Paper-core filter rod for cigarettes and manufacturing method thereof

A cigarette paper and filter rod technology, which is applied in the direction of e-liquid filter, application, tobacco, etc., can solve problems such as the degradation effect is not as good as that of paper materials, acetate fiber cannot be degraded quickly, flame retardancy, water resistance defects, etc. The manufacturing process is mature and reliable, the molding process is easy to control, and the product quality is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

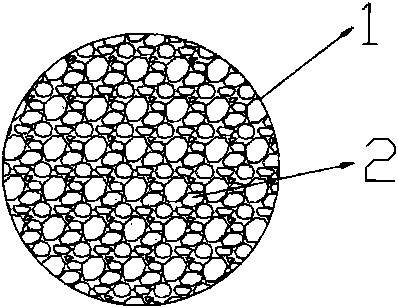

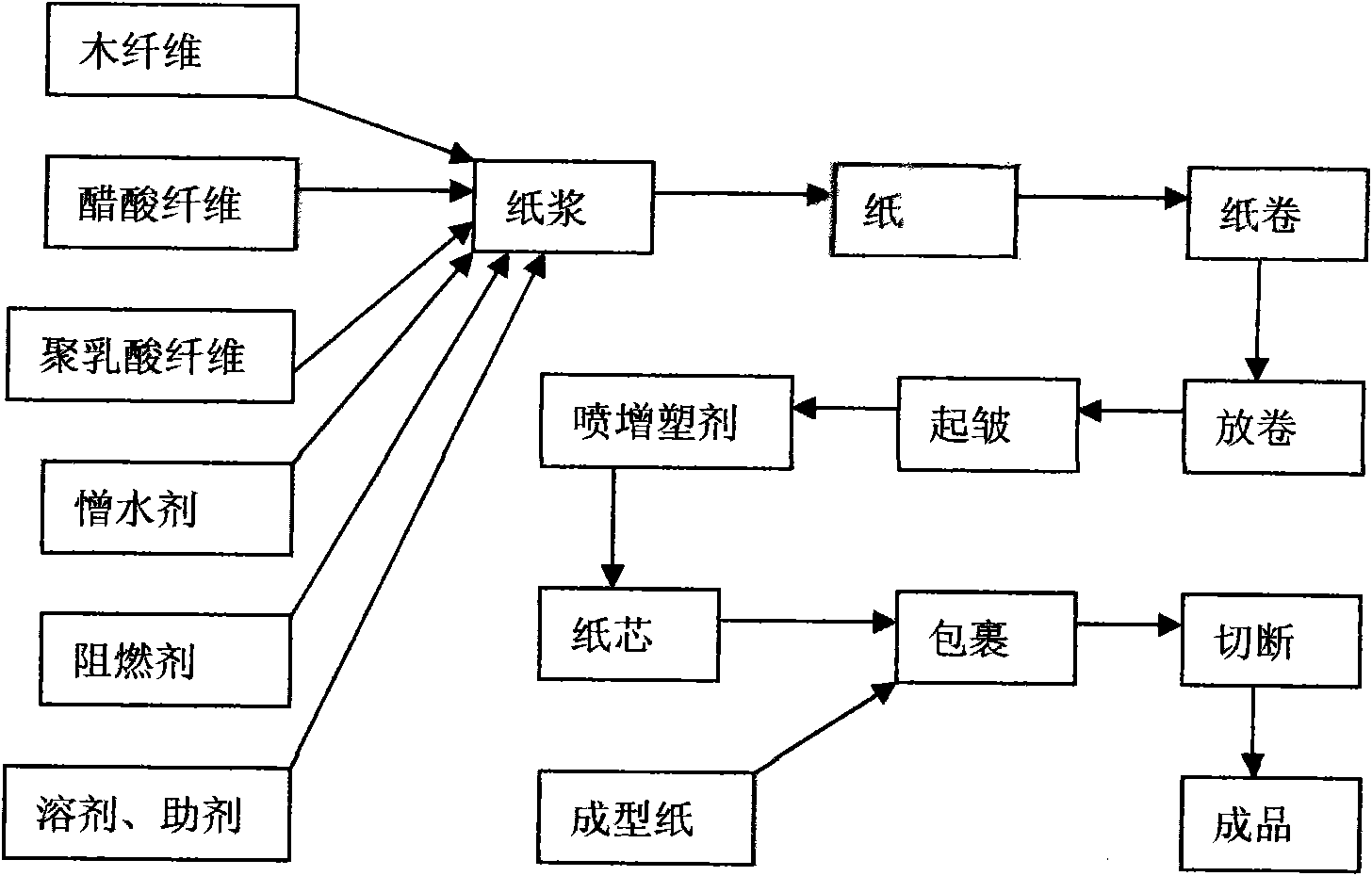

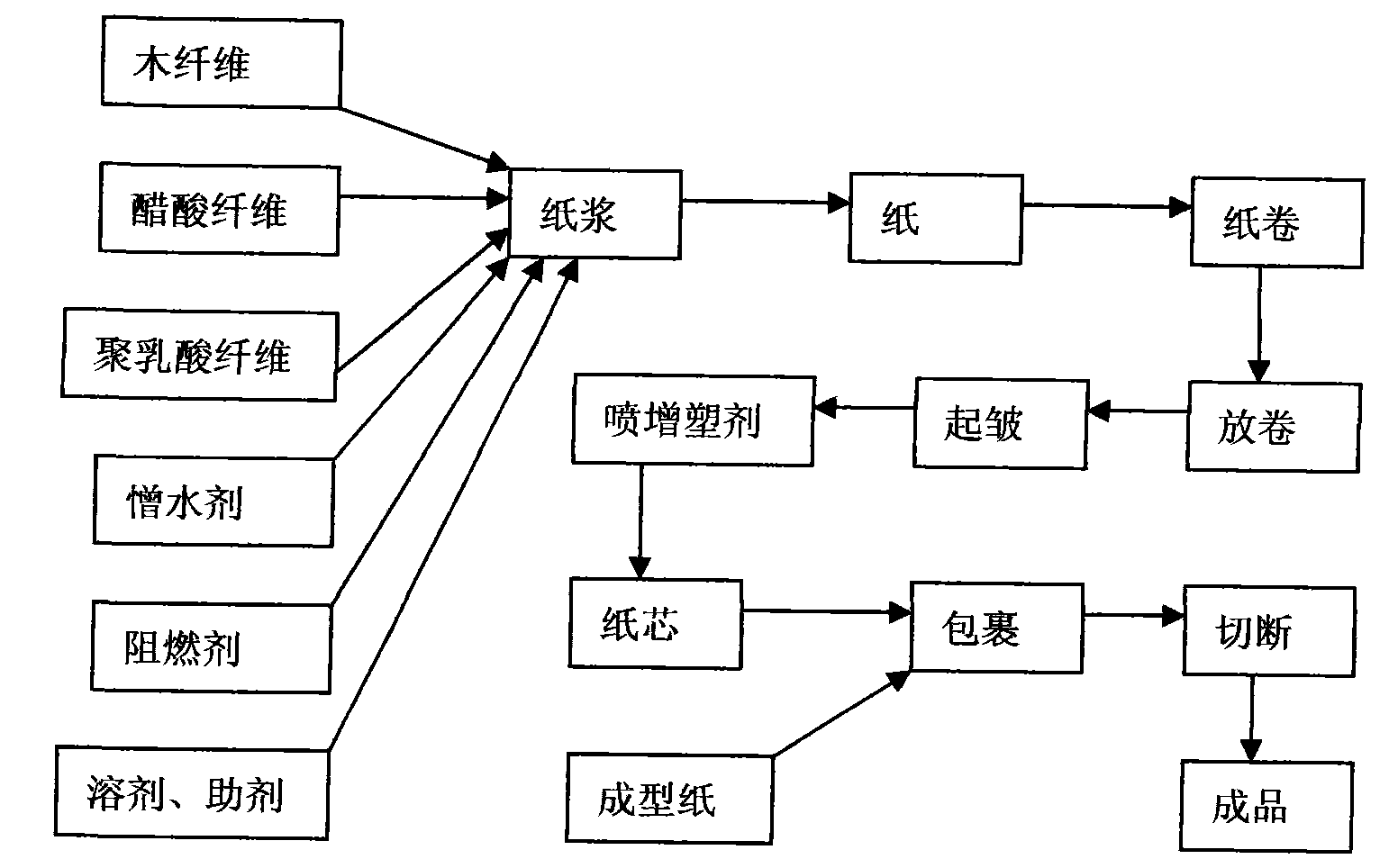

[0024] Choose weight percentage (dry weight, the same below) as 5% wood fiber, weight percentage is 10% acetate fiber, weight percentage is 80% polylactic acid fiber, weight percentage is 2% non-toxic organic silicon water repellent, There is also a non-toxic aluminum hydroxide flame retardant with a weight percentage of 3%, and solvents and auxiliary agents for papermaking are selected in addition. Such as figure 2 As shown, the above raw materials are added together to make a suspension-like pulp, and paper is made by conventional papermaking technology; after papermaking, 1g / m2 is coated on the paper surface 2 chitosan, dried; rolled into rolls..

[0025] According to the thickness specified in the national standard of cigarette filter rods, unwind the above-mentioned paper rolls at a certain speed in the filter rod forming machine, wrinkle them, spray an appropriate amount of triacetin plasticizer on the paper, and then roll them on the filter rods. Gather in a rod form...

Embodiment 2

[0028] Choose the grass fiber that is 25% by weight (dry weight, the same below), the polypropylene fiber that is 20% by weight, the polylactic acid fiber that is 50% by weight, the nontoxic polyvinyl alcohol hydrophobicity that is 1% by weight agent, as well as 4% by weight non-toxic dimethyl phosphate flame retardant, paper-making solvents, additives, derivatives of chitosan, etc. Such as figure 2 As shown, the above raw materials are added together to make a suspension-like pulp, which is made into paper using a suitable papermaking process and rolled into a paper roll.

[0029] According to the thickness stipulated in the enterprise standard for cigarette filter rods, the above paper rolls are unwound and wrinkled at a certain speed in a filter rod forming machine. The subsequent implementation process is the same as the subsequent process in Example 1.

Embodiment 3

[0031] Choose weight percentage (dry weight, the same below) as 45% cotton fiber, weight percentage is 40% acetate fiber, weight percentage is 5% polylactic acid fiber, weight percentage is 3% white activated carbon fiber, weight percentage is 2% % non-toxic polyvinyl alcohol water repellent, and 5% by weight non-toxic dimethyl methyl phosphate flame retardant, paper-making solvents, additives, chitosan derivatives, etc. Such as figure 2 As shown, the above-mentioned raw materials are added together to make a suspension-like pulp, which is made into paper by a suitable papermaking process and rolled into a paper roll.

[0032] According to the thickness of the filter rod agreed by the supplier and the buyer, the above-mentioned paper roll is unwound and wrinkled at a certain speed in the filter rod forming machine. Then spray an appropriate amount of triacetin plasticizer on the paper, and then gather it into a paper core 2 in a filter rod forming machine.

[0033] In the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com