Special-shaped high-precision optical double-glued lens processing process

A doublet lens, processing technology, applied in optics, optical components, chemical instruments and methods, etc., can solve the problems of decreased cutting force, glue opening, easy passivation, etc. of the stone, so as to improve processing efficiency and solve process and operation problems. , the effect of reducing equipment occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

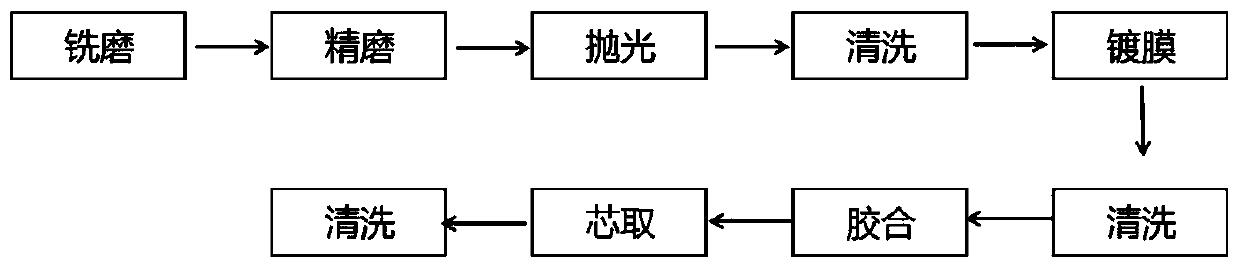

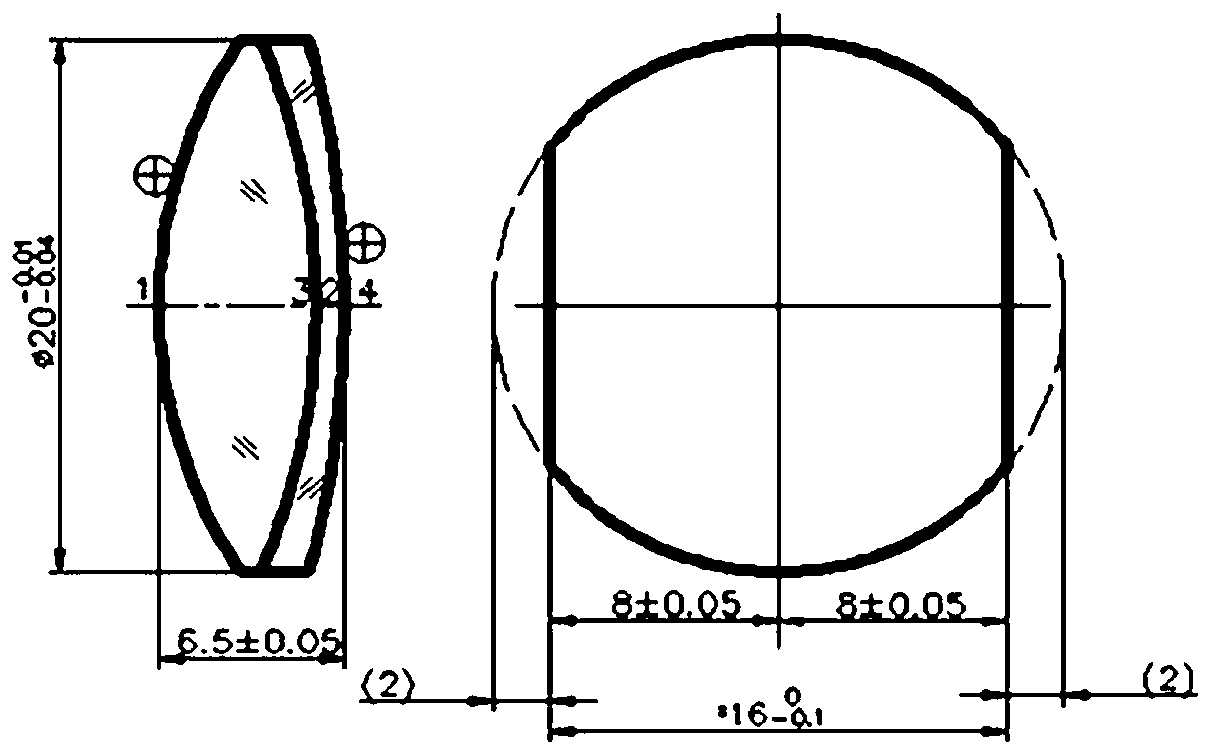

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as Figure 1-2 Shown: a special optical lens bonding optical processing technology, including the following steps: (1) milling: use diamond pellets to cut glass to achieve the required radius and thickness requirements; (2) fine grinding: improve the workpiece Radius, roughness and surface precision lay the foundation for polishing; (3) Polishing: use abrasive powder to refine the surface shape to ensure that the surface shape, size and appearance requirements required by the drawing are met; (4) Cleaning: Select appropriate lotion and ultrasonic frequency to remove abrasive powder impurities on the surface of the lens; (5) Coating: The surface of the substrate obtained in step 4) is alternately stacked with high refractive index materials and low refractive index materials to form a composite film layer, in which the high re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com