Ship steel plate dynamic three-dimension measurement method based on multi-camera vision

A three-dimensional measurement, multi-eye vision technology, applied in measurement devices, instruments, etc., can solve problems such as slow measurement speed, inconvenient use, and time axis mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

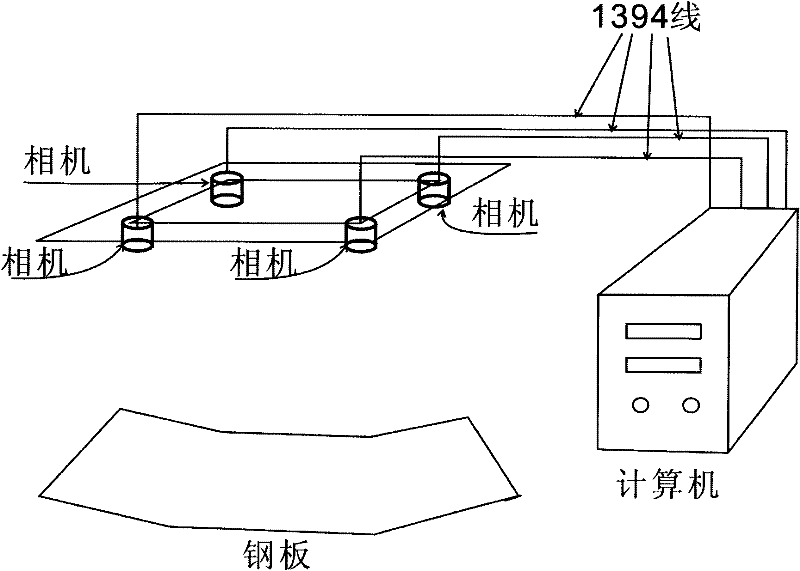

[0018] The hardware connection of the inventive method is as figure 1 As shown, it includes four synchronous high-resolution industrial cameras with a resolution above 1440*1080 and a frame rate of 10fps fixed on the measurement frame. The images taken by the four industrial cameras are transmitted to a computer with 1394 lines and 1394 cards for processing. The high-performance computer for storage and analysis can analyze the dynamic three-dimensional measurement data of ship steel plates.

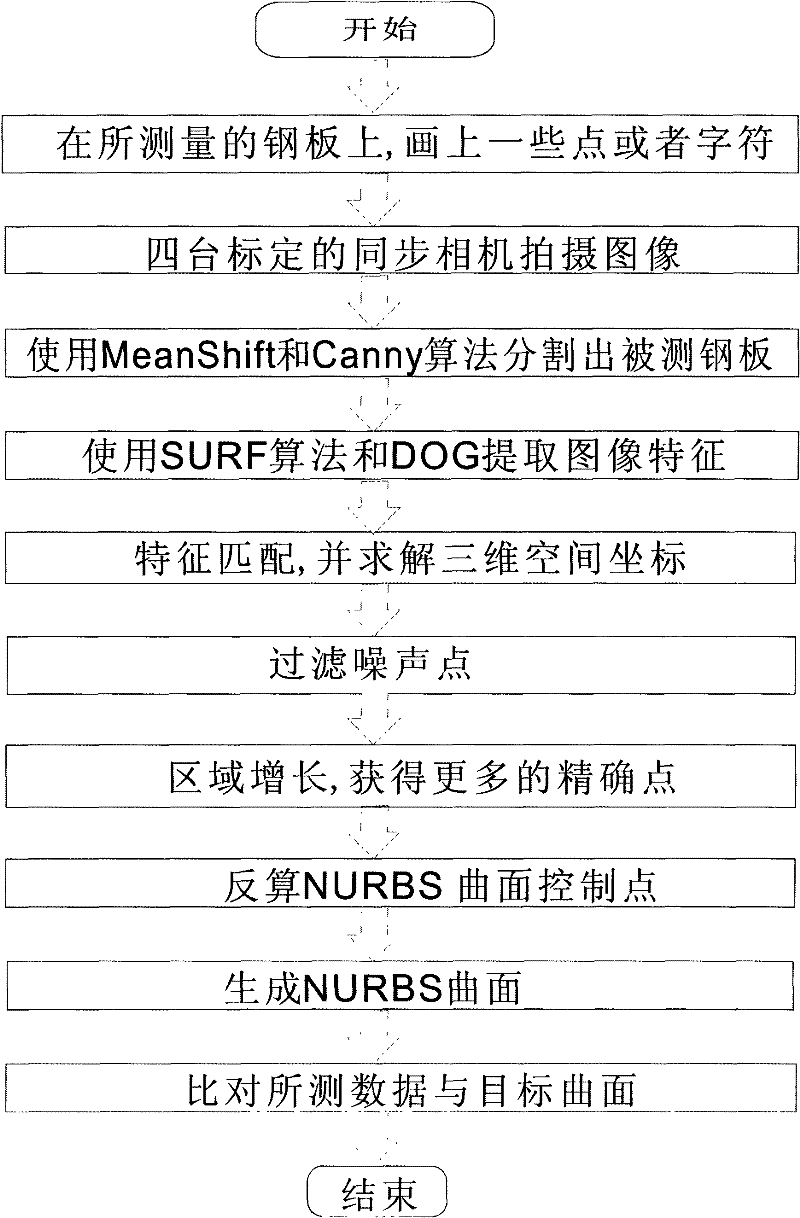

[0019] The flow process of the inventive method is as figure 2 Shown:

[0020] 1. Draw some sparse points or characters that will not be burned on the measured steel plate. These points or characters are used to find the corresponding relationship on the time axis. Try to draw more points on the edge of the measured steel plate. This helps to accurately measure the edge of the steel plate being tested.

[0021] 2. Four synchronous high-resolution industrial cameras fixed on the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com