Working clothes folding machine

A technology of work clothes folding machine and folding device, which is applied in the direction of folders, folding thin materials, laundry room devices, etc., which can solve the problems of work clothes re-contamination, low folding efficiency, and cost increase, so as to ensure flatness and consistency , Synchronization and coordination are good, and the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

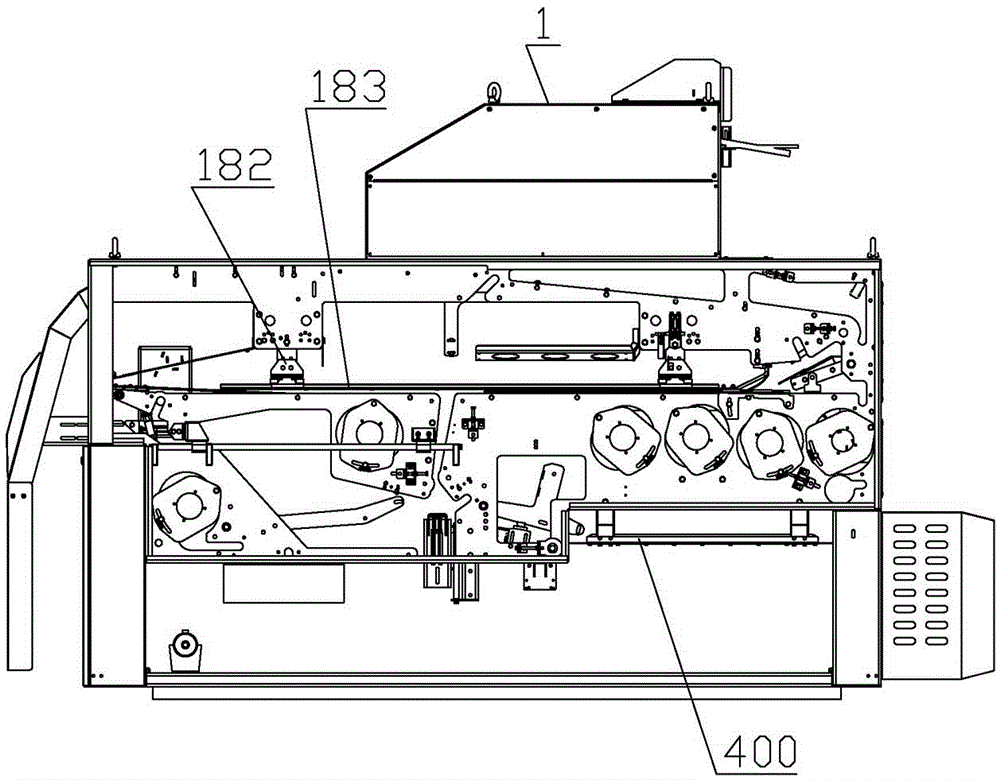

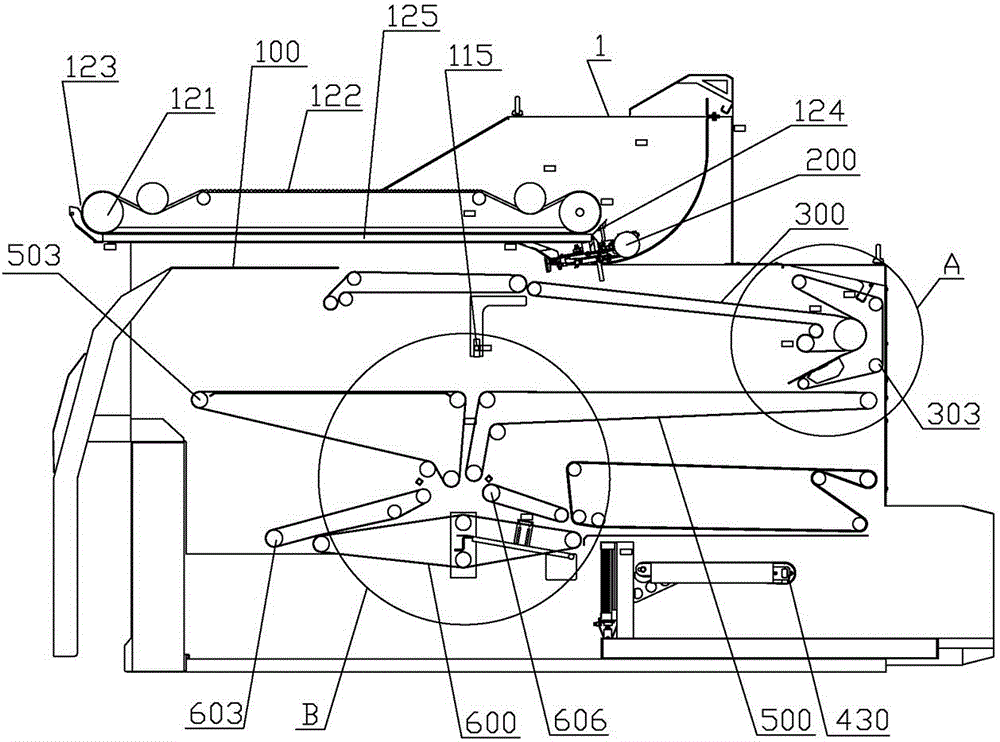

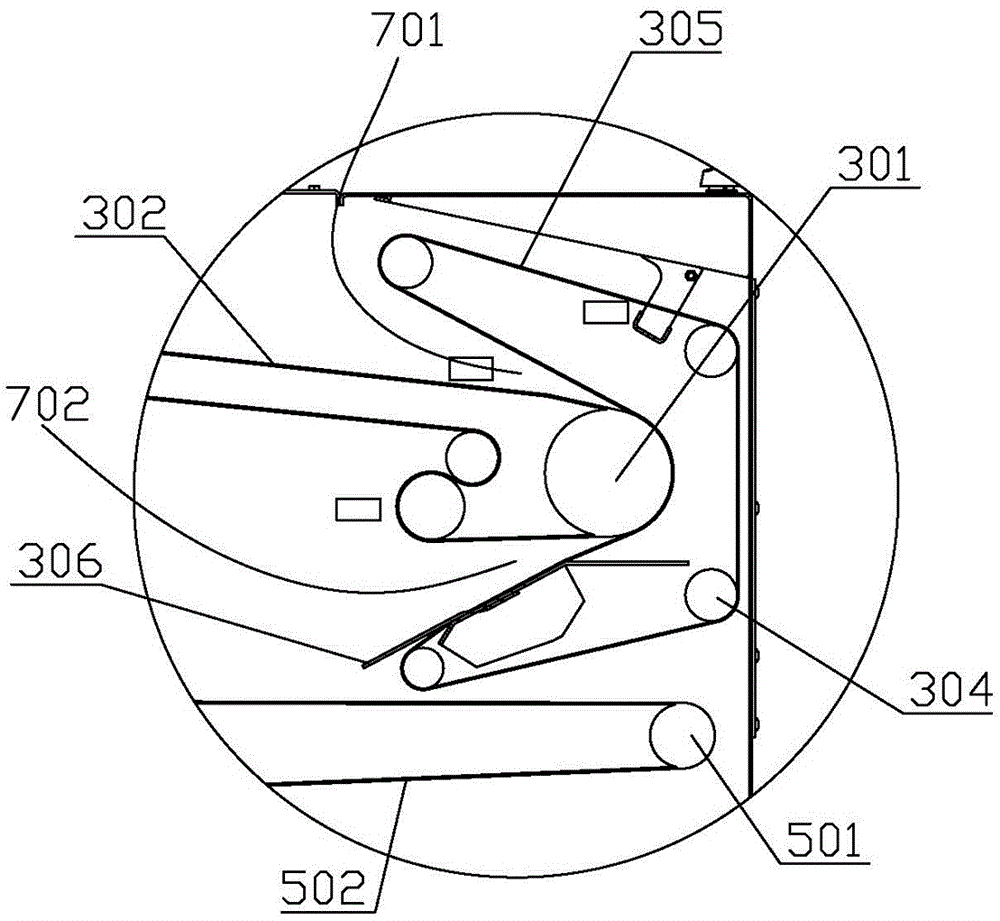

[0035] like figure 1 and figure 2 As shown, the garment folding machine of the present invention is provided with a sleeve folding device 100 capable of cross-folding two sleeves of the garment on the back of the garment at the feeding place of the frame body 1 . like Figure 5 and Image 6 As shown, the structure of the sleeve folding device 100 described in this embodiment is as follows: a garment support board 101 is provided at the feeding place of the frame body 1, and the work clothes on both sides of the garment support board 101 are spread flat. The sleeves hang down naturally from both sides of the garment supporting board 101, and a clothes hanger hook conveying device that hooks the clothes hanger hook and pulls the clothes hanger hook to move backward is arranged on the top of the clothes su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com