Anti-rollover device for cement pump truck

A cement pump truck and anti-rollover technology, which is applied in vehicle parts, transportation and packaging, and vehicle safety arrangements, etc., can solve the problems of cement pump truck rollover, limited ground conditions, and slow construction progress. flipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

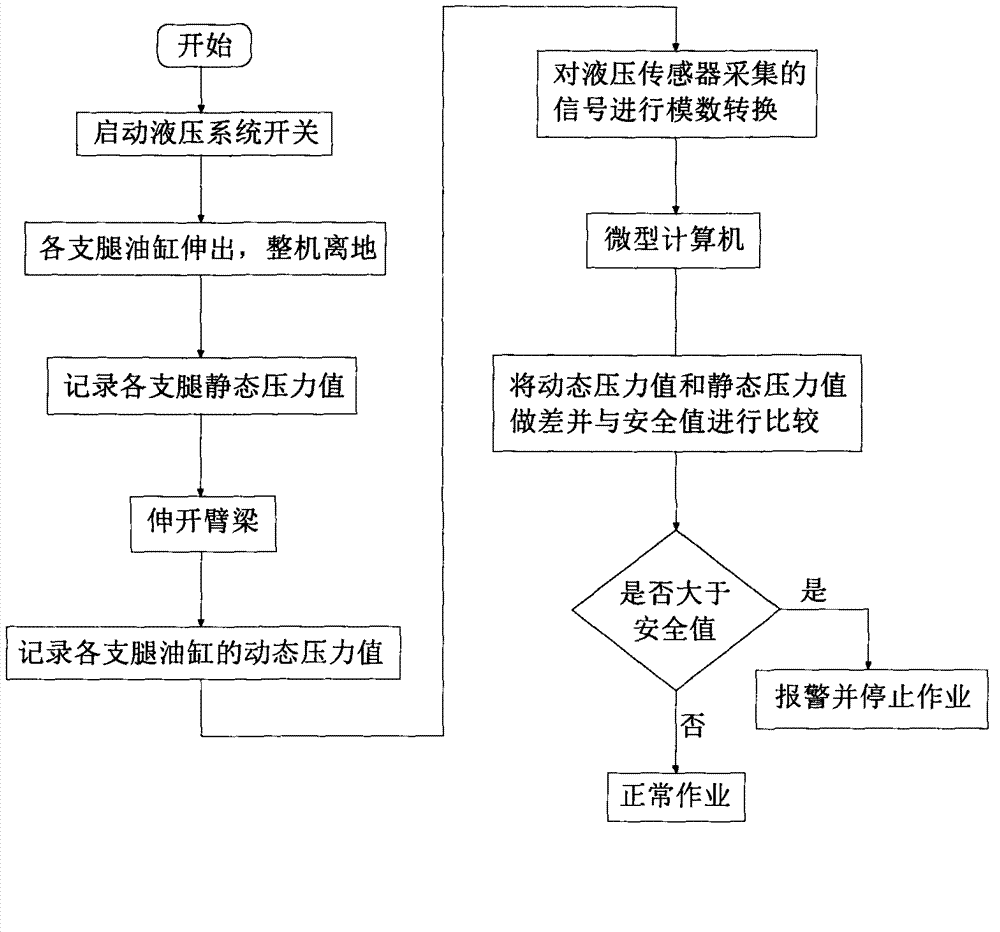

[0015] The cement pump truck anti-rollover device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

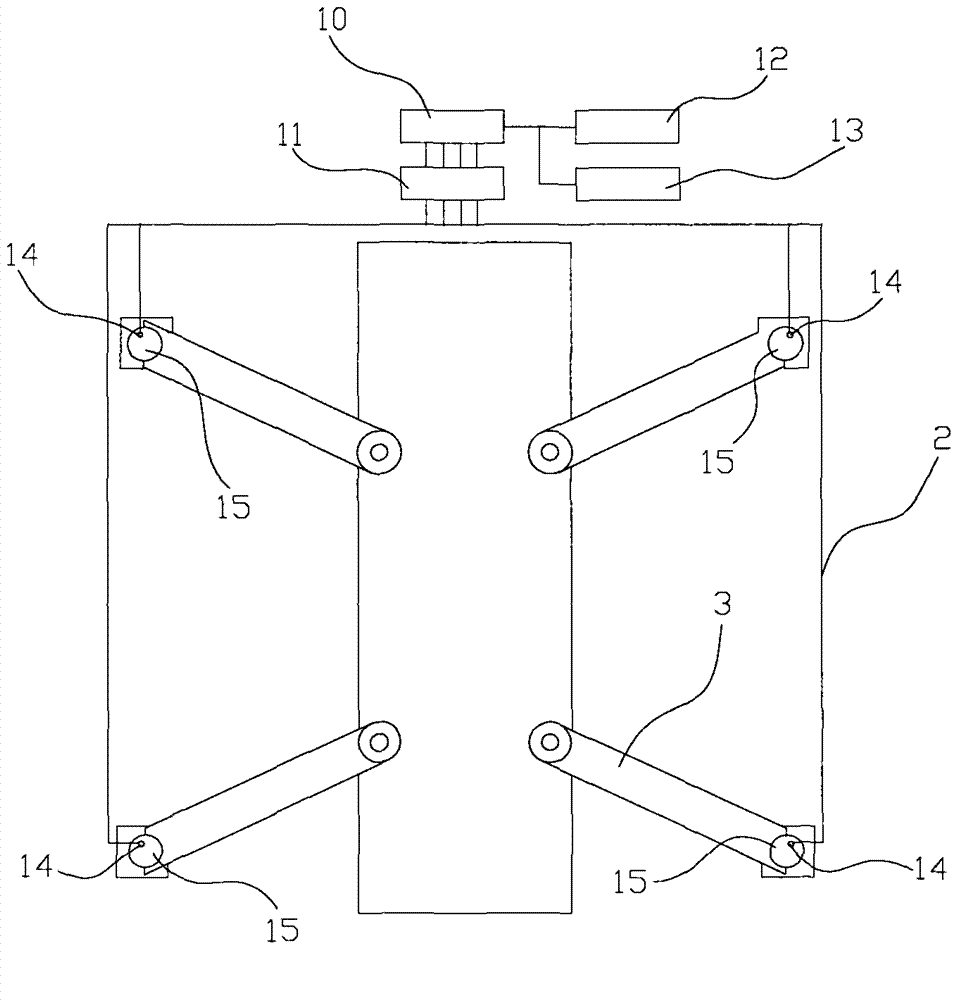

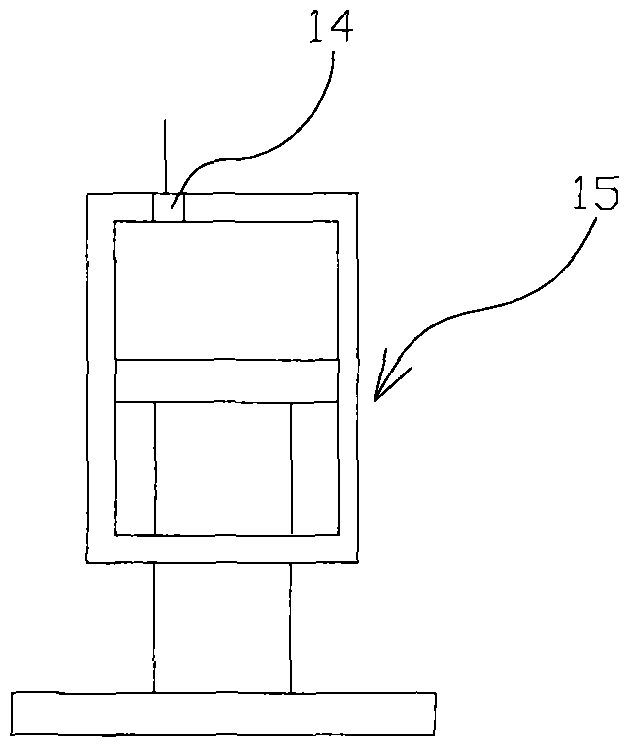

[0016] refer to figure 1 and figure 2 As shown in , the anti-rollover device for cement pump truck of the present invention includes a microcomputer 10, an analog-to-digital converter 11, an alarm device 12, a hydraulic system switch 13, a hydraulic sensor 14, and an outrigger cylinder 15, wherein the microcomputer 10 are respectively connected to the analog-to-digital converter 11, the alarm device 12 and the hydraulic system switch 13 through the data line 2, and the hydraulic pressure sensor 14 is installed on the top of each outrigger cylinder 15 and connected to the module Converter 11, said outrigger oil cylinder 15 is installed on each outrigger 3 of cement pump truck.

[0017] In the present invention, the microcomputer 10 is mainly used to receive the pressure signal data of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com