Inspection robot for underground coal mine

A technology for inspection robots and coal mines, applied in the field of inspection robots, can solve the problems of reducing the safety of inspection robots, low wheel grip, slippage, etc., and achieve the effects of easy disassembly, improved grip performance, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

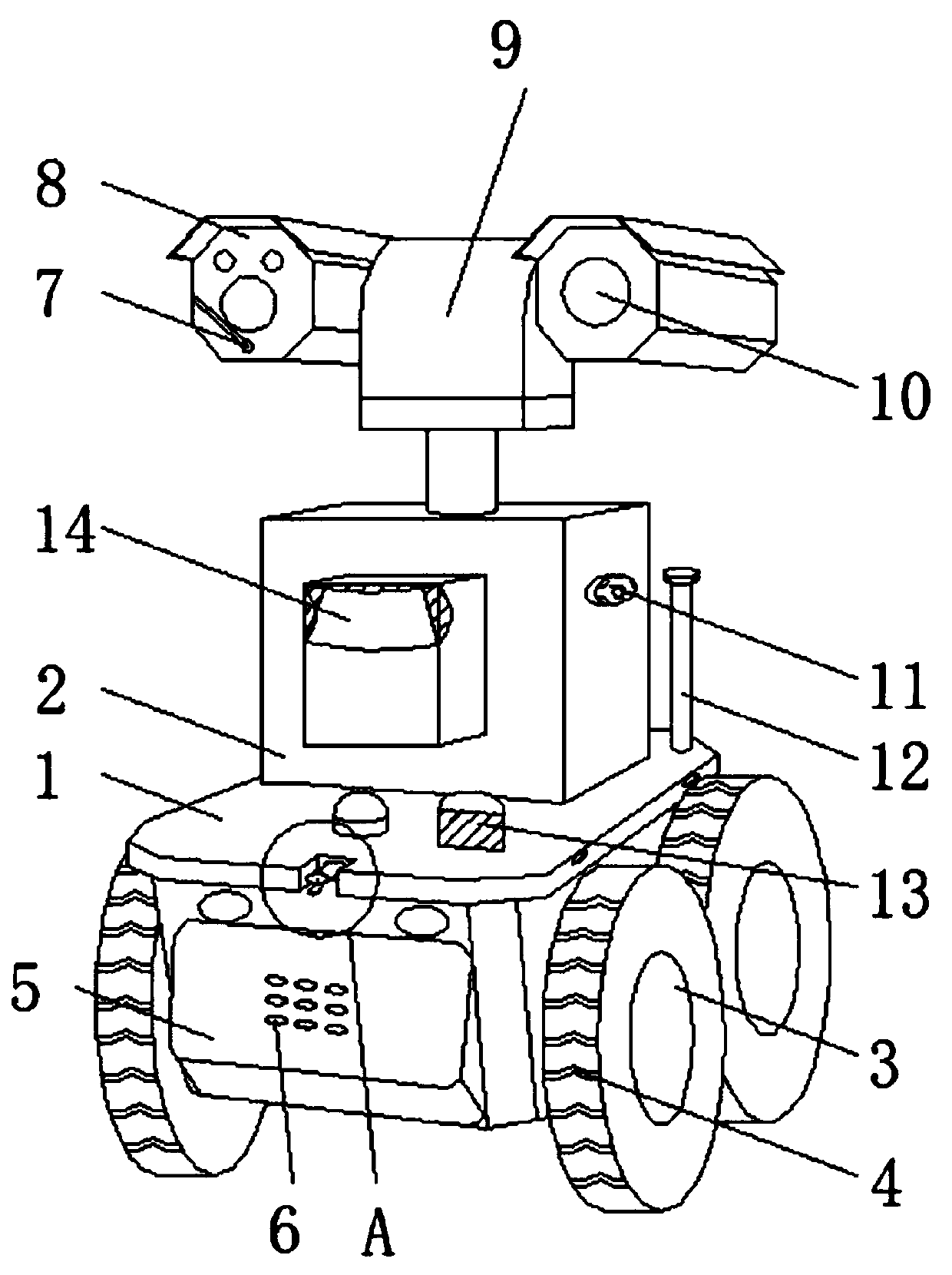

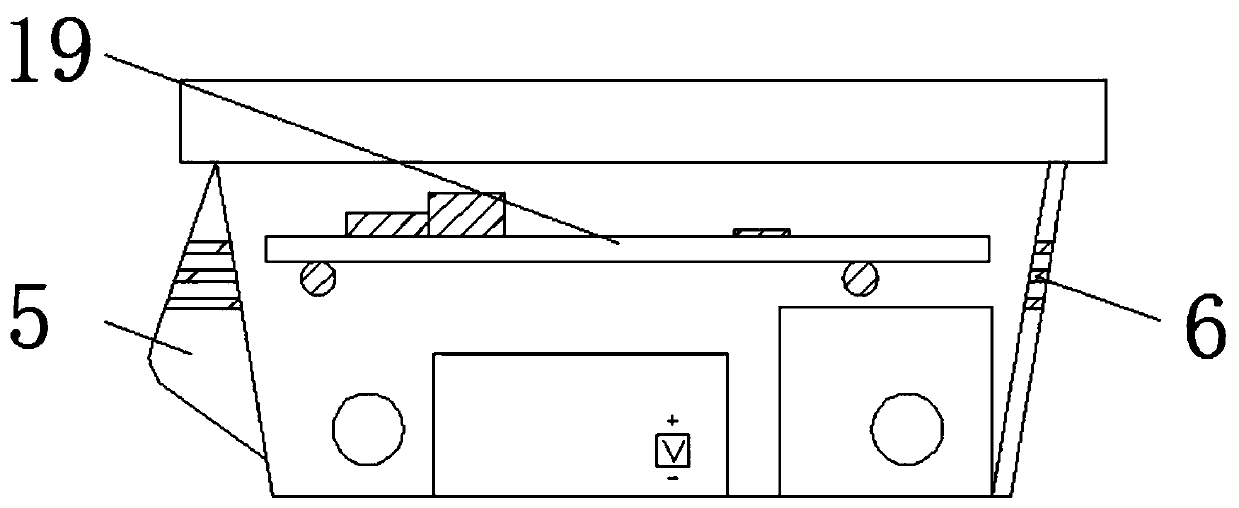

[0029] Such as Figure 1-6 As shown, a patrol robot used in underground coal mines includes a lower body 1 and an upper body 2. Four-wheel drive modules are provided on the left and right sides of the lower body 1, and the four-wheel drive module includes four wheels 3, The motor and the built-in power supply, the drive motor and the built-in power supply are installed in the lower body 1, the front side of the lower body 1 is installed with an anti-collision mechanism 5, and the top of the lower body 1 is installed on the side of the upper body 2 with a multifunctional sensor 13. A communication module is installed on the other side. The communication module includes an antenna 12. A circuit main board 19 is installed inside the lower body 1 and the multi-function sensor 13 and the communication module are electrically connected to the circuit main board 19.

[0030] A navigation module and a pickup 11 are respectively installed around the surface of the upper body 2, and the na...

Embodiment 2

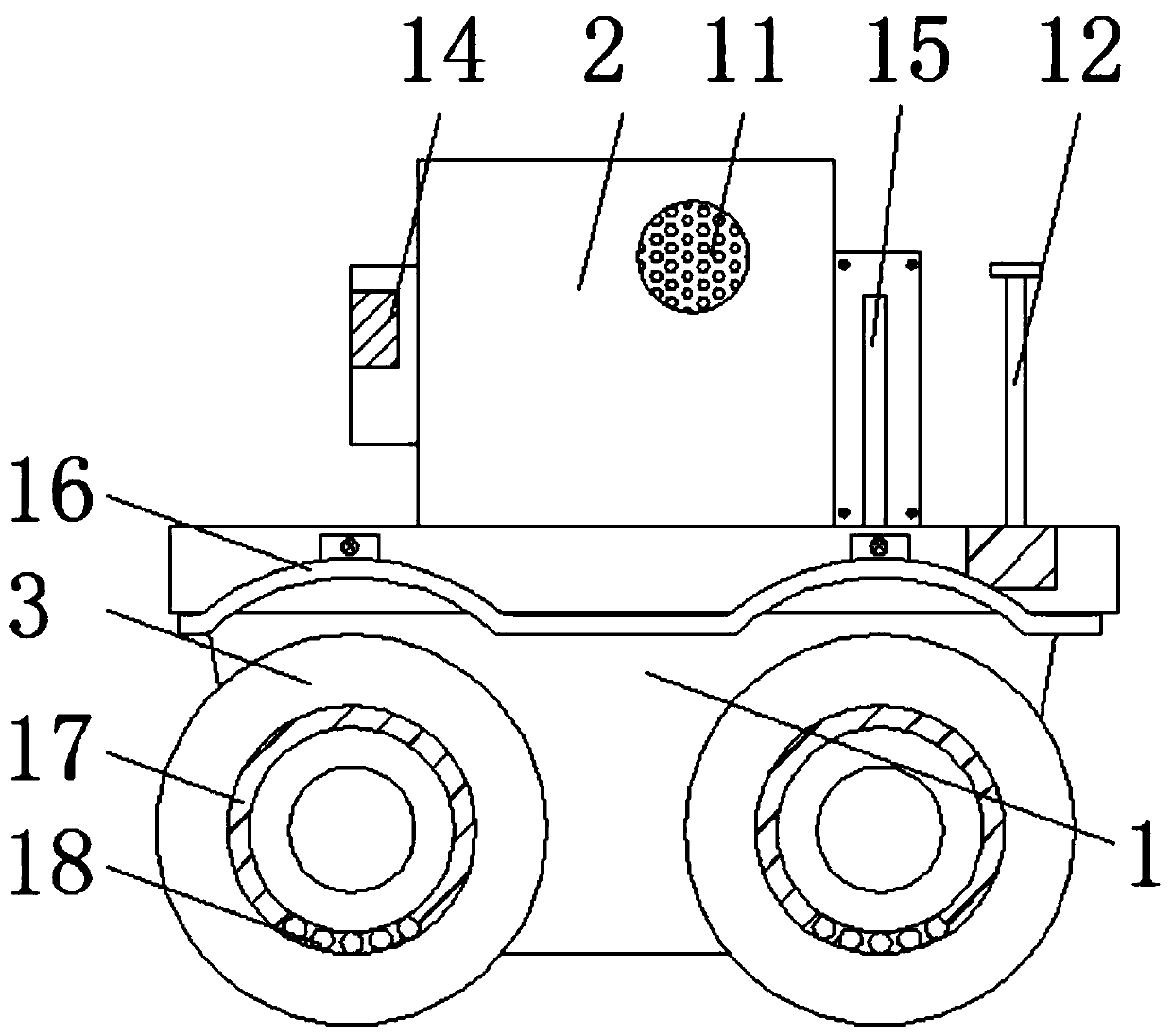

[0035] Such as Figure 1-6 As shown, a patrol robot used in underground coal mines. On the basis of embodiment 1, baffles 16 are installed on both sides of the lower body 1 through bolts, and the part of the baffle 16 directly above the wheel 3 is arc-shaped Structure of plastic sheet.

[0036] Such as figure 1 As shown, the wheel surface of the wheel 3 is uniformly provided with arrow-shaped anti-skid patterns 4, and the radial surface of the wheel 3 is evenly provided with an annular groove 17 at the position surrounding the axle, and a number of rolling balls are embedded in the annular groove 17 18.

[0037] Such as image 3 As shown, the anti-collision mechanism 5 is made of rubber with a triangular cross-section, and the anti-collision mechanism 5 extends 4-6cm from the lower body on the horizontal plane, and is located inside the anti-collision mechanism 5 and corresponding to the rear side of the lower body 1 A number of radiating holes 6 are opened, and under the autonom...

Embodiment 3

[0040] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the front side of the lower body 1 is provided with a groove at a position directly above the collision avoidance mechanism 5, and an ultrasonic module 20 is installed in the groove. The ultrasonic module 20 includes two sets of ultrasonic probes. , One of them is parallel to the ground, and the other is 45 degrees with the ground and is set toward the ground. The ultrasonic module 20 is electrically connected to the circuit main board 19.

[0041] By setting the ultrasonic module 20 and the multi-function sensor 13, the two ultrasonic probes use the principle of ultrasonic positioning to ultrasonically locate the area directly in front of the robot and the area on the ground where the robot is traveling, which respectively play the role of autonomous obstacle avoidance and groove detection. Ultrasound detects the location of potholes and ditches. Under the control of the single-chip microcomputer, the four-wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com