Automatic food package box sealing equipment

A food packaging and automatic technology, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of waste, the volume of items should not be too large, and the box cannot be sealed and packed well, so as to reduce labor intensity and speed up efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

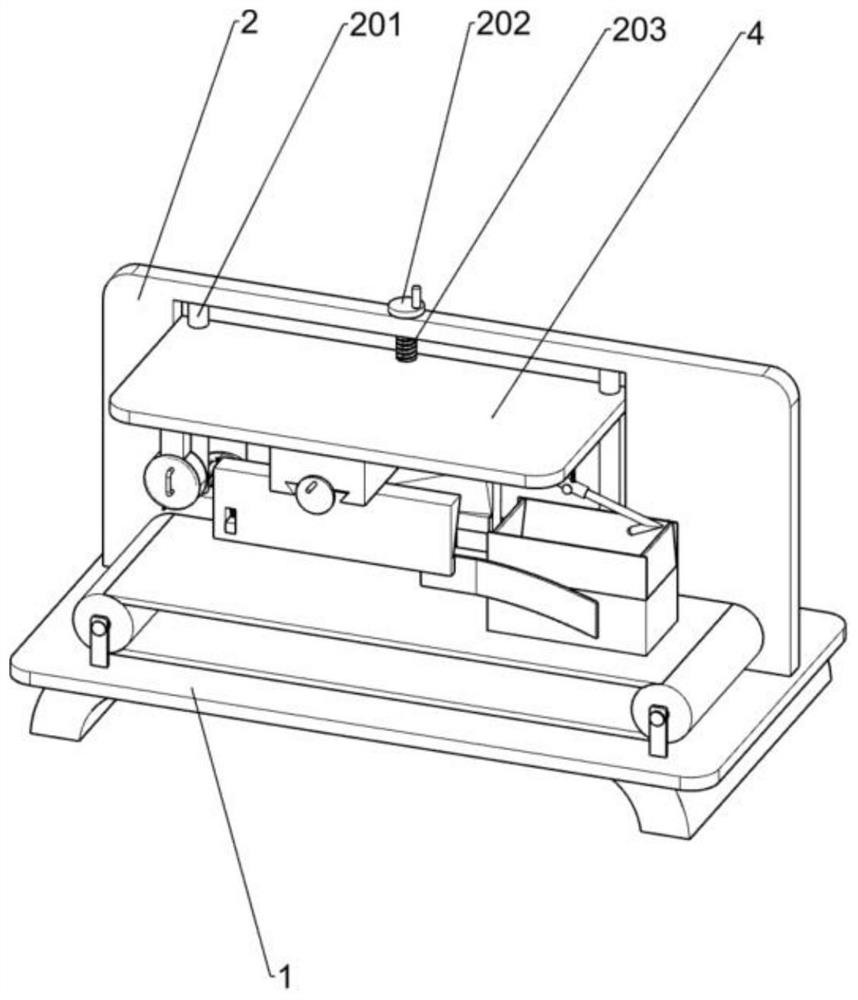

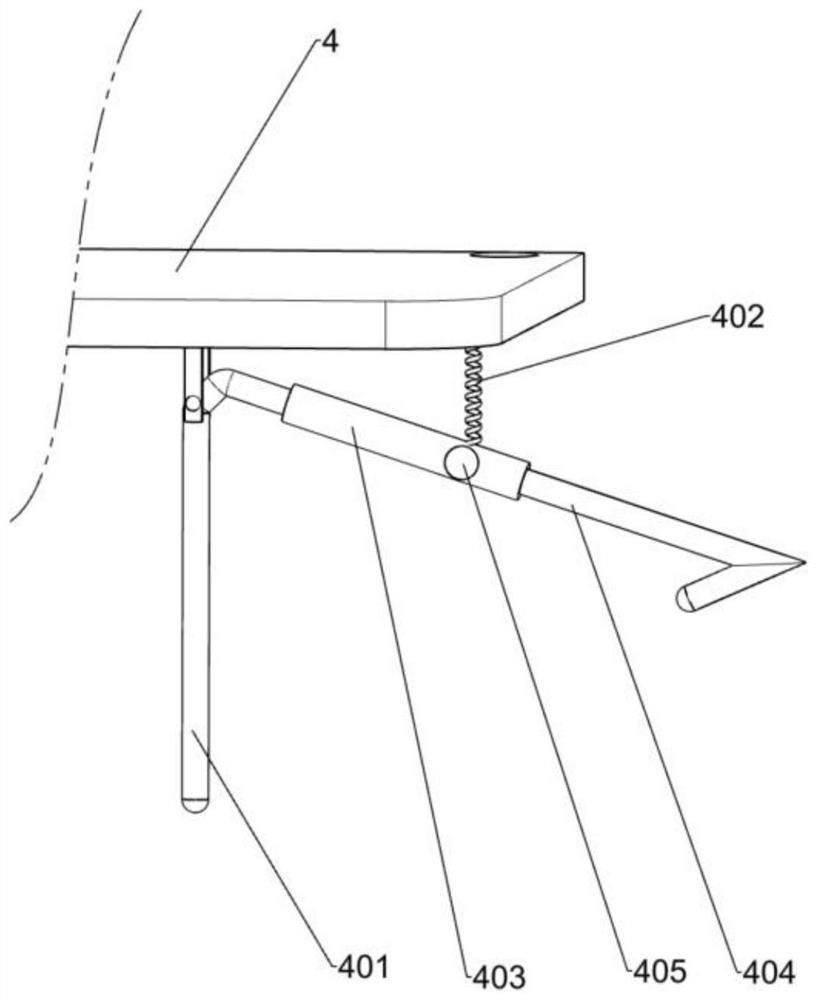

[0030] An automatic sealing device for food packaging, such as Figure 1-5 and Figure 7-8 As shown, it includes a base 1, a first support plate 2, a transmission mechanism, a second support plate 4, a first turning mechanism, a second turning mechanism and a sealing mechanism, and the first support plate 2 is fixedly installed on the upper part of the base 1. On the rear side, the transmission mechanism is fixedly installed on the upper front side of the base 1, the second support plate 4 is installed on the front upper side of the first support plate 2, and the first flip mechanism is fixedly installed on the lower right side of the second support plate 4 , the second turning mechanism is fixedly installed in the middle of the second support plate 4 , and the sealing mechanism is fixedly installed in the lower left side of the second support plate 4 .

[0031] Working principle: When the box is ready to be sealed, put the box on the conveyor belt 303 manually, start the tra...

Embodiment 2

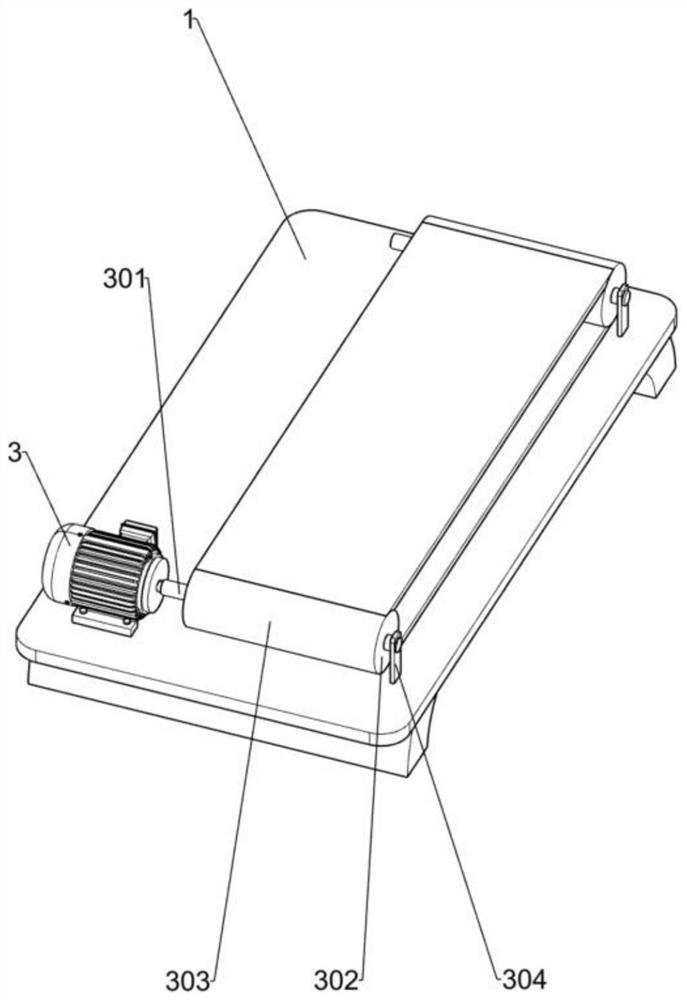

[0033] On the basis of Example 1, such as figure 2 As shown, the transmission mechanism includes a motor 3, a transmission shaft 301, a rotating drum 302 and a transmission belt 303. The motor 3 is fixedly installed on the upper left rear side of the base 1. There are two transmission shafts 301, and one transmission shaft 301 on the left side is fixed Installed on the output shaft of the motor 3, two drums 302 are fixedly installed on the two transmission shafts 301 respectively, and two connecting plates 304 are fixedly installed on the left and right sides of the upper front side of the base 1, and the two transmission shafts 301 are respectively Rotatingly connected with the two connecting plates 304 , the conveyor belt 303 winds on the two drums 302 .

[0034] Working principle: When preparing to transfer the box, start the motor 3, the output shaft of the motor 3 drives the rotation of the transmission shaft 301 on the left, and the drum 302 fixedly connected with the t...

Embodiment 3

[0042] On the basis of Example 2, such as figure 1 As shown, a height adjustment mechanism is also included. The height adjustment mechanism includes a sliding column 201, a first handle 202 and a bolt 203. The two sliding columns 201 are fixedly installed on the left and right sides of the slot opened in the middle of the first support plate 2. , the left and right sides of the second support plate 4 are slidably connected with the two sliding posts 201, the bolt 203 is rotationally connected with the rear side of the first support plate 2, the bolt 203 is screwed with the second support plate 4, and the first handle 202 is fixedly installed on the The upper end of the bolt 203.

[0043] Working principle: When it is necessary to seal boxes of different sizes, the height of the mechanism needs to be adjusted. At this time, the first handle 202 is manually turned, and the first handle 202 drives the rotation of the bolt 203. The thread of the bolt 203 and the second support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com