Titanium or titanium alloy seamless square tube and preparation method thereof

A technology of titanium alloy and square rectangular tube, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of complex preparation, low pipe yield, long production cycle, etc., and achieve simple and easy preparation method, The effect of high dimensional accuracy and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a titanium or titanium alloy seamless square tube, comprising the following steps;

[0028] Provide a circular tube blank, the circular tube blank is a round titanium tube blank or a round titanium alloy tube blank;

[0029] Carrying out first annealing, one-pass cold rolling, second annealing, straightening and machining treatment of scale on the inner and outer surfaces of the circular tube blank in sequence to obtain a semi-finished round tube;

[0030] Carrying out multi-pass cold rolling to the semi-finished round pipe to obtain a seamless round pipe with the same perimeter and wall thickness as the square rectangular pipe;

[0031] Carrying out the third annealing to the seamless tube to obtain the annealed seamless tube;

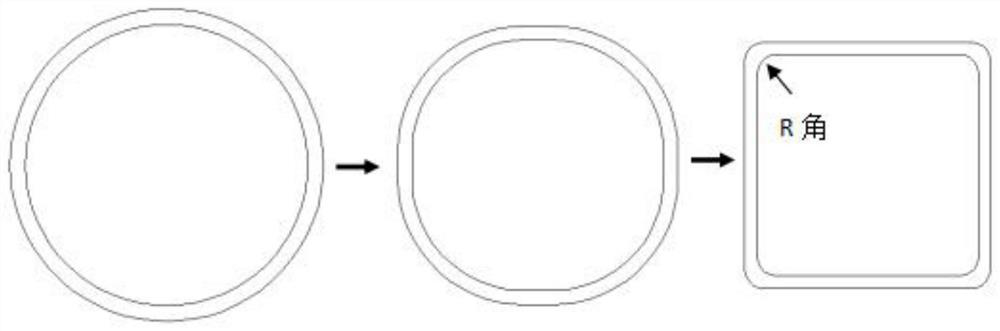

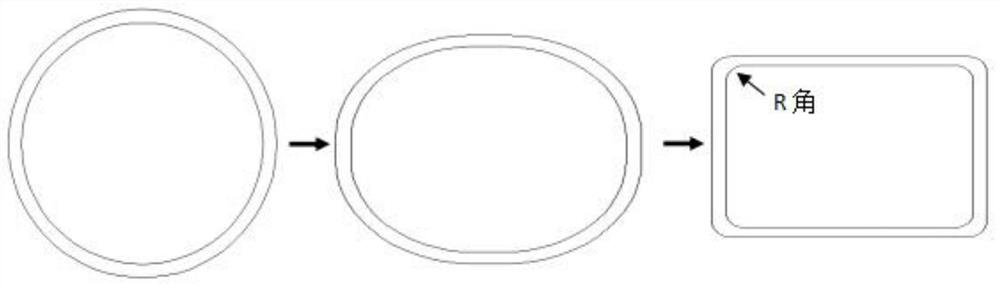

[0032] The annealed seamless round tube is formed and straightened by using a square tube forming equipment to gradually change from a circle to a square to obtain a square tube;

[0033] The four...

Embodiment 1

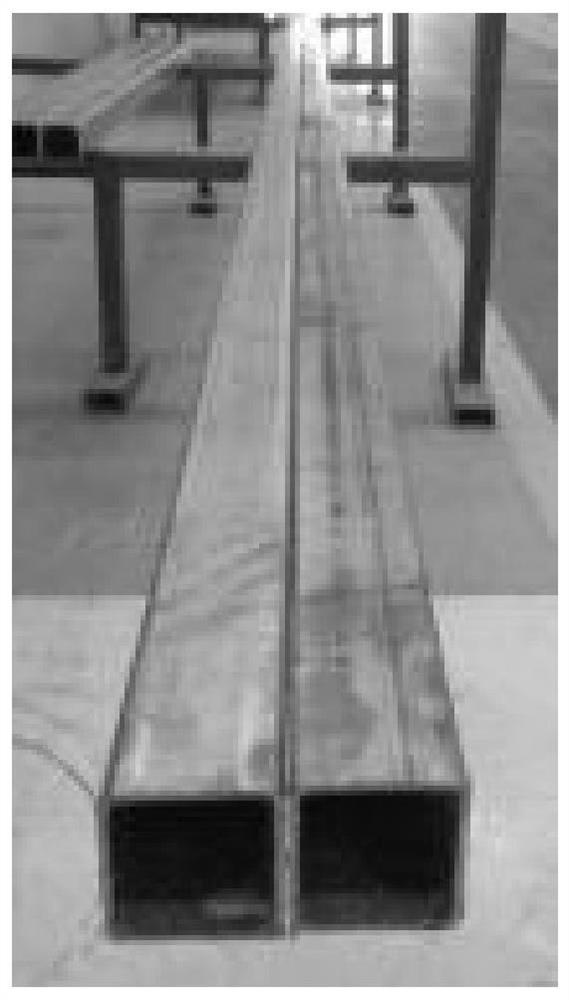

[0056] TA18 titanium alloy seamless square tube (60×3mm, R=3mm) was prepared.

[0057] image 3 The physical figure of the TA18 titanium alloy seamless square tube provided for Example 1 of the present invention;

[0058] Heat the Φ122mm bar to T β +20°C, heat preservation for 100-220min, cross-rolling and piercing to prepare TA18 tube blank of Φ128×11mm. The tube blank is vacuum annealed at 750°C for 1h (vacuum degree 1×10 -1 After Pa), cold rolling is carried out one time, Φ128×11mm→Φ108×9mm. The Φ108×9mm semi-finished pipe is vacuum annealed and straightened at 700°C / 3h, then internally bored and externally scraped to remove the scale on the inner and outer surfaces to obtain a Φ107×8mm semi-finished pipe. After the surface treatment, the semi-finished pipe is rolled twice (Φ107×8mm→Φ94×5mm→Φ74.8×3mm) to obtain a seamless titanium alloy round pipe of Φ74.8×3mm. The semi-finished pipe after each pass of rolling needs to be vacuum annealed at 700°C for 3 hours (vacuum de...

Embodiment 2

[0060] Low-cost high-strength Ti-3.5Al-2.5Mo-1.5Cr-1.5Fe titanium alloy seamless rectangular tube (100×80×4mm, R=6mm) was prepared.

[0061] Heat the Φ165mm bar to T β +80°C, heat preservation for 132-310min, cross-rolling and piercing to prepare a tube blank of Φ170×13.5mm. After the tube billet is annealed at 850°C for 3 hours, it is air-cooled, and then cold-rolled once, Φ170×13.5mm→Φ138×11.5mm. Anneal Φ138×11.5mm semi-finished pipes at 850°C for 3 hours (vacuum degree 1×10 -2 Pa), straightening, and then internally boring and externally removing scales on the inner and outer surfaces to obtain semi-finished pipes of Φ137×10.5mm. The Φ137×10.5mm semi-finished pipe is rolled in two passes (Φ137×10.5mm→Φ120×6.5mm→Φ100.6×4mm) to obtain a Φ100.6×4mm seamless titanium alloy round pipe. The semi-finished pipe after each pass of rolling needs to be vacuum annealed at 800 °C for 3 hours (vacuum degree 1×10 -2 Pa). The finished seamless titanium alloy round tube obtained by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com