Method for controlling non-metallic slag inclusion in medium and heavy plate of hydrogen-induced cracking resistance pipe line steel

A non-metallic inclusion and anti-hydrogen-induced cracking technology, which is applied in the manufacture of converters, etc., can solve the problem of unqualified anti-hydrogen-induced cracking inspection and achieve the effect of stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

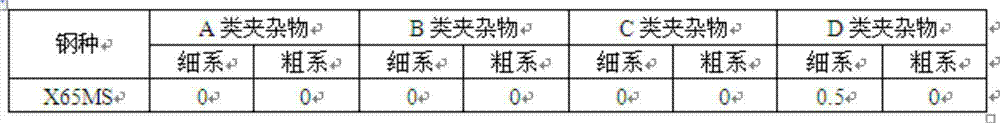

Embodiment 1

[0020] Steel type X65MS, the main finished product components are: [C]=0.035wt%, [S]=0.0006wt%, the control process of non-metallic inclusions in steel is as follows:

[0021] The carbon content at the end of converter smelting is 0.028wt%, and the oxygen content in the steel is 985ppm.

[0022] During the converter tapping process, strong deoxidizer, alloy, and small-grained lime are added in sequence. The feeding process is completed 1 / 4 before the converter is tapped. The strong deoxidizer is metal aluminum, and the addition amount is 2.0kg / t steel; the particle size of small-grained lime is 15~30mm , the addition amount is 8kg / t steel; the [Al] content in the steel at the end of tapping is 0.065wt%.

[0023] Ladle furnace refining is refined by adding high-alkalinity refining slag. During the refining process, the ladle bottom blowing argon flow rate is controlled to 12NL / (min·t steel), the bottom blowing time of argon gas is 25min, and the refining slag composition is con...

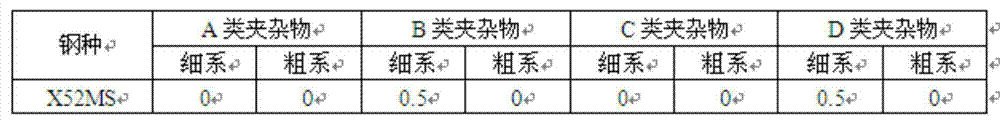

Embodiment 2

[0032] Steel type X52MS, the main finished product components are: [C]=0.042wt%, [S]=0.00010wt%, the control process of non-metallic inclusions in steel is as follows:

[0033] The carbon content at the end of converter smelting is 0.032wt%, and the oxygen content in the steel is 780ppm.

[0034] During the converter tapping process, strong deoxidizer, alloy, and small-grained lime are added in sequence. The feeding process is completed 1 / 4 before the converter is tapped. Among them, the strong deoxidizer is metal aluminum, and the addition amount is 1.8kg / t steel; the particle size of small-grained lime is 15~30mm , the addition amount is 8kg / t steel; the [Al] content in the steel at the end of tapping is 0.055wt%.

[0035] Ladle furnace refining is refined by adding high-alkalinity refining slag. During the refining process, the ladle bottom blowing argon flow rate is controlled to 10NL / (min·t steel), and the bottom blowing time of argon gas is 18min. After refining, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com