Rapid immersion type metal solidification heat transfer test device and application and application method thereof

A technology of metal solidification and testing device, which is applied in the direction of material thermal development, etc., can solve problems such as inability to test heat flow, and achieve the effect of simple testing method, accurate measurement and less operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

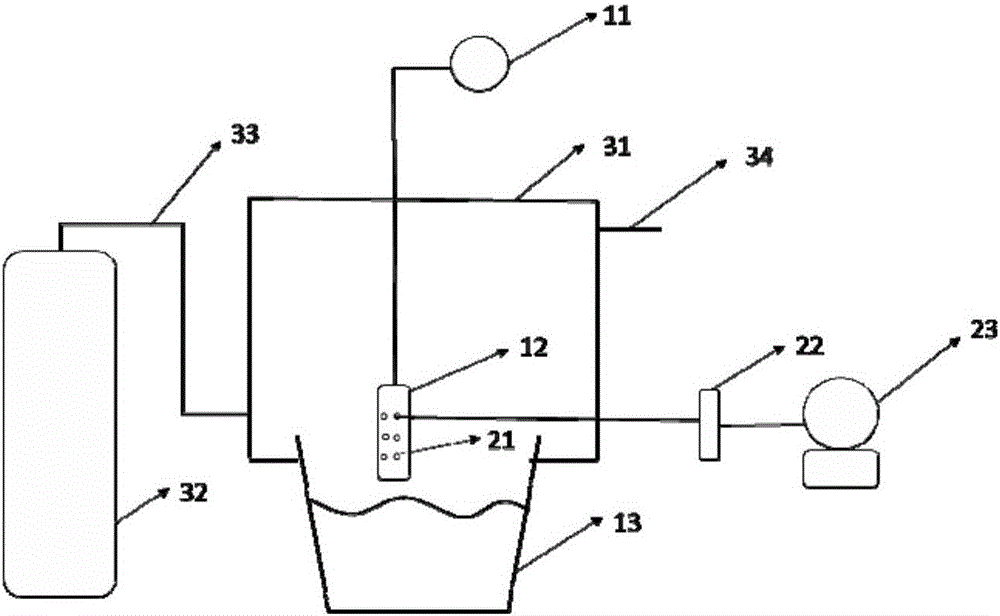

[0052] The rapid immersion metal solidification heat transfer test experiment adopts such as figure 1 The shown rapid immersion metal solidification heat transfer test device is used to determine the rapid solidification heat transfer of metals, which specifically includes the following sequential steps:

[0053] (1) Loading: Open the protective gas cover with the sealing ring, put 23kg steel sample into the induction furnace, and close the cover of the protective gas cover.

[0054] (2) Gas protection: Seal the protective gas cover, then fill it with Ar protective gas, and continue to ventilate for a period of time, and finally make the protective gas cover full of protective gas.

[0055] (3) Molten metal: Heat the steel sample in the induction furnace to the target melting temperature by electric heating.

[0056] (4) Immersion test: Open the cooling water pipeline in the copper mold, and control the circulating flow of cooling water to 7.5L / min, control the copper mold to...

Embodiment 2

[0061] The rapid immersion metal solidification heat transfer test experiment adopts such as figure 1 The shown rapid immersion metal solidification heat transfer test device is used to determine the rapid solidification heat transfer of metals, which specifically includes the following sequential steps:

[0062] (1) Loading: Open the protective gas cover with the sealing ring, put 23kg steel sample into the induction furnace, and close the cover of the protective gas cover.

[0063] (2) Gas protection: Seal the protective gas cover, then fill it with Ar protective gas, and continue to ventilate for a period of time, and finally make the protective gas cover full of protective gas.

[0064] (3) Molten metal: Heat the steel sample in the induction furnace to the target melting temperature by electric heating.

[0065] (4) Immersion test: Open the cooling water pipeline in the copper mold, and control the cooling water circulation flow rate to 5L / min, control the copper mold to...

Embodiment 3

[0069] The rapid immersion metal solidification heat transfer test experiment adopts such as figure 1 The shown rapid immersion metal solidification heat transfer test device is used to determine the rapid solidification heat transfer of metals, which specifically includes the following sequential steps:

[0070] (1) Loading: Open the protective gas cover with the sealing ring, put 23kg steel sample into the induction furnace, and close the cover of the protective gas cover.

[0071] (2) Gas protection: Seal the protective gas cover, then fill it with Ar protective gas, and continue to ventilate for a period of time, and finally make the protective gas cover full of protective gas.

[0072] (3) Molten metal: Heat the steel sample in the induction furnace to the target melting temperature by electric heating.

[0073] (4) Immersion test: Open the cooling water pipeline in the copper mold, and control the cooling water circulation flow rate to 10L / min, control the copper mold t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com