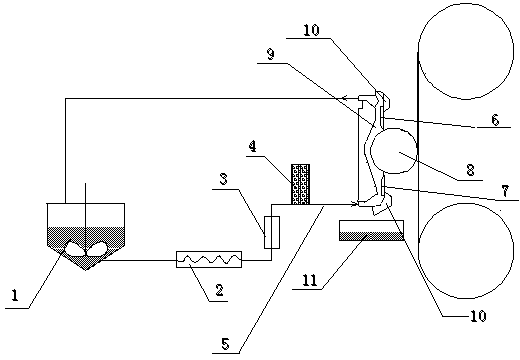

Surface coating device and method for lithium battery pole piece or diaphragm

A surface coating, lithium battery technology, applied in the device, battery electrode, coating and other directions of coating liquid on the surface, can solve the problem of inability to accurately coat the substrate material, achieve good filtration adsorption performance, high stability, The effect of convenient coating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A surface coating method for a lithium battery pole piece or separator, the surface coating method comprising the following steps:

[0037] a) Preparation of slurry: Dissolve the binder polyvinylidene fluoride in the solvent N-methylpyrrolidone to make glue, the glue has a solid content of 1%, and the viscosity is 600mPa·s. Aluminum oxide, the mass ratio of aluminum oxide to binder polyvinylidene fluoride is 1:20, the solid content of the ceramic slurry is 20.8%, the fineness is 8um, and the viscosity is 1250mPa·s, so that the aluminum oxide Aluminum is evenly dispersed in the glue solution, and then vacuumized to remove air bubbles for 1 hour to prepare a slurry;

[0038] b) Surface coating: set the pole piece roll or diaphragm roll to be coated on the coating device, the slurry prepared in step a) reaches the coating head through the feeding mechanism, and the coating head is close to the coating to be coated The material and the slurry are attached to the gravure ro...

Embodiment 2

[0040] A surface coating method for a lithium battery pole piece or separator, the surface coating method comprising the following steps:

[0041]a) Preparation of slurry: dissolve the binder polyvinylidene fluoride and polytetrafluoroethylene in the solvent N-methylpyrrolidone to make a glue solution, and the mass ratio of polytetrafluoroethylene to polyvinylidene fluoride is 1 : 3, the solid content of the glue is 2%, and the viscosity is 1000mPa s, adding aluminum oxide, aluminum phosphate and silicon dioxide in the glue, the mass ratio of aluminum oxide, aluminum phosphate, silicon dioxide is 1 : 1.7: 2.5, the solid content of the ceramic slurry is 65%, the fineness is 10um, and the viscosity is 2000mPa·s, so that the aluminum oxide, aluminum phosphate and silicon dioxide are evenly dispersed in the glue, and then vacuumed to remove air bubbles 1.5h, make the slurry;

[0042] b) Surface coating: set the pole piece roll or diaphragm roll to be coated on the coating device,...

Embodiment 3

[0044] A surface coating method for a lithium battery pole piece or diaphragm, the surface coating method comprising the following steps:

[0045] a) Preparation of slurry: dissolve the binder polytetrafluoroethylene in the solvent N-methylpyrrolidone to make glue, the solid content of the glue is 0.5%, the viscosity is 500mPa·s, and trioxide is added to the glue Aluminum, aluminum phosphate and silicon dioxide, the mass ratio of aluminum oxide, aluminum phosphate and silicon dioxide is 1: 1.2: 2.2, the solid content of the ceramic slurry is 10%, the fineness is 2um, and the viscosity is 600mPa· s, make aluminum oxide, aluminum phosphate, and silicon dioxide evenly dispersed in the glue solution, and then vacuumize to remove air bubbles for 2 hours to prepare a slurry;

[0046] b) Surface coating: set the pole piece roll or diaphragm roll to be coated on the coating device, the slurry prepared in step a) reaches the coating head through the feeding mechanism, and the coating h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com