Manufacturing method of imaging nano particle self assembly

A nanoparticle and manufacturing method technology, applied in nanotechnology, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as difficult patterning, limited scope of application, poor controllability, etc., achieve simple operation, improve application range, The effect of convenient batch and parallel processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

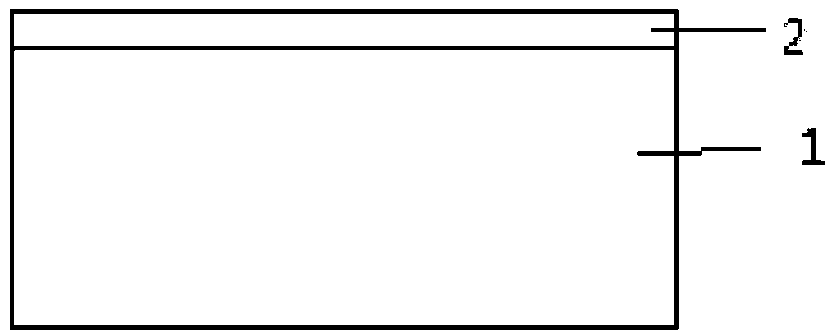

[0022] 1) if figure 1 As shown, a 4-inch single-sided polished single-crystal silicon substrate 1 is prepared, and a layer of parylene (Parylene) film 2 is deposited on the surface of the silicon substrate 1 by chemical vapor deposition (Chemical Vapor Deposition-CVD).

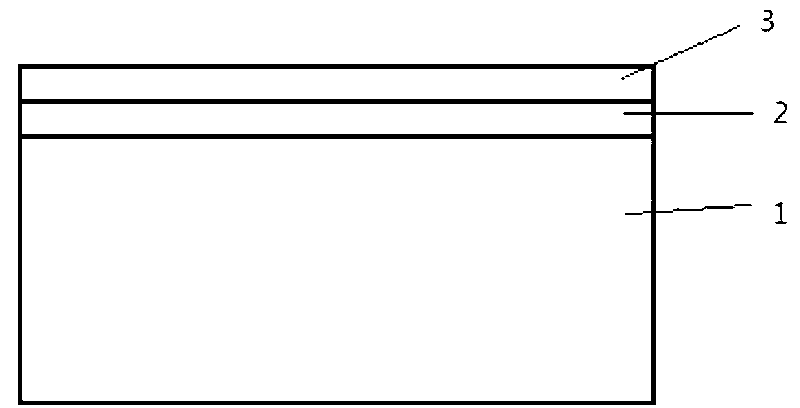

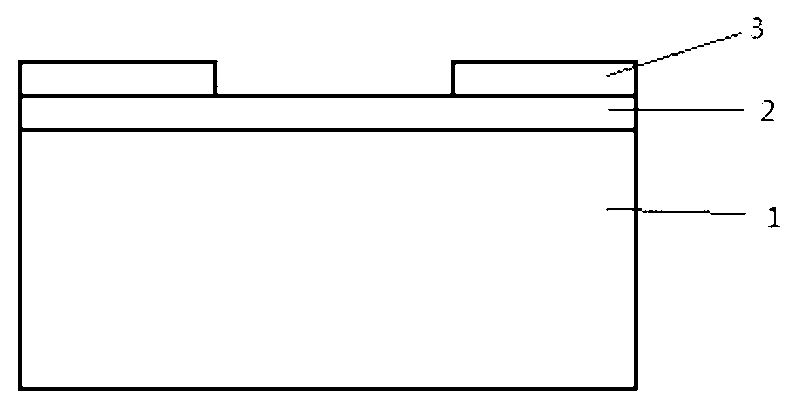

[0023] 2) As shown in Figure 2, by traditional photolithography method, on silicon substrate 1 surface, spin-coat photoresist 3 mask (such as Figure 2a shown), and then according to the production sequence of glue rejection, pre-baking, exposure, post-baking and developing, the required photoresist 3 mask pattern is made on the surface of the silicon substrate 1 (such as Figure 2b shown);

[0024] Wherein, the mask thickness of the photoresist 3 is 1.0 μm˜2.0 μm.

[0025] 3) if image 3 As shown, the exposed parylene film 2 is etched by an oxygen plasma etching method.

[0026]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com