Patents

Literature

36results about How to "Good filtration and adsorption effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

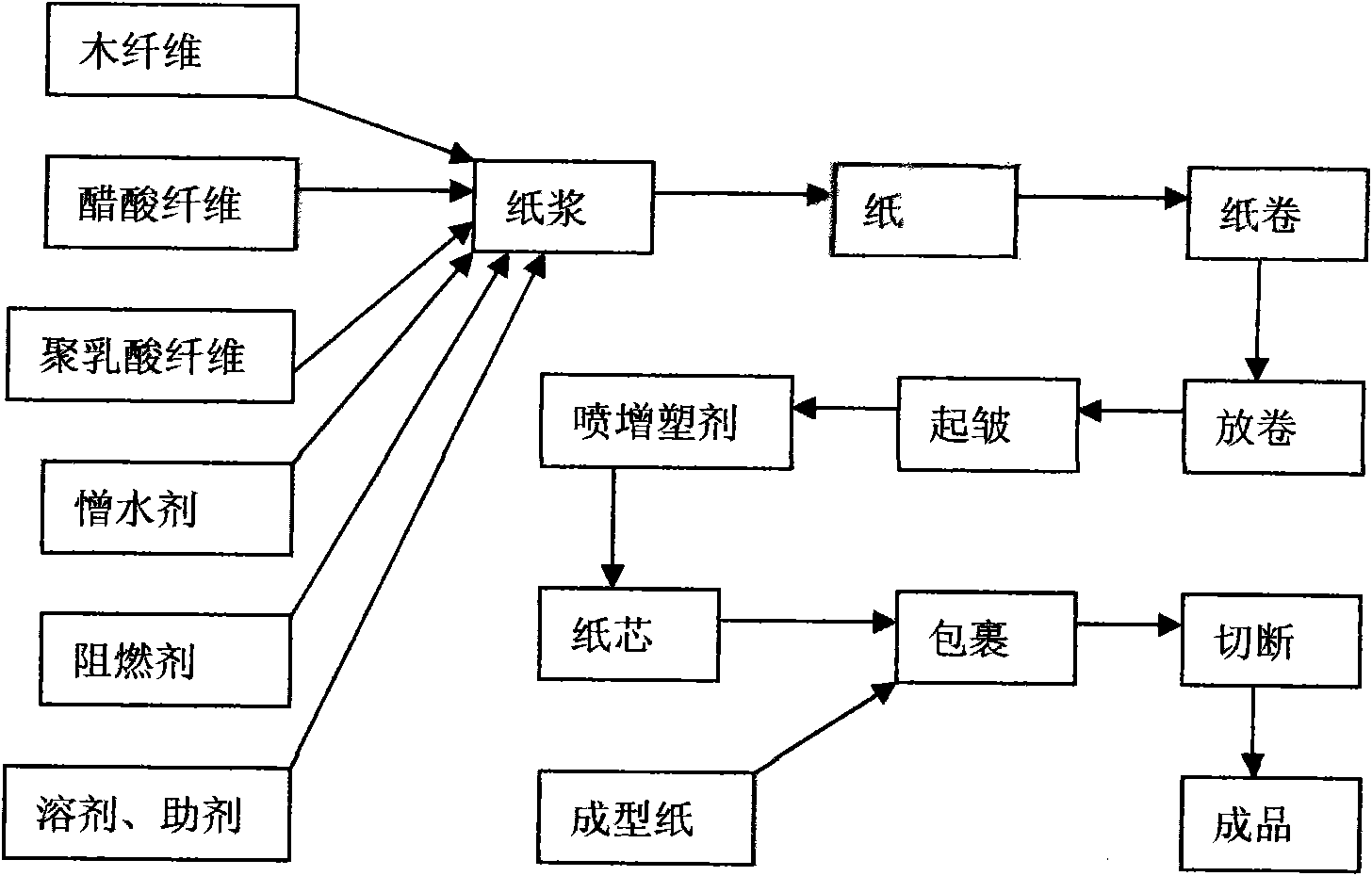

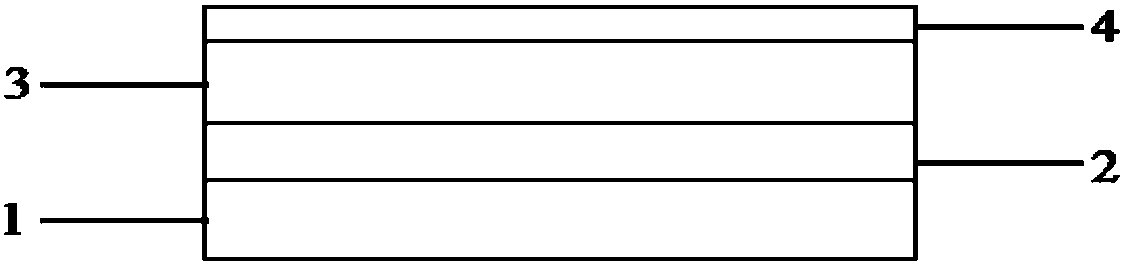

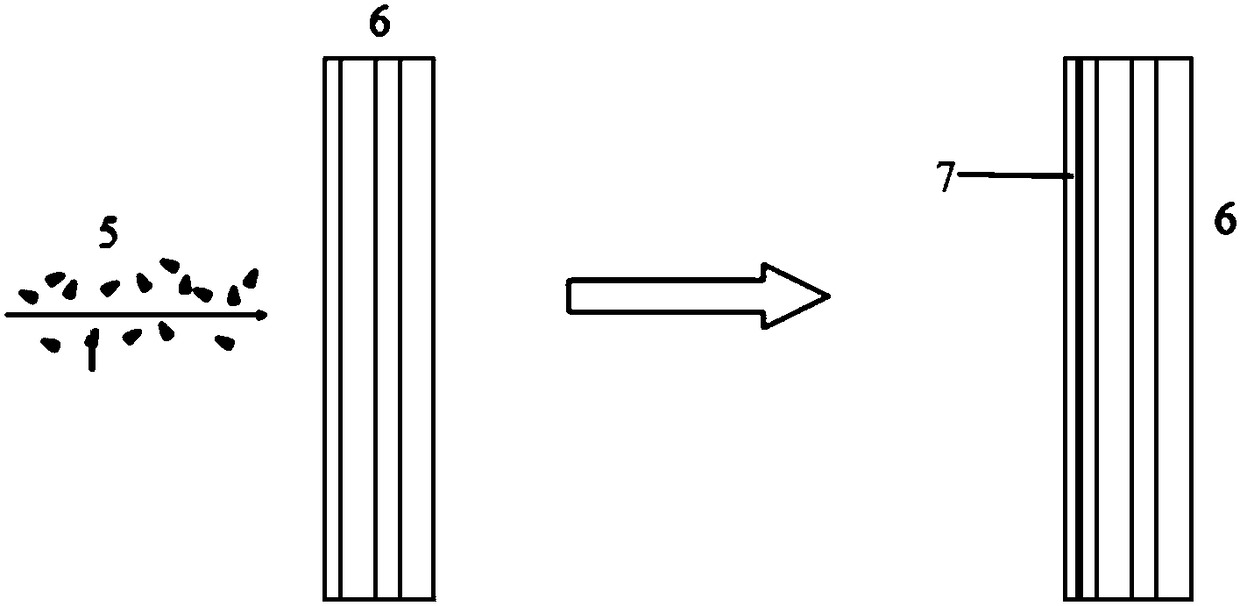

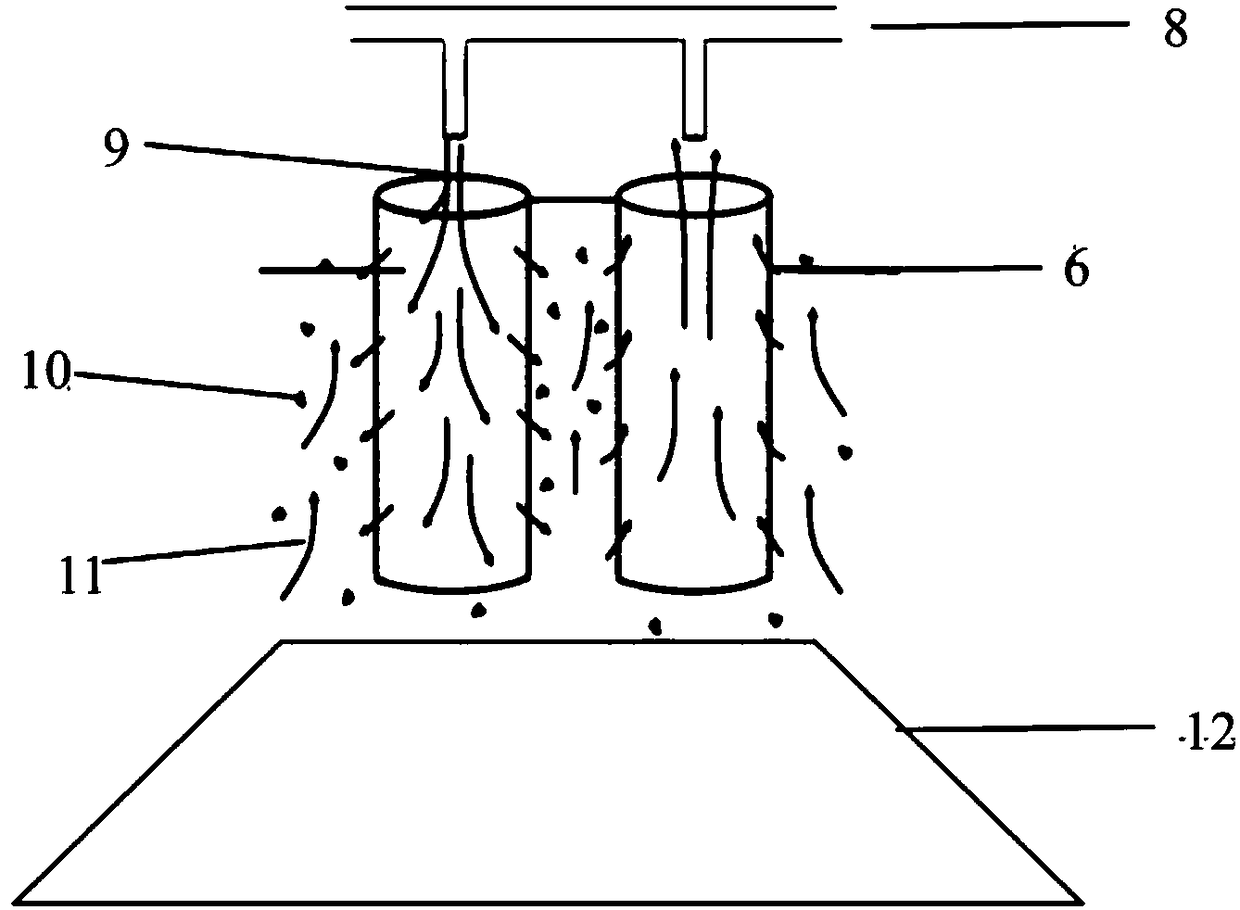

Paper-core filter rod for cigarettes and manufacturing method thereof

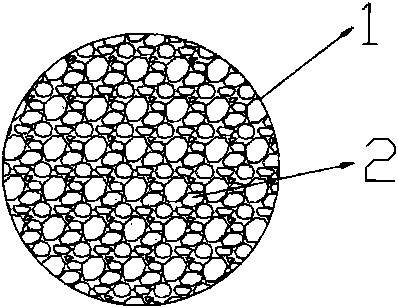

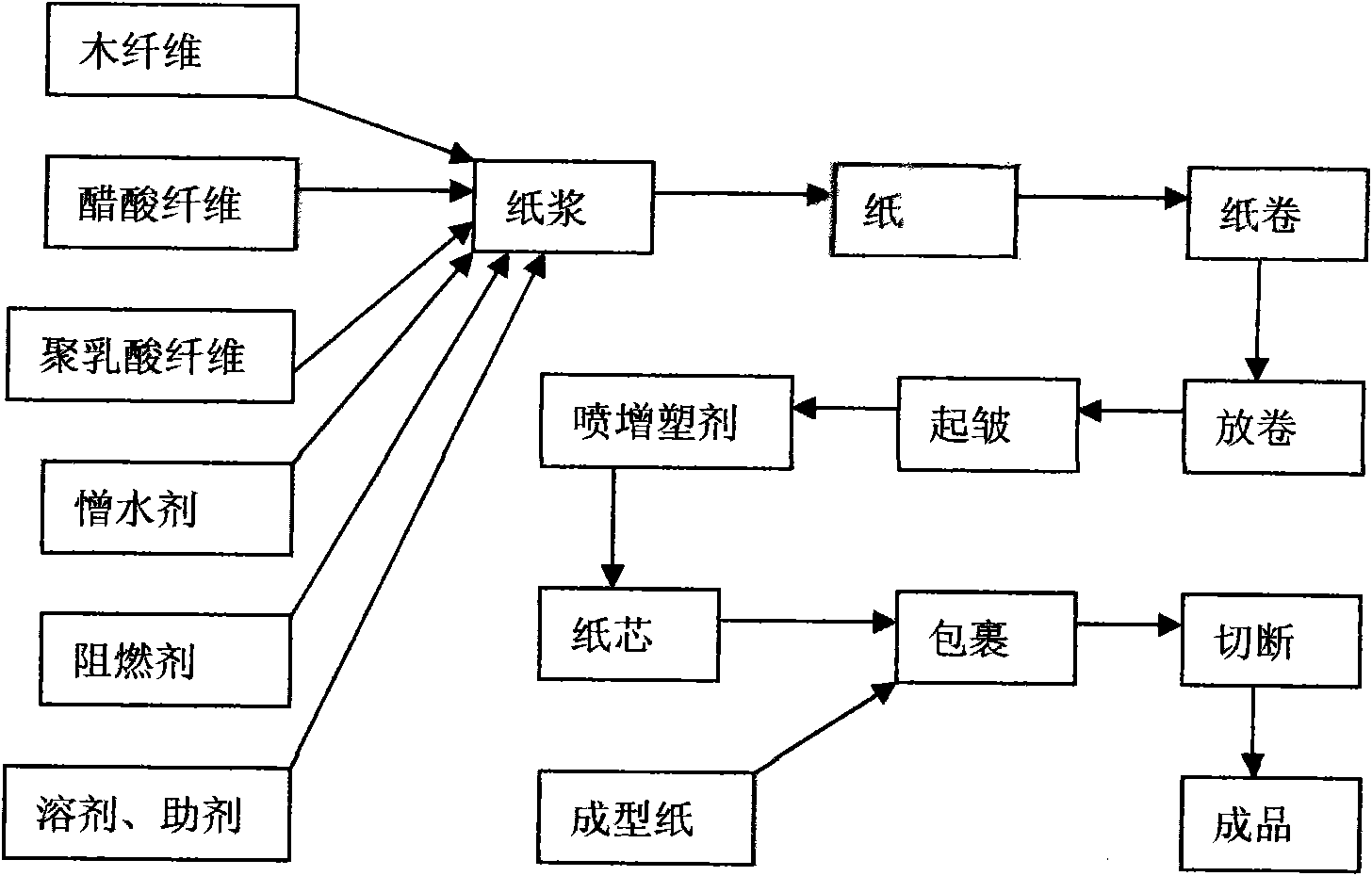

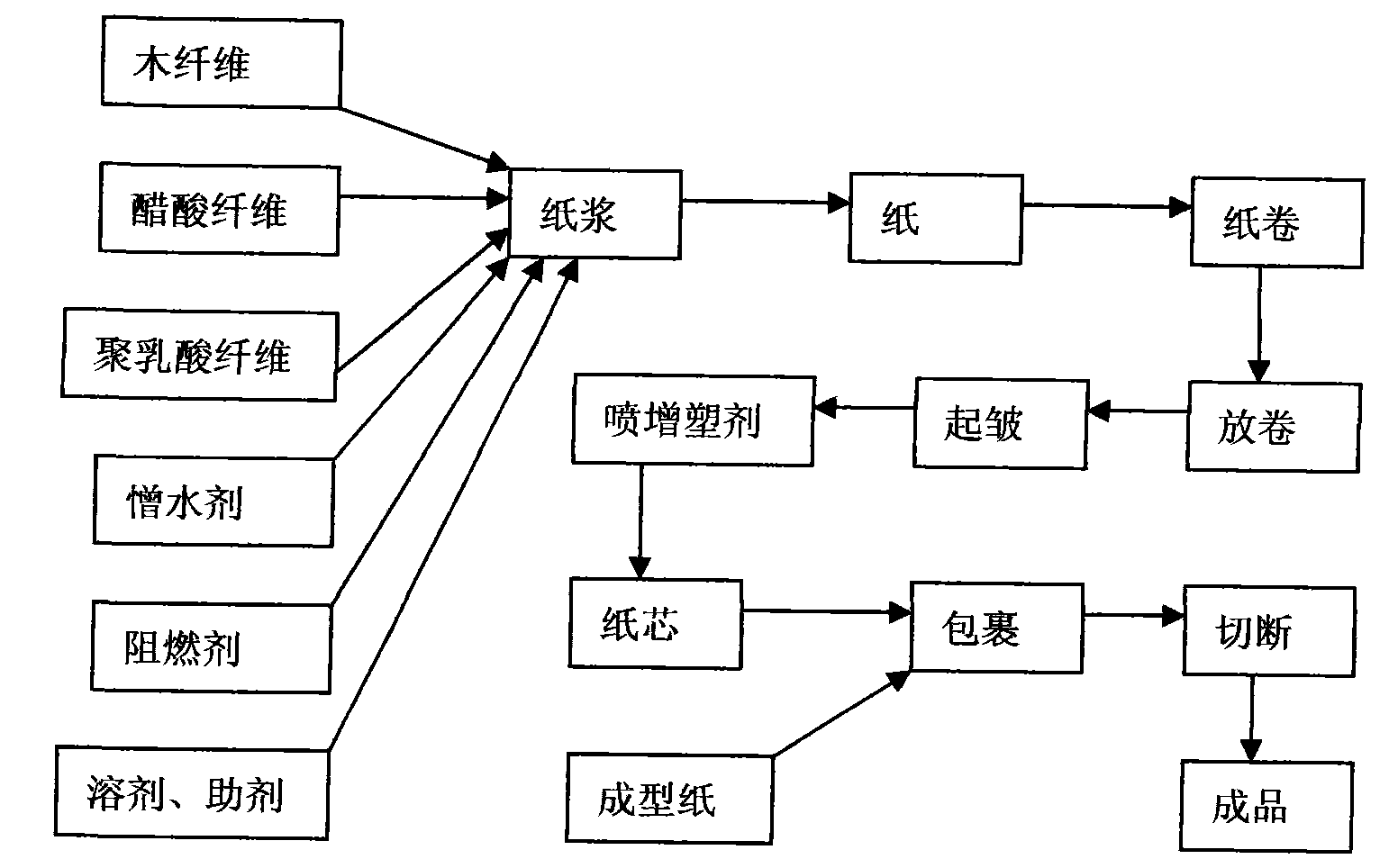

ActiveCN102334751APromote degradationImprove flame retardant performanceTobacco smoke filtersFiberPulp and paper industry

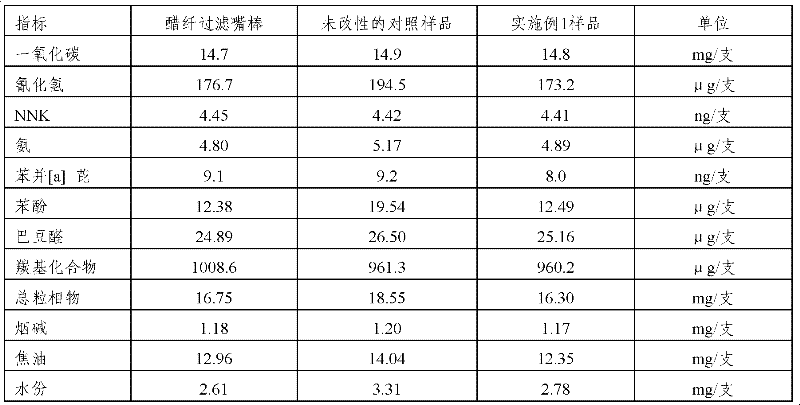

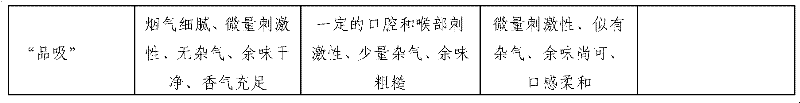

The invention discloses a paper-core filter rod for cigarettes and a manufacturing method thereof. A paper core containing polylactic acid fibers, non-toxic flame retardants and non-toxic water repellents is taken as a filter material of the filter rod, and the paper core also can contain acetate fibers and wood fibers and the like. The paper-core filter rod is manufactured by using a method comprising the steps of adding various components into a paper pulp to carry out paper making firstly, manufacturing the obtained product into a paper core, and then manufacturing the paper core into a filter rod. The paper-core filter rod achieves an excellent degradation effect and a good filtering effect, and has a good flame retardant property, a good moisture-resistant property; and a new paper-core filter rod which is economic in cost and really has an industrialization prospect can be provided for users in the tobacco industry.

Owner:NANTONG CIGARETTE FILTER

Load type nanocomposite oxide material for purifying environment and preparation thereof

InactiveCN101301605AHEPA filterGood filtration and adsorption effectMolecular sieve catalystsLighting and heating apparatusIon exchangeChemistry

The present invention provides a supported nanometer compound oxide environmental purification material and the preparation thereof, the diatomite and the zeolite are employed as carrier to load one of nanometer TiO2, nanometer ZnO and nanometer CeO2. The preparation method comprises preparing carriers by diatomite and zeolite; preparing compound oxide precursory sol by employing ethanol as medium and the zinc nitrate and / or cerium nitrate and butyl titanate as material; loading the compound oxid precursory sol on the carrier to obtain loading-body; drying, baking and cooling the loading-body to obtain the supported nanometer compound oxide environmental purification material of the present invention which has perfect filter, adsorption, ion exchange, catalytic degradation and antibacterial function, good chemical stability, convenient usage, reclaim and regeneration, safety, innocuity, simple preparation technique and low cost. The supported nanometer compound oxid environmental purification material of the present invention is suitable for batch production and used widely in purifying process of atmosphere and water system.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

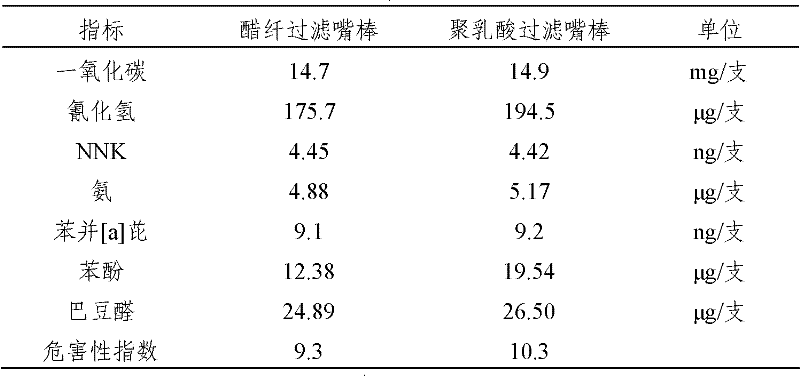

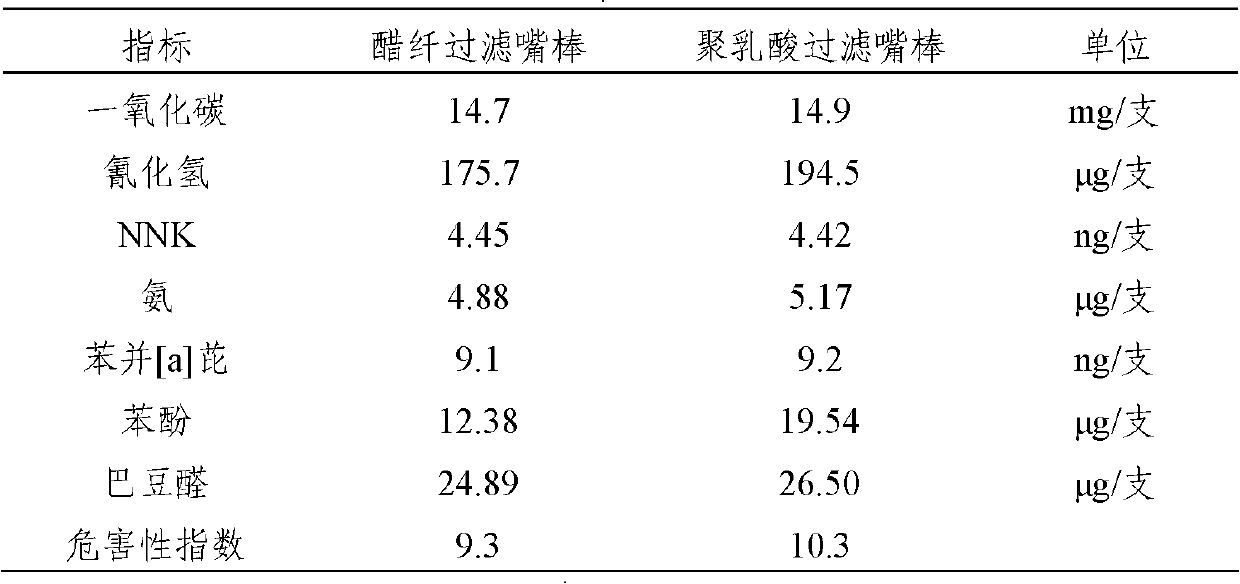

Modified polyactic acid composition for cigarette filter stick and preparation method thereof

ActiveCN102516728ASmall weight contentImprove adsorption capacityTobacco smoke filtersMonocomponent polyesters artificial filamentSODIUM PYRROLIDONE CARBOXYLATECellulose acetate

The invention relates to a modified polyactic acid composition for a cigarette filter stick and a preparation method thereof. The composition comprises following parts of raw materials, by weight, 100 parts of polyactic acid, 0.02-3 parts of polyactic acid-beta-cyclodextrin, 0.08-5 parts of sodium carbonate, 0.05-5 parts of sodium pyrrolidonecarboxylate, 0.01-4 parts of vitamin and 0.01-8 parts of polyacrylamide. The filter stick prepared through the polyactic acid composition is better in absorbing performance on smoke compared with the prior art and good in comprehensive performance, and a part of indexes of the filter stick exceed those of a cellulose acetate filter stick.

Owner:马鞍山同杰良生物材料有限公司

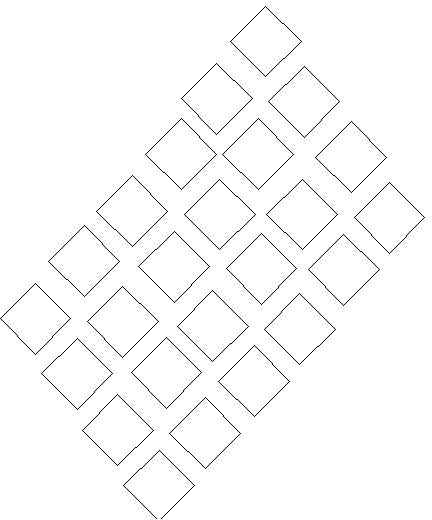

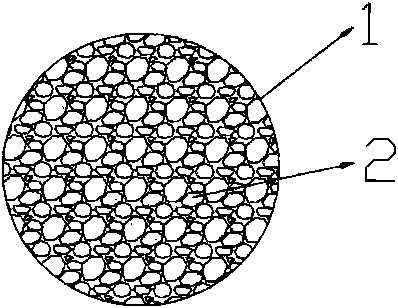

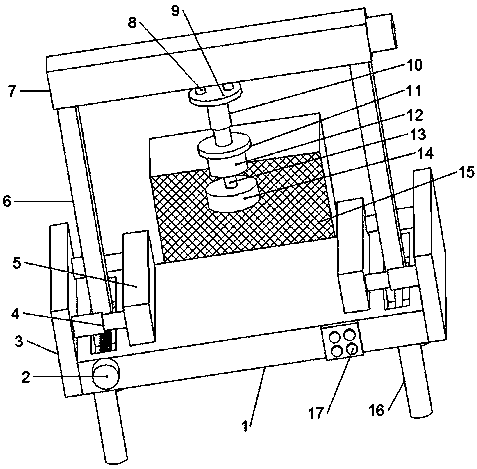

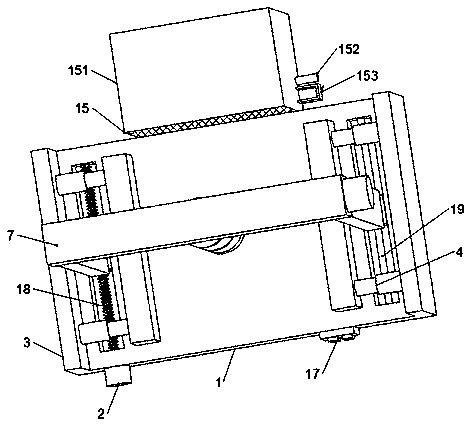

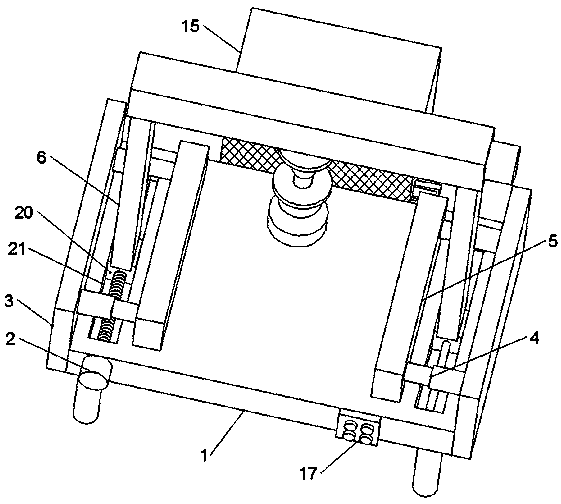

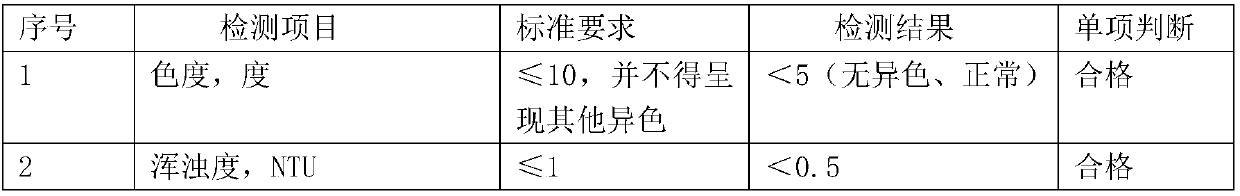

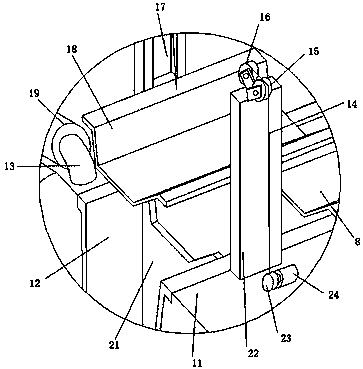

Nnano-silver diatomite antibacterial filter core and preparation method thereof

ActiveCN104043288AEnsure safetyGood filtration and adsorption effectBiocideOther chemical processesFiltrationTurbidity

The invention provides a nano-silver diatomite antibacterial filter core. The nano-silver diatomite antibacterial filter core is prepared from diatomite, a pore forming agent, a sintering aid, a binder and water. A preparation method for the nano-silver diatomite antibacterial filter core comprises the following steps: carrying out purification and fine treatment on diatomite; subjecting diatomite to silver loading; carrying out mixing and grinding solid raw materials until D50 is equal to 1 to 10 mu m; subjecting the ground raw materials to mixing with a liquid raw material; carrying out ageing; subjecting the aged raw materials to die casting or extruding to obtain a filter core blank; and drying and sintering the filter core blank so as to prepare the nano-silver diatomite antibacterial filter core. The nano-silver diatomite antibacterial filter core has good filtration and adsorption performance due to usage of the porous structure of diatomite; after loading of nano-silver on the diatomite and sinter molding, the prepared nano-silver diatomite antibacterial filter core can guarantee microbiological safety of water quality and provide safety guarantee for performance of the functions of a subsequent water purification film when applied to bacterium and turbidity removal of domestic water.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

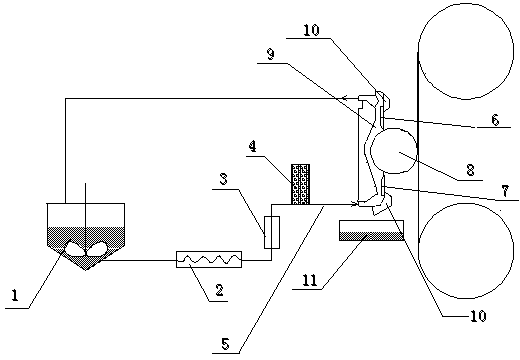

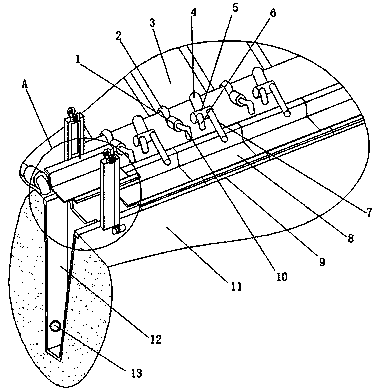

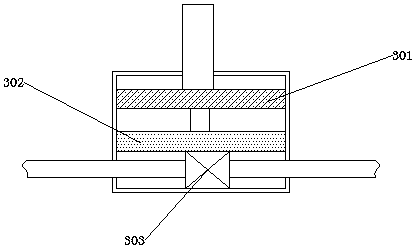

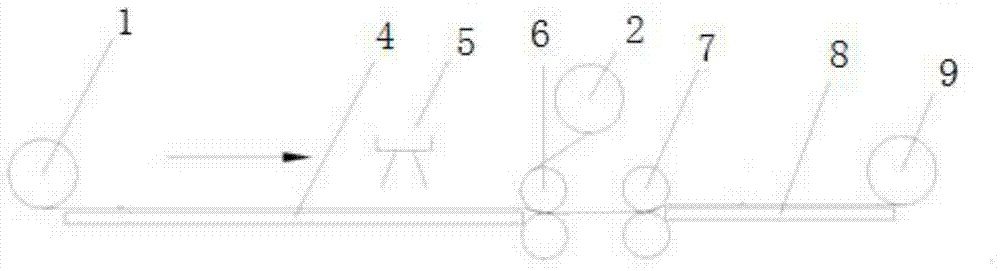

Surface coating device and method for lithium battery pole piece or diaphragm

InactiveCN104275268AChemically resistantHigh temperature resistantLiquid surface applicatorsCell electrodesRegular patternFiltration

The invention relates to a surface coating device and method for a lithium battery pole piece or diaphragm; a coating head is provided with an upper scraper which can be vertically and finely tuned, a lower scraper, an intaglio roller, a slurry cavity and a baffle plate for sealing the cavity; the upper scraper and the lower scraper are respectively positioned on the upper part and the lower part of the intaglio roller; the surface of an intaglio roller body is marked with regular patterns; the coating method comprises two steps: slurry preparation and surface coating. A ceramic slurry has the advantages of chemical corrosion resistance, high temperature resistance, good filtration and adsorption performance and higher stability, can prevent generation of diaphragm contraction due to heat emitting of a battery, and also can prevent a fire outbreak problem caused by crystal structure shifting and collapse due to unstable anode materials; and the influence of the cavity pressure fluctuation on the coating thickness can be avoided, the coating operation on an ultra-thin substrate material is facilitated, and the coating accuracy is ensured.

Owner:WANXIANG 123 CO LTD +2

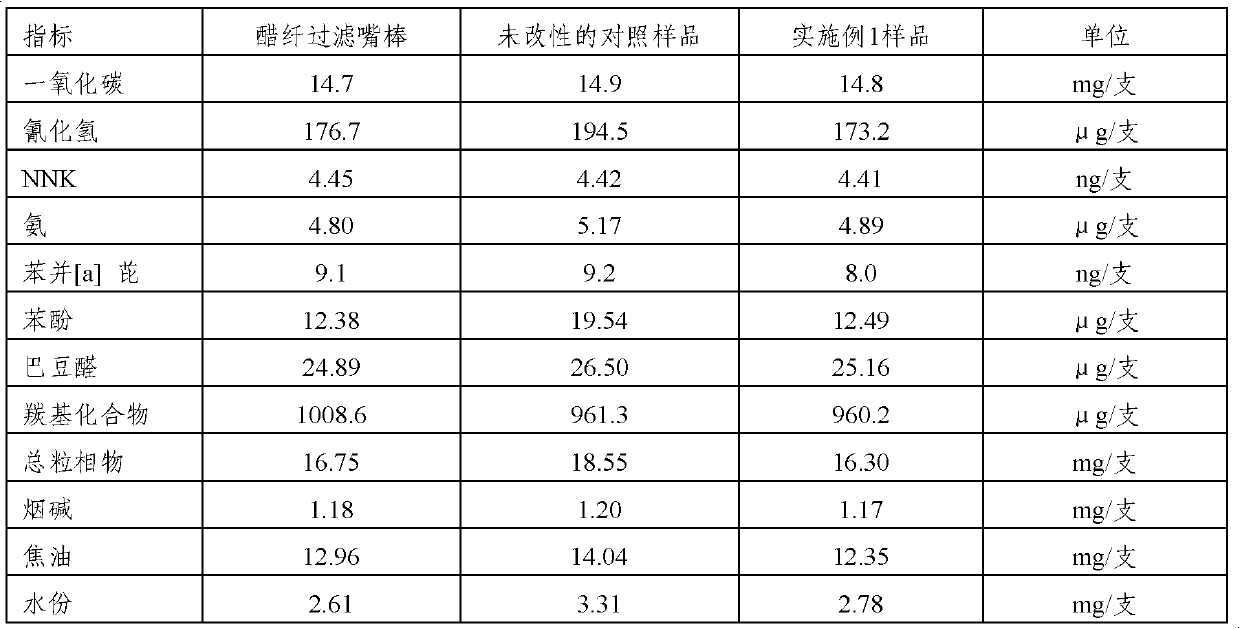

Method for making polylactic acid fiber filter stick

The invention discloses a method for making a polylactic acid fiber filter stick. The method comprises the following steps of: (1) loosening: loosening a polylactic acid fiber cigarette tow by using a filter stick molding machine set, wherein the line density of the polylactic acid fiber cigarette tow is 3.5-5.0Ktex; (2) gluing: spraying a degradable adhesive onto the loosened polylactic acid fiber cigarette tow; (3) molding and cutting down; (4) drying the filter stick; and (5) balancing: putting the dried filter stick into a balance chamber to be balanced more than 6 hours so as to make the polylactic acid fiber filter stick. With the adoption of the method for making the polylactic acid fiber filter stick, the problem of industrial production of the polylactic acid fiber filter stick can be solved, the production can be carried out by only using an existing filter stick molding machine set in market, the smoking taste of the made filter stick is approximate to that of a vinegar fiber stick, and the requirements on use of the cigarette can be met.

Owner:湖北金叶玉阳化纤有限公司 +1

Paper-core filter rod for cigarettes and manufacturing method thereof

ActiveCN102334751BEasy to gather and shapePromote degradationTobacco smoke filtersFiberPulp and paper industry

The invention discloses a paper-core filter rod for cigarettes and a manufacturing method thereof. A paper core containing polylactic acid fibers, non-toxic flame retardants and non-toxic water repellents is taken as a filter material of the filter rod, and the paper core also can contain acetate fibers and wood fibers and the like. The paper-core filter rod is manufactured by using a method comprising the steps of adding various components into a paper pulp to carry out paper making firstly, manufacturing the obtained product into a paper core, and then manufacturing the paper core into a filter rod. The paper-core filter rod achieves an excellent degradation effect and a good filtering effect, and has a good flame retardant property, a good moisture-resistant property; and a new paper-core filter rod which is economic in cost and really has an industrialization prospect can be provided for users in the tobacco industry.

Owner:NANTONG CIGARETTE FILTER

Filter bag for filtering and recovering nonferrous metal dust and preparation method thereof

ActiveCN108071020AHD Gray EffectivenessPrevent resorptionDispersed particle filtrationMembrane filtersEmulsionNonferrous metal

The invention discloses a filter bag for filtering and recovering nonferrous metal dust and a preparation method thereof. The filter bag comprises the following components in percentage by weight: 85-95% of a micro-porous composite filter material and 5-15% of an adsorption layer supported onto the micro-porous composite filter material, wherein the adsorption layer is a mixture obtained by blending magnetic nanocrystalline iron oxide, a polytetrafluoroethylene dispersion emulsion and a dispersing agent emulsion and performing curing treatment; the mixture comprises the following components inpercentage by weight: 3-25% of the magnetic nanocrystalline iron oxide, 55-70% of the polytetrafluoroethylene and the balance of a cured dispersing agent emulsion. The filter bag prepared by the invention has high adsorption capacity on the metal dust, the formation time of a pressed powder layer is effectively shortened, and the nonferrous metal recovery rate and ash removal effectiveness are improved. The filter bag disclosed by the invention is high in filtering precision, the conductivity is obviously improved, and excellent antistatic and explosion-proof properties are obtained.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Industrial robot grinding and polishing device

InactiveCN111002161AEasy to fixAchieve full grinding and polishingDispersed particle filtrationGrinding drivesElectric machineryEngineering

The invention discloses an industrial robot grinding and polishing device. The device comprises a workbench, a sliding groove is formed in the top of the workbench, a first sliding block is arranged in the sliding groove, a first lead screw is arranged in the sliding groove, the outer end of the first screw rod is connected with a first servo motor, the top of the first sliding block is connectedwith a supporting plate, the supporting plate is connected with a transmission assembly, the transmission assembly is connected with a first hydraulic telescopic rod through a first connecting rod anda first connecting plate, the first hydraulic telescopic rod is connected with a grinding motor through a second connecting plate, the grinding motor is connected with a grinding block through a rotating shaft, a fixing assembly is arranged on the workbench, and a dust collection assembly is arranged on the rear end face of the workbench. A part needing to be ground is fixed through the fixing assembly to achieve a good fixing effect on the part, the transmission assembly and the first servo motor can drive the grinding block to move in order to realize comprehensive grinding and polishing ofthe part, and the dust suction assembly can suck metal powder generated in the grinding process, so the device has a high automation degree, and is very convenient to use.

Owner:闫志伟

Method for preparing polyolefine micro/nano-fibre non-woven material

InactiveCN101338456AIncrease added valueEasy to achieve large-scale productionArtificial filament physical treatmentConjugated cellulose/protein artificial filamentsCelluloseMicro nano

The invention relates to a preparation method of polyolefin micro / nano fiber non-woven material. The preparation method comprises the procedures that (1) 50 to 800g of high polyme and 1200 to 1950g of cellulose ester are dried in an oven and mixed; then the high polymer and the cellulose ester undergo the process of melt spinning by a double-screw extruder; and the high polymer and the cellulose ester are winded at the winding speed of 300 to 1200m / min to form the multi-component fiber of the polyolefin / cellulose ester that is scattered at a micro / nano scale in a cellulose ester substrate; (2) the multi-component fiber is melted in acetone solution; and cellulose ester is removed to acquire the micro / nano fiber aggregate of the high polymer with thermo-plasticity; and (3) the fiber aggregate is carded by a carding machine; a net is crosswise made to form a fluffy fiber net; and after being strengthened and molded, the non-weaving material is made. The preparation method has the characteristics that the method is efficient, controllable and environment-friendly and has high added value. In addition, the preparation method facilitates mass-production.

Owner:DONGHUA UNIV

Method for preparing polyester micro/nano-fibre non-woven material

InactiveCN101338457AThe method of use is efficient and controllableUniversalArtificial filament physical treatmentConjugated cellulose/protein artificial filamentsCellulosePolyester

The invention relates to a preparation method of polyolefin micro / nano fiber non-woven material. The preparation method comprises the procedures that (1) high polymer and cellulose ester are mixed in the mass ratio of 1:2.3 to 20; then the high polymer and the cellulose ester undergo the process of melt spinning by a double-screw extruder; and the high polymer and the cellulose ester are winded at the winding speed of 300 to 800m / min to form the multi-component fiber of the polyester / cellulose ester that is scattered at a micro / nano scale in a cellulose ester substrate; (2) the cellulose ester in the multi-component fiber of polyester / cellulose ester is removed by acetone solution to acquire the micro / nano fiber aggregate of the high polymer with continuous thermo-plasticity; the fiber aggregate is carded by a carding machine; a net is crosswise made to form a fluffy fiber net; and after being strengthened and molded by aqua tex, pinpricking or thermo-compression, the non-weaving material is made. The preparation method has the characteristics that the method is efficient, controllable and environment-friendly and has high added value. In addition, the preparation method facilitates mass-production and the acquired polyolefin micro / nano fiber non-woven material non-weaving material has an outstanding effect on filtration absorption.

Owner:DONGHUA UNIV

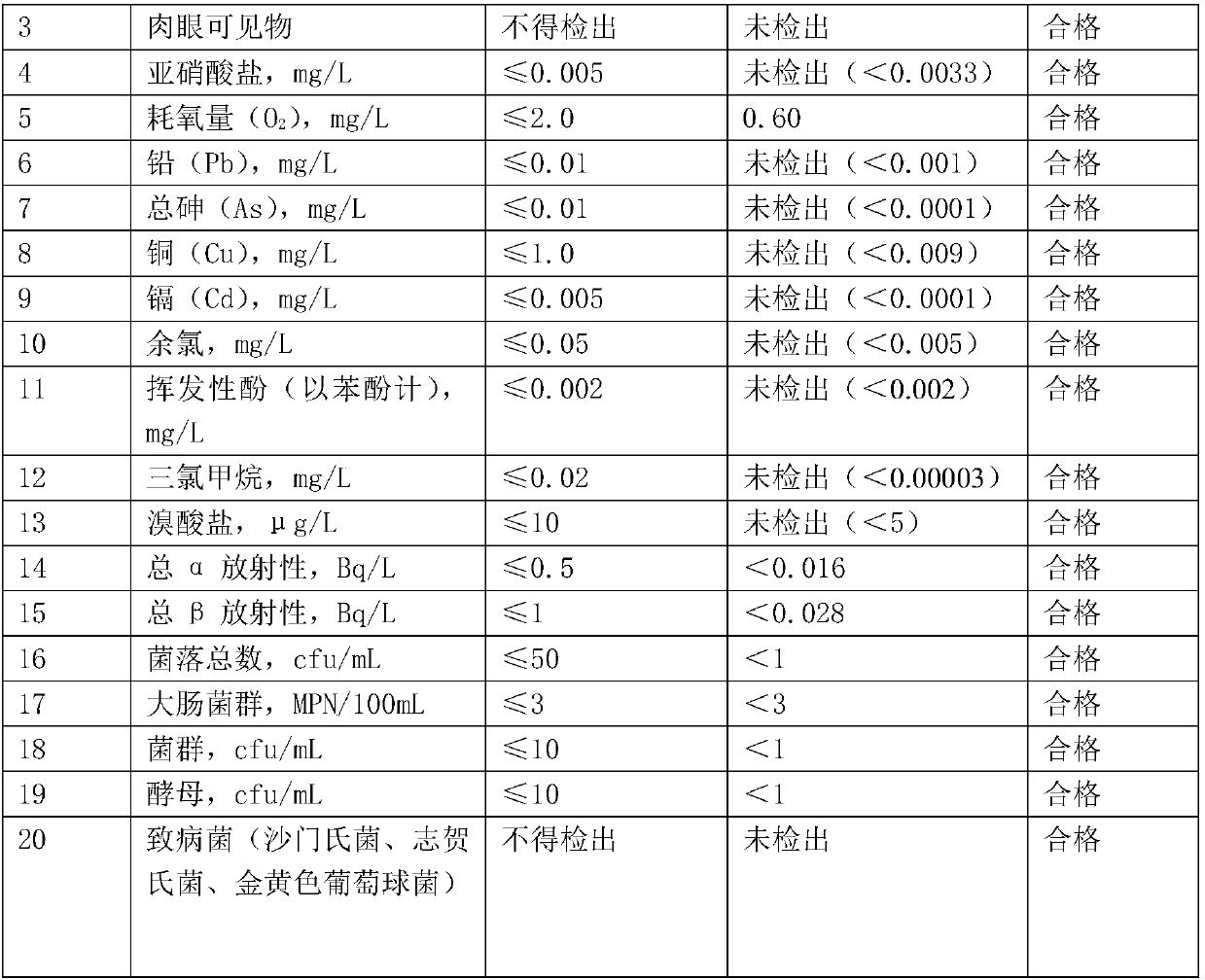

Process for producing mineral water

InactiveCN107585932ASimple production processIncrease oxygen contentMultistage water/sewage treatmentActivated carbon filtrationWater velocity

The invention relates to a process for producing mineral water. The process comprises the following steps: (1) selecting spring water of a main peak of Dabie Mountain, filtering the spring water withcocoanut shell activated charcoal, and filtering the water again by using sandstone and activated charcoal; (2) carrying out reverse osmosis filtering on the water treated in the step (1) to remove colloidal microbes from the water; (3) carrying out iron removal by using a manganese sand filtering device, wherein a water velocity is 18m<3> / h to 20m<3> / h during iron removal; (4) carrying out sterilization by using ozone, and then, carrying out disinfection by ultraviolet rays; (5) introducing clean carbon dioxide into the water; (6) introducing clean mixed gas into the water so as to enable theoxygen content of water of 25 DEG C to reach 65mg / L; (7) carrying out sterile filling on the water. The process provided by the invention is simple, the amount of chemical additives is small, and themineral water is good in taste and high in oxygen content and has very good health-care value.

Owner:ANHUI YELING BEVERAGE & FOOD

Bacteriostatic and antibacterial ceramic filter element and preparation method therefor

ActiveCN105060869AImprove filtering effectStable chemical propertiesBiocideTreatment involving filtrationSodium bicarbonateEpoxy

The present invention discloses a bacteriostatic and antibacterial ceramic filter element and a preparation method therefor. The bacteriostatic and antibacterial ceramic filter element is mainly prepared from glauconite, bryozoatum, bentonite, nano white metal charcoal, rice husk powder, razor king shell powder, limonite, sodium bicarbonate, acrylic emulsion, cane molasses, palm fibers, corn flour, phenolic resin, epoxy soybean oil, beeswax, and bacteriostatic additives. The ceramic filter element disclosed by the invention uses glauconite and bryozoatum as the main raw material; the raw materials such as nano white metal charcoal, rice husk powder, razor king shell powder, limonite and the like are added to ensure good filtering performance of the ceramic filter element, so that hazardous substances such as heavy metals and the like can be effectively adsorbed, and chemical stability and good water resistance can be achieved; hokutolite and crystal gravel contained in the antibacterial additives can release a great number of negative ions to exert good bactericidal antimicrobial effect; and natural manganese sand, nano silver carbon molecular sieve, and nano-zinc oxide contained in the antibacterial additives interact with each other to achieve good adsorption filtration performance, and good bactericidal properties.

Owner:JIAN CITY QINGYUAN DISTRICT QINGFENG FILTER EQUIP MATERIAL

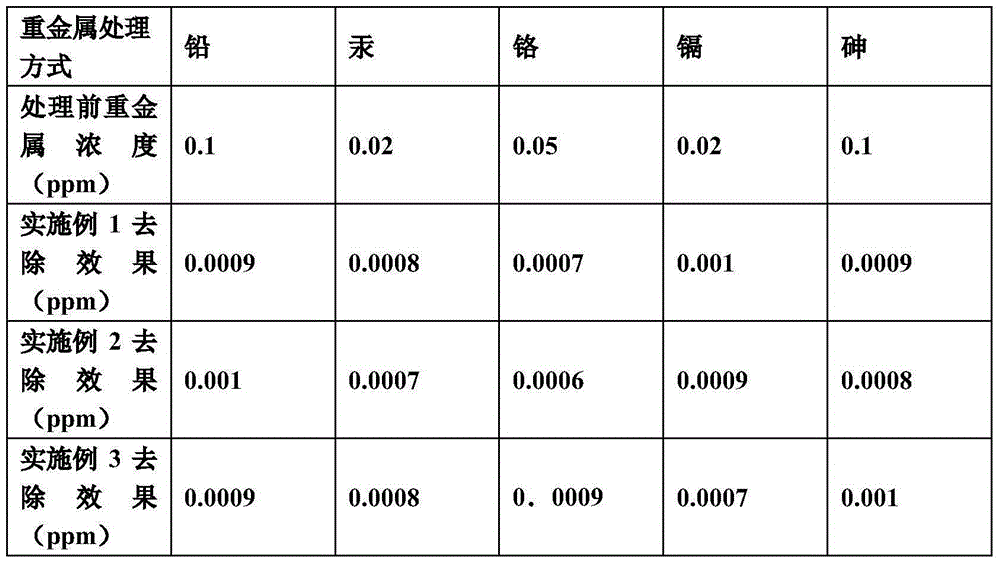

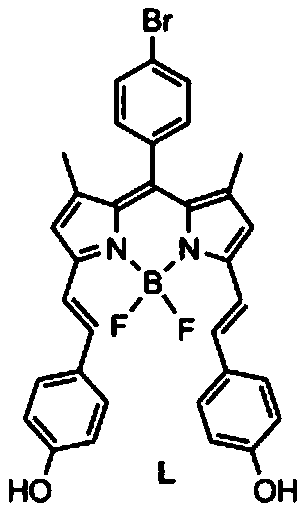

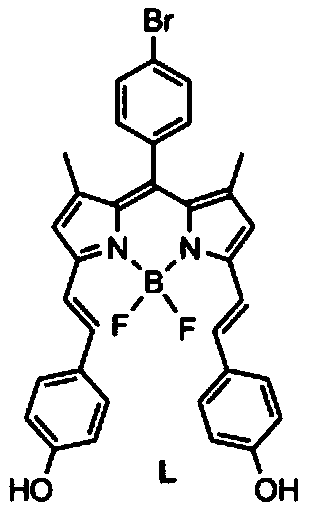

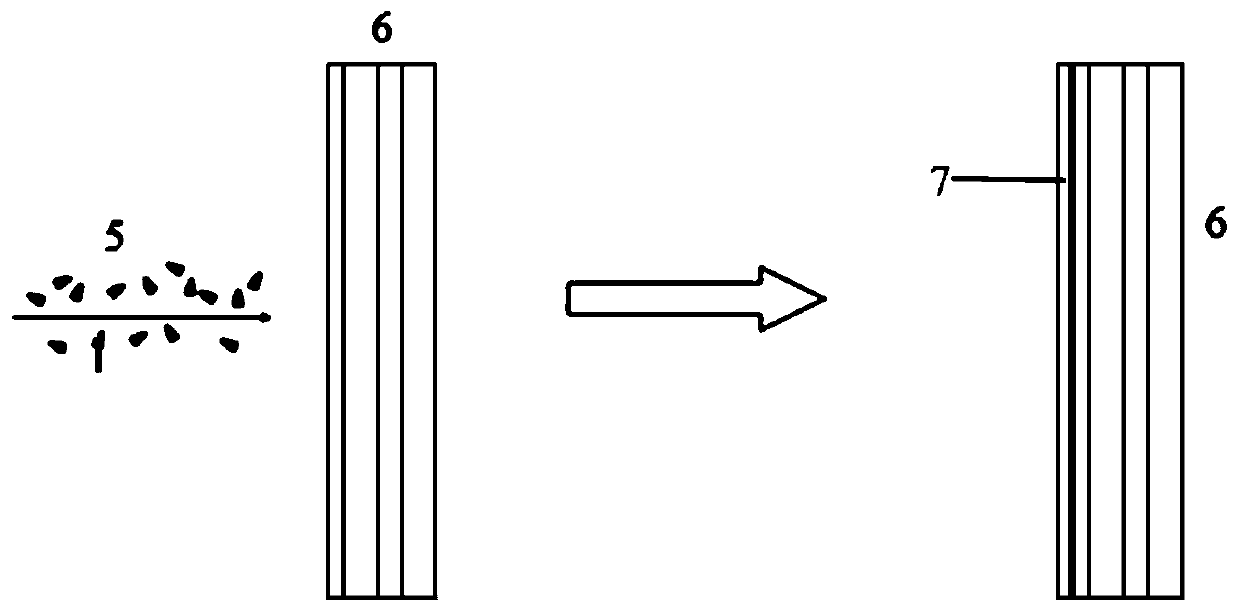

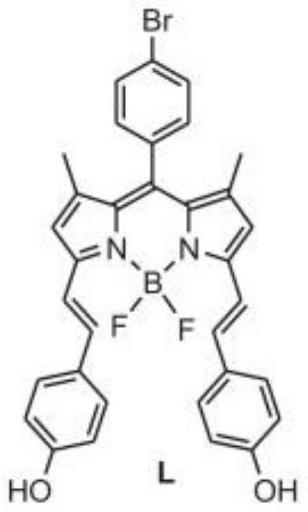

Nanofiber membrane material for filtering M<3+> in water and preparation method thereof

ActiveCN108654406ALarge specific surface areaImprove adsorption efficiencyMembranesWater contaminantsMicro nanoPolyvinyl alcohol

The invention relates to a nanofiber membrane material for filtering M<3+> in water and a preparation method thereof. According to the preparation method, by taking graphene oxide, p-phenolic fluoroboron dipyrrole L, polyvinylpyrrolidone PVP and polyvinyl alcohol PVA as raw materials, micro-nano membrane fiber with high specific surface area and high stability is prepared by a solution jet spinning technology. By virtue of specific coordination recognition of Fe<3+>, Al<3+> and Cr<3+> by the p-phenolic fluoroboron dipyrrole L, the adsorption of the Fe<3+>, the Al<3+> and the Cr<3+> by the nanofiber membrane material is improved; the nanofiber membrane material has excellent effects of filtering and adsorbing the metal Fe<3+>, the metal Al<3+> and the metal Cr<3+> in industrial wastewater;by the preparation method, the production efficiency is high, the production cost is low, a technology is simple, and fiber diameter distribution is uniform; the nanofiber membrane material is high infiltration and adsorption efficiencies, can achieve thorough removal, and is suitable for large-scale industrial production.

Owner:ZETTA NANO TECH CO LTD

Antibacterial ceramic filter element and preparation method thereof

InactiveCN107899303AImprove filtering effectStable chemical propertiesBiocideOther chemical processesSodium bicarbonateSodium Bentonite

The invention discloses an antibacterial ceramic filter element and a preparation method thereof. The antibacterial ceramic filter element is mainly prepared from glauconite, bryozoatum, bentonite, nano black ebony carbon, rice hull powder, razor clam king shell powder, hollow stone, sodium bicarbonate, an acrylic emulsion, cane molasses, a palm fiber, corn flour, a phenolic resin, epoxidized soybean oil, beewax and antibacterial additives. Due to adoption of glauconite and bryozoatum as main raw materials, and together with raw materials such as nano black ebony carbon, rice hull powder, razor clam king shell powder and hollow stone, the ceramic filter element is very good in filtration performance, capable of effectively adsorbing harmful substances such as heavy metals, in addition stable in chemical property and good in water resistance; as a great deal of anion is released from radiobarite and crystal macadam in the antibacterial additives, a very good antibacterial function is achieved; due to cooperation of natural manganese sand, a nanosilver molecular sieve and nano zinc oxide, not only is good filtration and adsorption performance achieved, but also very good sterilization performance is achieved.

Owner:张琴

Method for preparing polyolefine micro/nano-fibre non-woven material

InactiveCN101338456BIncrease added valueEasy to achieve large-scale productionArtificial filament physical treatmentConjugated cellulose/protein artificial filamentsCellulosePolymer science

The invention relates to a preparation method of polyolefin micro / nano fiber non-woven material. The preparation method comprises the procedures that (1) 50 to 800g of high polyme and 1200 to 1950g of cellulose ester are dried in an oven and mixed; then the high polymer and the cellulose ester undergo the process of melt spinning by a double-screw extruder; and the high polymer and the cellulose ester are winded at the winding speed of 300 to 1200m / min to form the multi-component fiber of the polyolefin / cellulose ester that is scattered at a micro / nano scale in a cellulose ester substrate; (2) the multi-component fiber is melted in acetone solution; and cellulose ester is removed to acquire the micro / nano fiber aggregate of the high polymer with thermo-plasticity; and (3) the fiber aggregate is carded by a carding machine; a net is crosswise made to form a fluffy fiber net; and after being strengthened and molded, the non-weaving material is made. The preparation method has the characteristics that the method is efficient, controllable and environment-friendly and has high added value. In addition, the preparation method facilitates mass-production.

Owner:DONGHUA UNIV

Method for preparing polyester micro/nano-fibre non-woven material

InactiveCN101338457BIncrease added valueEasy to achieve large-scale productionArtificial filament physical treatmentConjugated cellulose/protein artificial filamentsCellulosePolyester

The invention relates to a preparation method of polyolefin micro / nano fiber non-woven material. The preparation method comprises the procedures that (1) high polymer and cellulose ester are mixed in the mass ratio of 1:2.3 to 20; then the high polymer and the cellulose ester undergo the process of melt spinning by a double-screw extruder; and the high polymer and the cellulose ester are winded at the winding speed of 300 to 800m / min to form the multi-component fiber of the polyester / cellulose ester that is scattered at a micro / nano scale in a cellulose ester substrate; (2) the cellulose ester in the multi-component fiber of polyester / cellulose ester is removed by acetone solution to acquire the micro / nano fiber aggregate of the high polymer with continuous thermo-plasticity; the fiber aggregate is carded by a carding machine; a net is crosswise made to form a fluffy fiber net; and after being strengthened and molded by aqua tex, pinpricking or thermo-compression, the non-weaving material is made. The preparation method has the characteristics that the method is efficient, controllable and environment-friendly and has high added value. In addition, the preparation method facilitates mass-production and the acquired polyolefin micro / nano fiber non-woven material non-weaving material has an outstanding effect on filtration absorption.

Owner:DONGHUA UNIV

A filter bag for filtering and recovering non-ferrous metal dust and its preparation method

ActiveCN108071020BHD Gray EffectivenessPrevent resorptionDispersed particle filtrationMembrane filtersEmulsionPhysical chemistry

The invention discloses a filter bag for filtering and recovering non-ferrous metal dust and a preparation method thereof. The filter bag contains 85% to 95% by weight of microporous composite filter material and the weight loaded on the microporous composite filter material. The adsorption layer with a percentage of 5%-15%, the adsorption layer is a mixture obtained by blending magnetic nano iron oxide, polytetrafluoroethylene dispersion emulsion and dispersant emulsion after curing treatment, and the weight percentage of magnetic nano iron oxide in the mixture is 3%-25%, the weight percentage of polytetrafluoroethylene is 55%-70%, and the balance is the cured product of the dispersant emulsion. The filter bag prepared by the invention has stronger adsorption force for metal dust, effectively shortens the formation time of the powder cake layer, and improves the recovery rate of non-ferrous metals and the effectiveness of cleaning dust; the filter bag of the invention has higher filtration precision and electrical conductivity. It will be significantly improved to obtain excellent anti-static and explosion-proof capabilities.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Rainwater drainage pipe additionally provided with filter screen

InactiveCN105544700AImprove safety and patencyRelieve pressureSewer pipelinesActivated carbonPonding

The invention discloses a rainwater drainage pipe additionally provided with a filter screen. The filter screen is arranged at the connection portion of an upper pipe half and a lower pipe half, a transverse semipermeable drainage pipe is arranged on the inner wall of a drill hole of the upper pipe half, a water stop material is arranged between the lower half portion of the transverse semipermeable drainage pipe and the lower half portion of the drill hole, multiple independent branch pipes are arranged inside the lower pipe half, each branch pipe is arranged between corresponding adjacent tree-shaped rainwater pipe drainage sub-systems, the multiple branch pipes are connected together for forming a netlike rainwater pipe drainage net, each filter screen is arranged to be of a three-layer structure, an upper filter screen body and a lower filter screen body are each a large-hole steel mesh, and an intermediate filter screen body is provided with an activated carbon adsorption film. By means of a netlike rainwater pipe drainage system, the void volume of pipes on other lines can be utilized sufficiently, high water level pressure can be effectively lowered, the phenomena of ponding can be effectively reduced, and drainage safety and smoothness are improved; the filter screen is good in filtering and adsorbing effect, easy to produce and low in cost, and it is helpful to improve the drainage effect.

Owner:QINGDAO AIHUA HIGH TECH INSTR CO LTD

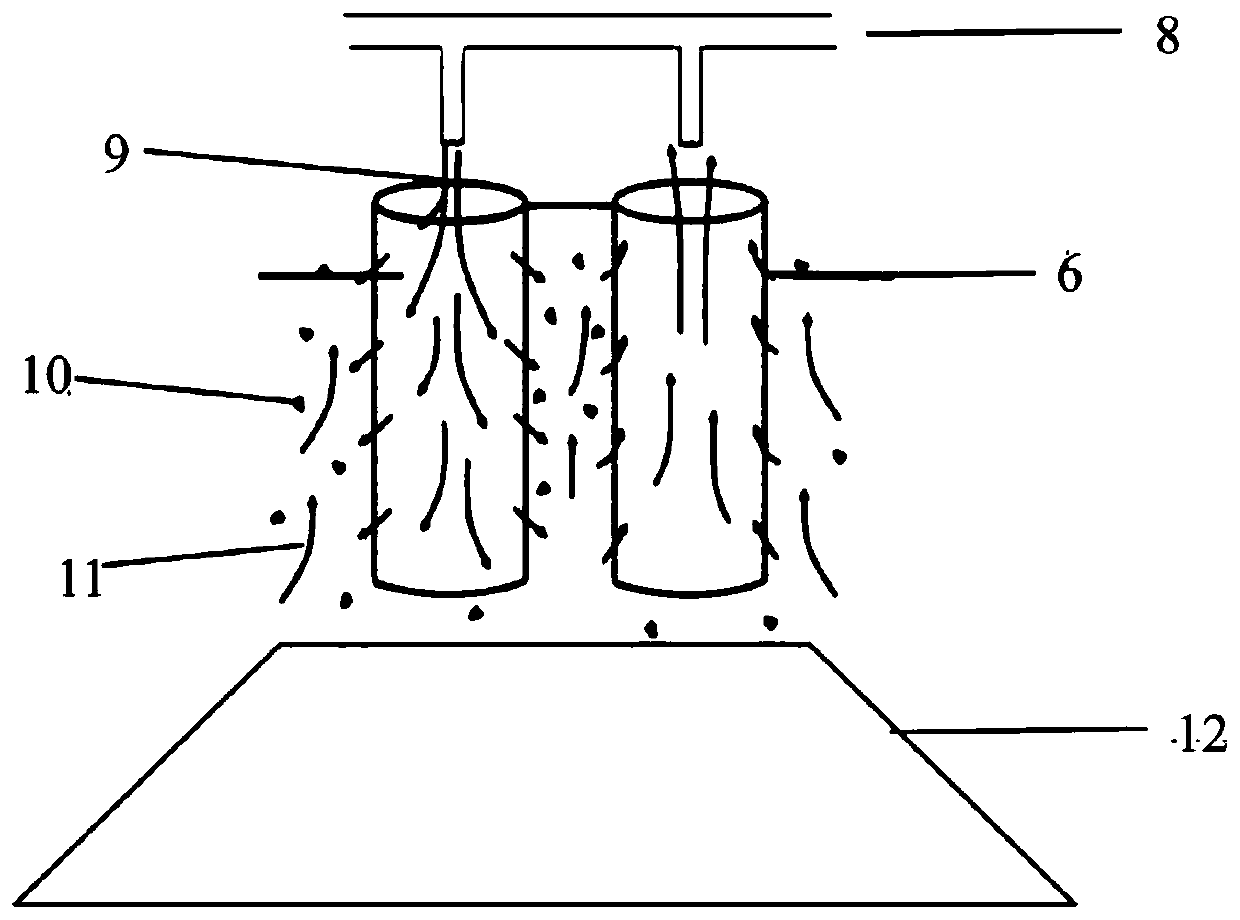

Technology for removing tetrabromobisphenol A in wastewater based on iron-carbon micro-electrolysis technology

ActiveCN112979009AImprove conductivityHigh removal rateSpecific water treatment objectivesWater contaminantsActivated charcoal powderTetrabromobisphenol A

The invention discloses a process for removing tetrabromobisphenol A in wastewater based on an iron-carbon micro-electrolysis technology, which is specifically carried out according to the following steps: preparing a spherical iron-carbon filler which mainly comprises the following raw materials in parts by weight: 35-45 parts of scrap iron, 15-18 parts of graphite, 20-25 parts of activated carbon and 5-8 parts of a phenolic adhesive, adding the scrap iron into a vacuum smelting furnace for smelting, spraying the smelted liquid iron out through an atomizing nozzle, conducting cooling to form spherical powder, punching hole grooves in the surface of the iron scrap spherical powder, smashing and mixing graphite and activated carbon, then adding the mixture, the iron scrap spherical powder and a phenolic adhesive into a centrifugal machine together, and preparing an iron-carbon filler; introducing the wastewater into a purification tank, and adjusting the pH value of the wastewater to 3-4; enabling the wastewater to pass through the filler in an electrolytic purification pipe; and adding sodium hydroxide into a purification cylinder to enable the pH value of the purified water to be 6-10, conducting stirring, standing and precipitating, and taking supernate of the purified water. The method is simple in process, low in cost and suitable for wide popularization.

Owner:中日友好环境保护中心 +1

Method for making polylactic acid fiber filter stick

The invention discloses a method for making a polylactic acid fiber filter stick. The method comprises the following steps of: (1) loosening: loosening a polylactic acid fiber cigarette tow by using a filter stick molding machine set, wherein the line density of the polylactic acid fiber cigarette tow is 3.5-5.0Ktex; (2) gluing: spraying a degradable adhesive onto the loosened polylactic acid fiber cigarette tow; (3) molding and cutting down; (4) drying the filter stick; and (5) balancing: putting the dried filter stick into a balance chamber to be balanced more than 6 hours so as to make the polylactic acid fiber filter stick. With the adoption of the method for making the polylactic acid fiber filter stick, the problem of industrial production of the polylactic acid fiber filter stick can be solved, the production can be carried out by only using an existing filter stick molding machine set in market, the smoking taste of the made filter stick is approximate to that of a vinegar fiber stick, and the requirements on use of the cigarette can be met.

Owner:湖北金叶玉阳化纤有限公司 +1

Modified polyactic acid composition for cigarette filter stick and preparation method thereof

ActiveCN102516728BSmall weight contentImprove adsorption capacityTobacco smoke filtersMonocomponent polyesters artificial filamentCellulose acetateBeta-Cyclodextrins

The invention relates to a modified polyactic acid composition for a cigarette filter stick and a preparation method thereof. The composition comprises following parts of raw materials, by weight, 100 parts of polyactic acid, 0.02-3 parts of polyactic acid-beta-cyclodextrin, 0.08-5 parts of sodium carbonate, 0.05-5 parts of sodium pyrrolidonecarboxylate, 0.01-4 parts of vitamin and 0.01-8 parts of polyacrylamide. The filter stick prepared through the polyactic acid composition is better in absorbing performance on smoke compared with the prior art and good in comprehensive performance, and a part of indexes of the filter stick exceed those of a cellulose acetate filter stick.

Owner:马鞍山同杰良生物材料有限公司

A process for removing tetrabromobisphenol-a in wastewater based on iron-carbon micro-electrolysis technology

ActiveCN112979009BImprove conductivityHigh removal rateSpecific water treatment objectivesWater contaminantsActivated charcoal powderTetrabromobisphenol A

The invention discloses a process for removing tetrabromobisphenol A in wastewater based on iron-carbon micro-electrolysis technology, which is specifically carried out according to the following steps: preparing spherical iron-carbon fillers, and the iron-carbon fillers mainly include the following raw materials in parts by weight: iron filings 35-45 parts, 15-18 parts of graphite, 20-25 parts of activated carbon, and 5-8 parts of phenolic adhesive, add the iron filings into the vacuum melting furnace for smelting, spray the smelted liquid iron through the atomizing nozzle, and cool it to form a spherical shape The surface of the spherical powder of iron filings is filled with holes and grooves, and the graphite and activated carbon are crushed and mixed, and then added to the centrifuge together with the spherical powder of iron filings and phenolic adhesive to prepare iron-carbon fillers; the waste water is passed into the purification tank Inside, adjust the pH value of the waste water to be between 3-4; pass the waste water through the packing in the electrolytic purification tube; add sodium hydroxide to the purification cylinder to make the pH of the purified water 6-10, stir and let stand for precipitation, and take the purified water. The supernatant of water; the process of the invention is simple, the cost is low, and it is suitable for wide popularization.

Owner:中日友好环境保护中心 +1

A farmland rainwater collection and treatment equipment

InactiveCN107190835BEasy to storeAvoid direct dischargeSewerage structuresSewer pipelinesPesticide residueWater resources

The invention discloses a farmland rainwater collection processing device and belongs to the field of farmland rainwater processing. The farmland rainwater collection processing device comprises a plurality of U-shape cement deep groove plates, wherein the U-shape cement deep groove plates are all embedded in ravines on the ground, the U-shape cement deep groove plates are fixedly connected with each other, and U-shape shallow groove plates are fixedly connected to the U-shape cement deep groove plates; water pipes are placed on the ground, one end of each water pipe is located in the farmland, flow dividing pipes are connected to the other ends of the water pipes, and a first outlet pipe and a second outlet pipe are connected to the flow dividing pipes. According to the farmland rainwater collection processing device, the situation that a large amount of rainwater which is washed out in the farmland is stored can be achieved; meanwhile, the situation that the rainwater with fertilizer and pesticide residual is directly discharged to the river is effectively avoided, and environment pollution is effectively lowered; when irrigation is needed, the stored water in the U-shape cement deep groove plates is directly pumped to conduct irrigation through water pumps and the water pipes, the rainwater resource is sufficiently used, and the water resource is saved.

Owner:杨秦一 +2

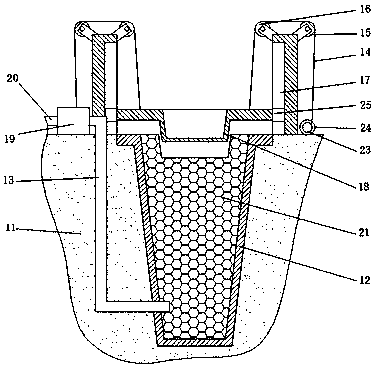

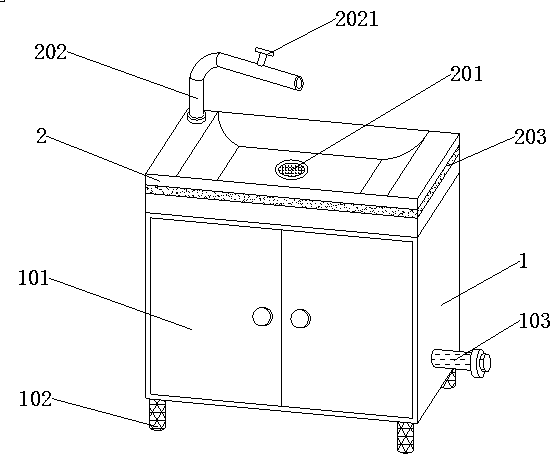

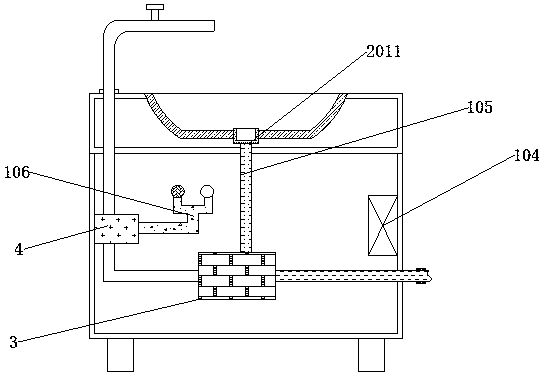

Environment-friendly hand washing table with water-saving function

InactiveCN109958165AWith water saving functionSolve the lack of a single control methodWash-standsDomestic plumbingWater savingWater flow

The invention discloses an environment-friendly hand washing table with a water-saving function. The environment-friendly hand washing table comprises a storage box and a ceramic basin, the ceramic basin is arranged on the upper part of the storage box, the ceramic basin is fixedly connected into the storage box, a door plate is arranged on the obverse side of the storage box, the door plate is rotatably arranged in the storage box, supporting feet are arranged on the lower part of the storage box, the supporting feet are arranged in the storage box in a welded mode, an electric box is arranged in the storage box, the electric box is fixedly connected into the storage box through screws, and a water inlet pipe is arranged in the storage box. According to the environment-friendly hand washing table with the water-saving function, in order to prevent people from deliberately wasting water resources when using the hand washing table, induction strips are arranged around the ceramic basin,the induction strips induct whether people use a faucet or not around the hand washing table, when no people uses the hand washing table, the induction strips feed signals back into an electronic control valve to turn off the faucet, the water-saving purpose is achieved, and the defect that a traditional faucet is always at a no-water-flowing state and thus waste is caused is overcome.

Owner:GUILIN SHIHUAN WASTE GAS TREATMENT EQUIP

A kind of nano-silver diatomite antibacterial filter element and preparation method thereof

ActiveCN104043288BEnsure safetyGood filtration and adsorption effectBiocideOther chemical processesFiltrationDie casting

The invention provides a nano-silver diatomite antibacterial filter core. The nano-silver diatomite antibacterial filter core is prepared from diatomite, a pore forming agent, a sintering aid, a binder and water. A preparation method for the nano-silver diatomite antibacterial filter core comprises the following steps: carrying out purification and fine treatment on diatomite; subjecting diatomite to silver loading; carrying out mixing and grinding solid raw materials until D50 is equal to 1 to 10 mu m; subjecting the ground raw materials to mixing with a liquid raw material; carrying out ageing; subjecting the aged raw materials to die casting or extruding to obtain a filter core blank; and drying and sintering the filter core blank so as to prepare the nano-silver diatomite antibacterial filter core. The nano-silver diatomite antibacterial filter core has good filtration and adsorption performance due to usage of the porous structure of diatomite; after loading of nano-silver on the diatomite and sinter molding, the prepared nano-silver diatomite antibacterial filter core can guarantee microbiological safety of water quality and provide safety guarantee for performance of the functions of a subsequent water purification film when applied to bacterium and turbidity removal of domestic water.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

Load type nanocomposite oxide material for purifying environment and preparation thereof

InactiveCN100574872CPromote degradationImprove antibacterial propertiesMolecular sieve catalystsLighting and heating apparatusCerium nitrateIon exchange

The present invention provides a supported nanometer compound oxide environmental purification material and the preparation thereof, the diatomite and the zeolite are employed as carrier to load one of nanometer TiO2, nanometer ZnO and nanometer CeO2. The preparation method comprises preparing carriers by diatomite and zeolite; preparing compound oxide precursory sol by employing ethanol as medium and the zinc nitrate and / or cerium nitrate and butyl titanate as material; loading the compound oxid precursory sol on the carrier to obtain loading-body; drying, baking and cooling the loading-body to obtain the supported nanometer compound oxide environmental purification material of the present invention which has perfect filter, adsorption, ion exchange, catalytic degradation and antibacterial function, good chemical stability, convenient usage, reclaim and regeneration, safety, innocuity, simple preparation technique and low cost. The supported nanometer compound oxid environmental purification material of the present invention is suitable for batch production and used widely in purifying process of atmosphere and water system.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

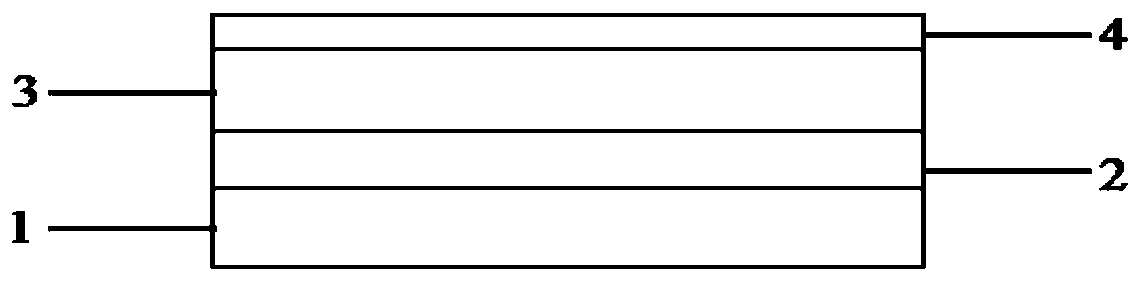

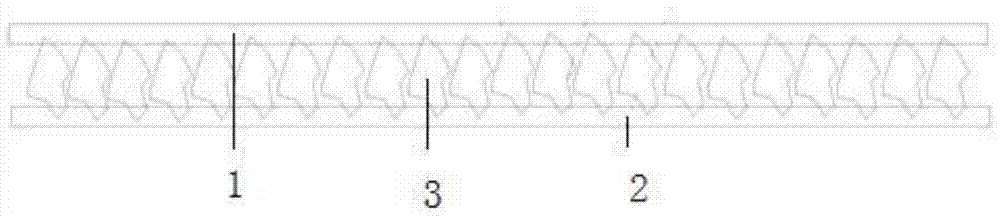

A kind of composite filter disc and preparation method thereof

ActiveCN105582743BIncrease contentSolve the problem of bond fastnessDispersed particle filtrationLaminationToxic gasActivated carbon

The invention relates to a composite filter sheet, comprising an upper layer of non-woven fabric, a lower layer of non-woven fabric and an intermediate layer of activated carbon particles; The average fineness of the fiber is 1-5μm, and the gram weight is 8-25g / m2; the composite filter has excellent filtration and adsorption performance, the product structure is ingeniously designed, and it is easy to produce. The carbon particle diameter is large and has high adsorption efficiency for toxic gases. The time is long; in addition, the invention also provides a preparation method of the composite filter.

Owner:ZHANGJIAGANG JUNMA NON WOVEN CO LTD

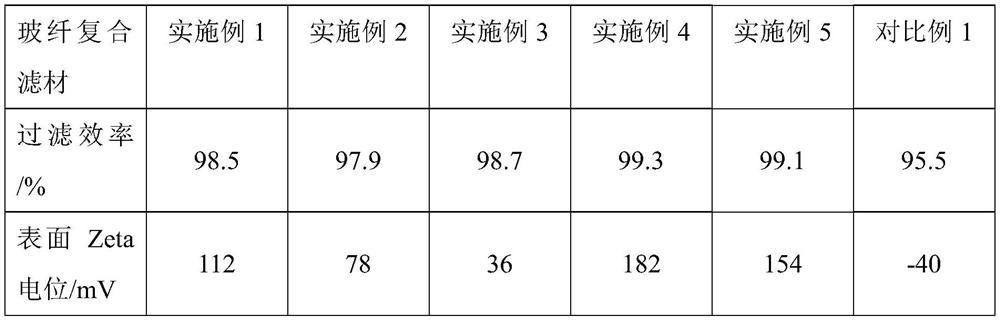

Glass fiber filter material with positive Zeta potential and preparation method and application thereof

InactiveCN113737570AImprove filtration efficiencyImprove adsorption capacityLamination ancillary operationsSynthetic resin layered productsGlass fiberPore diameter

The invention relates to the field of filtration and separation, and discloses a glass fiber filter material with positive Zeta potential and a preparation method and application thereof. The glass fiber filter material with the positive Zeta potential comprises a glass fiber filter material body and a cation protection film wrapping the surface of the glass fiber filter material body, the cation protection film endows the surface of the filter material with positive electricity, and a strong adsorption effect on negative charge particles is realized so that the glass fiber filter material not only can intercept particles of which the size is larger than the pore diameter, but also can adsorb particles of which the size is smaller than the pore diameter, and the filtering efficiency of the filter material is greatly improved. In water with the pH value of 7, the positive Zeta potential on the surface of the glass fiber filter material is as high as 200mV, and the filtering efficiency on solid particles with the size of 1 mu m is as high as 99.3%.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

a filtered water m 3+ Nanofiber membrane material and preparation method thereof

ActiveCN108654406BLarge specific surface areaImprove adsorption efficiencyMembranesWater contaminantsMicro nanoIndustrial waste water

The invention relates to a nanofiber membrane material for filtering M<3+> in water and a preparation method thereof. According to the preparation method, by taking graphene oxide, p-phenolic fluoroboron dipyrrole L, polyvinylpyrrolidone PVP and polyvinyl alcohol PVA as raw materials, micro-nano membrane fiber with high specific surface area and high stability is prepared by a solution jet spinning technology. By virtue of specific coordination recognition of Fe<3+>, Al<3+> and Cr<3+> by the p-phenolic fluoroboron dipyrrole L, the adsorption of the Fe<3+>, the Al<3+> and the Cr<3+> by the nanofiber membrane material is improved; the nanofiber membrane material has excellent effects of filtering and adsorbing the metal Fe<3+>, the metal Al<3+> and the metal Cr<3+> in industrial wastewater;by the preparation method, the production efficiency is high, the production cost is low, a technology is simple, and fiber diameter distribution is uniform; the nanofiber membrane material is high infiltration and adsorption efficiencies, can achieve thorough removal, and is suitable for large-scale industrial production.

Owner:ZETTA NANO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com