to an oriented tree cultivation height, binding tree twigs on the tree cultivation template in an oriented manner; and (5) carrying out shaped nursery stock management, mainly including bud fixing, bud picking, binding and unbundling, and thickening cultivation. The method provided by the invention has the advantages of simpleness in operation, good shaping effect and long shaping retention period; the ornamental value is improved, and the watch time is prolonged; the scaling ladder type plastic-dipped metal rack and the supporting frame are durable, and can be continuously shaped for many years, so that the requirement of a shaping length can be met; the polarized shaping can be realized; the trees are prevented from being damaged; and the standard scale production can be realized by accurately shaping according to the pattern.

Owner:TONGREN MANTANGHONG AGRI TECH

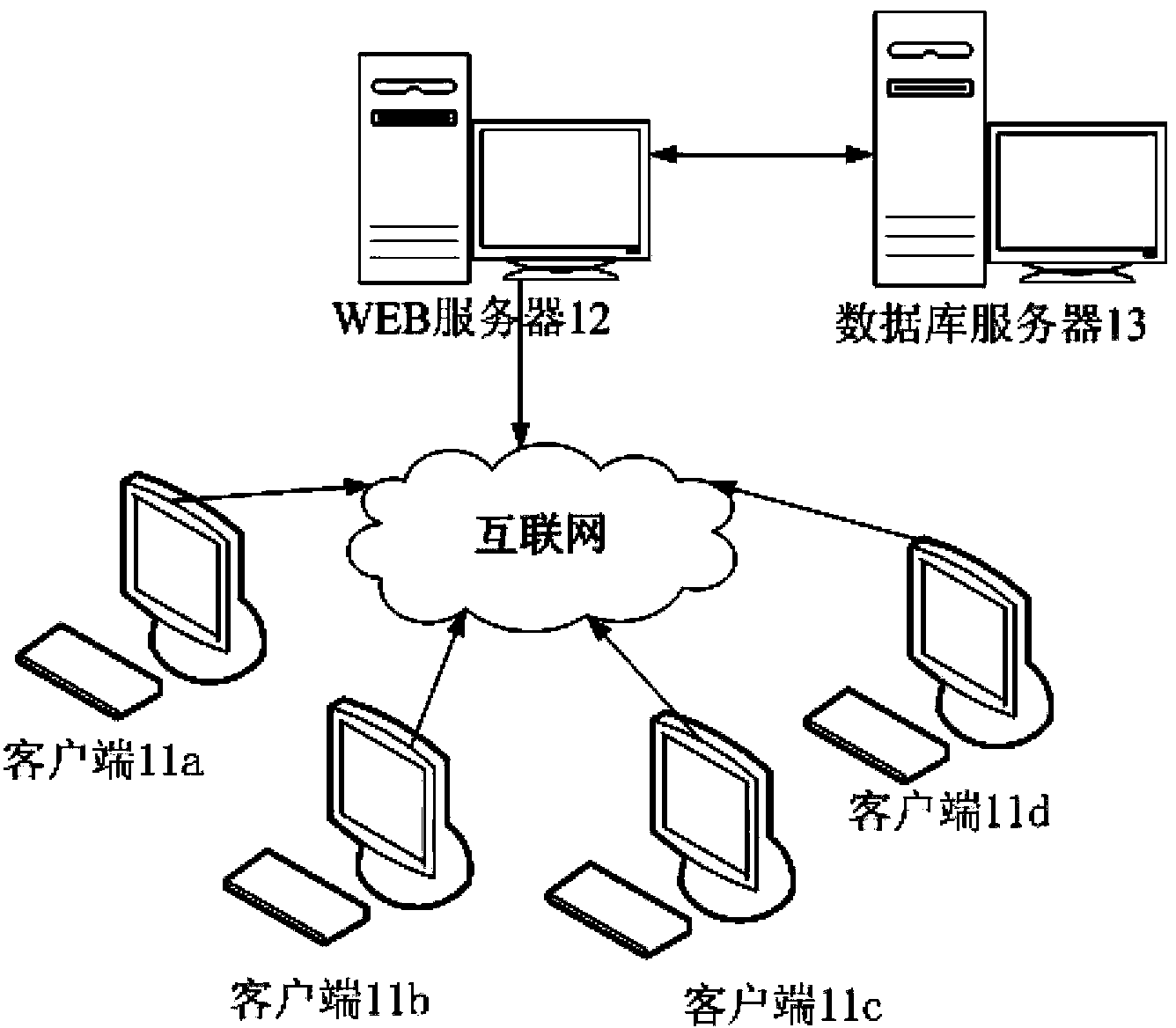

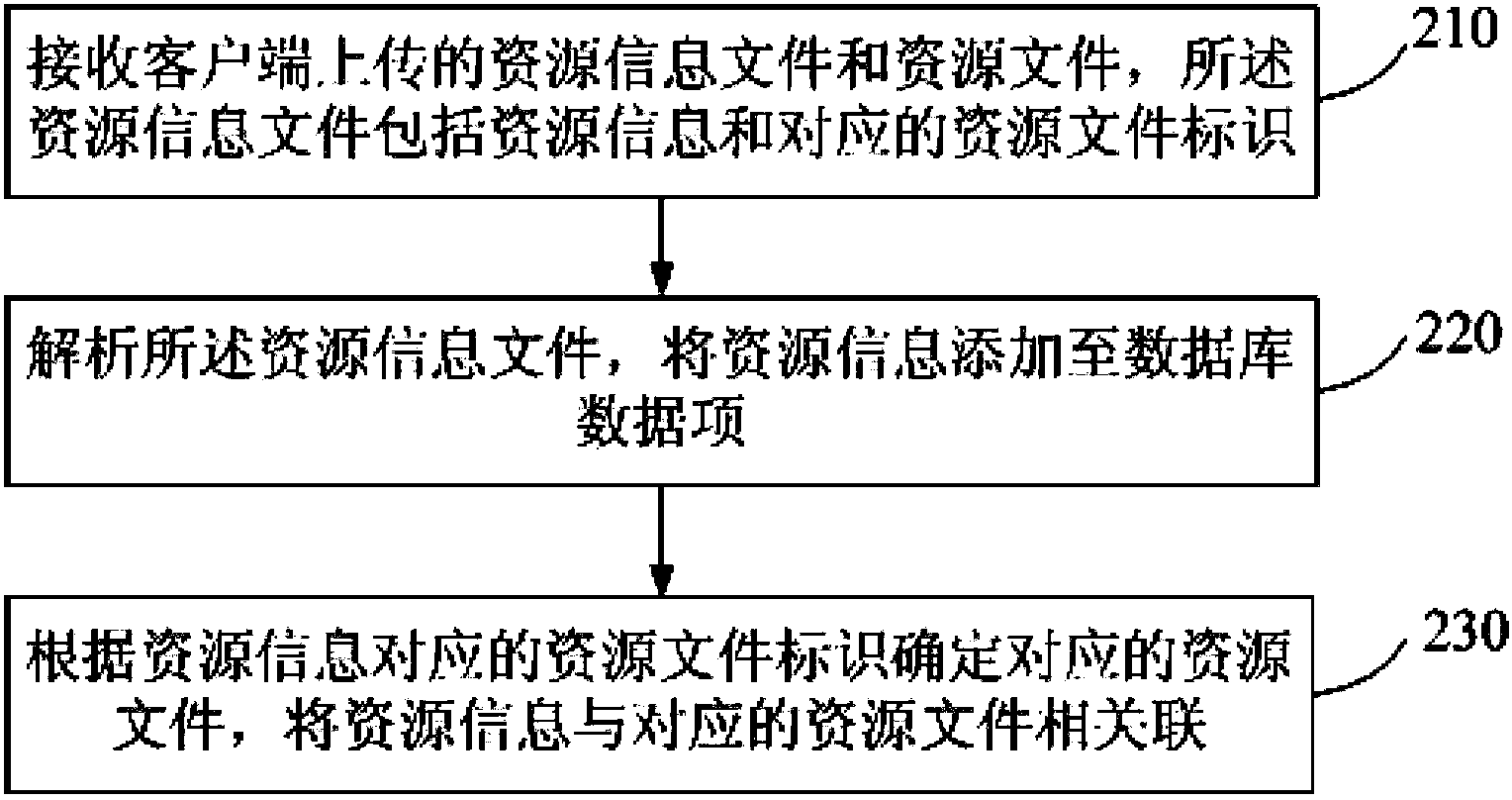

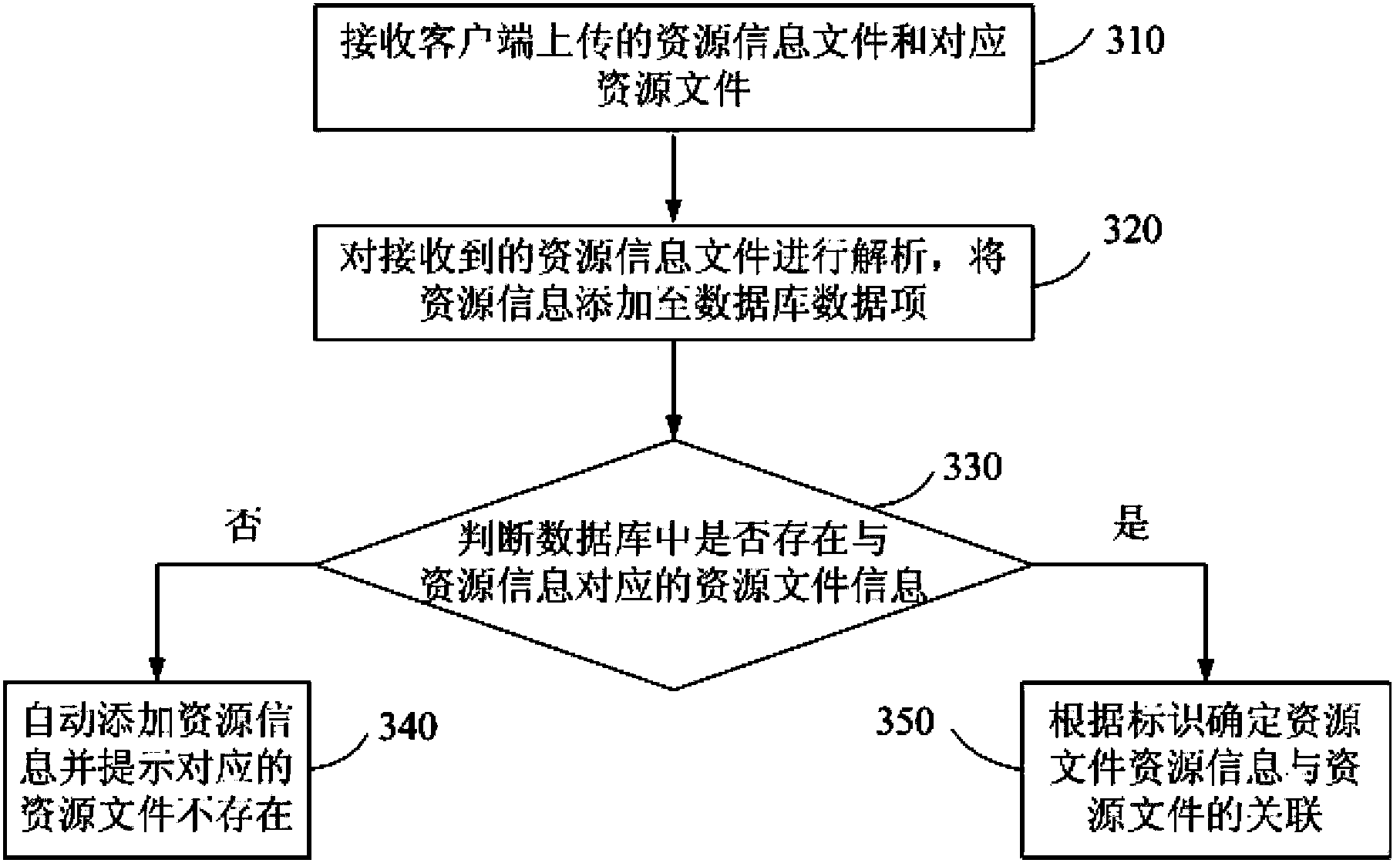

Method and system for batch uploading resource information and corresponding resource file

ActiveCN103401933AQuick uploadUpload efficientTransmissionSpecial data processing applicationsResource informationData library

The invention discloses a method and a system for batch uploading resource information and a corresponding resource file. The method comprises the following steps of receiving a resource information file and the resource file which are uploaded by a client, wherein the resource information file comprises the resource information and a corresponding resource file identifier; analyzing the resource information file and adding the resource information to a database data item; determining the corresponding resource file according to the resource file identifier of the resource information, and correlating the corresponding database item of the resource information with the corresponding resource file. By the method disclosed by the invention, the batch upload of the resource information and the corresponding resource file is effectively realized; the batch input after the resource information is uploaded is realized; the resource file is automatically correlated with the resource information; and the working efficiency is improved.

Owner:TIANWEN DIGITAL MEDIA TECH HUNAN

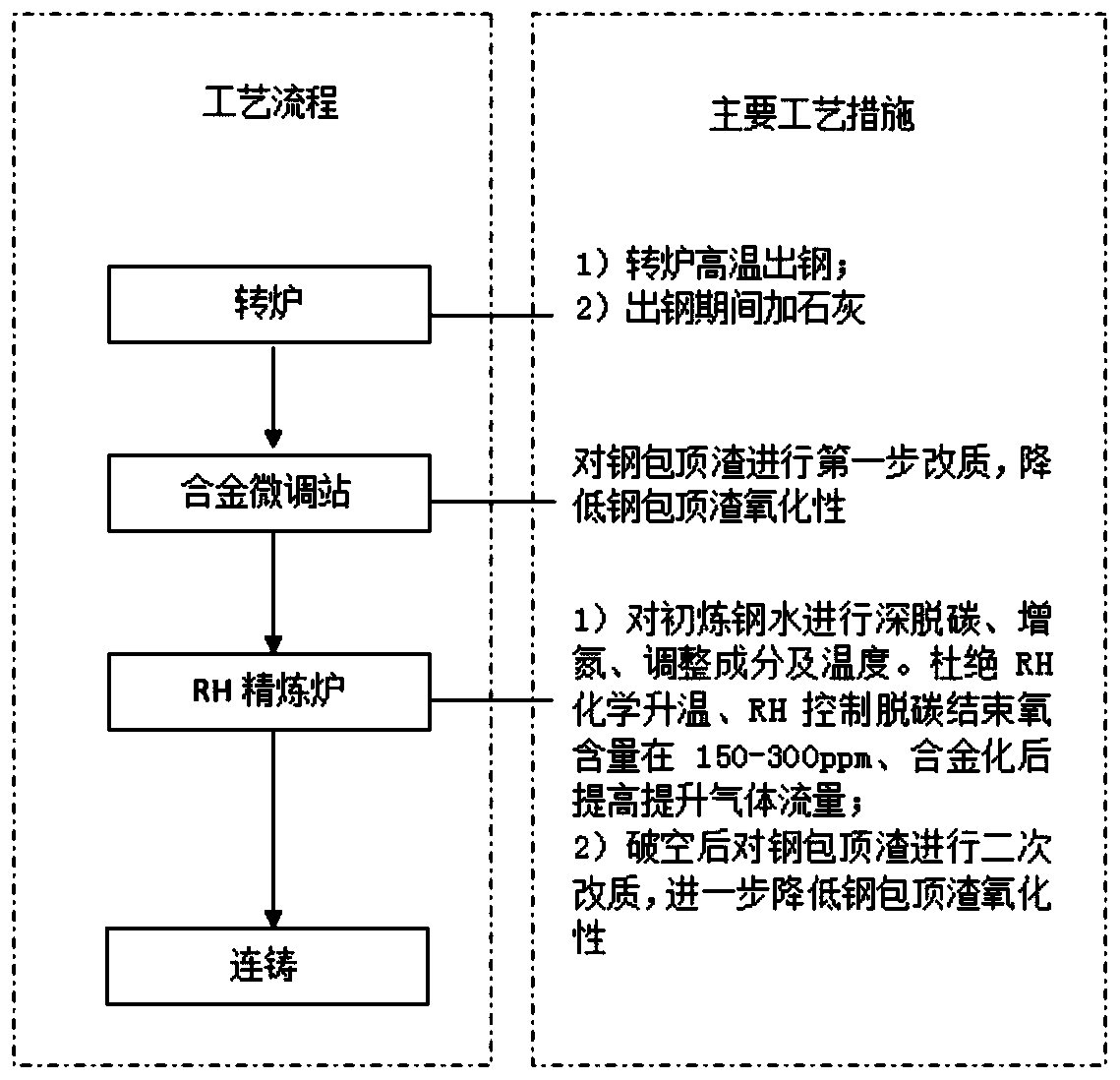

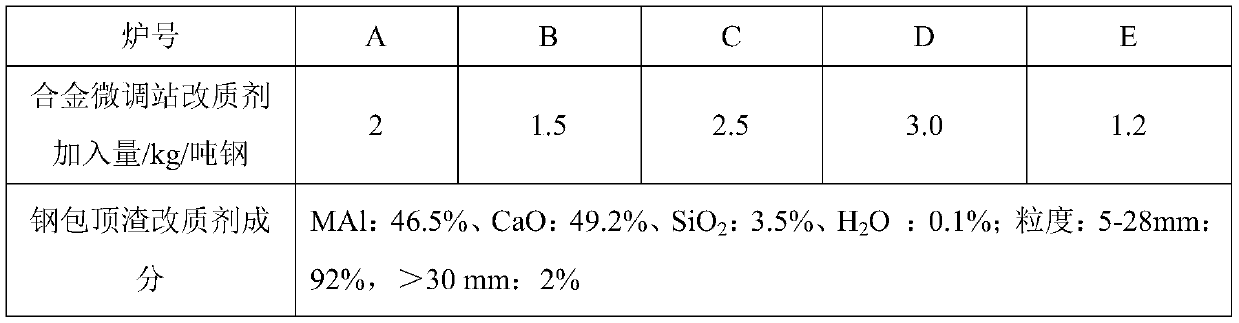

External refining method capable of increasing continuous casting heats of ultra-deep drawing cold-rolled enamel steel

The invention discloses an external refining method capable of increasing continuous casting heats of ultra-deep drawing cold-rolled enamel steel. The external refining method comprises the following steps: smelting molten iron and waste steel into primarily molten steel; performing first-step modifying on steel ladle slag in an alloy fine-tuning station process; performing decarburization and nitrogen pickup after RH molten steel is circulated, starting to measure oxygen before decarburization starts, adding aluminum particles to perform deoxidizing and alloying after decarburization is ended, and adding a steel ladle slag modifying agent to perform secondary modifying after performing RH vacuum-breaking. The external refining method disclosed by the invention increases continuous casting heats of ultra-deep drawing cold-rolled enamel steel to five-heat casting from three-heat casting with an increase rate of 66.7%, realizes batch, efficient and stable production of ultra-deep drawing cold-rolled enamel steel, and has remarkable economic benefits.

Owner:MAANSHAN IRON & STEEL CO LTD

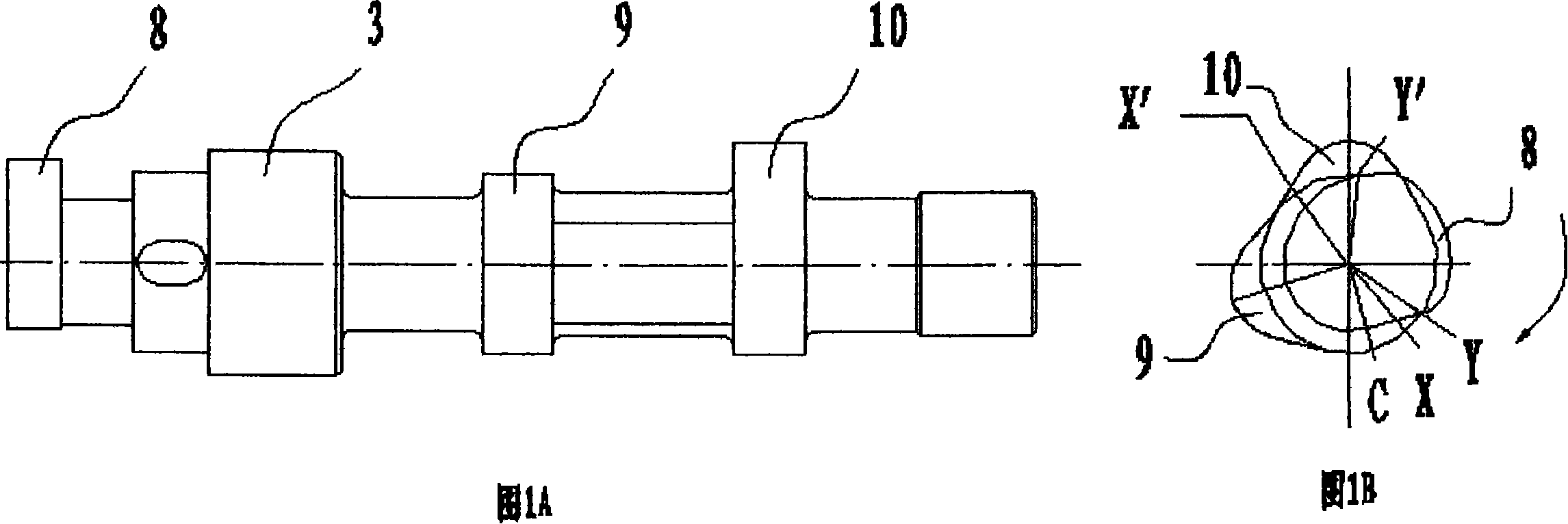

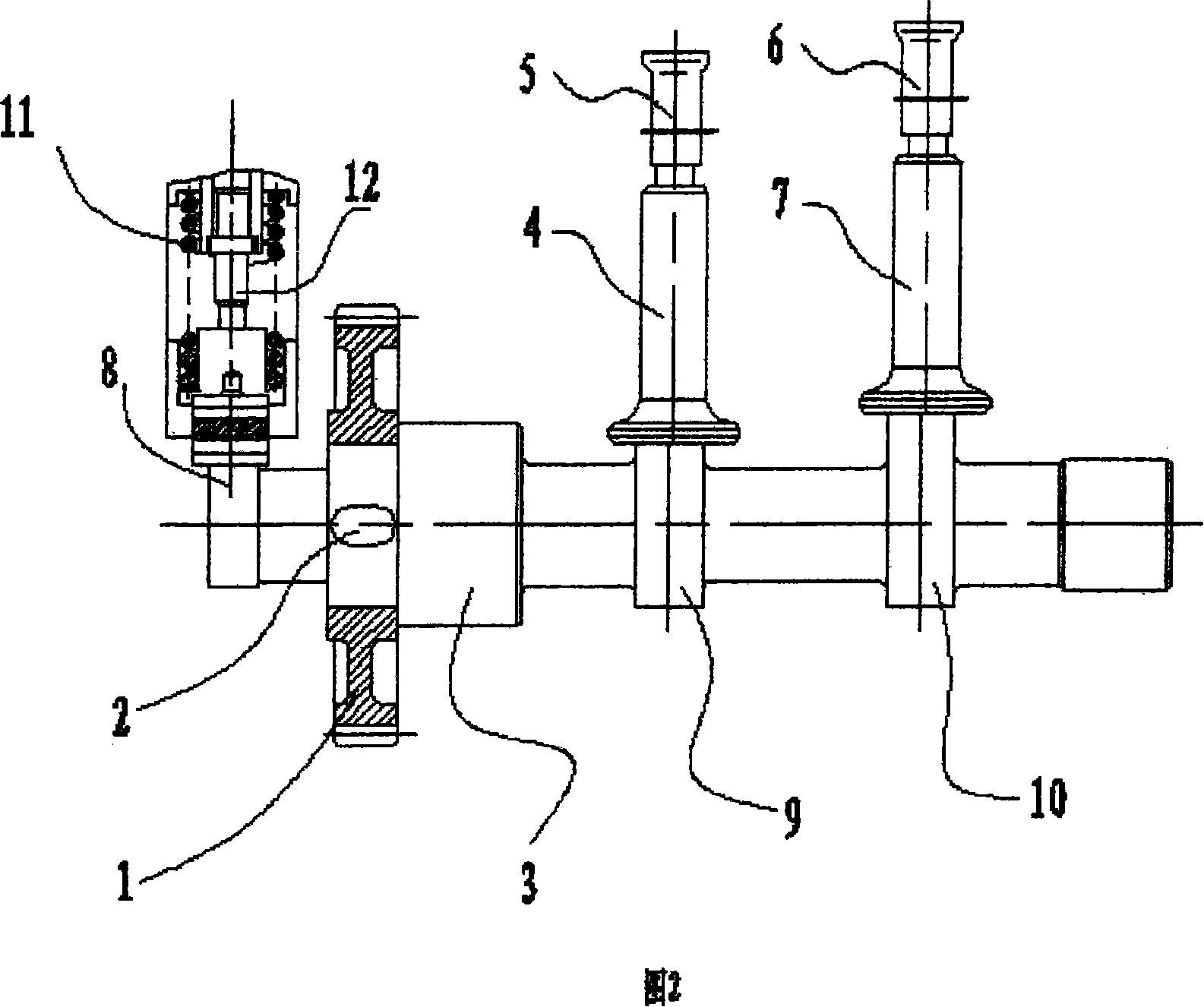

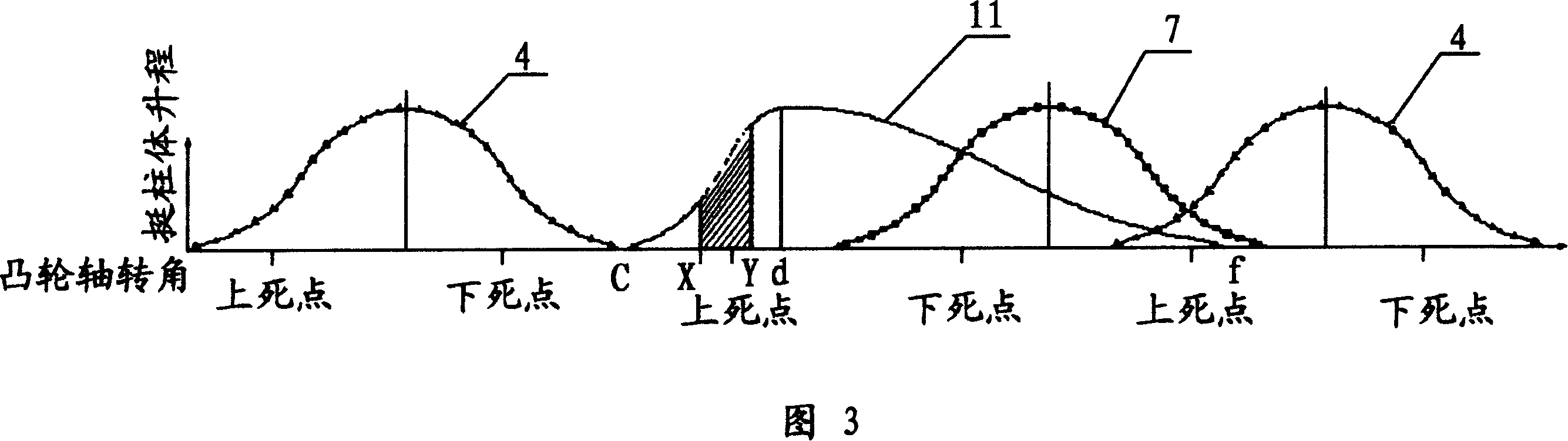

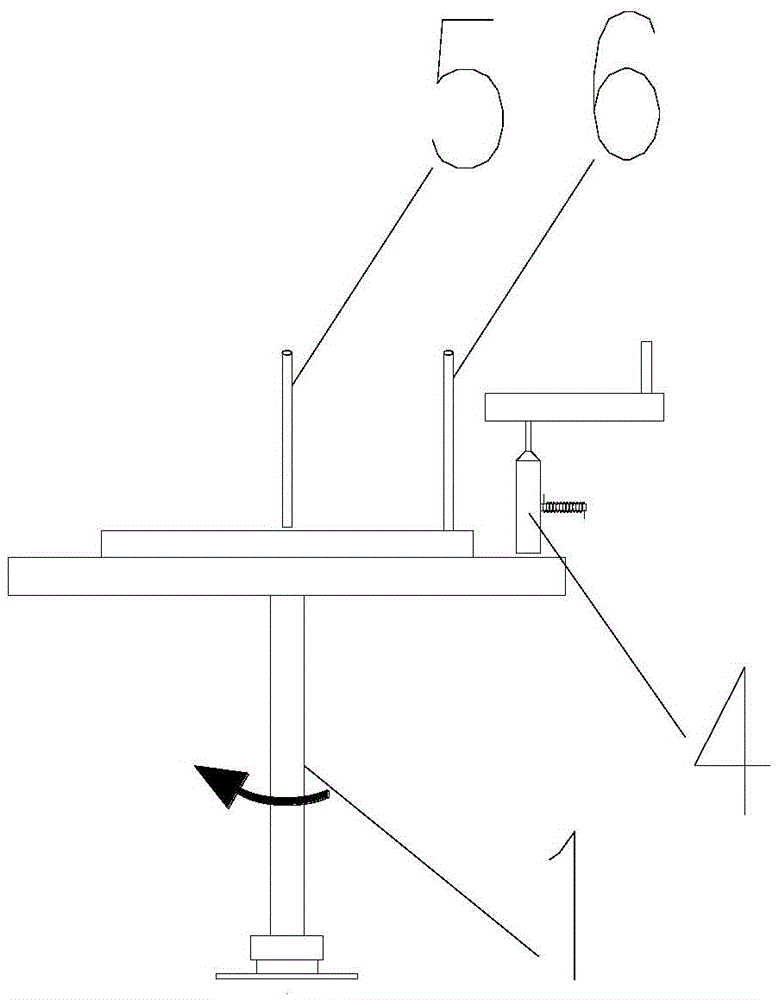

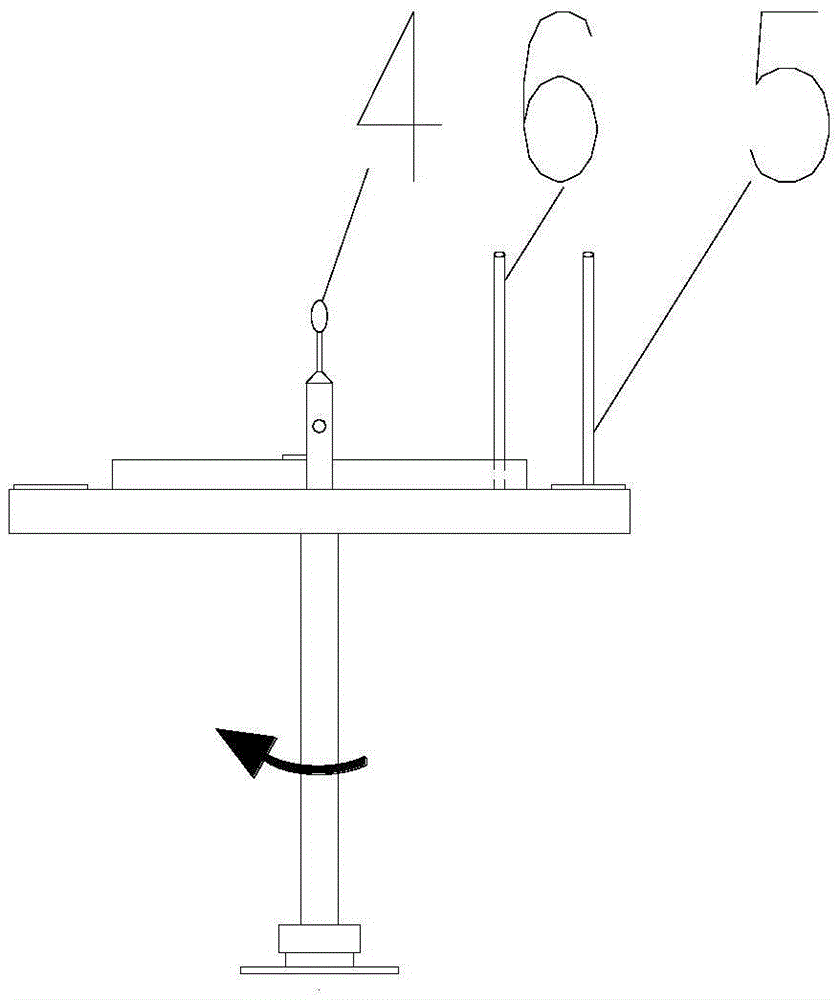

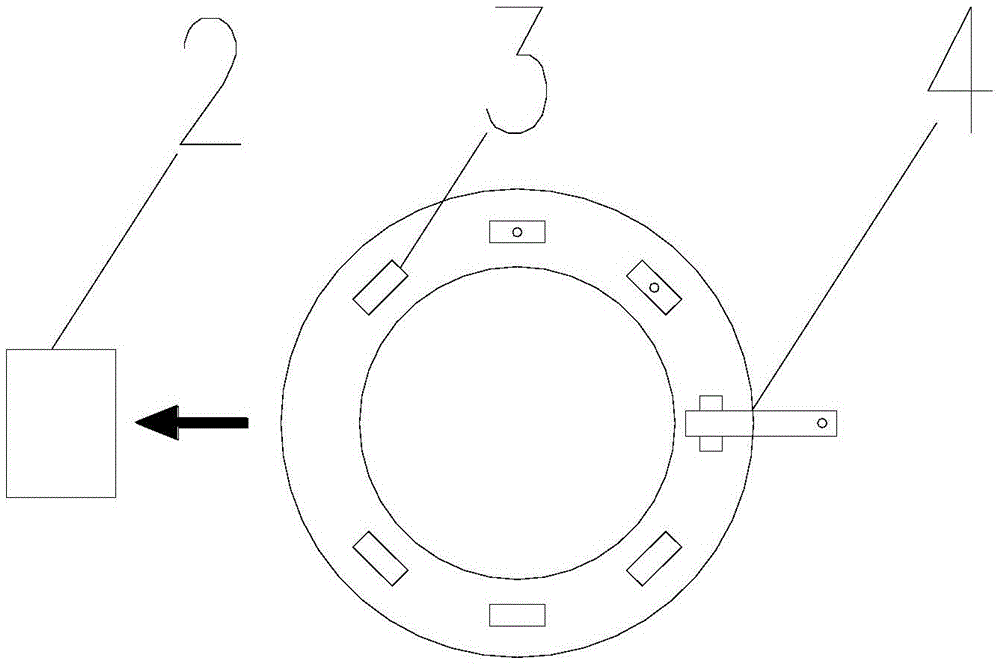

Reversal firing resisting single-cylinder diesel engine and reversal firing resisting method for single-cylinder diesel engine

The invention relates to a single cylinder diesel which can prevent the reverse ignition and comprises a camshaft main body (3'), an oil pump cam (8'), an inlet cam (9'), an exhaust cam (10'); the oil pump cam (8') arranged on the camshaft main body (3') drives a high pressure oil pump, the high-pressure fuel is injected into a cylinder through an oil injector; the inlet cam (9') arranged on the camshaft main body (3') drives an inlet jib body (4') to actuate an inlet pushrod (5'), and drive a valve rocker to drive an inlet valve to open or close in time; The exhaust cam (10') arranged on the camshaft main body (3') drives the exhaust jib body (7'), to actuate an exhaust push rod (6') and drive an exhaust valve rocker to drive the exhaust valve to open or close in time; the invention is characterized in that when the diesel engine reverses to the oil injection state, any of the inlet valve or exhaust valve of the engine is in the open state.

Owner:JIANGSU NONGHUA WISDOM AGRICULTURAL SCIENCE AND TECHNOLOGY CO LTD +1

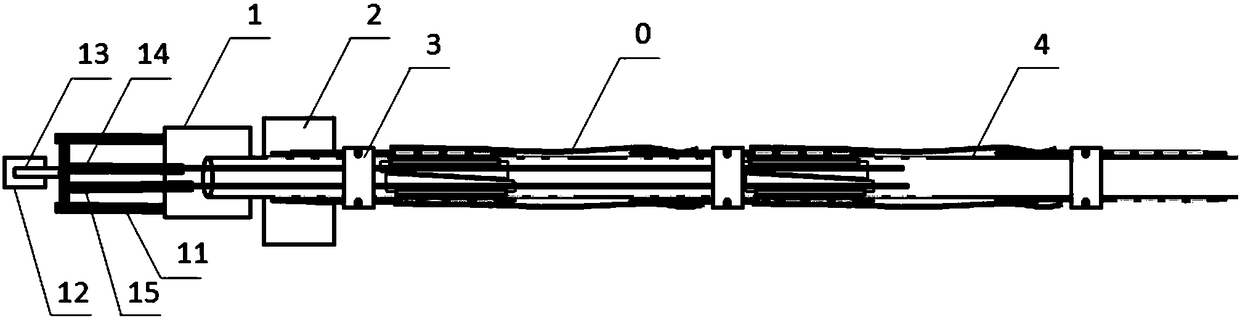

High performance liquid chromatography and Fourier transform infrared spectroscopy combined interface device

InactiveCN105606718ARealize complementary advantagesMake up for the lack of qualitative analysisComponent separationRotary stageBatch processing

The invention discloses a high performance liquid chromatography (HPLC) and Fourier transform infrared spectroscopy (FTIR) combined interface device, and belongs to the field of environmental studies. The device is composed of seven components: an optical table, a zinc selenide (ZnSe) crystal, a round drive rotary table, a heating casing pipe, an atomizer, a cleaning device and a drying device. A target pollutant enters a heating casing pipe and atomizer integrated device after being separated by a chromatography column, is heated and atomized, and then is evenly sprayed on the surface of the ZnSe crystal, and the ZnSe crystal is rotated to the optical table from the round drive rotary table. Infrared light enters the ZnSe crystal at a certain angle through the optical table, is reflected, then enters an FTIR detector and is subjected to atlas analysis. The ZnSe crystal having testing completed is transferred to the cleaning device and the drying device successively, is washed and dried respectively and then is re-used. The round rotary table carries the crystal and a sample for reciprocating detection by means of rotation, and sample batch processing and on-line detection are realized.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

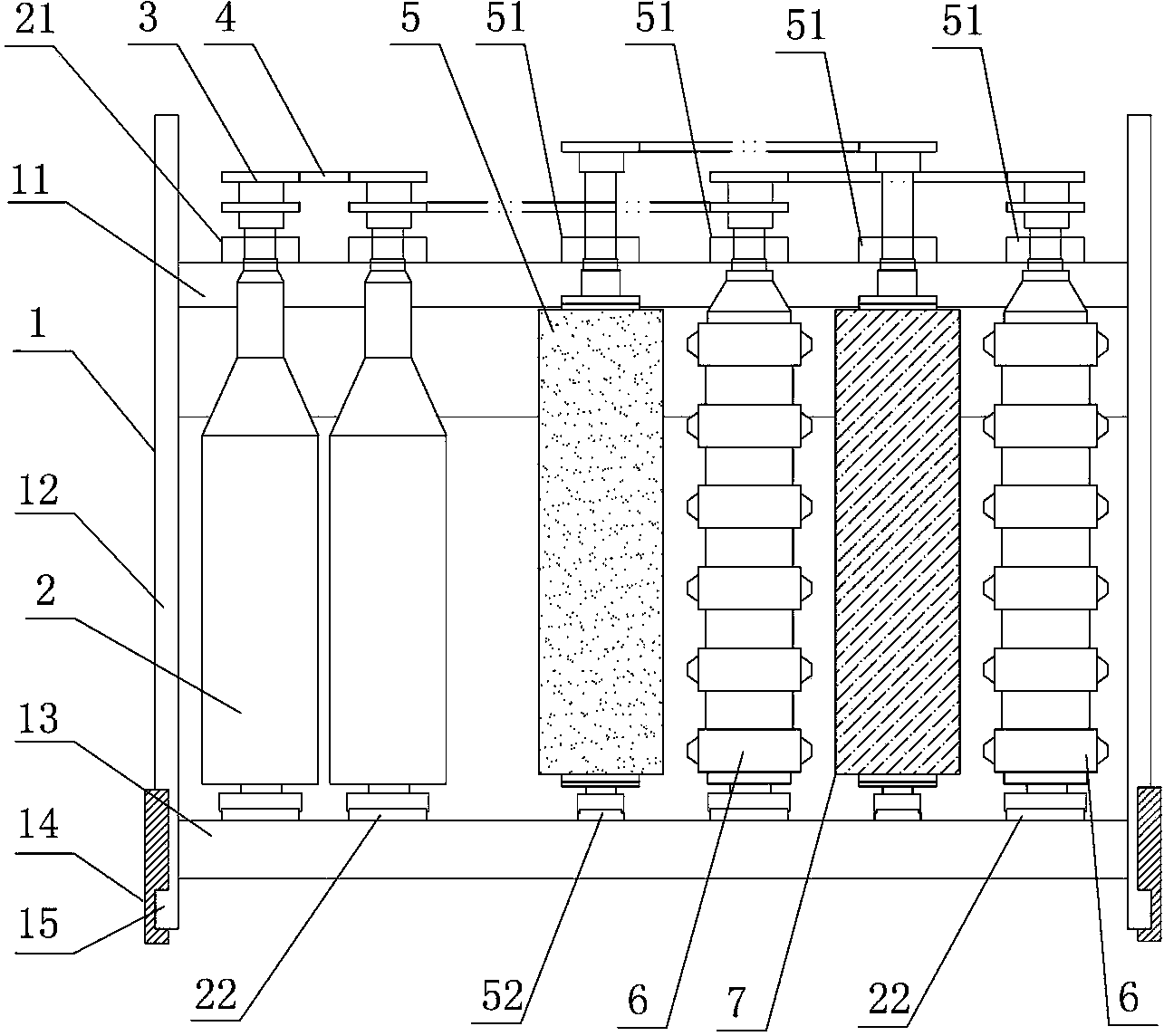

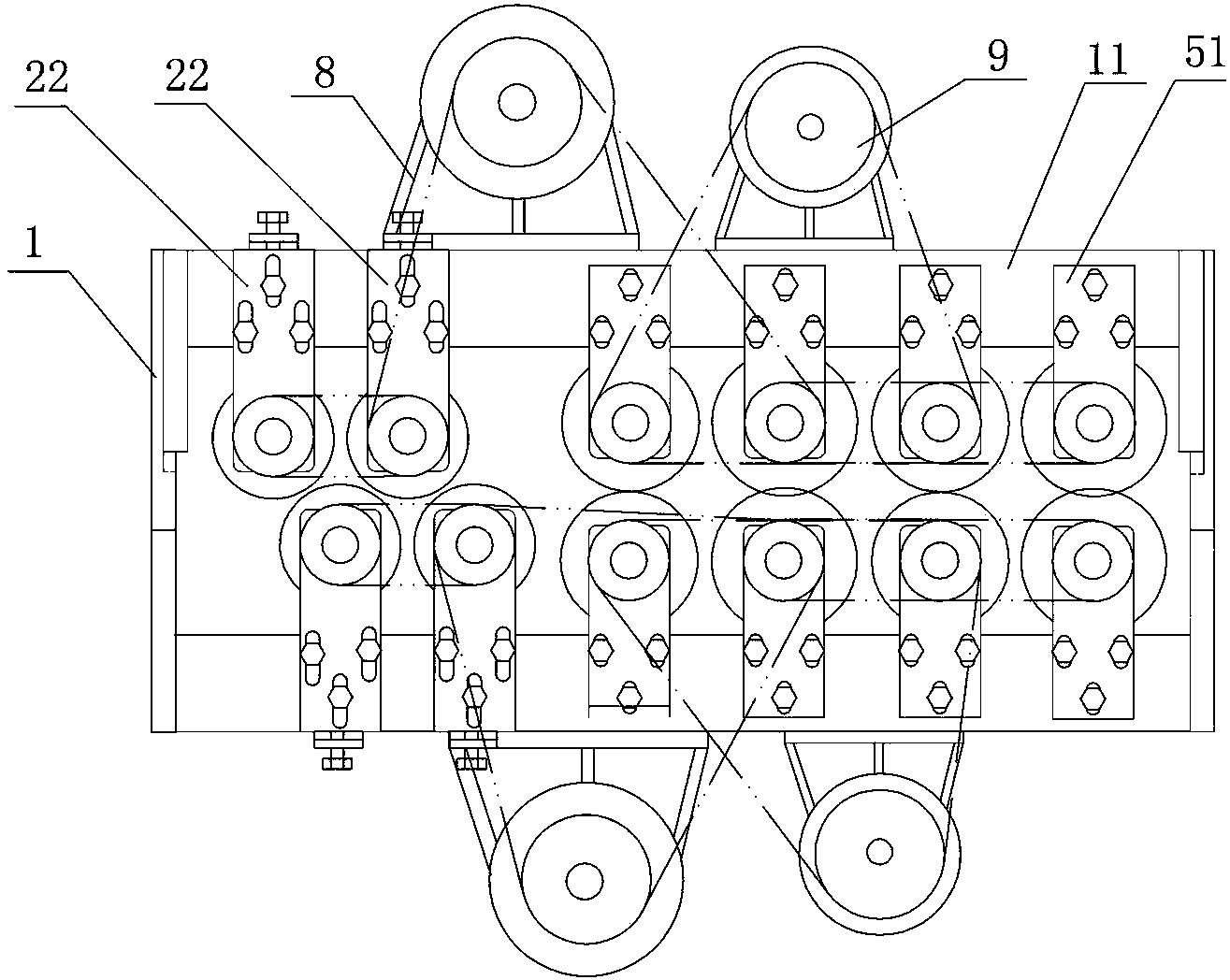

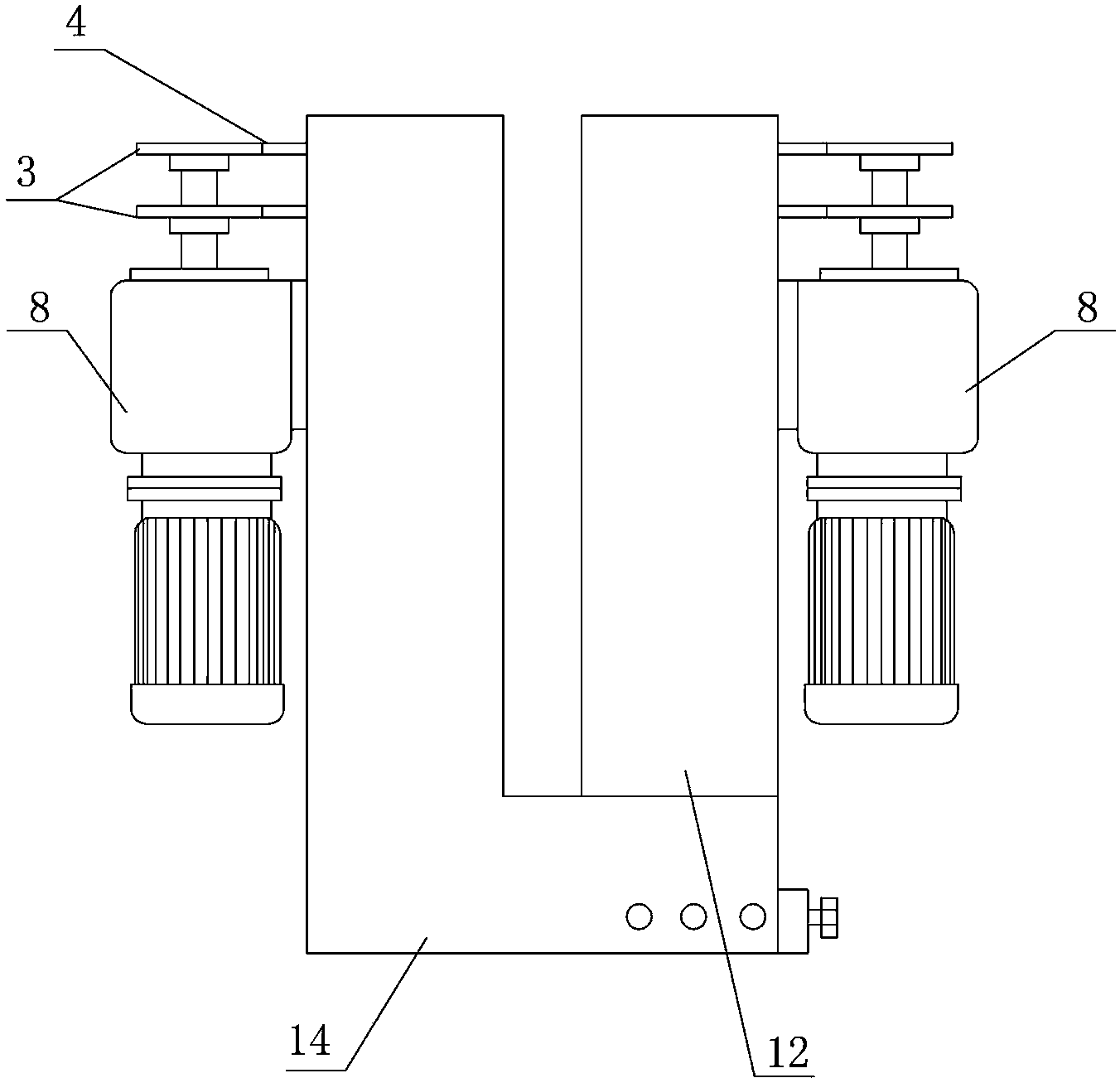

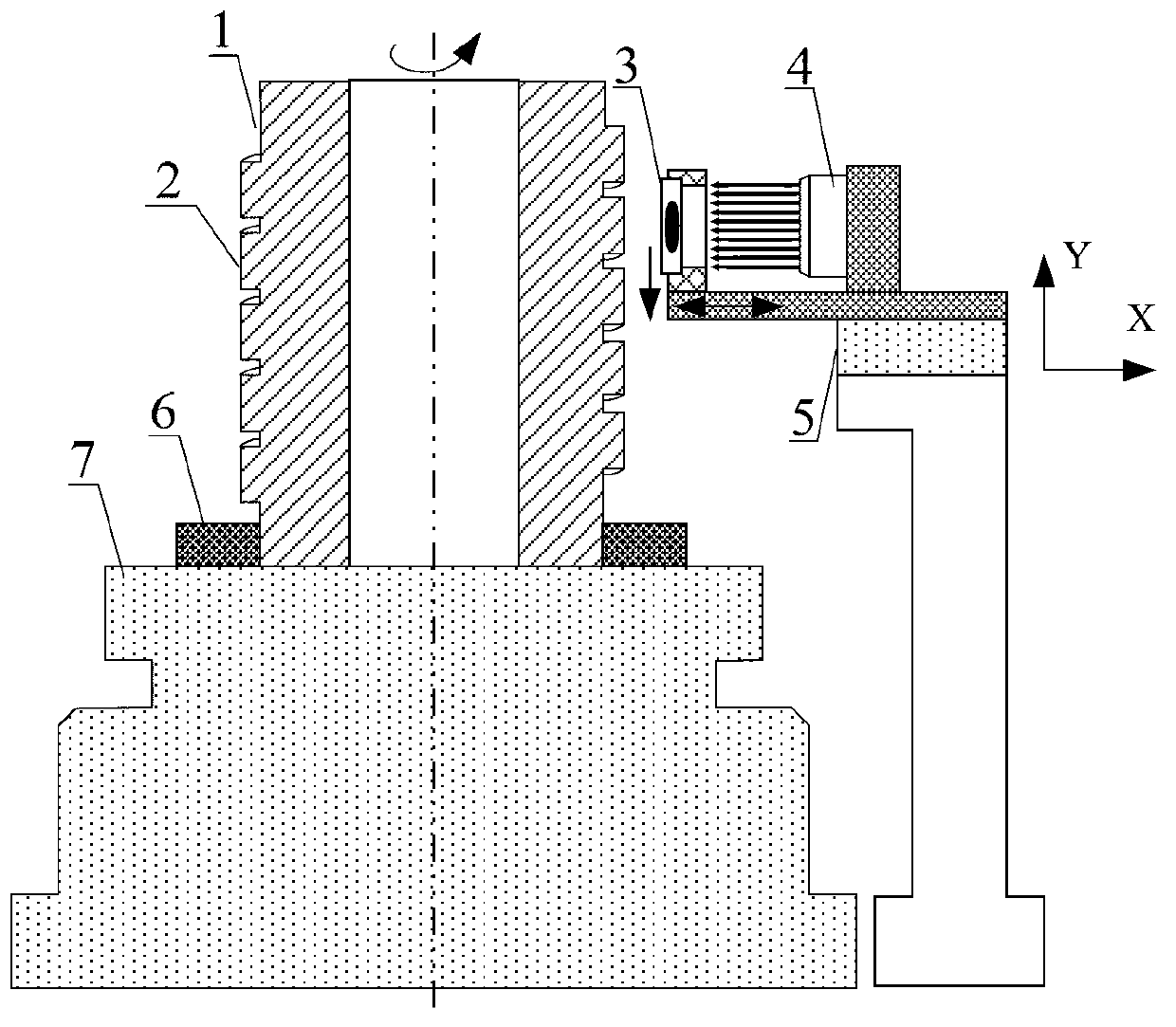

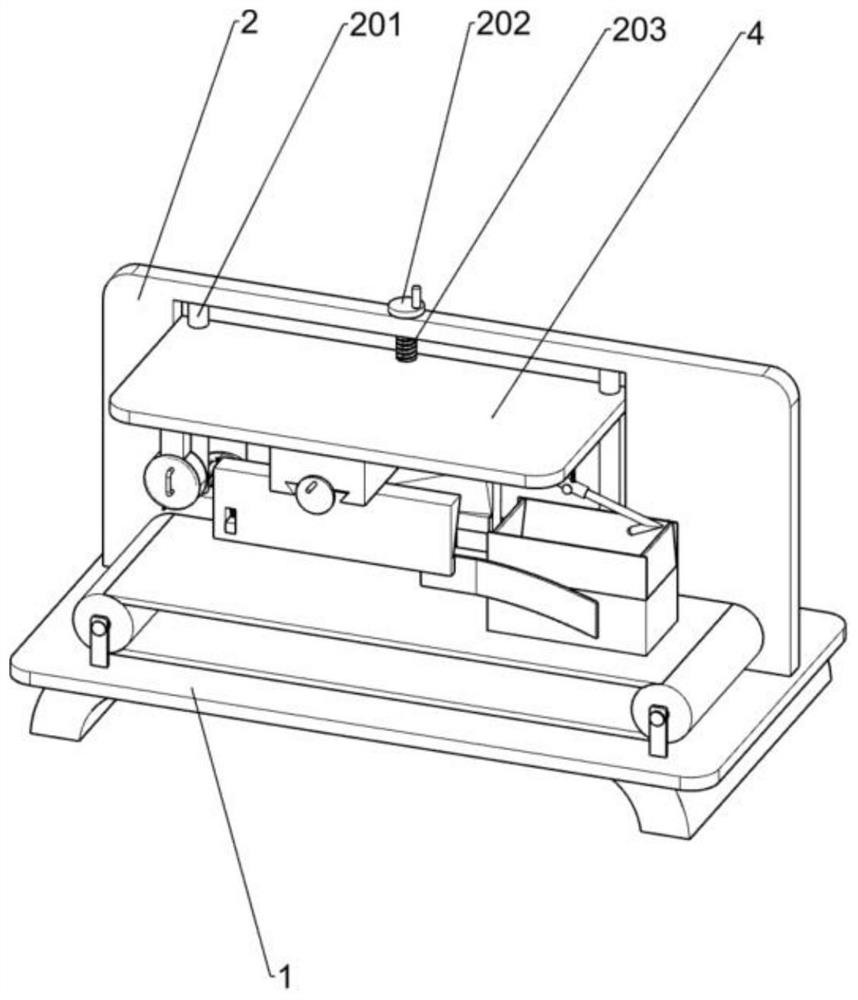

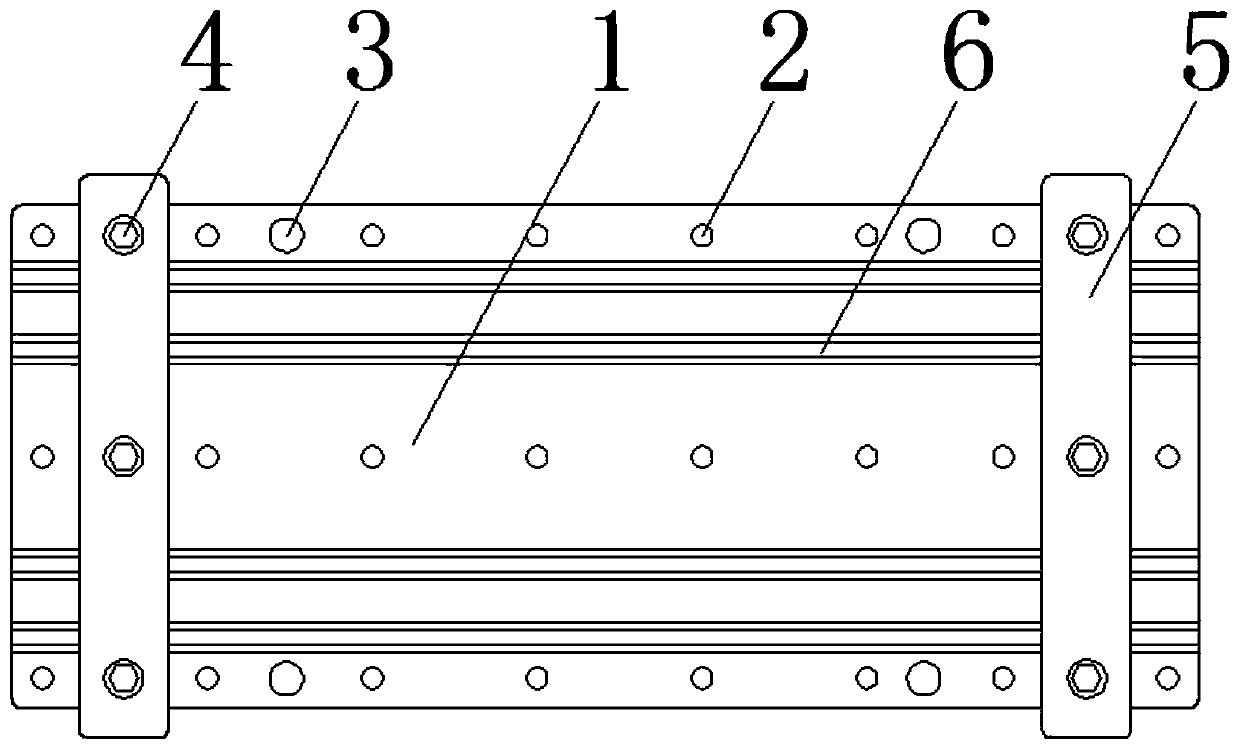

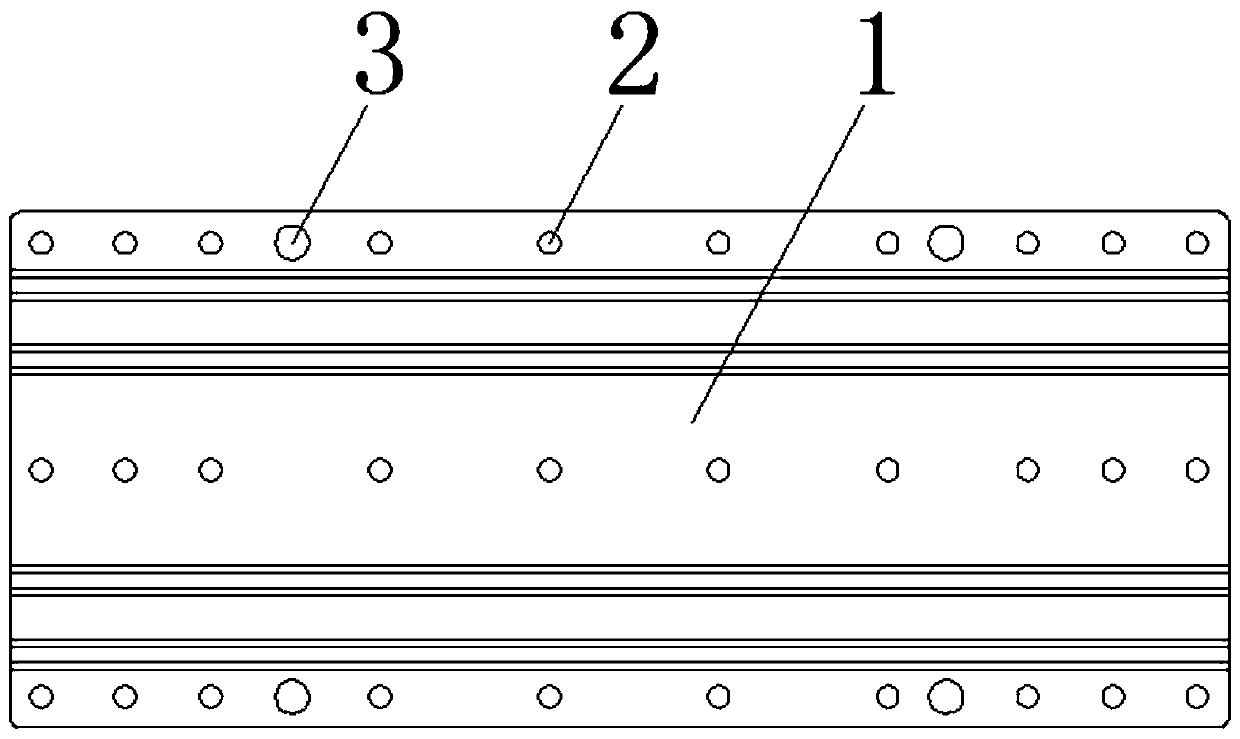

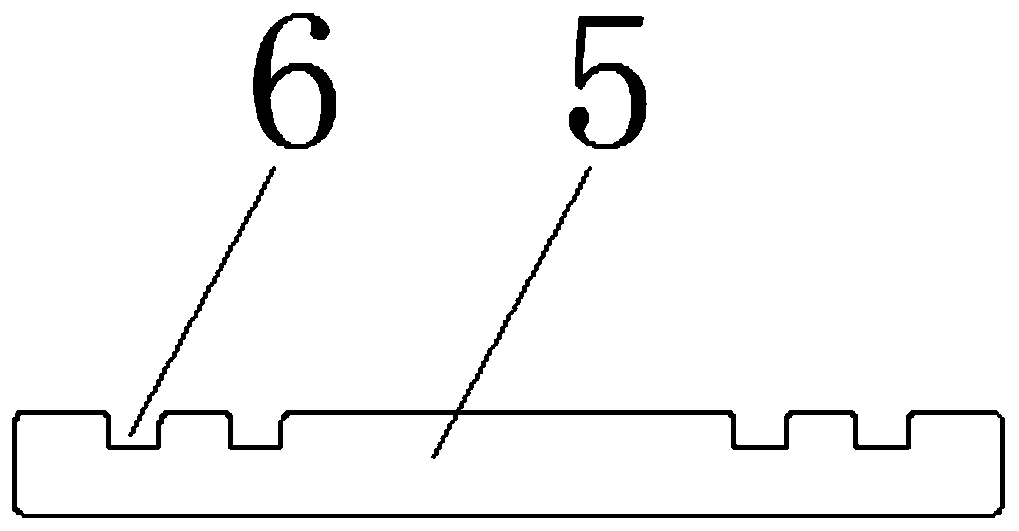

Leveling polishing machine for electrolytic manganese negative plate

The invention relates to a leveling polishing machine for an electrolytic manganese negative plate and belongs to leveling polishing machines. The leveling polishing machine mainly solves the technical problems that an existing process is scattered, the mechanization degree is low, a plant use area is large, working efficiency of workers is low, and the working environment is poor, and the like. The technical scheme is that the leveling polishing machine is characterized by comprising a machine frame part, a leveling part and a polishing part. The machine frame part is a machine frame (1) formed by plate welding and comprises a pair of L-shaped mainboards (14). The leveling part comprises more than two pairs of steel wheels 2 shaped like a Chinese character pin, and the polishing part comprises at least one pair of steel wire wheels, a pair of conveying wheels 6, a pair of polishing cloth wheels and a pair of conveying wheels 6, wherein the at least one pair of steel wire wheels, the pair of conveying wheels 6, the pair of polishing cloth wheels and the pair of conveying wheels 6 are sequentially arranged on the machine frame part from front to back. The leveling polishing machine is mainly used for leveling, clearing and polishing treatment of the electrolytic manganese negative plate and similar electrolytic metal negative plates and positive plates.

Owner:湘潭大众整流器制造有限公司

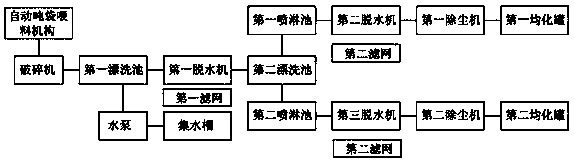

Automatic cycling type crushing cleaning equipment for waste and old plastic and realizing method thereof

ActiveCN104385483AAchieve brokenAchieve batchPlastic recyclingMechanical material recoverySaline waterMaterials processing

The invention discloses automatic cycling type crushing cleaning equipment for waste and old plastic and a realizing method thereof. The equipment comprises a crushing machine which is connected with a material inlet and is used for automatically ton-bag feeding mechanism, a first rinsing pool which is connected with a material outlet of the crushing machine and holds a rinsing solution being prepared by mixing sodium chloride, calcium chloride and water and possessing the salinity of 15-25 ppm, a brine-removal filtering cycling device which is communicated with the first rinsing pool, a second rinsing pool which is communicated with the first rinsing pool and holds a rinsing solution being prepared by mixing sodium, calcium chloride and water and possessing the salinity of 7-8 ppm, an environment-friendly material processing system and a sediment-material processing system which both are communicated with the second rinsing pool, and second filter screens which are respectively arranged in the environment-friendly material processing system and the sediment-material processing system. The equipment is reasonable in design, convenient to operate and high in automation degree, is capable of stably cleaning PS or ABS waste and old plastic in batches, is high in impurity removal rate, and also is capable of synchronously cleaning out environment-friendly materials and non-environment-friendly materials.

Owner:四川塑金科技有限公司

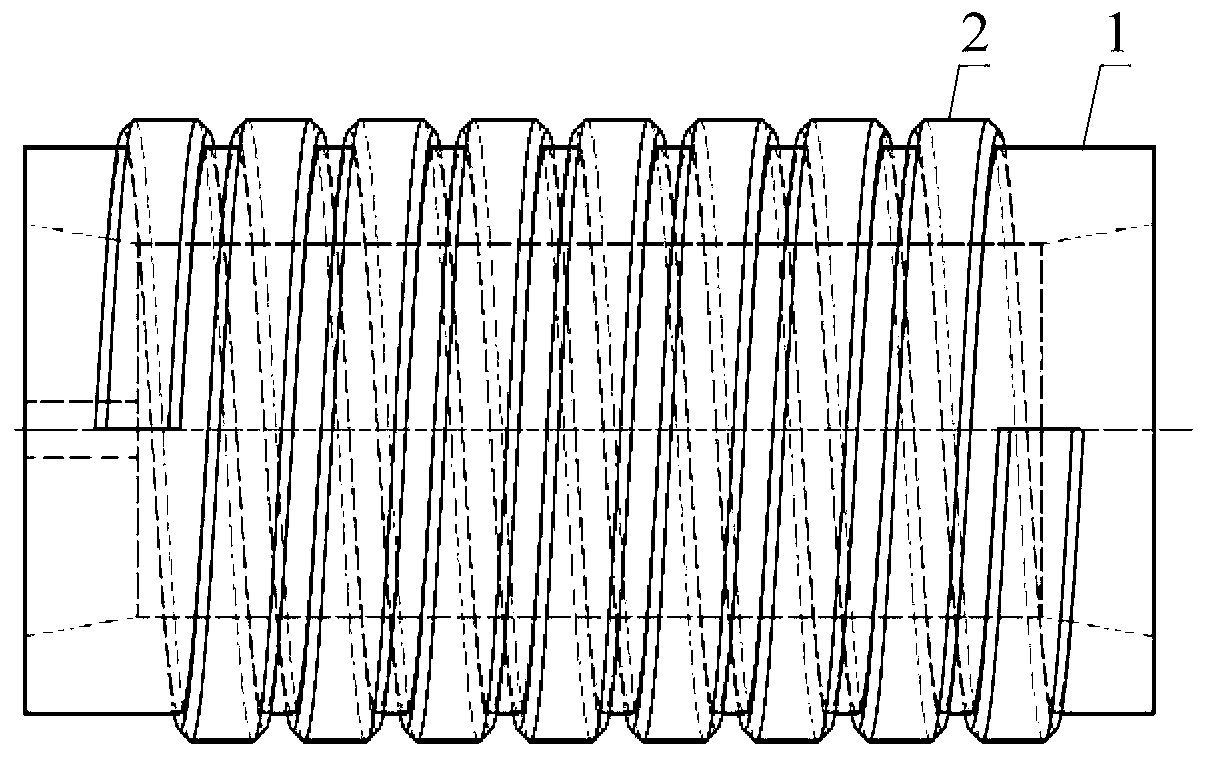

Single code channel absolute grating scale rolling and impressing mould manufacturing method

InactiveCN102759855AAchieve preparationAchieve long scalePhotomechanical apparatusUsing optical meansGratingUltraviolet lights

The invention discloses a single code channel absolute grating scale rolling and impressing mould manufacturing method, which comprises the following steps: a spiral single code channel absolute grating scale rolling and impressing mould base body is machined; photoresist is coated; rotary exposure of grid lines on the entire spiral line belt is performed through the way that the encoding of a single code channel absolute grating is adopted to control the rotation angle of a precise rotary circular dividing table, the movement of a mask, and the on / off of an ultraviolet light source; and the development and wet process etching are performed to form a single code channel absolute grating scale grid line structure, and the rolling and impressing mould is produced. According to the method, the spiral line belt is wound on the mould base body for a plurality of circles, so that a single code channel absolute grating scale grid line pattern with custom-built length is produced on a cylindrical base body of limited diameter; and the single code channel absolute grating scale rolling and impressing mould prepared through adopting the method is combined with the rolling and impressing pleomorphism technology, and can be used for realizing the efficient, low-cost and batch manufacture of meter-grade super-long single code channel absolute grating scales.

Owner:XI AN JIAOTONG UNIV +1

Production smelting method of saw blade steel

The invention discloses a production smelting method of saw blade steel, and belongs to the technical field of steelmaking. The process comprises pretreatment of molten iron-converter-LF refining-RH refining-continuous casting of slabs. The process has the following advantages: the process realizes the requirements of stable control of carbon content, low-sulfur and low-hydrogen contents and excellent continuous-cast slab quality of the saw blade steel: the requirement of the carbon content of final finished product in a range of 0.30-0.60 weight% is satisfied; the low sulfur content [S] is not more than 0.0030 weight%; the low-hydrogen content [H] is not more than 0.0002 weight%; the levels of various inclusions are controlled not more than 2.0; the center segregation grade of the continuous-cast slabs is not more than C type 1.5; and the industrial, large-batch and stable production of the saw blade steel is realized.

Owner:SHOUGANG CORPORATION

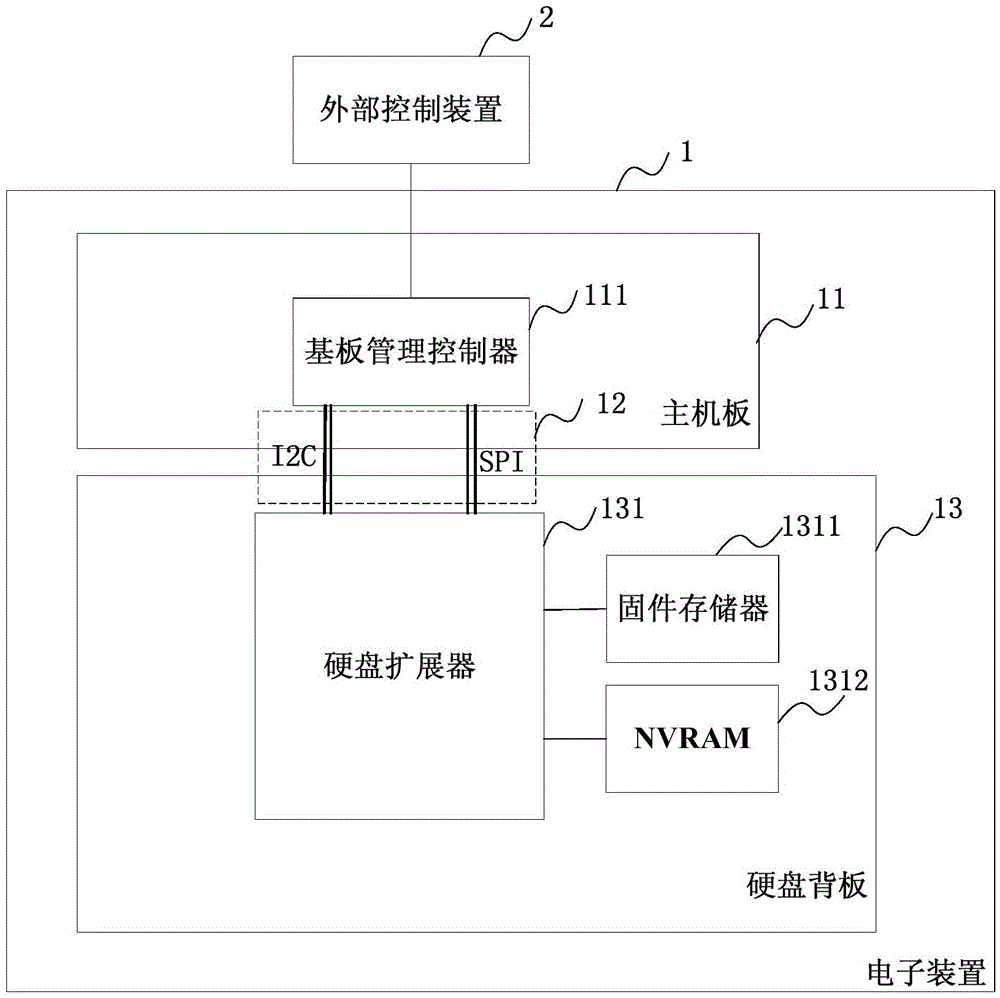

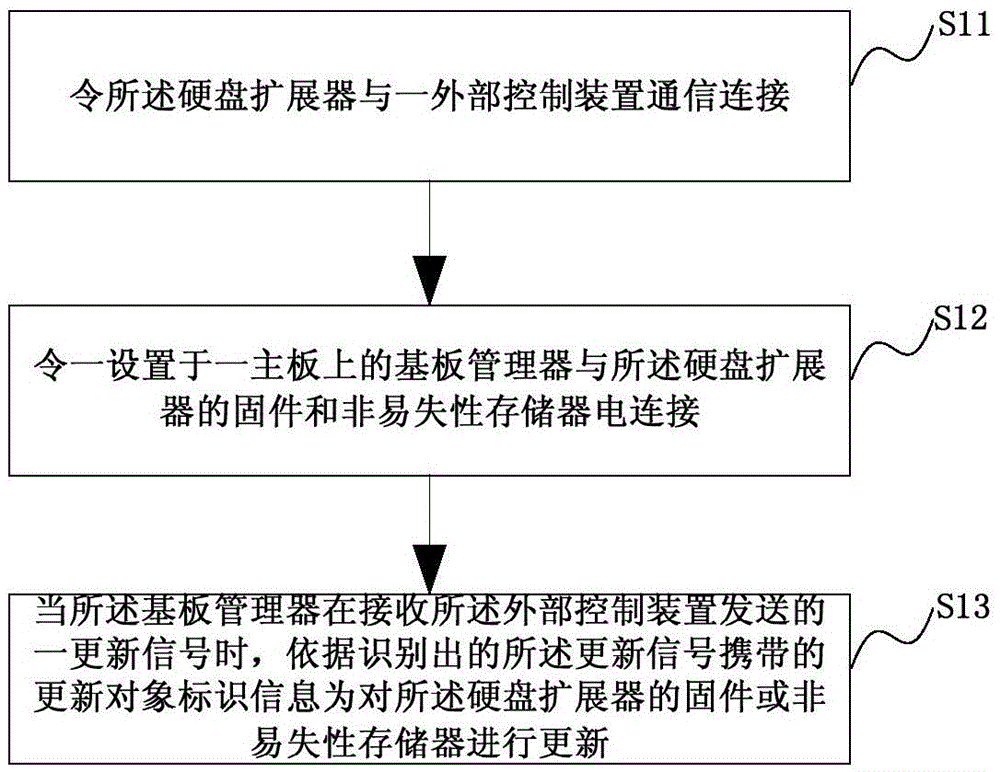

Electronic device

InactiveCN105487621AReal-timeAchieve batchDigital processing power distributionCommunication unitHardware architecture

The invention provides an electronic device. The electronic device comprises a main board, a communication unit and at least one hard disk back board, wherein the main board comprises a base board management controller in communication connection with an external control device; the communication unit is electrically connected with the base board management controller, and comprises a first data channel for transmitting a first hard disk data signal of the main board, and a second data channel for transmitting a management signal of the base board management controller; and the at least one hard disk back board comprises a hard disk expander, and the hard disk expander is electrically connected with the communication unit, and is also electrically connected with a firmware memory and a nonvolatile memory for performing data storage. When receiving an updating signal transmitted by the external control device, the base board management controller sends the management signal to perform data updating for the firmware memory or the nonvolatile memory of the hard disk expander. The electronic device provided by the invention performs real-time and batch updating for the firmware memory or the nonvolatile memory of the hard disk expander according to the updating signal through the existing hardware architecture, is convenient to operate in updating and is high-efficiency.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

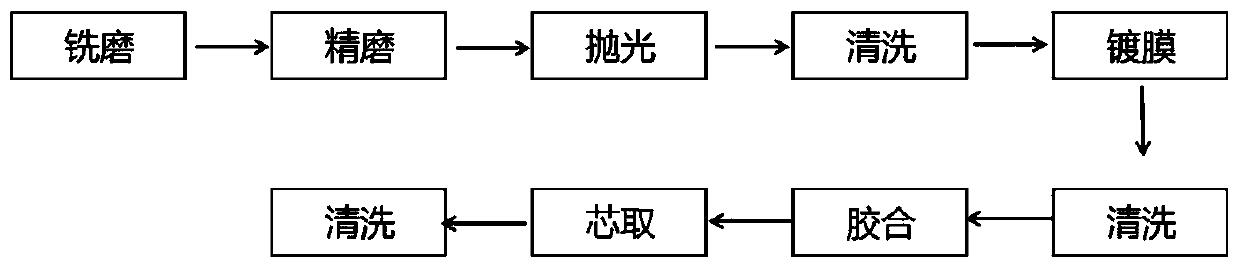

Special-shaped high-precision optical double-glued lens processing process

The invention discloses a special-shaped high-precision optical double-glued lens processing process. The process includes the following steps: (1) a step of milling, namely a step of cutting glass byusing a diamond pellet to meet required radius and thickness requirements; (2) a step of fine grinding, namely a step of improving the radius, roughness and surface precision of a workpiece to lay afoundation for polishing; (3) a step of polishing, namely a step of using grinding power to refine the surface shape to ensure that the surface shape, size and appearance requirements required by a drawing are met; and (4) a step of cleaning, namely a step of selecting an appropriate lotion and ultrasonic frequency to remove a grinding power impurity on the surface of a lens. The special-shaped high-precision optical double-glued lens processing process effectively solves the process and operation difficulty of double-sided or single-sided square lens gluing processing, realizes the productionof the square glued lens, breaks the limitation of a conventional process, realizes the batch and high-quality production of specific products.

Owner:NANYANG LIDA PHOTOELECTRIC

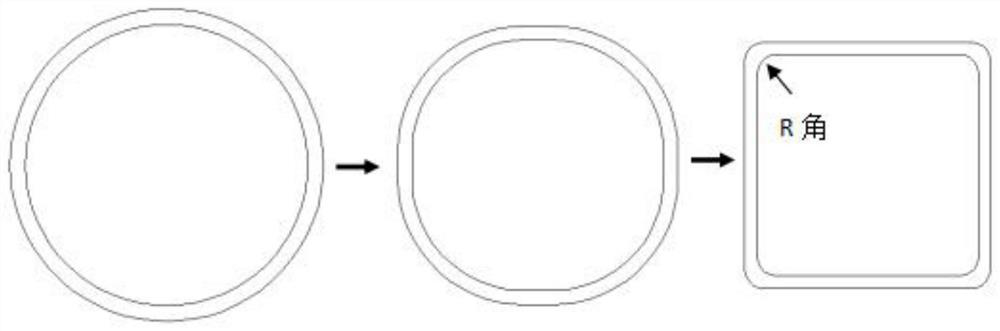

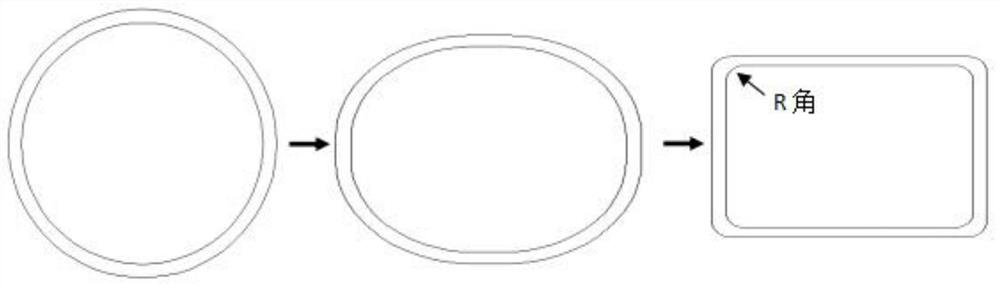

Titanium or titanium alloy seamless square tube and preparation method thereof

ActiveCN112496052AHigh dimensional accuracyAchieve batchTemperature control deviceFurnace typesWeld seamTitanium

The invention provides a titanium or titanium alloy seamless square tube and a preparation method thereof, and belongs to the field of titanium alloy tube preparation. The method includes the steps: providing a circular tube blank; sequentially carrying out first annealing, first-pass cold rolling, second annealing, straightening and machining treatment of inner and outer surface oxide skin on theround tube blank to obtain a semi-finished round tube; carrying out multi-pass cold rolling on the semi-finished round tube to obtain a seamless round tube with the same perimeter and wall thicknessas a square tube; carrying out third annealing on the seamless round tube to obtain an annealed seamless round tube; forming and straightening the annealed seamless round tube by adopting square tubeforming equipment from round to square gradually to obtain the square tube; and sequentially carrying out fourth annealing and straightening on the square tube to obtain the titanium or titanium alloyseamless square tube. The preparation method is simple and easy to implement, short in construction period and low in cost, no mold is needed, and the titanium or titanium alloy seamless square tubewithout welding seams and high size precision can be obtained.

Owner:WESTERN METAL MATERIAL

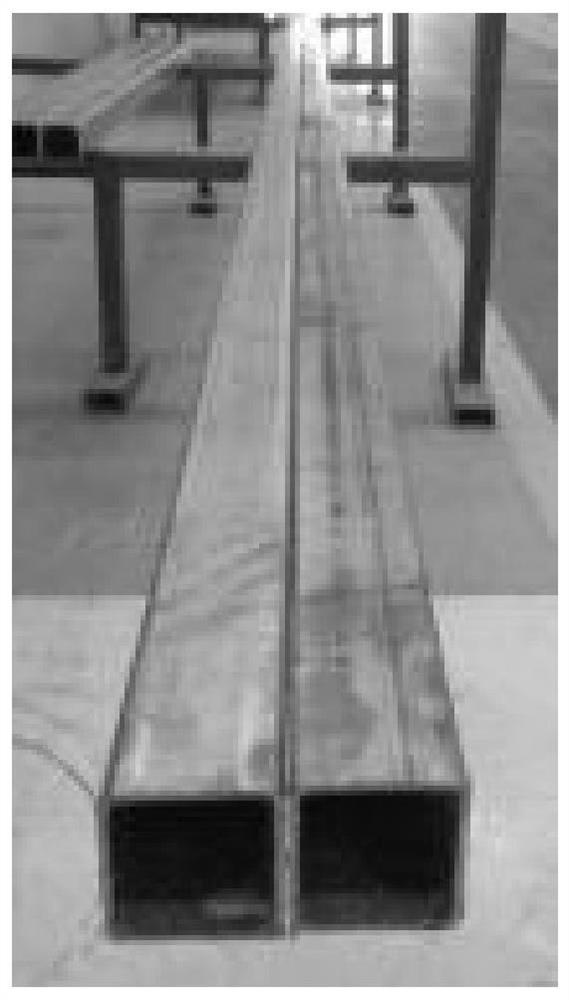

Method for making steamed pork belly with preserved greens by taking streaky pork of Suhuai pigs as raw material

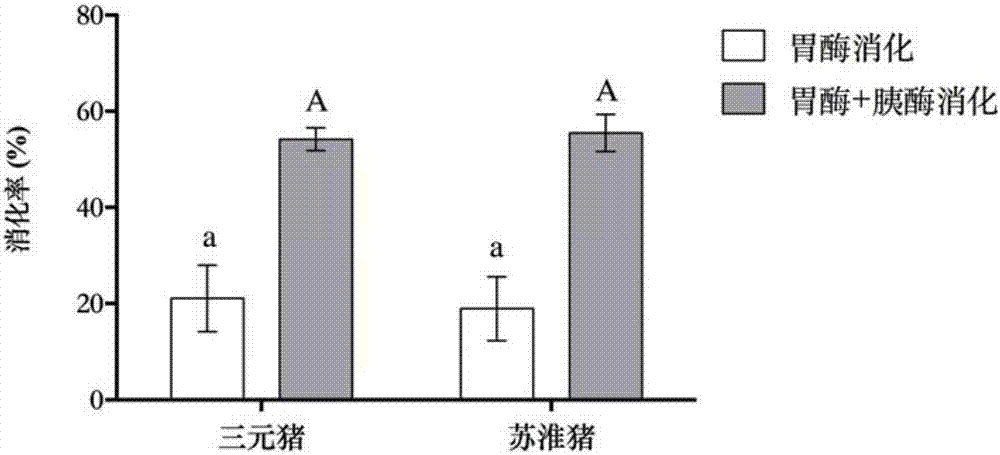

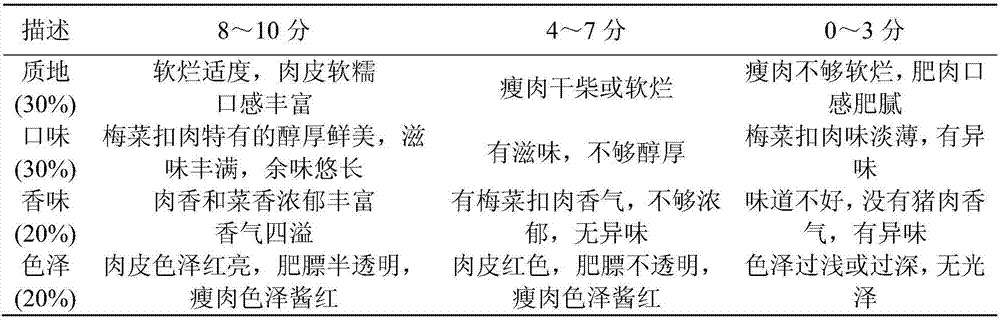

ActiveCN107529414AGuaranteed nutritional qualityGuaranteed Flavor QualityFood scienceIn vitro digestionSolid-phase microextraction

The invention relates to the technical field of processing of meat products and in particular relates to a method for making steamed pork belly with preserved greens by taking streaky pork of Suhuai pigs as a raw material. The processing method disclosed by the invention comprises the following steps: taking streaky pork of Suhuai pigs and Shaoxing preserved vegetables as raw materials, cutting, coloring and slicing the streaky pork, cleaning and frying the preserved vegetables, blending juice, steaming, packaging, pre-cooling, quick-freezing and the like, thereby obtaining the steamed pork belly with preserved greens. Digestion conditions of foods in the in-vivo gastrointestinal tract are simulated by utilizing an in-vitro digestion model, and the bioavailability of the foods is reflectedby the food digestion degree. Moreover, flavor is an important index of sensory quality of foods and directly influences selections of consumers. The raw material selection is a basis of meat productprocessing. According to the process disclosed by the invention, the raw material varieties are subjected to process optimization by combining in-vitro digestion, headspace solid-phase micro-extraction-gas chromatography-mass spectrometry and sensory evaluation. The invention aims to produce standardized steamed pork belly with preserved greens with excellent sensory quality and nutritional quality, and the requirements of consumers on food safety, health, convenience and rapidness are met.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for smelting high-strength wear-resisting steel

InactiveCN105177225ARealize industrializationAchieve batchManufacturing convertersProcess efficiency improvementSulfurHydrogen content

The invention discloses a method for smelting high-strength wear-resisting steel, and belongs to the technical field of medium-thickness plate steel-making. The process comprises the following steps: molten steel pretreatment, treatment in a converter, LF refining, RH refining and plate blank continuous casting. The method has the advantage that the process is adopted to realize requirements of carbon content stable control, low sulfur, low-hydrogen content and good continuous-casting billet quality of rear-resisting steel, i.e., meet the requirements of controlling carbon content of a finished product to 0.15%-0.30%, wherein sulfur [S] content is less than or equal to 0.0050%, low-hydrogen content [H] is less than or equal to 0.0002%, grade for various impurities is controlled to be lower than or equal to 2.0, and segregation level of a continuous-casting center is lower than or equal to class-C 1.5; and industrial, large-scale and stable production for the wear-resisting steel is realized.

Owner:SHOUGANG CORPORATION

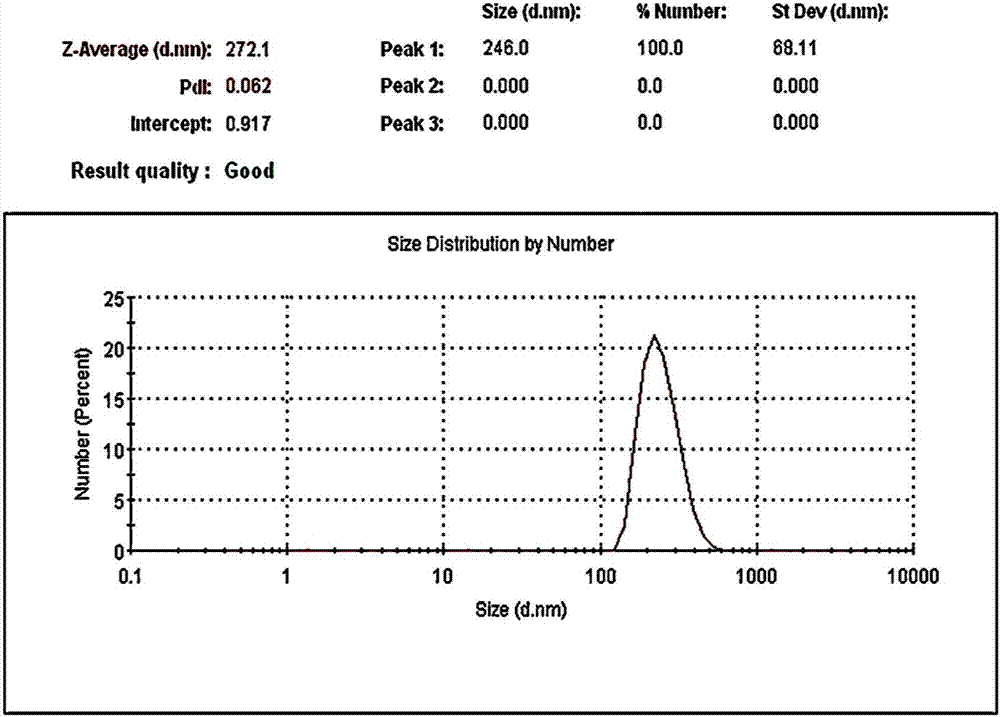

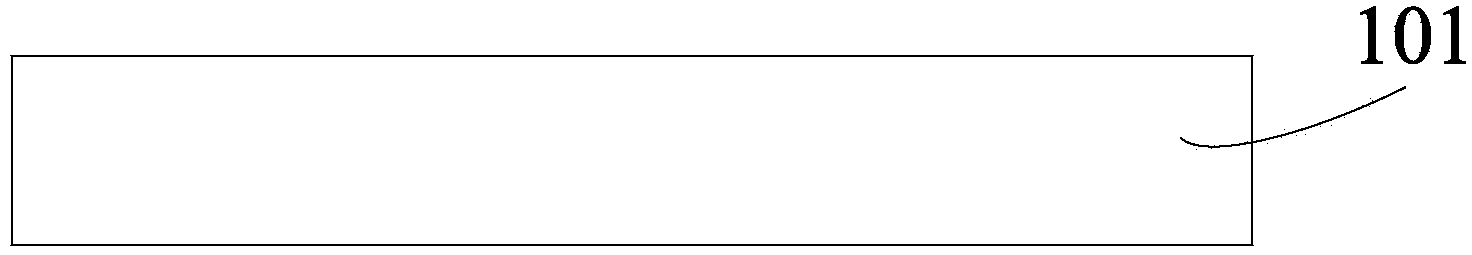

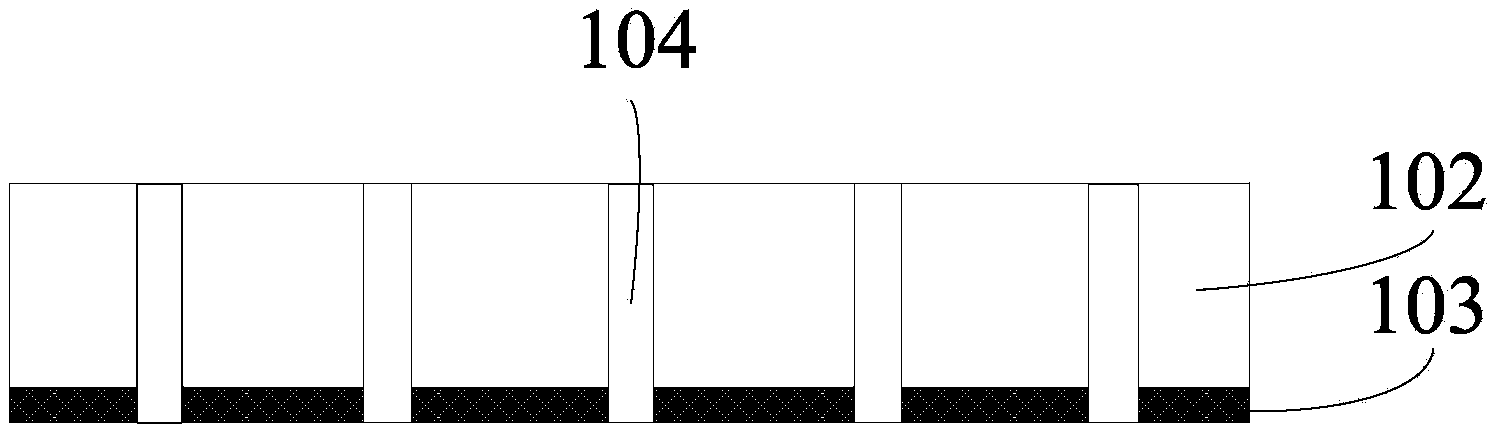

Manufacturing method of imaging nano particle self assembly

ActiveCN103227102ARegular advantageAchieve batchSemiconductor/solid-state device manufacturingNanotechnologyXylyleneGas phase

The invention relates to a manufacturing method of imaging nano particle self assembly, which comprises the steps of adopting a one-side polishing single-crystal silicon substrate, depositing a poly-p-xylylene membrane on the surface of the silicon substrate by a chemical vapor deposition method, fabricating a required photoresist mask pattern on the surface of the silicon substrate by the traditional photoetching method, etching the exposed poly-p-xylylene membrane by adopting an oxygen plasma etching method, using a diamond scribing machine to scribe the silicon substrate, using acetone to remove a photoresist on the surface of the silicon substrate, soaking the silicon substrate after the photoresist is removed in mixed liquid of concentrated sulfuric acid and hydrogen peroxide, taking out the silicon substrate, using deionized water to clean the silicon substrate, taking a certain amount of prepared nano particle suspension liquid to drop into a container containing ethanol, uniformly mixing the two liquid, slowly pouring into a culture dish containing the deionized water, completely soaking the obtained silicon substrate in the liquid in the culture dish, taking the silicon substrate out, placing the silicon substrate in another culture dish, horizontally placing the silicon substrate in a drying oven, and obtaining the silicon substrate with the imaging nano particle self assembly after natural evaporation at a room temperature.

Owner:PEKING UNIV

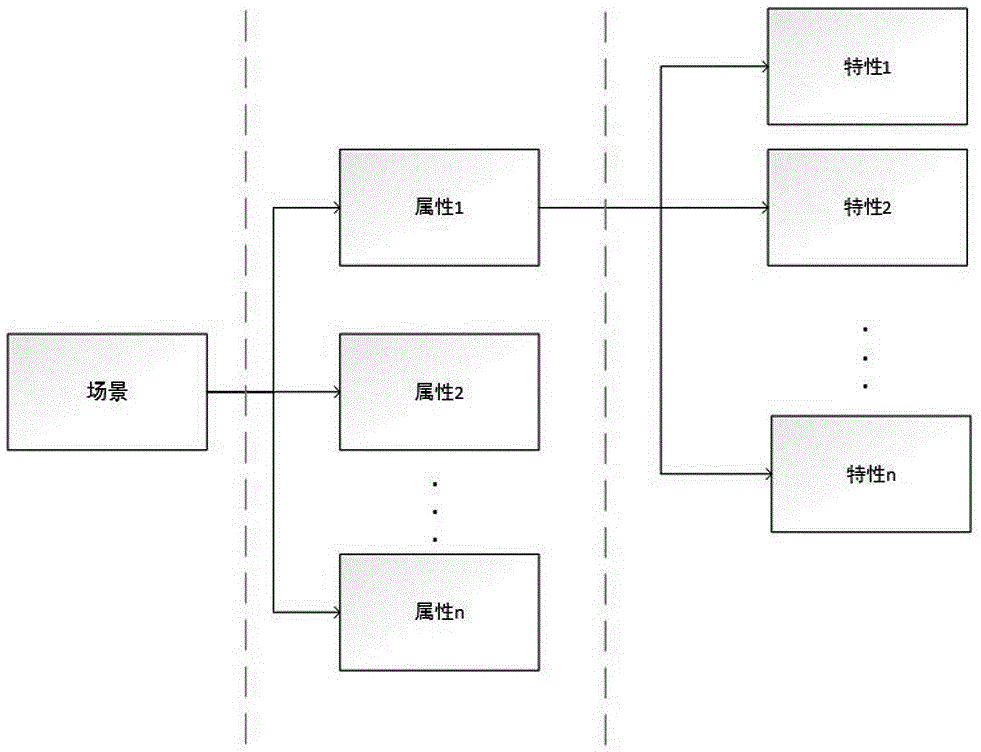

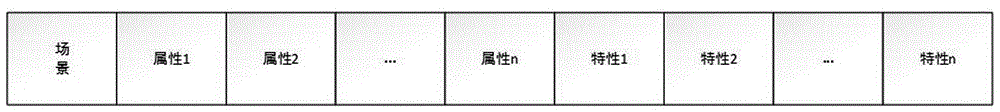

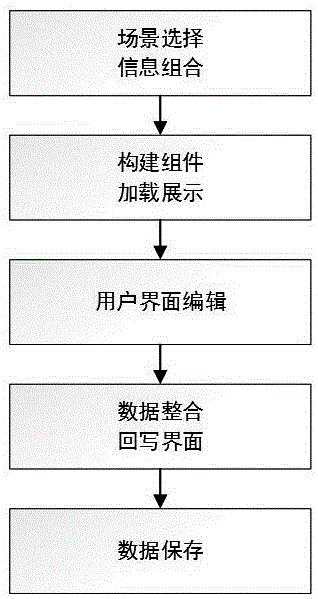

Scene-based column information dynamic loading and displaying method

ActiveCN106484899AIncrease flexibilityEasy to expandSpecial data processing applicationsData needsDynamic loading

The present invention discloses a scene-based column information dynamic loading and displaying method. The method comprises the following steps: S1, a user selects a scene, and after selection, captures given information according to the scene, and integrates the information of the scene; S2, on the basis of the integrated information, corresponding components are constructed, and the components are integrated to complete interface display in a certain order; S3, the user performs data and text inputting and related editing operations on an interface; and S4, the operations are completed, and after save or complete is triggered, data is read from the interface, a specific database table is constructed, dynamic data is stored, and because construction of a data table is based on a single component, the data needs to be integrated, that is, a column of the data needs to be switched, and the interface is written back. The components can be dynamically loaded according to user scenes, so that the method is high in flexibility, convenient for extension, and not limited to the number of the components to be loaded.

Owner:YONYOU NETWORK TECH

Allisartan isoproxil pharmaceutical composition, preparation containing pharmaceutical composition and preparation method of pharmaceutical composition

InactiveCN107441048AEasy to operateStrong process controllabilityPowder deliveryOrganic active ingredientsNanoparticleAllisartan isoproxil

The invention provides an allisartan isoproxil pharmaceutical composition. Through the stabilizing and protecting effects of a prescription, allisartan isoproxil can be conveniently prepared into nano-scale particles through a milling process, the nano-scale particles are stably dispersed in a pharmaceutical composition, and allisartan isoproxil exists in the form of the stable nanoparticles in the follow-up process. The invention further provides an allisartan isoproxil preparation which has the characteristics of high loading capacity, high stability and the like.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

Square steel pipe cold-drawing repairing device and method

The invention provides a square steel pipe cold-drawing repairing device and method. The repairing device comprises a clamp, a die holder, an outer die, hollow pulling rods and a plurality of connecting sleeves, a plurality of square steel pipes are connected in a supporting fit mode through the connecting sleeves, and the ends of the sides, away from the clamp, of the hollowing pulling rods are provided with the connecting sleeves. The guiding sections of the connecting sleeves at the ends enable the to-be-repairedsquare steel pipes at the tail ends to be mounted on the pulling rods in limited and sleeving mode, one end of each to-be-repaired square steel pipe is sleeved with the locking section of the corresponding connecting sleeve, and the other end of the each to-be-repaired square steel pipe is sleeved with the guiding section of the corresponding connecting sleeve. Therefore, in the drawing repairing process of the large-curvature square steel pipes, the size is released in theprocess from bending to straightening, the tail ends of the square steel pipes extend, the distance can exactly enable the tail ends of the square steel pipes in the repairing process to freely extend, and the technological problems that the surfaces of the steel pipes wrinkle in the drawing repairing process and materials are stacked at the tail ends are solved; and the technological effects thatbatch repairing of the square steel pipes is achieved, the repairing range is wide, and the repairing effect is good are achieved.

Owner:潍坊浩泰机械有限责任公司

Method for imaging processing of nanorod/nanoneedle forest structure

ActiveCN104310307ARealize graphical distributionBreak through the limitations of batch processingNanostructure manufactureBatch processingImaging processing

The invention relates to a method for imaging processing of a nanorod / nanoneedle forest structure. The method comprises a step (a) of cleaning a first substrate and a second substrate; a step (b) of enabling a first substrate similar material layer similar to a first substrate material to be arranged on the lower surface of the second substrate, and arranging a plurality of punchthrough structures on the second substrate so as to form a hollow substrate; a step (c) of pasting the hollow substrate to the upper surface of the first substrate so as to form a corrosion cavity between the lower surface of the hollow substrate and the upper surface of the first substrate; a step (d) of utilizing the punchthrough structures of the hollow substrate to etch the upper surface of the first substrate; and a step (e) of removing the hollow substrate from the upper surface of the first substrate, so as to obtain the nanorod / nanoneedle forest structure on the first substrate. According to the method, the limitation of an electron beam photoetching and focused ion beam etching technology in the aspect of batch processing can be overcome, the process complexity can be effectively reduced, and the imaging nanorod / nanoneedle forest structure having controllability is achieved.

Owner:中科芯未来微电子科技成都有限公司

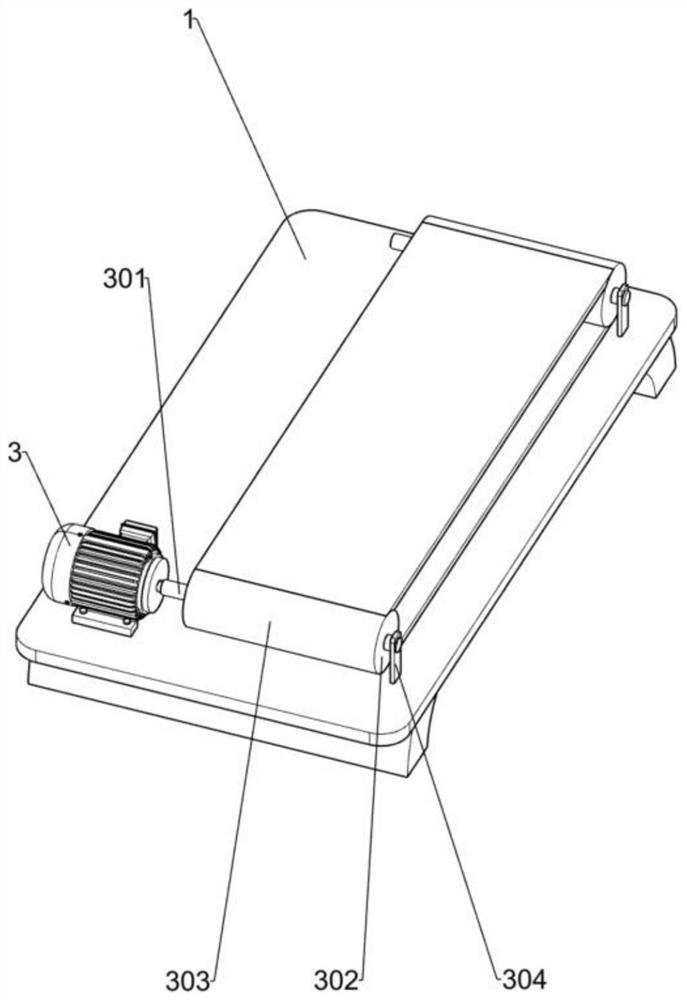

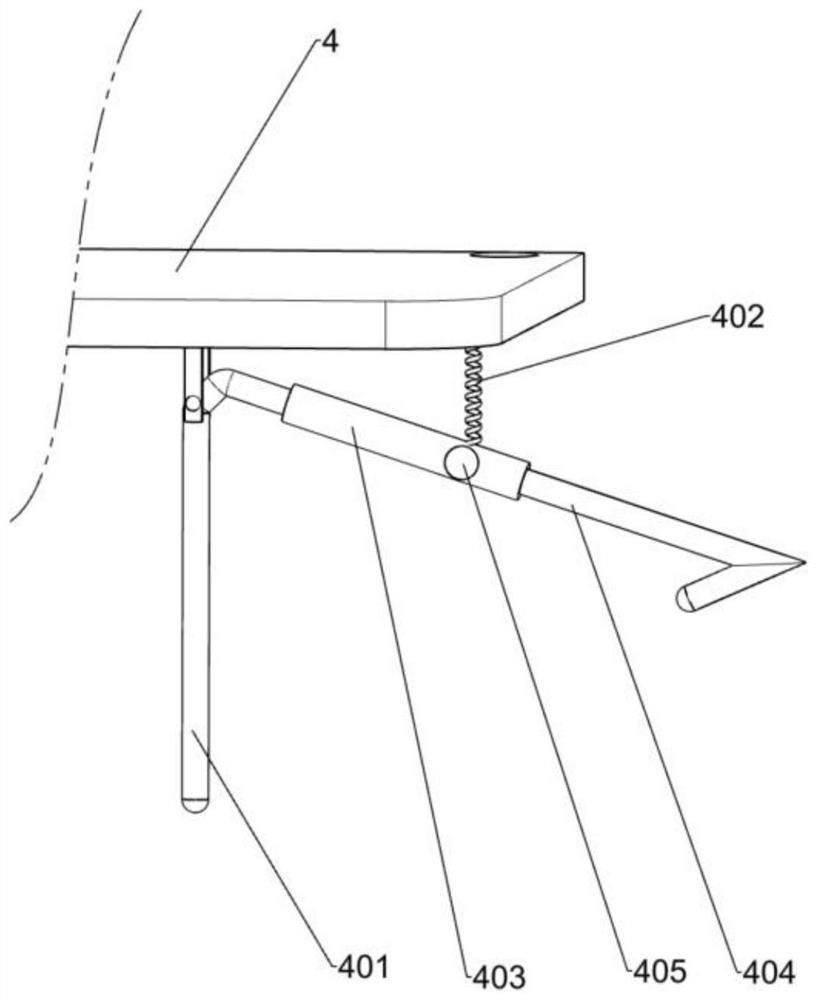

Automatic food package box sealing equipment

ActiveCN112298688AHeight adjustableAdjustable widthWrapper twisting/gatheringProcess engineeringFood packaging

The invention relates to box sealing equipment, in particular to automatic food package box sealing equipment. The technical problem to be solved by the invention is to provide the automatic food package box sealing equipment which adapts to box bodies with different sizes. The automatic food package box sealing equipment comprises a base, a first supporting plate, a conveying mechanism, a secondsupporting plate, a first cover closing mechanism and the like; the first supporting plate is fixedly installed on one side of the base; the conveying mechanism is fixedly installed on the side, closeto the first supporting plate, of the base; the second supporting plate is installed on one side of the first supporting plate; and the first cover closing mechanism is fixedly installed on one sideof the second supporting plate, and a second cover closing mechanism is fixedly installed in the middle of the second supporting plate. According to the automatic food package box sealing equipment, by additionally arranging a height adjusting mechanism and a width adjusting mechanism, the height and width of the mechanism can be adjusted, and the equipment adapts to the process of sealing box bodies of different sizes.

Owner:福州伟华食品有限公司

Manufacturing process for aluminum alloy tooling plate for titanium rod punching

InactiveCN110653575AHard oxidation treatment is smoothHigh strengthAnodisationNumerical controlAnodizing

The invention relates to the technical field of machining, and discloses a manufacturing process for an aluminum alloy tooling plate for titanium rod punching. According to the manufacturing process,the aluminum alloy tooling plate is manufactured. The manufacturing process has the advantages that an aluminum alloy raw material plate is subjected to material preparation, numerical control machining and grinding machine machining to manufacture the special tooling plate suitable for titanium bar punching machining clamping, so that the problem of the blank of an existing special clamp for titanium bar punching machining can be solved, the purpose of stably clamping a titanium bar is achieved, oil stains on the tooling plate are cleared through cleaning and chemical polishing, the tooling plate is subjected to pretreatment before hard anodizing, finally, in an oxidation treatment tank with an oxidation solution composed of 5-10% sulfuric acid and 95-96% of distilled water, the direct current of 20 V-24 V, the current density of 2 A / dm<2>-2.8 A / dm<2> and the oxidation temperature of -5 DEG C-+5 DEG C, after 90 min-100 min of oxidation reaction, a layer of hard oxidation film is generated on the surface of the tooling plate, the strength, the wear resistance and the corrosion resistance of the tooling plate are improved, furthermore, the tooling plate can be recycled, and the machining cost is lowered.

Owner:陆金云

Smelting method for producing medium-thickness plate through RH single-linkage process

InactiveCN106011595ARealize industrializationSolve the problem of flaw detection pass rateSteelmakingHydrogen

The invention discloses a smelting method for producing medium and thick plates by adopting an RH single process, belonging to the technical field of steelmaking. Desulfurization pretreatment of molten iron; converter smelting: the moisture content of all raw and auxiliary materials is controlled at ≤0.50wt%, and the steel is deoxidized and stirred; RH vacuum treatment: argon is 6-12NL / min per ton of steel, and the hydrogen content in the steel is ≤2.0 at the end of vacuum ppm; Calcium treatment: use calcium treatment to denature the non-metallic inclusions and control the calcium content in the steel at 15-20ppm; continuous casting for plate failure: constant casting speed, superheat ≤ 25°C, reduction 5.5-6.5mm, etc. The craft is complete. The advantages are: the quality of the finished product is excellent, the pass rate of flaw detection is controlled above 99.6%, and the industrialized, batch and stable production of this type of steel is realized.

Owner:SHOUGANG CORPORATION

Graphene sensor for rapidly detecting Gram negative bacteria lipopolysaccharide and preparation method

InactiveCN106290541AChange electrical propertiesGuide diagnosisMaterial electrochemical variablesSurface modificationClinical disease

The invention discloses a graphene sensor for rapidly detecting Gram negative bacteria lipopolysaccharide and a preparation method thereof. The sensor consists of an insulating substrate, a back gate electrode at one side of the substrate, an antibody-decorated graphene layer at the other side of the substrate, and a source electrode and a drain electrode, which are disposed at two ends of the graphene layer, and a sample cell disposed above the graphene. Factors C decorated on the surface of the graphene layer are specifically combined with the Gram negative bacteria lipopolysaccharide to change the electrical properties of the graphene sensor, the content of the Gram negative bacteria lipopolysaccharide can be quantitatively determined by virtue of an external circuit so as to instruct the diagnosis of clinical diseases. The sensor can rapidly simply sensitively and specifically determine the Gram negative bacteria lipopolysaccharide. Meanwhile, by virtue of the preparation method, the stable and low-cost mass preparation of the graphene-based biological sensor can be realized, and high efficiency and accuracy in biological detection can be facilitated.

Owner:天津喜诺生物医药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com