Device for largely and continuously preparing two-dimensional nanometer films in large

A two-dimensional nano-film technology, which is applied in the field of preparation devices for new materials, can solve the problems of poor electronic transmission performance of thin films, restricting the application of two-dimensional nano-films, and being unsuitable for large-scale continuous preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

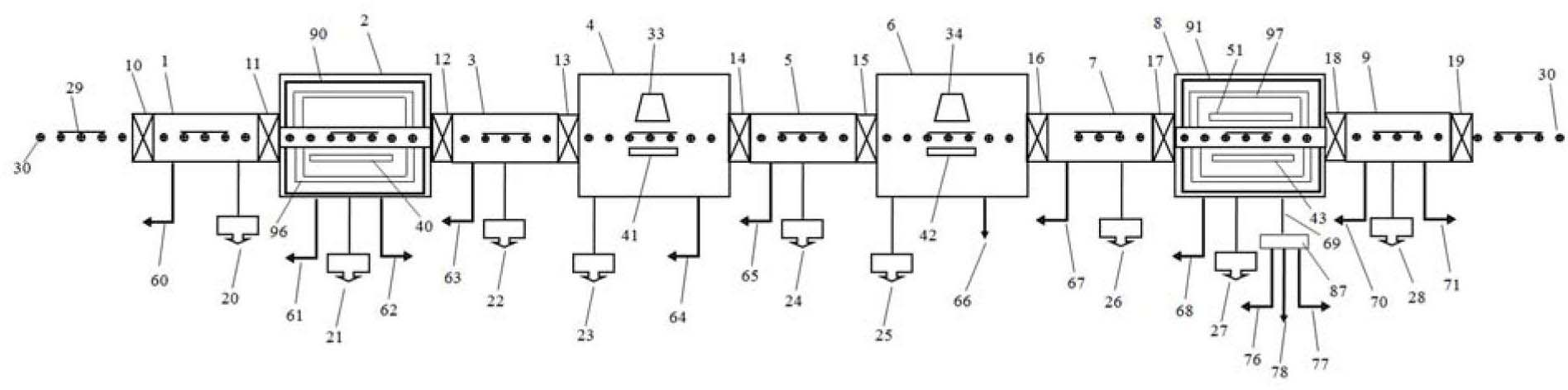

Embodiment 1

[0059] see figure 1 , the device for large-scale continuous preparation of two-dimensional nano-films of the present invention is provided with a feeding chamber 1, a processing chamber 2, a first balance chamber 3, a first film preparation chamber 4, a second balance chamber 5, The second film preparation chamber 6, the third balance chamber 7, the chemical vapor deposition chamber 8 and the discharge chamber 9; A valve 11 is provided between the chambers 2, a valve 12 is provided between the processing chamber 2 and the first balance chamber 3, a valve 13 is provided between the first balance chamber 3 and the first film preparation chamber 4, and the first A valve 14 is provided between the film preparation chamber 4 and the second balance chamber 5, a valve 15 is provided between the second balance chamber 5 and the second film preparation chamber 6, and the second film preparation chamber 6 and the third film preparation chamber A valve 16 is provided between the balance...

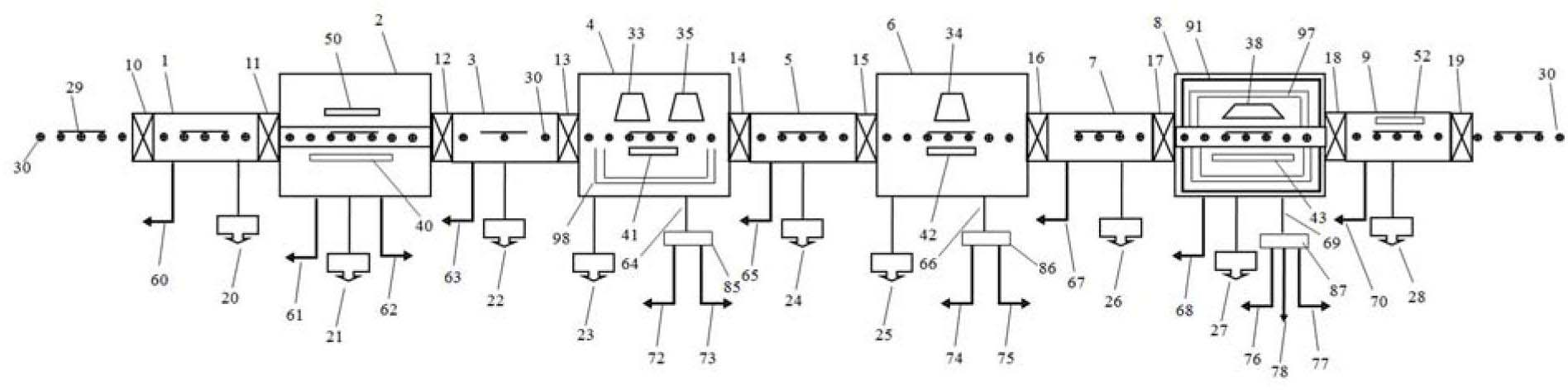

Embodiment 2

[0073] see figure 2 , the device for large-scale continuous preparation of two-dimensional nano-films of the present invention is provided with a feeding chamber 1, a processing chamber 2, a first balance chamber 3, a first film preparation chamber 4, a second balance chamber 5, The second film preparation chamber 6, the third balance chamber 7, the chemical vapor deposition chamber 8 and the discharge chamber 9; A valve 11 is provided between the chambers 2, a valve 12 is provided between the processing chamber 2 and the first balance chamber 3, a valve 13 is provided between the first balance chamber 3 and the first film preparation chamber 4, and the first A valve 14 is provided between the film preparation chamber 4 and the second balance chamber 5, a valve 15 is provided between the second balance chamber 5 and the second film preparation chamber 6, and the second film preparation chamber 6 and the third film preparation chamber A valve 16 is provided between the balanc...

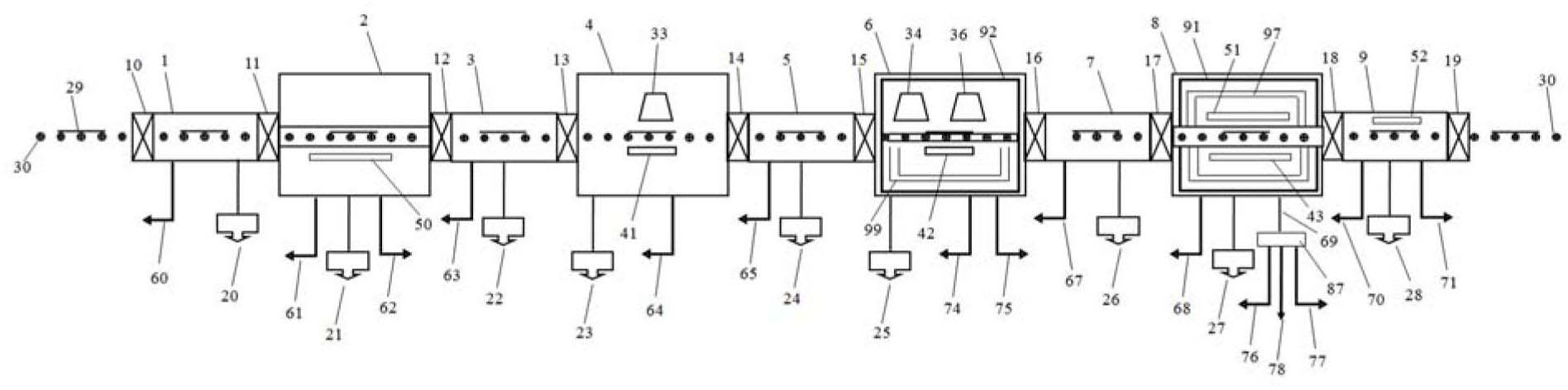

Embodiment 3

[0090] see image 3 , the device for large-scale continuous preparation of two-dimensional nano-films of the present invention is provided with a feeding chamber 1, a processing chamber 2, a first balance chamber 3, a first film preparation chamber 4, a second balance chamber 5, The second film preparation chamber 6, the third balance chamber 7, the chemical vapor deposition chamber 8 and the discharge chamber 9; A valve 11 is provided between the chambers 2, a valve 12 is provided between the processing chamber 2 and the first balance chamber 3, a valve 13 is provided between the first balance chamber 3 and the first film preparation chamber 4, and the first A valve 14 is provided between the film preparation chamber 4 and the second balance chamber 5, a valve 15 is provided between the second balance chamber 5 and the second film preparation chamber 6, and the second film preparation chamber 6 and the third film preparation chamber A valve 16 is provided between the balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com