A filter bag for filtering and recovering non-ferrous metal dust and its preparation method

A non-ferrous metal and filter bag technology is applied in the field of filter bags for filtration and recovery of non-ferrous metal dust and its preparation, which can solve the problems of low filtration efficiency and low dust cleaning and recovery rate, so as to improve the filtration efficiency, improve the effectiveness of dust removal, The effect of reducing the emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

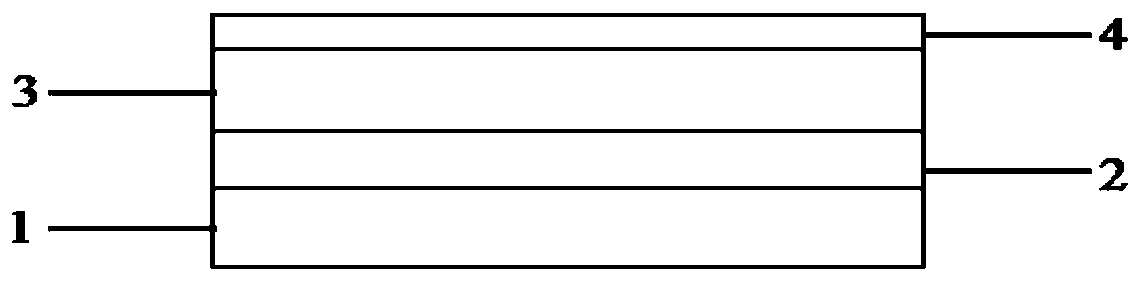

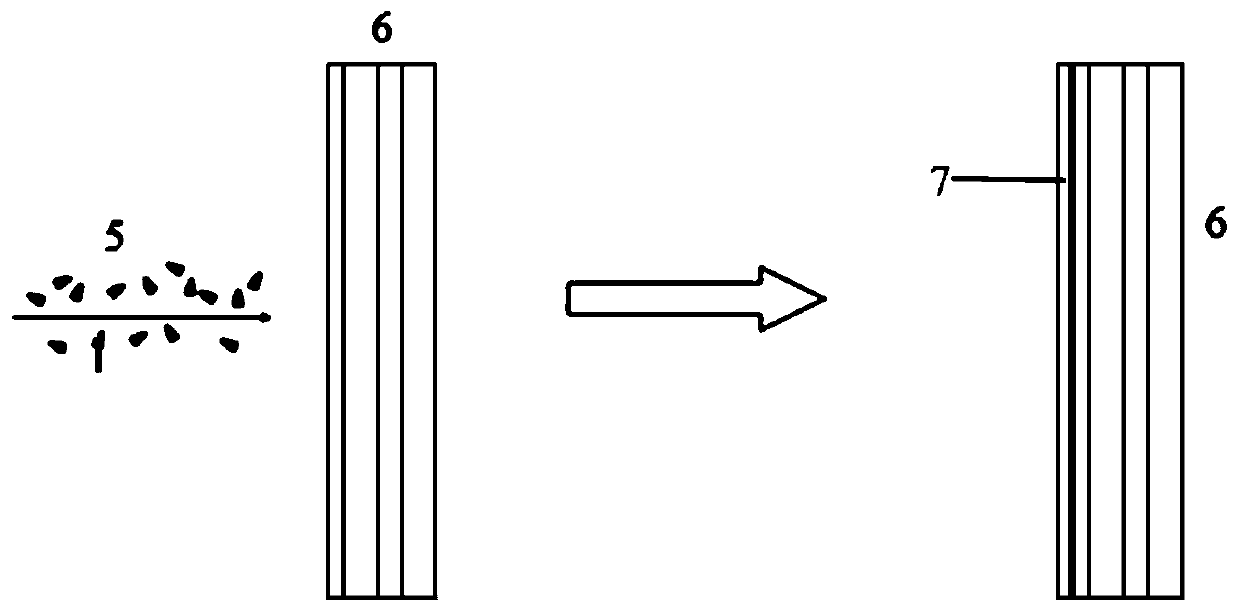

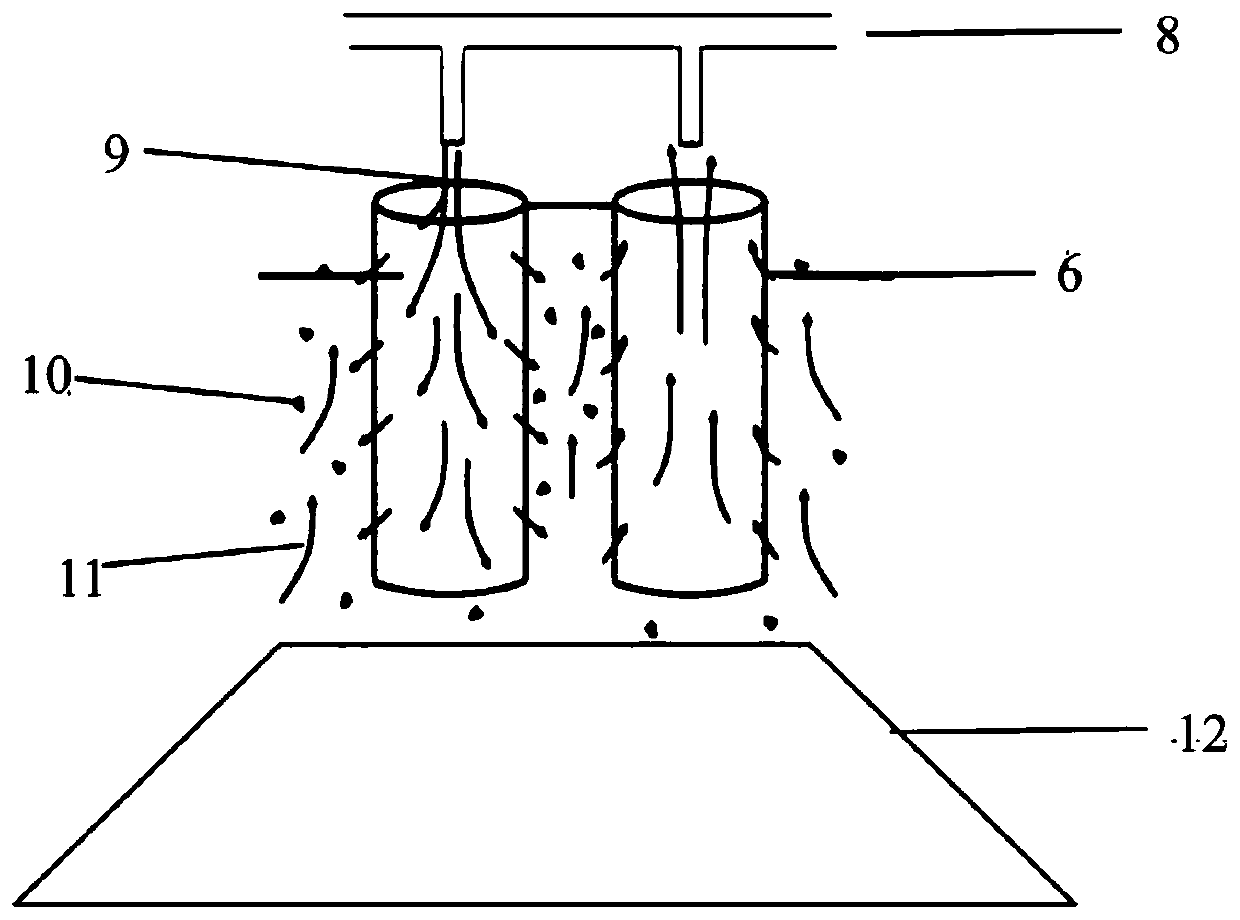

[0044] A filter bag for filtering and recovering non-ferrous metal dust, comprising a filter bag body, the filter bag body contains 85% by weight of microporous composite filter material and 15% by weight of microporous composite filter material with an average particle size of 30nm. Magnetic nano-iron oxide, dispersant emulsion and solid content of 60% polytetrafluoroethylene dispersion emulsion three blends are solidified to form an adsorption layer; the microporous composite filter material from top to bottom is surface layer, Needle-punched felt with needle-punched mechanical consolidation of the base fabric layer and the bottom layer, wherein the bottom layer and the surface layer are both obtained by blending ultra-fine polyphenylene sulfide fibers and polytetrafluoroethylene fibers, and the base fabric layer is polytetrafluoroethylene yarns The mesh structure formed by interweaving warp and weft; the dispersant emulsion is a mixed emulsion of titanate coupling agent, pol...

Embodiment 2

[0055] A filter bag for filtering and recovering non-ferrous metal dust, comprising a filter bag body, the filter bag body contains 90% by weight of microporous composite filter material and 10% by weight of microporous composite filter material with an average particle size of 90nm. Magnetic nano iron oxide, dispersant emulsion and solid content of 60% polytetrafluoroethylene dispersion emulsion three mixtures are solidified to form the adsorption layer; the microporous composite filter material is surface layer, Needle-punched felt with needle-punched mechanical consolidation of the base fabric layer and the bottom layer, wherein the bottom layer and the surface layer are both obtained by blending ultra-fine polyphenylene sulfide fibers and polytetrafluoroethylene fibers, and the base fabric layer is polytetrafluoroethylene yarns The mesh structure formed by interweaving warp and weft; the dispersant emulsion is a mixed emulsion of titanate coupling agent, polyvinyl alcohol s...

Embodiment 3

[0066] A filter bag for filtering and recovering non-ferrous metal dust, comprising a filter bag body, the filter bag body contains 95% by weight of microporous composite filter material and 5% by weight of microporous composite filter material with an average particle size of 150nm. The adsorption layer formed after the blend of magnetic nano iron oxide, dispersant emulsion and polytetrafluoroethylene dispersion emulsion with solid content of 60% is cured; the microporous composite filter material is surface layer, base cloth from top to bottom The needle-punched felt with the needle-punched mechanical consolidation of the layer and the bottom layer, in which the bottom layer and the surface layer are both obtained by blending ultra-fine polyphenylene sulfide fibers and polytetrafluoroethylene fibers, and the base fabric layer is polytetrafluoroethylene yarns interwoven in warp and weft The formed network structure; the dispersant emulsion is a mixed emulsion of titanate coupl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com