Automobile hub double-face full-automatic polishing production line

An automobile wheel hub, fully automatic technology, applied in the direction of grinding automatic control device, grinding machine, grinding frame, etc., can solve the problems of wheel hub shaking and vibration, unstable force, low cleaning efficiency, etc., to avoid shaking and vibration, running Stable and reliable effect with high traction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

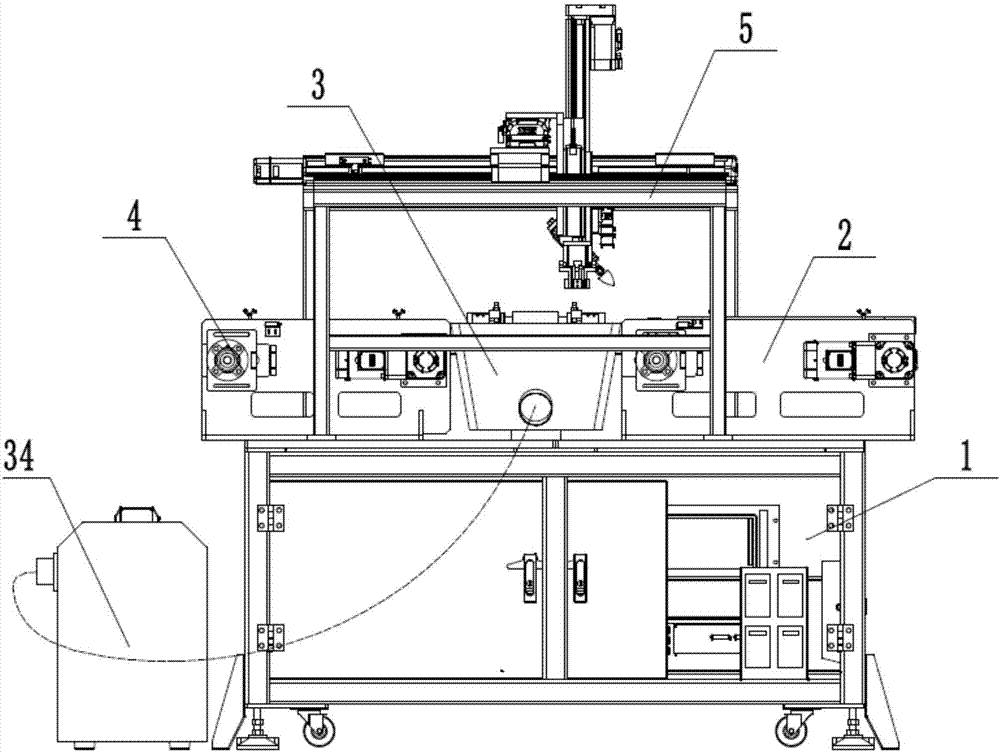

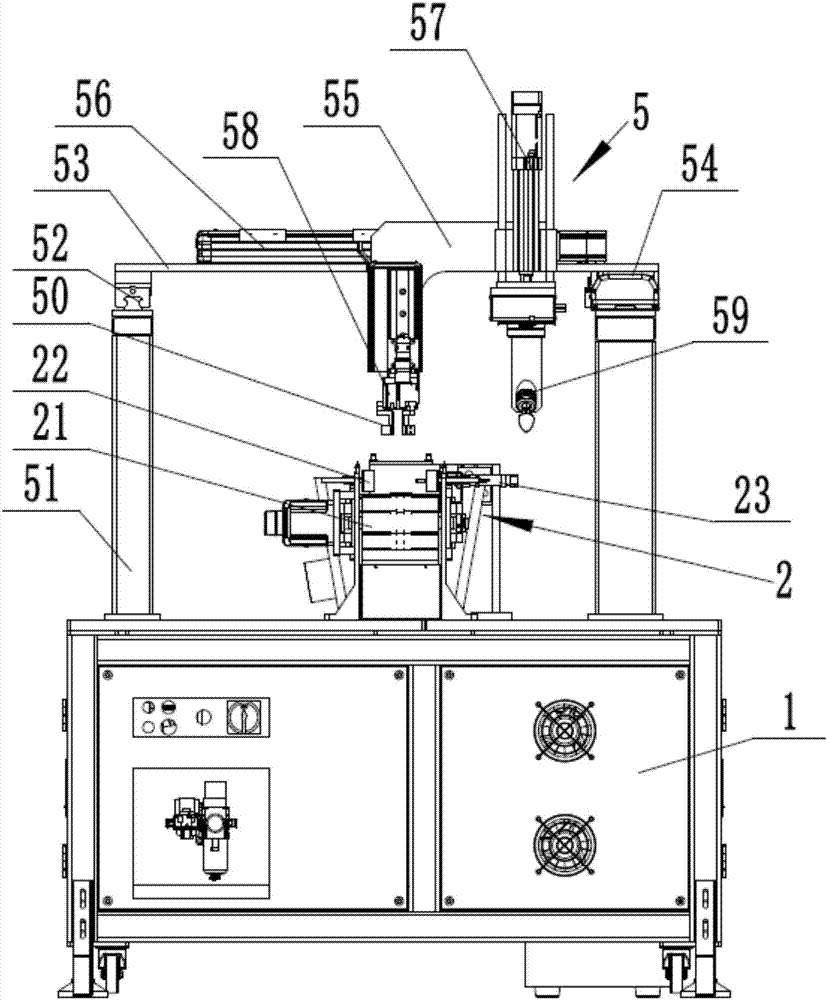

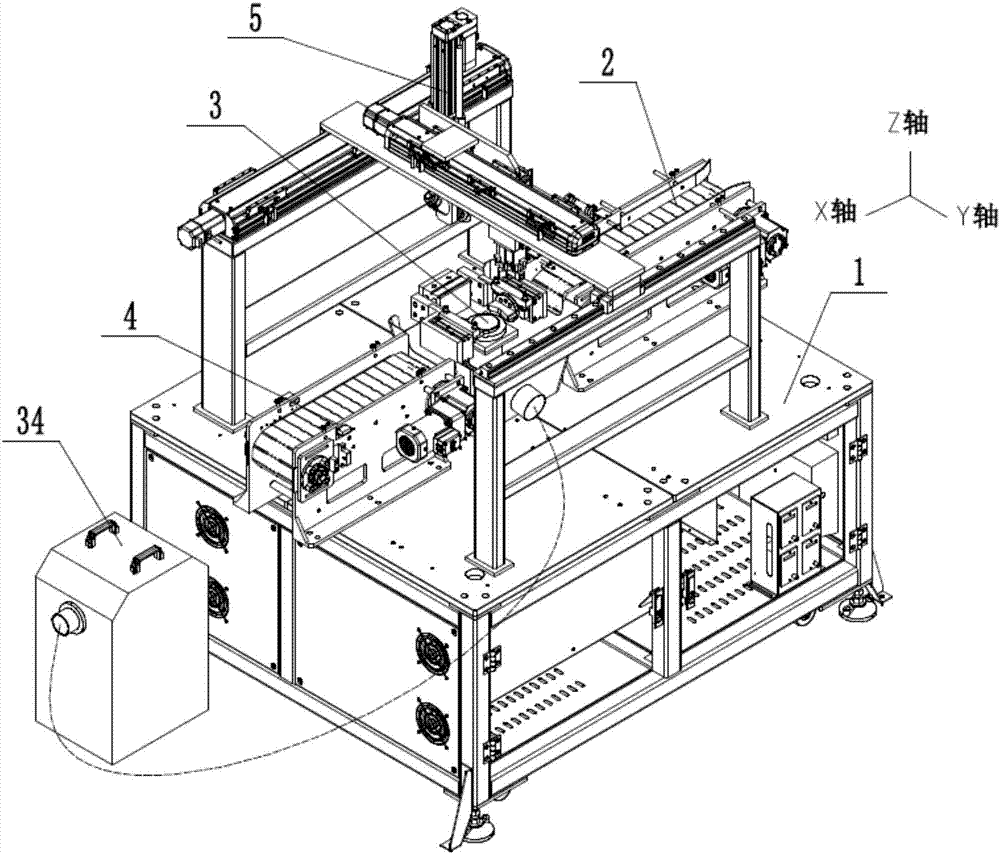

[0046] see Figure 1-3 Shown: a double-sided automatic grinding production line for automobile wheels, including a frame 1 and a grinding mechanism 5. The frame 1 is sequentially provided with a feeding mechanism 2, a wheel grinding turntable 3 and a discharging mechanism 4 along the X-axis direction. The grinding mechanism 5 is located above the hub grinding turntable 3 .

[0047] see Figure 4 , the frame 1 has a horizontal working surface, the feeding mechanism 2, the hub grinding turntable 3 and the discharging mechanism 4, and the grinding mechanism 5 is fixedly installed on the horizontal working surface.

[0048] see Figure 4 , In addition, an electrical room 10 is provided in the rack 1, and a control cabinet is installed in the electrical room 11.

[0049] see Figure 4 The feeding mechanism 2 includes a first chain conveyor 21, two guide plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com