Calcium silicate high-filling polymer modified paper

A technology of filling polymers and calcium silicate, which is applied in the direction of special paper, inorganic compound addition, paper, etc., can solve the problems of high water absorption, damage to ecological balance, and paper is not waterproof or moisture-proof, so as to achieve good printing performance and improve absorption Ink resistance and low lateral shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

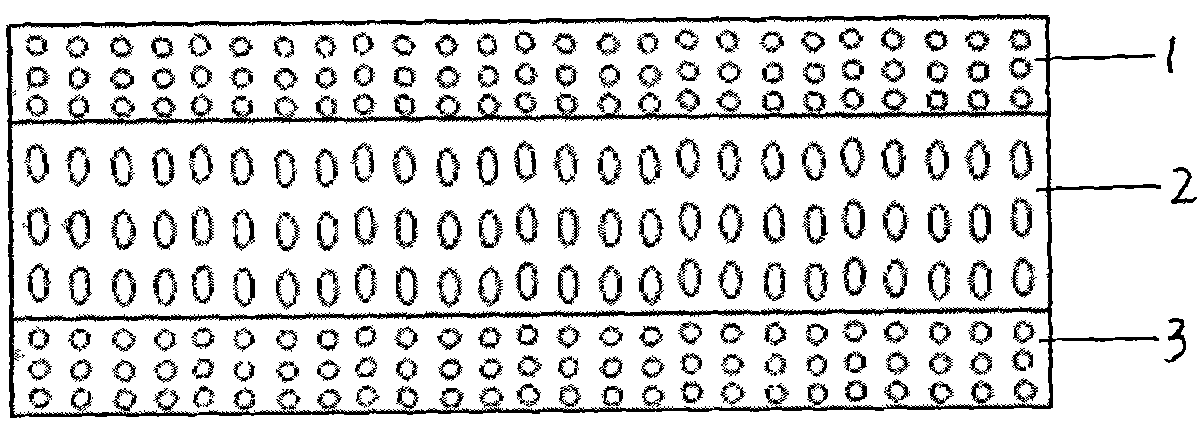

[0036] A calcium silicate high-filling polymer modified paper, which is composed of three layers of non-plant fiber calcium silicate, calcium carbonate and polymer materials, and is co-extruded by three extruders. The first and third layers are non-vegetable The base material of plant fiber calcium silicate paper is 2% ethylene bis stearamide, 8% high density polyethylene, 9% metallocene polyethylene, 58% activated calcium silicate, 21% calcium carbonate, low molecular weight polyethylene Ethylene 1% and antioxidant (1010), its molecular formula is C73H108O12, 1% composition; The second layer of paper raw material is made up of activated calcium silicate 60%, calcium carbonate 23%, styrene-butadiene block copolymer 5%, 8% of high-density polyethylene, 3% of linear low-density polyethylene and 1% of antioxidant; the above-mentioned first layer and third layer respectively account for 25% of paper weight.

Embodiment 2

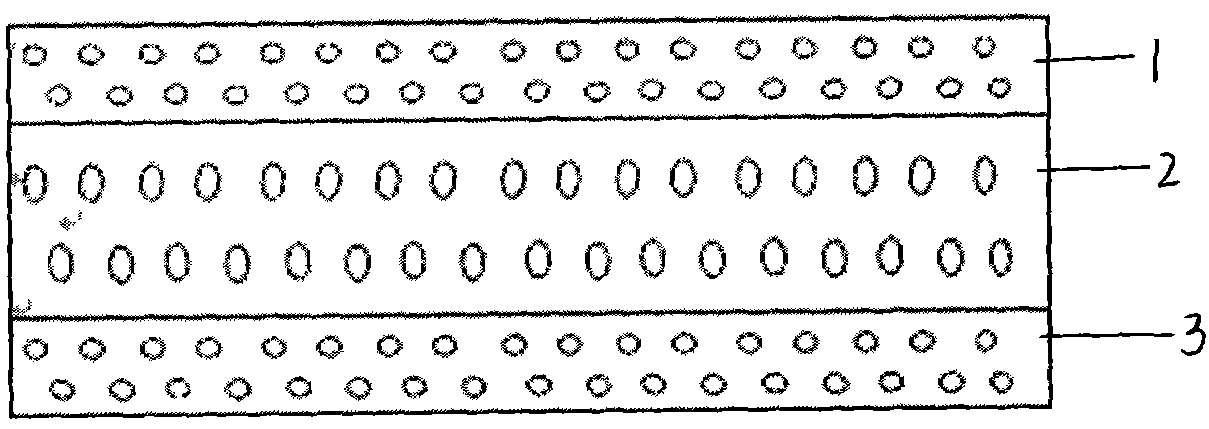

[0038] A calcium silicate high-filling polymer modified paper, which is composed of three layers of non-plant fiber calcium silicate, calcium carbonate and polymer materials, and is co-extruded by three extruders. The first and third layers are non-vegetable The base material of plant fiber calcium silicate paper is 5% ethylene bis stearamide, 18% high density polyethylene, 3% metallocene polyethylene, 52% activated calcium silicate, 19% calcium carbonate, low molecular weight polyethylene 1% ethylene and 2% antioxidant; the second layer of paper is made of activated calcium silicate 58.5%, calcium carbonate 16%, styrene-butadiene block copolymer 2%, high-density polyethylene 15%, linear low Density polyethylene 8% and antioxidant 0.5% (1010) its molecular formula is C73H108O12, composition;

Embodiment 3

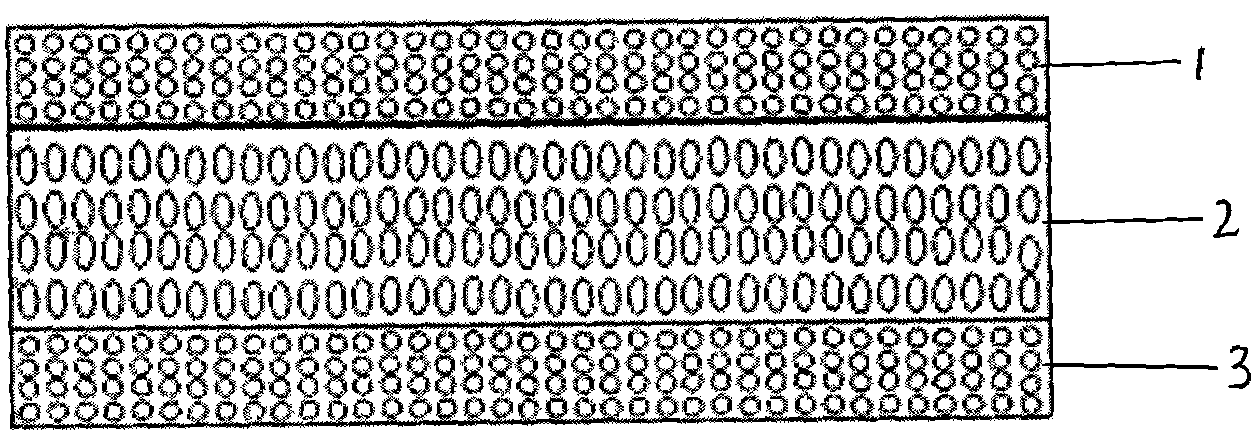

[0040] A calcium silicate high-filling polymer modified paper, which is composed of three layers of non-plant fiber calcium silicate, calcium carbonate and polymer materials, and is co-extruded by three extruders. The first and third layers are non-vegetable The base material of plant fiber calcium silicate paper is 6% ethylene bis stearamide, 20% high density polyethylene, 5% metallocene polyethylene, 51% activated calcium silicate, 14% low molecular weight polyethylene 1% and antioxidant 3%; the second layer of paper is composed of activated calcium silicate 50%, calcium carbonate 16%, styrene-butadiene block copolymer 9%, high-density polyethylene 18%, linear low-density Polyethylene 6% and antioxidant 1% composition;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com