Single code channel absolute grating scale rolling and impressing mould manufacturing method

A mold manufacturing, absolute technology, applied in optics, opto-mechanical equipment, using optical devices, etc., can solve the problems of large precision loss, complicated process steps, etc., and achieve the effect of low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below through the accompanying drawings and specific embodiments. But the following implementation examples are only limited to explain the present invention, and the protection scope of the present invention just includes the whole content of claim.

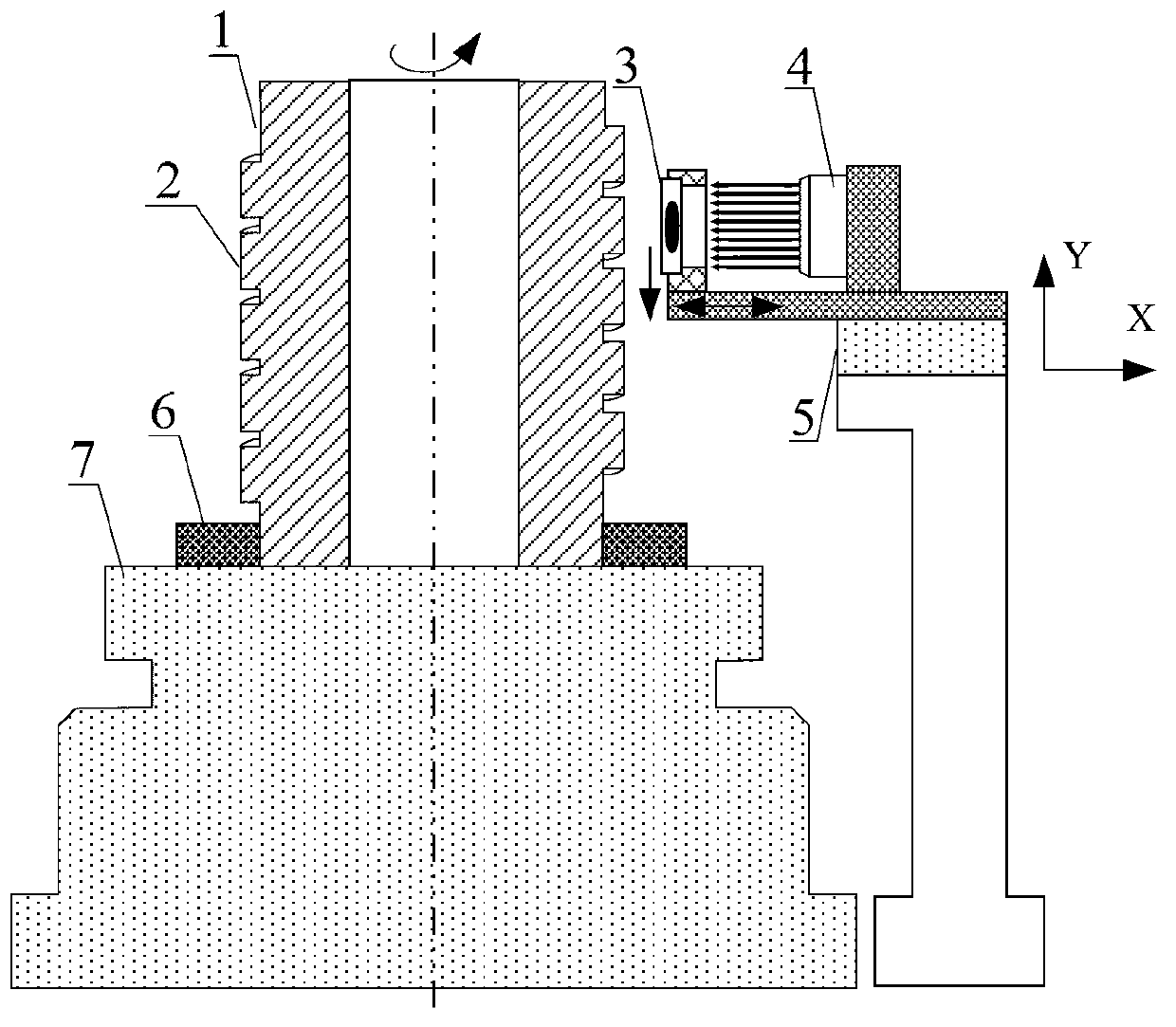

[0036] A specific embodiment of the manufacturing method of the single-track absolute grating ruler roller embossing mold of the present invention is realized through the following steps. The method includes the following steps:

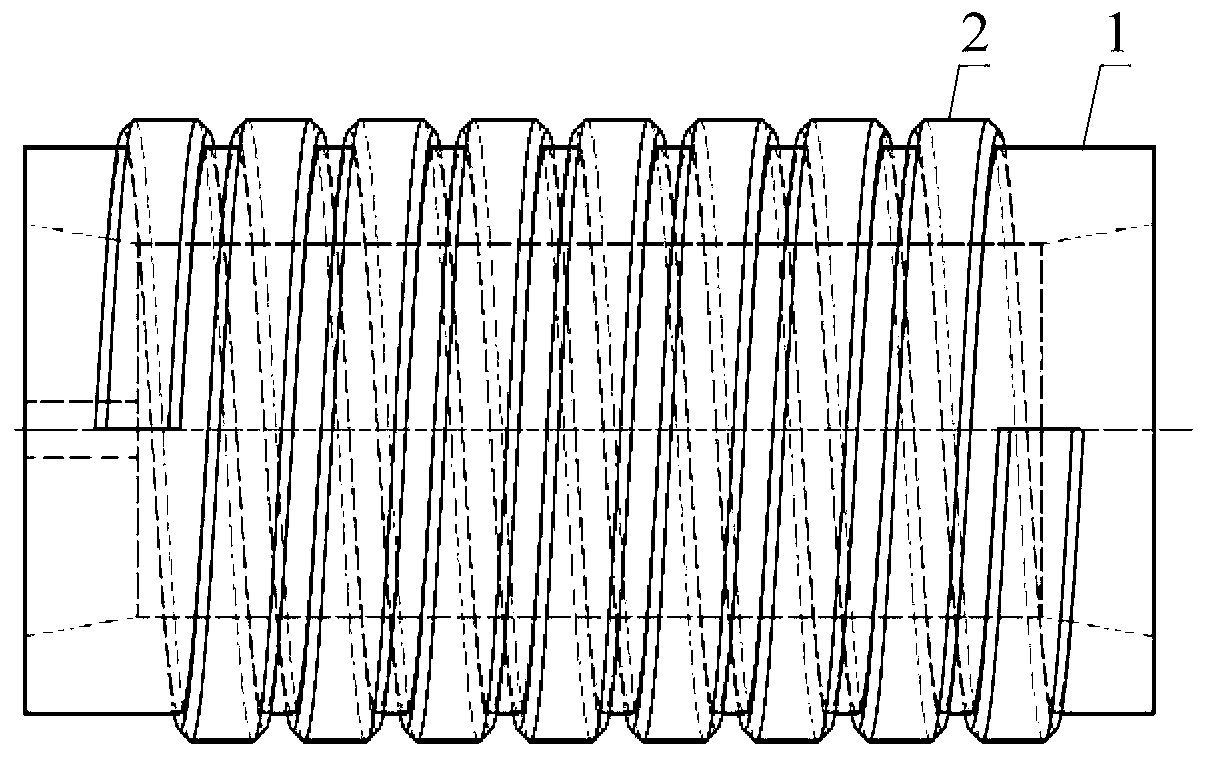

[0037] (1) Roll embossing mold processing: process a spiral strip 2 with a certain angle of rise, width and number of turns on the cylindrical mold base 1, such as figure 1 shown;

[0038] The material of the roll embossing mold base 1 used in this embodiment is stainless steel 4Cr13, the outer diameter of the spiral belt 2 on the roll embossing mold base 1 is D=100mm, the width is d=15mm, the angle of rise is θ=10 degrees, and the circle The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com