Method for detecting and compensating floor-type boring and milling machine space position by using double-frequency laser measurement system

A measurement system, dual-frequency laser technology, applied in measurement devices, optical devices, other manufacturing equipment/tools, etc., can solve the problems of machine tool manufacturing precision accuracy error, poor product stability, verticality change, etc., to improve accuracy and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

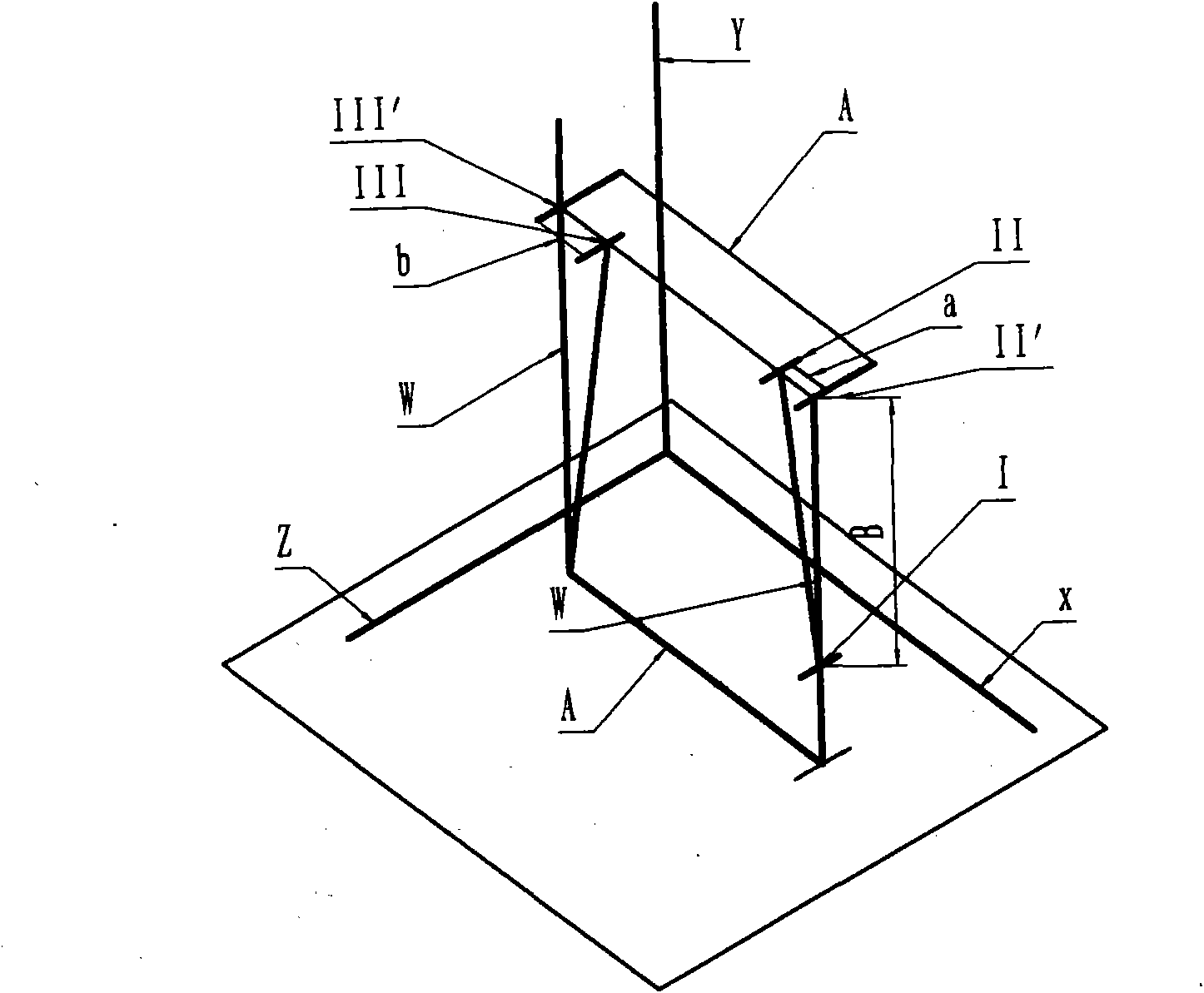

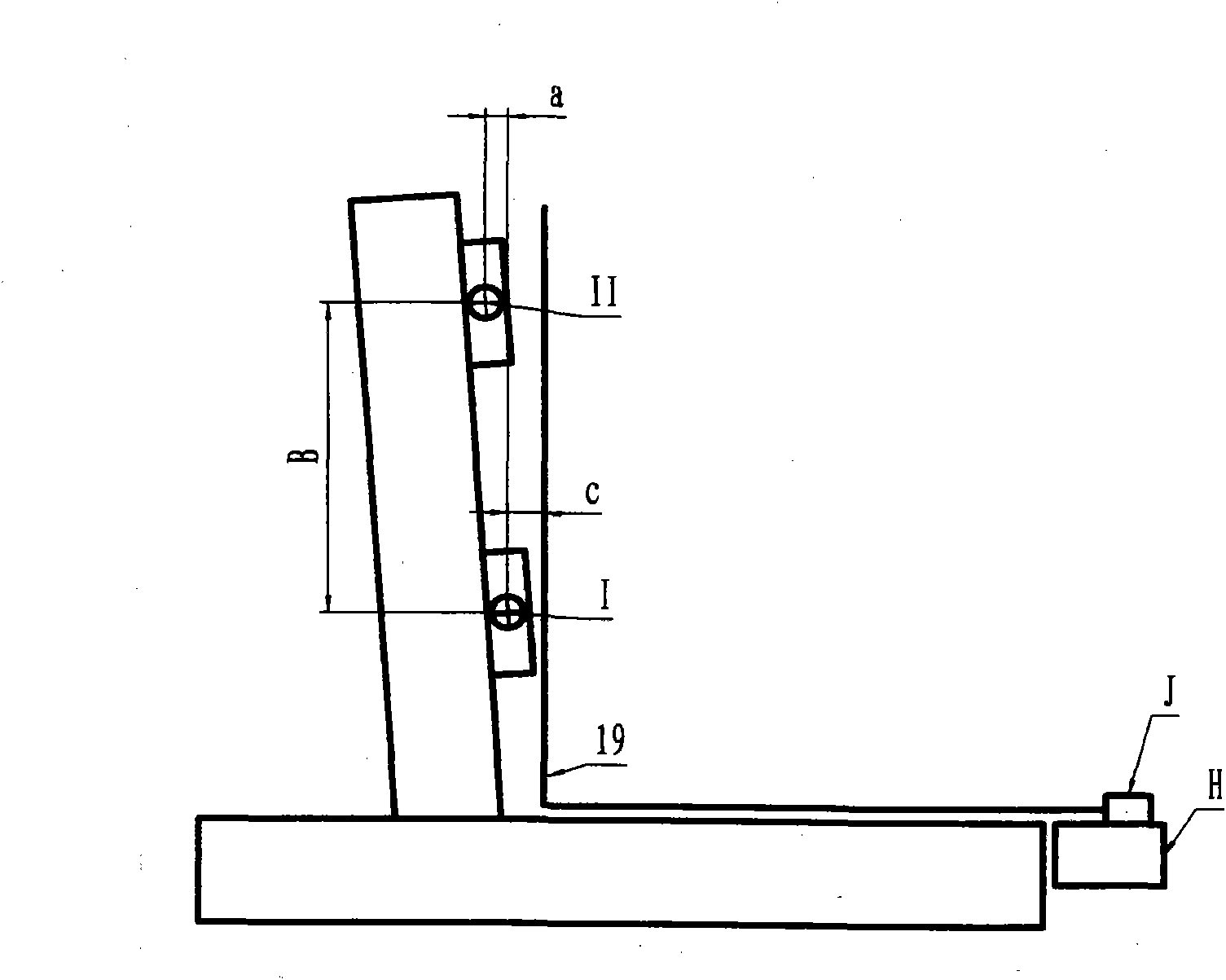

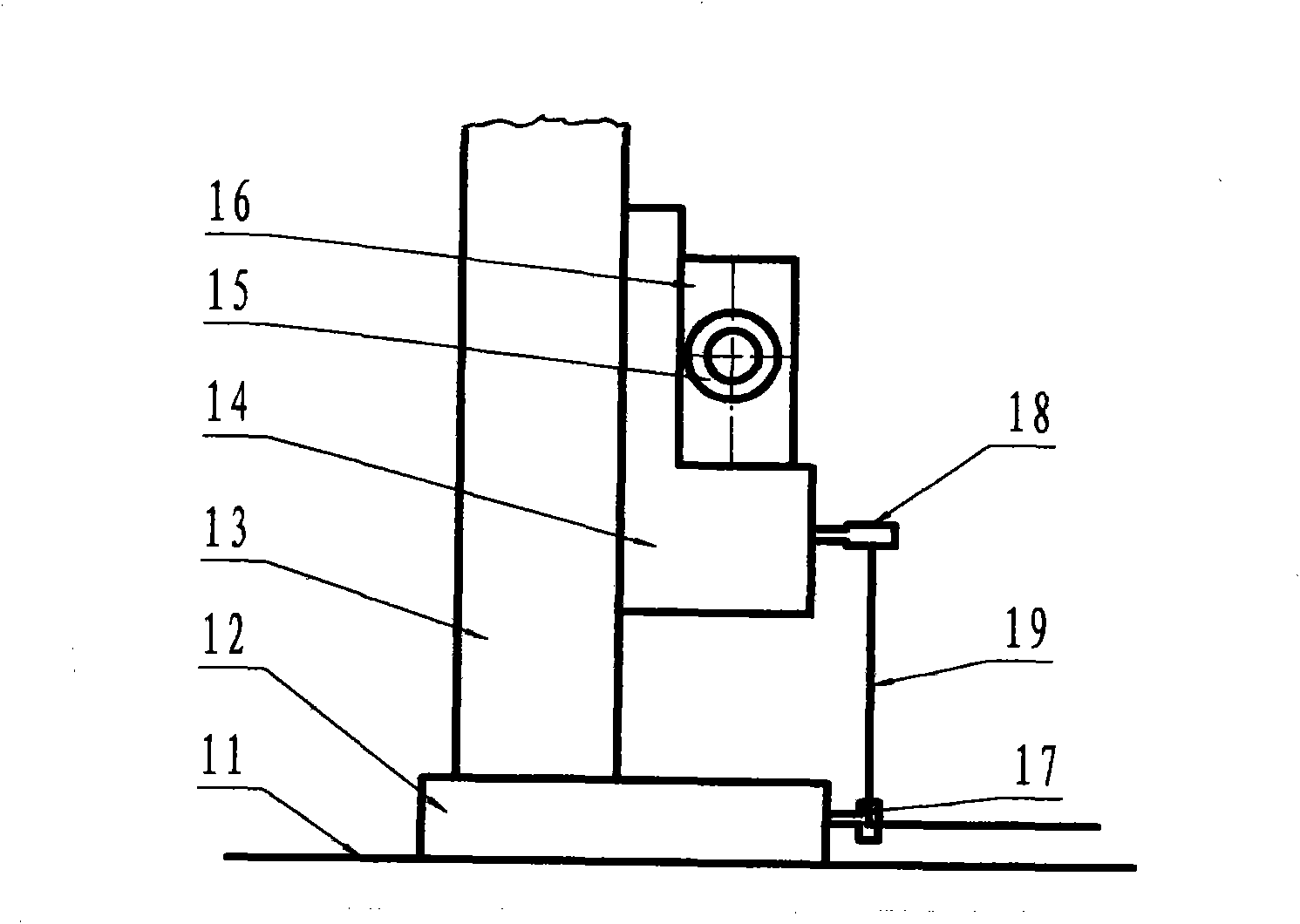

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the examples do not limit the present invention.

[0019] Embodiment, with the same floor boring and milling machine (model is TK6920) the test piece before adopting this method and after adopting this method is processed, then on the three-coordinate inspection instrument, the test piece obtained by processing is detected, with It illustrates the effect of this method on improving the precision and stability of the machined parts. During the machining, the machine column and the ram seat are moved. Figure 4 It is the processing drawing of the test piece, and the distance between adjacent holes of ①, ②, ③, and ④ is 1000mm. For the first time, the cutting test piece is subjected to conventional cutting, that is, the cutting without error compensation, and the obtained cutting test piece is tested on the three-coordinate inspection instrument. Based on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com