Reversal firing resisting single-cylinder diesel engine and reversal firing resisting method for single-cylinder diesel engine

A diesel engine, anti-reverse technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as easily hurting people, and achieve the effect of increased cost and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

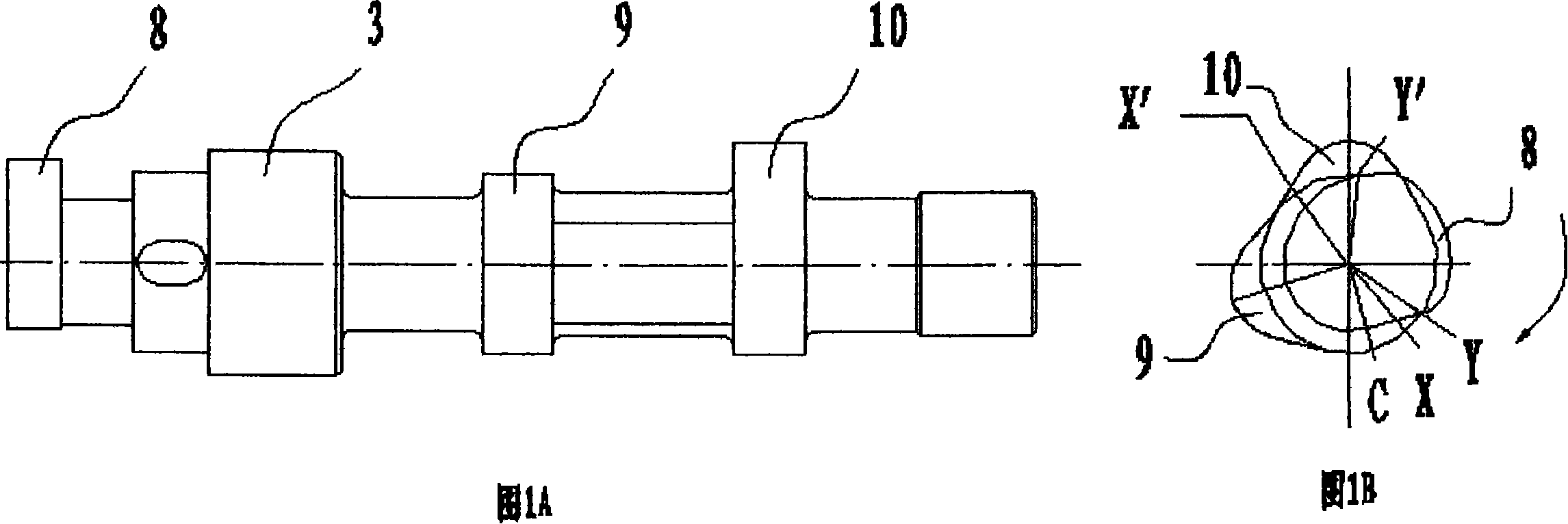

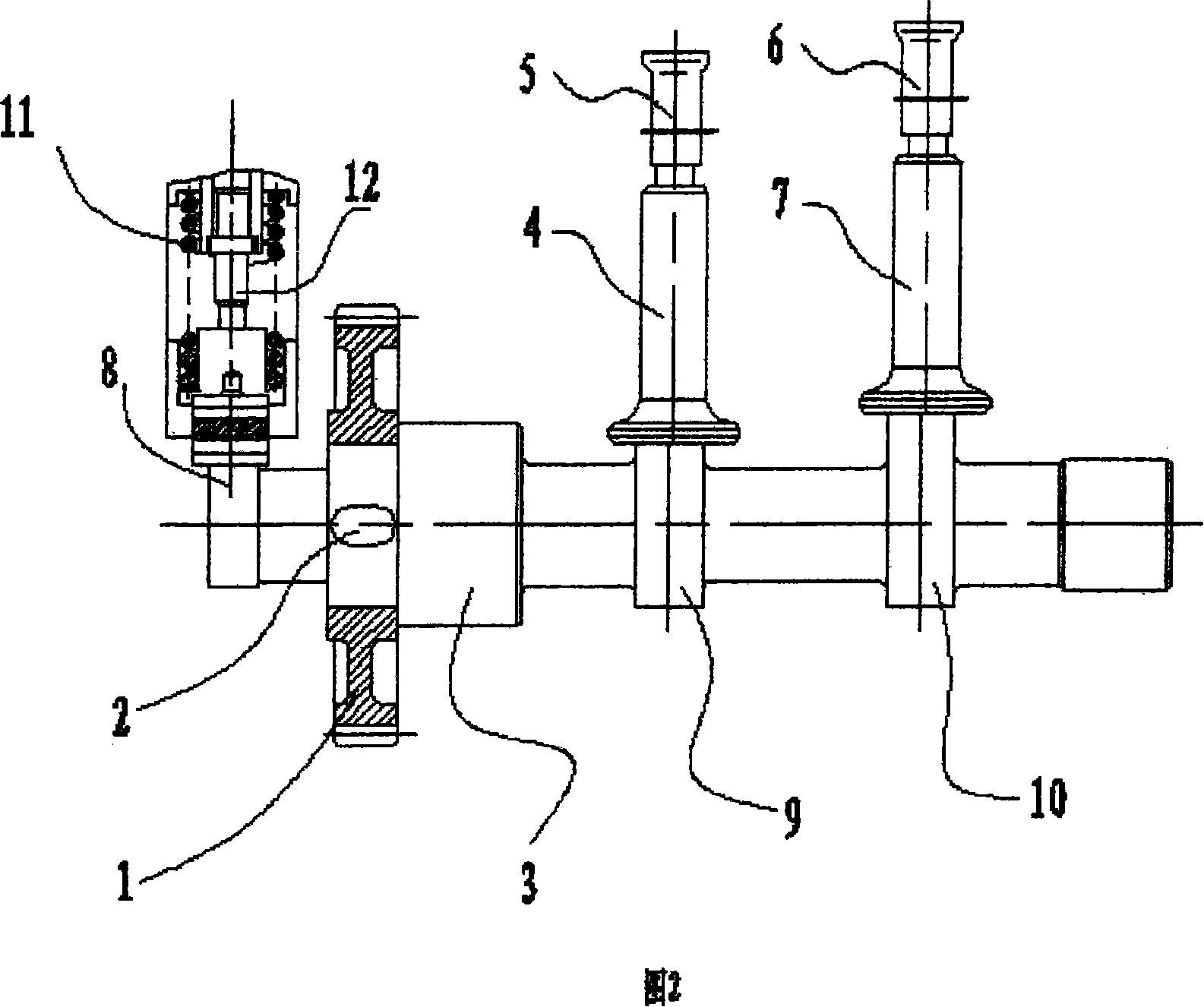

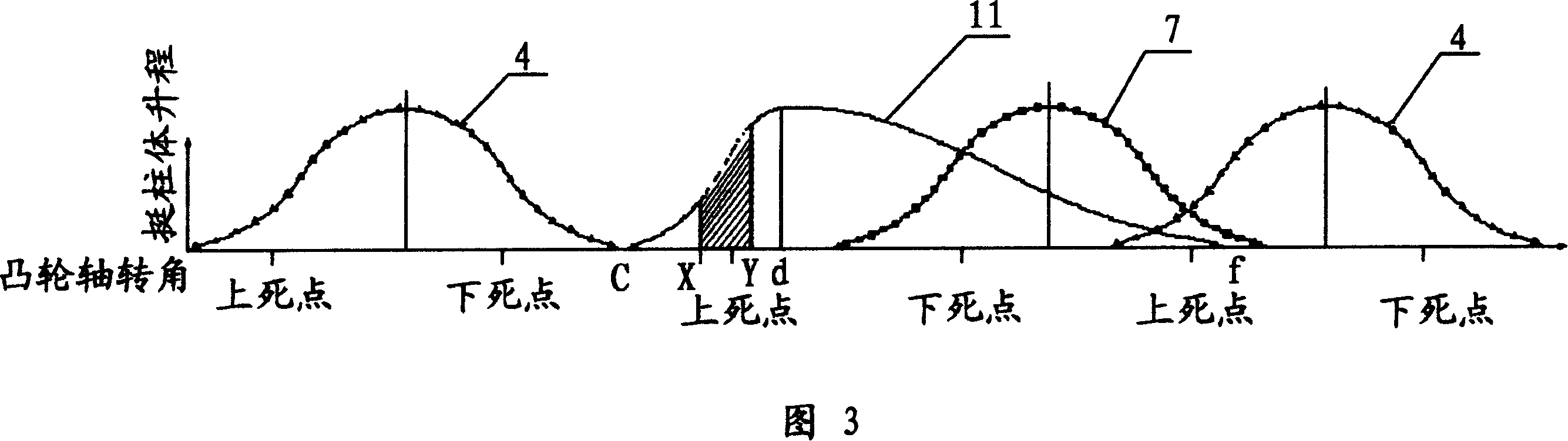

[0030] As shown in Figures 1A, 1B and 2, Figures 1A and 1B are schematic diagrams of the shapes and phase angles of the single-cylinder diesel engine oil pump cam and the intake and exhaust cams in the prior art. Figure 1B is a side view of Figure 1A, and Figure 2 is A schematic diagram of the driving of camshaft components of a single-cylinder diesel engine in the prior art. The camshaft assembly includes a camshaft 3, an oil pump cam 8, a camshaft gear 1, an intake cam 9, and an exhaust cam 10. Through the angle phase shown in Figure 1A and Figure 1B, the fuel injection and the intake and exhaust are ensured to achieve the intake stroke, compression stroke, power stroke, and exhaust stroke of a single-cylinder diesel engine, which completes a complete and continuous working cycle. .

[0031] As shown in Fig. 2, Fig. 2 is a schematic diagram of the driving of camshaft components of a single-cylinder diesel engine in the prior art. When the diesel engine is working normally, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com